09.28.17

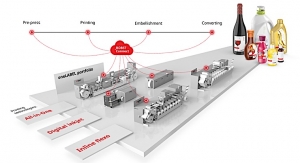

Germany-based digital press manufacturer mprint is introducing its new generation of hybrid UV inkjet presses, the mlabel GEN3 at Labelexpo.

Aside from the facelift from GEN2, Michael Morlock, owner and managing director of mprint, promises several technological advances and additional modules. The base machine will have a standard mechanical width of 330 mm (13”) but does not have to be outfitted with a print engine of the full print width from the beginning. This will allow a technology implementer to start with a lower cost system and expand the print engine in the future, adding capacity without having to purchase a new machine.

Aside from being equipped with CMYK+W the machine shown at Labelexpo offers something else entirely new: the first fully integrated digital cold foiling unit, allowing not only to generate metallic effects on labels and packaging in a single pass, but also to customize these effects with every print. This state-of-the-art module was developed in cooperation with KURZ using their Digital Metal UV Ink technology and presents a technological milestone in digital printing. Especially suited for wine and spirit labels, cosmetics and other high value label and packaging applications, the seamless integration of cold foiling into the digital workflow will give brand owners drastically more possibilities to enhance their products.

While recycling the inks used for purging and flushing the print heads is engrained in mprint’s environmentally friendly commitment, Morlock promises true digital hybrid printing by using different print head technologies together. In adherence to the philosophy of mprint to adapt the machines to the customer’s requirements, the machines can be equipped with a vast array of color options of the digital print engine – CMYK+W+OV+G plus/or spot colors or spot varnishes, etc. – aside from analog options like flexo print stations, etc.

Other “under-the-hood” developments have been integrated for some time in the still available mlabel GEN2 series and will be standard for this new machine generation. By introducing the mlabel GEN3 series mprint advances its standard narrow-web machine portfolio to seamlessly cover print widths from 108mm to 324 mm (4.25” – 12.75”) and single to multi-color (seven or more) by giving the customer all possible choices in initial price and future machine expansion. Custom machines with print widths of 432 mm (17”) and above are also available.

Founded in 1999 and headquartered in Baiersbronn, Germany with a North American Sales and Service organization based in Charlotte, NC mprint has developed one of the fastest UV inkjet printing systems currently available in the market. The mlabel UV inkjet press – and other machine derivatives developed by mprint – reaches a maximum print speed of up to 75 m/min (246 ft/min) combined with one of the highest available native resolutions (600 x 600 dpi plus gray scales). The first machine design that is entirely modular – allowing to add modules in the future onsite – the mlabel prints, laminates and die cuts in a single pass. Machines and print engines for retrofits are available in print widths from 108 mm to 540 mm (4.25 – 21.25 in).

Aside from the facelift from GEN2, Michael Morlock, owner and managing director of mprint, promises several technological advances and additional modules. The base machine will have a standard mechanical width of 330 mm (13”) but does not have to be outfitted with a print engine of the full print width from the beginning. This will allow a technology implementer to start with a lower cost system and expand the print engine in the future, adding capacity without having to purchase a new machine.

Aside from being equipped with CMYK+W the machine shown at Labelexpo offers something else entirely new: the first fully integrated digital cold foiling unit, allowing not only to generate metallic effects on labels and packaging in a single pass, but also to customize these effects with every print. This state-of-the-art module was developed in cooperation with KURZ using their Digital Metal UV Ink technology and presents a technological milestone in digital printing. Especially suited for wine and spirit labels, cosmetics and other high value label and packaging applications, the seamless integration of cold foiling into the digital workflow will give brand owners drastically more possibilities to enhance their products.

While recycling the inks used for purging and flushing the print heads is engrained in mprint’s environmentally friendly commitment, Morlock promises true digital hybrid printing by using different print head technologies together. In adherence to the philosophy of mprint to adapt the machines to the customer’s requirements, the machines can be equipped with a vast array of color options of the digital print engine – CMYK+W+OV+G plus/or spot colors or spot varnishes, etc. – aside from analog options like flexo print stations, etc.

Other “under-the-hood” developments have been integrated for some time in the still available mlabel GEN2 series and will be standard for this new machine generation. By introducing the mlabel GEN3 series mprint advances its standard narrow-web machine portfolio to seamlessly cover print widths from 108mm to 324 mm (4.25” – 12.75”) and single to multi-color (seven or more) by giving the customer all possible choices in initial price and future machine expansion. Custom machines with print widths of 432 mm (17”) and above are also available.

Founded in 1999 and headquartered in Baiersbronn, Germany with a North American Sales and Service organization based in Charlotte, NC mprint has developed one of the fastest UV inkjet printing systems currently available in the market. The mlabel UV inkjet press – and other machine derivatives developed by mprint – reaches a maximum print speed of up to 75 m/min (246 ft/min) combined with one of the highest available native resolutions (600 x 600 dpi plus gray scales). The first machine design that is entirely modular – allowing to add modules in the future onsite – the mlabel prints, laminates and die cuts in a single pass. Machines and print engines for retrofits are available in print widths from 108 mm to 540 mm (4.25 – 21.25 in).