12.15.16

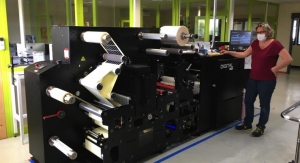

WS Packaging, one of North America's top PS label converters with 17 facilities throughout the region, has purchased its second Mark Andy Digital Series hybrid press. The new press, custom configured to fit the company’s prime label production requirements, will augment the business growth resulting from their original Digital Series investment, which has been running full production since December 2015. The new press will be installed before year-end at WS Packaging's Dallas facility.

The existing Digital Series installation is running two 12-hour shifts, seven days per week and supports the company’s growing customer demands for fast response, short lead times, multiple SKUs, variable data printing, and versioned graphics. The press runs are anywhere from 350 to 8000 feet (106 to 2438 meters), with about 25 changeovers in a shift. This second investment will further expand this digital printing capacity.

The Mark Andy Digital Series is a true production-level hybrid solution, supporting high-quality jobs at speeds up to 240 fpm (73 mpm), and built on the highly successful Performance Series platform. “Mark Andy’s Performance Series is a solid piece of flexo equipment, very accessible, and very easy to operate and get people up to speed on,” says Ryan Reding, general manager for WS Packaging’s Dallas and Phoenix plants. “With the Digital Series, all of the things we learned about flexo over the years are still applicable; it’s just from this section to this section we are laying down digital ink," Reding adds.

The Mark Andy Digital Series press comes with the backing of Mark Andy's position as a Total Solutions Partner, with end-to-end solutions through the entire production workflow. “It’s all about integrating around the converter,” explains Ray Dickinson, VP of marketing and business development for digital solutions. “We are standing with our customers with an ongoing customer-supplier relationship that includes training and education, pressroom materials and supplies, rebuilds and upgrades, service contracts, and slitting/rewinding equipment. Especially with the new Digital Series, our emphasis is to deliver the process capabilities in terms of man, machine, and materials to ensure our customers’ success.”

The acquisition of a second Mark Andy Digital Series press is a direct result of this partnership. “One of the things that is a huge differentiator is the support and service that Mark Andy has provided us,” says Reding. “I have a high level of confidence working with Mark Andy; the fact that they really are supporting us on a constant basis and looking for opportunities for us to improve.”

The existing Digital Series installation is running two 12-hour shifts, seven days per week and supports the company’s growing customer demands for fast response, short lead times, multiple SKUs, variable data printing, and versioned graphics. The press runs are anywhere from 350 to 8000 feet (106 to 2438 meters), with about 25 changeovers in a shift. This second investment will further expand this digital printing capacity.

The Mark Andy Digital Series is a true production-level hybrid solution, supporting high-quality jobs at speeds up to 240 fpm (73 mpm), and built on the highly successful Performance Series platform. “Mark Andy’s Performance Series is a solid piece of flexo equipment, very accessible, and very easy to operate and get people up to speed on,” says Ryan Reding, general manager for WS Packaging’s Dallas and Phoenix plants. “With the Digital Series, all of the things we learned about flexo over the years are still applicable; it’s just from this section to this section we are laying down digital ink," Reding adds.

The Mark Andy Digital Series press comes with the backing of Mark Andy's position as a Total Solutions Partner, with end-to-end solutions through the entire production workflow. “It’s all about integrating around the converter,” explains Ray Dickinson, VP of marketing and business development for digital solutions. “We are standing with our customers with an ongoing customer-supplier relationship that includes training and education, pressroom materials and supplies, rebuilds and upgrades, service contracts, and slitting/rewinding equipment. Especially with the new Digital Series, our emphasis is to deliver the process capabilities in terms of man, machine, and materials to ensure our customers’ success.”

The acquisition of a second Mark Andy Digital Series press is a direct result of this partnership. “One of the things that is a huge differentiator is the support and service that Mark Andy has provided us,” says Reding. “I have a high level of confidence working with Mark Andy; the fact that they really are supporting us on a constant basis and looking for opportunities for us to improve.”