11.15.18

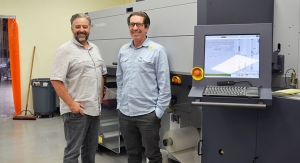

Originally known as “All American Label,” the Dublin, CA, USA-based company recently installed three Heidelberg machines to add packaging services to its list of product offerings – inspiring their new name: All American Label and Packaging. The new equipment includes a Suprasetter A 106 CtP, Speedmaster CD 102-6+L, and Easymatrix 106 CS, which is Heidelberg’s 100th installed diecutter worldwide.

“We want to be like a local convenience store for our customers — a one-stop shop for everything they need. Our customers can purchase their labels, sheetfed, offset-web, foiled embossed, inkjet, wide-format inkjet, grand format inkjet, all the way to simple signs, banners, and commercial print,” says Brad Brown, CEO of All American Label and Packaging. “This is what made us go with this large Heidelberg suite of products — we wanted to offer everything to our customers, and we wanted to offer the best.”

“More Than Just Labels”

With customer requests for packaging and the company’s own desire to be “More Than Just Labels,” All American Label and Packaging looked to Heidelberg to expand their product portfolio. First stop was installing the 100th Easymatrix 106 CS.

Running at speeds up to 7,700 sheets per hour, the Easymatrix allows All American Label and Packaging to keep all diecutting work in-house, which is important for projects on a tight timeline. With a full 41” format and non-stop functionality in the feeder and delivery, longer runs can be cut and stripped efficiently. All American Label and Packaging will now have shorter makeready times thanks to the intuitive touchscreen interface, along with the motorized cutting pressure adjustment and quick-lock technology for dies and stripping tools.

“For customers wanting to differentiate their packaging, we are now able to diecut, deboss, emboss, and strip in-line,” said Brown. “Thanks to the diecutter, labor is reduced, which will help us save money.”

Speedmaster CD 102

In order to start offering high quality packaging print jobs, All American Label and Packaging chose the Heidelberg Speedmaster CD 102-6+L, which provides flexible processing of a large variety of jobs and materials.

“We keep ourselves in the market by giving our customers short lead times; however, when we wanted to run a good carton with all the bells and whistles, we just couldn’t do it to the standard that our customers were expecting. With the CD 102, we are able to give our customers a high quality product that we could set up and run quickly. The machine is opening a whole new avenue for us to increase revenue,” adds Brown.

Running at speeds up to 15,000 sheets an hour, the Speedmaster CD 102 is the world’s most popular range of machines in the 70x100 cm format. Delivering up to 40 million impressions per year, the easy-to-use CD 102 offers short makeready times and an attractive price/performance ratio — maximizing the profit potential of its output.

“In a really competitive market like the printing industry, it’s crucial to differentiate yourself. How do you do that? You purchase the industry-leading technology, and then you offer your customers something that is going to differentiate their packaging on the shelf. And that’s what the CD 102 is going to help us do,” said Brown

To partner alongside All American Label and Packaging’s highly productive press, the company installed a Suprasetter A 106 CtP. Holding 110 plates of each press size, the Suprasetter A 106 fully automates the loading of plates direct from the Dual Cassette Loader with slip sheet removal, imaging, punching, and plate stacking. The Suprasetter offers an extremely accurate internal punching system for maximum register accuracy.

Along with their three new pieces of Heidelberg equipment, All American Label and Packaging has Prinect Pressroom Manager and a high-speed POLAR 137 cutter. All machines are fully equipped with Saphira consumables, which include plates, inks, coatings, and chemistry. However, when it comes to why they chose Heidelberg with their equipment, technology and consumables, the answer was always service.

“I could go on about how the quality from Heidelberg is next to none, but what really sets Heidelberg apart is their service,” says Brown. “Heidelberg has so many highly trained technicians and such a quick response rate. We have presses from everywhere, and honestly, the technology and service from Heidelberg is always top of the line.”

In September 2013, L&NW editor Steve Katz sat down with Brad Brown for a Narrow Web Profile story on All American Label. Check it out at: https://www.labelandnarrowweb.com/issues/2013-09/view_features/narrow-web-profile-all-american-label/

“We want to be like a local convenience store for our customers — a one-stop shop for everything they need. Our customers can purchase their labels, sheetfed, offset-web, foiled embossed, inkjet, wide-format inkjet, grand format inkjet, all the way to simple signs, banners, and commercial print,” says Brad Brown, CEO of All American Label and Packaging. “This is what made us go with this large Heidelberg suite of products — we wanted to offer everything to our customers, and we wanted to offer the best.”

“More Than Just Labels”

With customer requests for packaging and the company’s own desire to be “More Than Just Labels,” All American Label and Packaging looked to Heidelberg to expand their product portfolio. First stop was installing the 100th Easymatrix 106 CS.

Running at speeds up to 7,700 sheets per hour, the Easymatrix allows All American Label and Packaging to keep all diecutting work in-house, which is important for projects on a tight timeline. With a full 41” format and non-stop functionality in the feeder and delivery, longer runs can be cut and stripped efficiently. All American Label and Packaging will now have shorter makeready times thanks to the intuitive touchscreen interface, along with the motorized cutting pressure adjustment and quick-lock technology for dies and stripping tools.

“For customers wanting to differentiate their packaging, we are now able to diecut, deboss, emboss, and strip in-line,” said Brown. “Thanks to the diecutter, labor is reduced, which will help us save money.”

Speedmaster CD 102

In order to start offering high quality packaging print jobs, All American Label and Packaging chose the Heidelberg Speedmaster CD 102-6+L, which provides flexible processing of a large variety of jobs and materials.

“We keep ourselves in the market by giving our customers short lead times; however, when we wanted to run a good carton with all the bells and whistles, we just couldn’t do it to the standard that our customers were expecting. With the CD 102, we are able to give our customers a high quality product that we could set up and run quickly. The machine is opening a whole new avenue for us to increase revenue,” adds Brown.

Running at speeds up to 15,000 sheets an hour, the Speedmaster CD 102 is the world’s most popular range of machines in the 70x100 cm format. Delivering up to 40 million impressions per year, the easy-to-use CD 102 offers short makeready times and an attractive price/performance ratio — maximizing the profit potential of its output.

“In a really competitive market like the printing industry, it’s crucial to differentiate yourself. How do you do that? You purchase the industry-leading technology, and then you offer your customers something that is going to differentiate their packaging on the shelf. And that’s what the CD 102 is going to help us do,” said Brown

To partner alongside All American Label and Packaging’s highly productive press, the company installed a Suprasetter A 106 CtP. Holding 110 plates of each press size, the Suprasetter A 106 fully automates the loading of plates direct from the Dual Cassette Loader with slip sheet removal, imaging, punching, and plate stacking. The Suprasetter offers an extremely accurate internal punching system for maximum register accuracy.

Along with their three new pieces of Heidelberg equipment, All American Label and Packaging has Prinect Pressroom Manager and a high-speed POLAR 137 cutter. All machines are fully equipped with Saphira consumables, which include plates, inks, coatings, and chemistry. However, when it comes to why they chose Heidelberg with their equipment, technology and consumables, the answer was always service.

“I could go on about how the quality from Heidelberg is next to none, but what really sets Heidelberg apart is their service,” says Brown. “Heidelberg has so many highly trained technicians and such a quick response rate. We have presses from everywhere, and honestly, the technology and service from Heidelberg is always top of the line.”

In September 2013, L&NW editor Steve Katz sat down with Brad Brown for a Narrow Web Profile story on All American Label. Check it out at: https://www.labelandnarrowweb.com/issues/2013-09/view_features/narrow-web-profile-all-american-label/