05.09.18

Mark Andy Europe held another of its educational workshops at its demo center in Warsaw, Poland recently. The event was organized for the students of the Printing Technologies Unit that is part of the Faculty of Production Engineering at Warsaw Technical University.

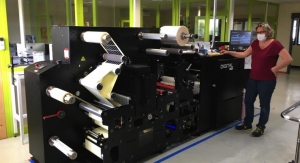

The Open House, which was supported by Mark Andy’s partners, including Dupont, Flint Group, Flexmar and PC Print (the local representative of Kurz), provided an opportunity to show several narrow web presses from the company’s flexo and digital portfolio.

The Open House began with a presentation by Przemyslaw Polkowski, project manager at Mark Andy Europe. He explained the history of the company and its current portfolio of technology, which has grown with the recent acquisition of Presstek. He then focussed on Mark Andy’s narrow web solutions and its increasing popularity among printers, especially in Poland.

The theory session was followed by Michal Mokrzycki and Grzegorz Rostkowski, print instructors at Mark Andy Europe, giving a practical demonstration of the three different presses installed at the demo center: a P7 Performance Series flexo press, and two flexo/digital hybrid models, Digital Series and Digital One. Print demonstrations included jobs prepared by the participating students. On the P7, a set of self-adhesive white labels, prepared by Flexmar prepress studio, was printed using two different Dupont plates (ESX and ESM).

Lena Chmielewska, marketing manager at Mark Andy Poland, explained, “The students were able to judge the job quality, and prior to printing, were involved in mounting plates on cylinders and adjustment of the press. =They could also see how adjustment of the print cylinder impression and the amount of ink delivered ink made changes to the print quality.”

The hybrid Digital One press was also demonstrated using a job prepared by the students. It was printed on a self-adhesive white paper and laminated with Kurz Casten Foil. Digital One also printed a test job for Mark Andy using the same substrate.

The second session at the Open House was devoted to Mark Andy’s technology partners. Tomasz Nojszewski, sales manager NCE Dupont Advanced Printing at Dupont Poland, presented Easy flexo plates from Dupont’s catalog, and Jacek Wacinski, technical service specialist, Narrow Web at Flint Group Poland, talked about color management in narrow web label and packaging printing.

“We are delighted and proud that Mark Andy’s comprehensive solutions attracted so much attention from the students who attended. Their interests ranged from the presses themselves up to today’s global situation in label production, and what the future holds,” explained Chmielewska.

The meeting culminated with an open discussion between the students and representatives of all the companies involved in Open House, who all said that events of this kind are essential in keeping the next generation in touch with the dynamics of a constantly changing print market.

“We, at Mark Andy, have always been very supportive of technical universities that are devoted to the printing industry, and value the opportunity to improve their knowledge of label and packaging production – the students, after all, are the printers and consumers of the future,” she concluded.

The Open House, which was supported by Mark Andy’s partners, including Dupont, Flint Group, Flexmar and PC Print (the local representative of Kurz), provided an opportunity to show several narrow web presses from the company’s flexo and digital portfolio.

The Open House began with a presentation by Przemyslaw Polkowski, project manager at Mark Andy Europe. He explained the history of the company and its current portfolio of technology, which has grown with the recent acquisition of Presstek. He then focussed on Mark Andy’s narrow web solutions and its increasing popularity among printers, especially in Poland.

The theory session was followed by Michal Mokrzycki and Grzegorz Rostkowski, print instructors at Mark Andy Europe, giving a practical demonstration of the three different presses installed at the demo center: a P7 Performance Series flexo press, and two flexo/digital hybrid models, Digital Series and Digital One. Print demonstrations included jobs prepared by the participating students. On the P7, a set of self-adhesive white labels, prepared by Flexmar prepress studio, was printed using two different Dupont plates (ESX and ESM).

Lena Chmielewska, marketing manager at Mark Andy Poland, explained, “The students were able to judge the job quality, and prior to printing, were involved in mounting plates on cylinders and adjustment of the press. =They could also see how adjustment of the print cylinder impression and the amount of ink delivered ink made changes to the print quality.”

The hybrid Digital One press was also demonstrated using a job prepared by the students. It was printed on a self-adhesive white paper and laminated with Kurz Casten Foil. Digital One also printed a test job for Mark Andy using the same substrate.

The second session at the Open House was devoted to Mark Andy’s technology partners. Tomasz Nojszewski, sales manager NCE Dupont Advanced Printing at Dupont Poland, presented Easy flexo plates from Dupont’s catalog, and Jacek Wacinski, technical service specialist, Narrow Web at Flint Group Poland, talked about color management in narrow web label and packaging printing.

“We are delighted and proud that Mark Andy’s comprehensive solutions attracted so much attention from the students who attended. Their interests ranged from the presses themselves up to today’s global situation in label production, and what the future holds,” explained Chmielewska.

The meeting culminated with an open discussion between the students and representatives of all the companies involved in Open House, who all said that events of this kind are essential in keeping the next generation in touch with the dynamics of a constantly changing print market.

“We, at Mark Andy, have always been very supportive of technical universities that are devoted to the printing industry, and value the opportunity to improve their knowledge of label and packaging production – the students, after all, are the printers and consumers of the future,” she concluded.