Steve Katz, Editor01.26.15

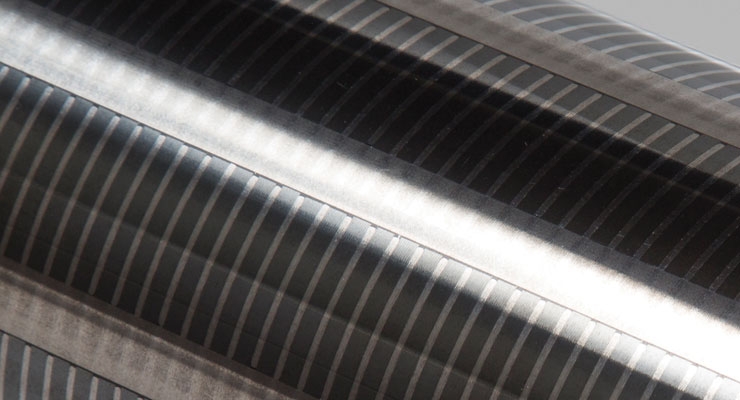

Wink’s GapControl adjustable anvil system

Flexible dies have overtaken solid tools as the rotary diecutting method of choice. For North America, industry expert estimates range from anywhere between 60-80% market share for flexible dies versus solid tooling. The North American flexible die market is quickly catching up to its European peers, where the flexible tooling share is thought to be close to 80%, with some suppliers even suggesting a 90% market share.

Why the switch? Reasons include ease and economics of transport, storage and handling. Also, flexible die technology has improved since it was first introduced to the label market. Prevailing trends in today’s label industry such as short run printing and a move toward increasingly thinner materials are also contributing factors in flexible tooling’s growth. However, above all, the most obvious answer – as is often the case with components of any process or workflow – is cost savings.

“The question of flexible dies versus solid tools for the label industry is not only about the abilities of the tools themselves, but also the demands placed on the label industry as a whole,” states David Morris, president of Kocher + Beck USA. “From a technical standpoint, there have been tremendous advances made in the production of flexible dies. These products are quickly produced, with fully machined blade profiles and extremely tight tolerances as standard. With the industry continuing to move toward synthetic facestocks and thinner liners, the flexible die is very well suited to these applications.”

Andre Gysbers, marketing director for Wink, points to numerous advantages flexible dies have over solid. He says, “Not only are production and delivery times very fast, but flexible dies allow a converter to diecut very intricate shapes. And they facilitate transport, storage and handling enormously. Overall, this makes them more cost-effective compared to solid dies. Also, thanks to special surface treatments, flexible dies have become very durable, so that service lives are also now comparable to solid dies.”

RotoMetrics’ Flexible Die Product Manager Ulrich Kretzschmar emphasizes that while a flexible die is an affordable tool, it goes through a very complex multi-stage process before it’s delivered to the customer. “Over the past few years, RotoMetrics has significantly improved manufacturing processes. Aside from cost savings, other advantages to a converter using flexible dies over solid dies include fast turnaround – so it’s perfectly suited for shorter runs, with easy changeover from one die to the next. Using flexible dies is a great way to optimize press time.”

Discussing the growth and acceptance of flexible dies, Markus Marfurt, president of Electro Optic USA, says it’s been an “evolutionary process.” Markfurt maintains that Electro Optic, a supplier that is devoted solely to flexible dies, has been a driving force in flexible tools gaining acceptance. “Flexible dies are a highly technical product. When we first introduced our flexible dies to the label market in 2003, we said our products were as good or better than the benchmark of solid tools. And today that is still the case. Moreover, flexible dies will always be a more cost effective solution than solid dies.

“You have to consider the whole cost,” Marfurt adds. “In addition to being significantly less expensive to ship a flexible die than a solid tool, a flexible die is less costly than a solid tool’s resharpening fee.”

Marfurt stresses the critical nature of having a trusted, top quality die supplier. He says, “When you consider how much of a label converter’s material costs are passing through a diecutting unit – labelstock and ink, for example – you better trust that you are using a reliable flexible die.”

Thin is in

The AccuSmart flexible die from RotoMetrics

In developing new products, rotary die suppliers must take into account the evolving label marketplace, and consider the materials their tools will be cutting.

“Today, film and synthetic materials are becoming thinner and thinner,” says Todd Westover, sales and service representative for Wilson Manufacturing. “Both face and liner construction can be at or under .002" on some popular substrates. This requires extreme consistency in the blade profile and blade height. The tolerances required today are nearly impossible to hold unless you are sharpening with specialized CNC machinery in controlled environments. Our most recent machine design guarantees total variance not to exceed .0001". Without this technology, the new materials would pose a real threat to both converters and die makers alike.”

Kocher + Beck’s David Morris emphasizes the critical role diecutting plays in converting thinner and thinner materials. He says, “The thin liners in use today are .92 (23 microns), and some converters are trialing materials with a thickness of .75 (19 microns). Some in the industry are even looking at the possibility of .5 (12-13 micron). When going to such liners, the level of control the press operator has over the diecutting process is significantly reduced, so all components of the die station and tooling have to be in perfect condition.”

It’s critical that converters work with their die suppliers, Morris says, to not only make sure they are ordering the correct tools, but to also have audits done on the anvils, magnetic cylinders and other components of the station. “At Kocher + Beck, all of our regional sales managers have been trained to be able to offer this service, and have a lot of experience when cutting down to such liners. We are also seeing more converters installing our world-renowned Gapmaster adjustable anvil system. The Gapmaster’s ultra-fine level of adjustment allows us to increase the level of control a press operator can have on such thin liners,” explains Morris.

Wink’s Gysbers says that in addition to thin PET liners, the use of MDO (machine direction orientation) face materials adds to the challenge. He explains: “These PET liners are very demanding in terms of diecutting, because they are not compressible like glassine liners, and thus much more sensitive for die strikes. To achieve perfect diecutting results, all components need to be in a perfect and absolutely clean condition – the diecutting unit and its cylinders, and of course the cutting tool, as well. We use special engraving and hardening techniques for our SuperCut dies to guarantee minimum tolerances, and we recommend using GapControl, our adjustable anvil roller.”

Electro Optic’s Gold Line Special is another product that meets the challenges presented by MDO and thin gauge materials. Says Markus Marfurt, “The quality of Electro Optic’s Gold Line Special precisely meets the challenge of thin gauge liner diecutting applications. The Gold Line Special has perfect cutting ability and unmatched height parallelism, due to our patented back grinding process, guaranteeing the best cutting results on ultra thin liners.”

Ulrich, of RotoMetrics, sees an increase in the converting of thin films that require tighter tolerance control and in-depth solutions to manage thermal deviations. “Thin film applications tend to be longer running jobs that require wider webs and faster speeds. It’s very important to consider the whole stack – not just the die – when converting these materials.”

RotoMetrics’ AccuStrike anvil offers press operators the ability to adjust bearers independently or together for what Ulrich says is “unparalleled control” over die strike on various liner thicknesses. “So the anvil and other components are just as important to the success of converting thin film as a cutting die,” he says. “They work in concert.”

RESPONSIVE SUPPLIERS

Another trend in the label market affecting diecutting is the proliferation of the short run and digital printing markets, where one of the hallmarks is quick turnaround time.

“The digital printing market clearly favors flexible dies for short runs with a quick turnaround. In order to effectively embrace digital printing, converting these short runs requires quick tooling changeover and cost-effective cutting. In fact, digital printing served to influence RotoMetrics to develop AccuSmart, an economical flexible die to tackle today’s popular short and mid run projects,” Uhlrich says. “And, like all of our flexible dies, AccuSmart has an impressive 24-hour turnaround time to produce because, as our customers know, speed to market is imperative.”

Die suppliers must keep up with the demands that label customers place on converters. “Everyone is under pressure to produce a high quality product, in a shorter delivery time, but at the same or lower price level,” Morris says. “At Kocher + Beck, we have continued to invest in the latest and most efficient manufacturing equipment, allowing us to reduce the production time required and therefore meet the needs of our customers.

“Such investments have also helped to bring further efficiencies,” Morris adds. “We have so far been able to offset the ever-increasing cost of raw material, and this means we have not had to implement a price increase to our customers. However, we will not sacrifice the quality of our product, for gains in both delivery time and price. With thinner liners, high machine speeds and the need for less press downtime, it is even more important than ever to supply an accurate and high quality product, the first time every time.”

Andre Gysbers at Wink observes demands for higher quality products in developing markets. “There is a clear trend towards higher quality demands in markets like China or Southeast Asia, which is driven by the multinational label companies who are now producing there and insisting on high quaility printing and diecutting,” he says.

A magnetic cylinder from Wilson Manufacturing

Solid’s niche

Despite the increasing preference for flexible dies, solid tools will always have a place in the industry. By and large, suppliers stress there will always be materials beyond the capabilities of flexible dies, and solid tools also make sense for very long runs.

“The major advantage of solid dies is their ability to have higher cutting edges,” explains Gysbers. “These are necessary to cut very thick and/or tough materials, where flexible dies reach their physical limit. For this reason, solid dies will surely have a future in the market, but probably only for niche applications.”

Adds Westover, “Both types of tooling certainly have distinct advantages, which are typically based on the substrate and volume of the project. There are certain applications that will always require solid tooling – there are limits with flexible die capabilities mostly constrained by overall thickness of the substrate.”

“Additionally, solid dies have the ability to be re-sharpened numerous times, optimal for those longer runs,” adds Ulrich.

To maximize converting efficiency, diecutting is often done inline, however, not all presses are equipped for inline diecutting. Schober offers diecutting modules, with and without matrix removal, as retrofit machine-driven or servo-driven units.

Schober’s diecutting modules can work with web widths up to 1000 mm and are designed for production speeds of up to 350 m/min for the modular line shaft driven machines, as well as a hybrid machine concept with individual drive technology.

These high capacity diecutting modules feature preset and calibrated pressure adjustment, high-precision bearing assemblies and housings for low temperature running, vibration-free design, micrometric die wear compensation adjustment (GCS) as well as central quick magnetic/anvil disengagement (without loss of registration) in order to ease web threading, save material during start-up and consequently shorten the set-up time.