L&NW Staff05.12.20

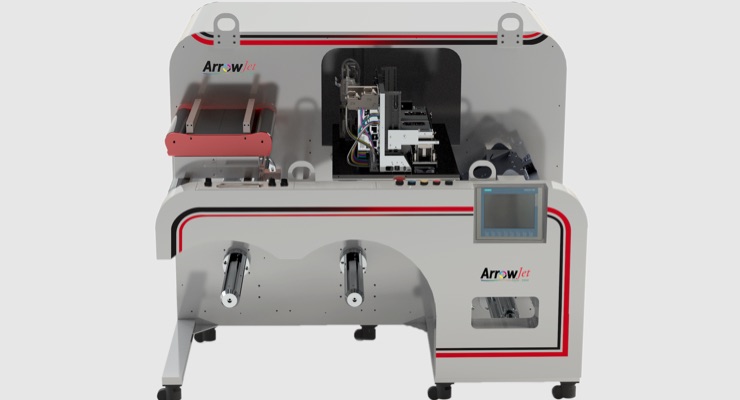

Arrow Systems has unveiled the new ArrowJet Aqua 330R, the latest in digital label printing equipment. This new product is a high-speed, aqueous pigment press that provides enhanced print quality and greater production flexibility than previous aqueous inkjet technologies, the company says.

The ArrowJet Aqua 330R, powered by Memjet’s DuraFlex printhead technology, provides customers with the benefits of digital printing, as well as enhanced durability and fast speeds, by using aqueous pigment inkjet technology. The digital workflow adds the flexibility to change designs on the fly, print on demand, implement variable data and make color alterations without changing inks, plates, or tooling. Plus, using an aqueous pigment-based inkjet ink provides greater substrate compatibility than previous aqueous inkjet technologies.

“The ArrowJet Aqua 330R is the first USA-manufactured, roll-to-roll press with an integrated ChromaPlex LT inkjet print engine from Colordyne,” says Shaan Patel, business development manager of Arrow Systems. “The impressive speeds and capabilities of the system offer several benefits, including improving production efficiency, reducing run costs and providing exceptional resolution. Designed with the end user in mind, the modularity of the ArrowJet Aqua 330R gives customers the flexibility to tailor the press to their specific market and application needs.”

The new press offers high resolution, up to 1600 x 1600 dpi, and print speeds up to 150 fpm (50 m/m). The ArrowJet Aqua 330R can be configured for either off-line operation, or paired with various inline finishing options, including both laser diecutting and traditional analog finishing. Fast speeds and low ink costs allow this system to provide one of the highest production rates and lowest print costs in digital narrow web label printing.

“We are excited to work with Arrow Systems, as a Strategic Integration Partner of our ChromaPlex LT print engine,” states Taylor Buckthorpe, director of sales at Colordyne. “With the integration of our aqueous pigment inkjet engine, the ArrowJet Aqua 330R is compatible with a wide range of applications to add greater value to customers’ businesses.”

The ArrowJet Aqua 330R features a large unwind and rewind with capacity up to standard 20" rolls, an inline edge guide, inline IR curing, and an integrated RIP software for precise color matching and variable data printing. The modularity of the print engine technology offers the ability to stitch multiple printheads together for wider print widths. Arrow Systems is currently working on a 17’’ model for the flexible packaging market and will be looking at other custom widths for customers in various industries around the world.

The ArrowJet Aqua 330R, powered by Memjet’s DuraFlex printhead technology, provides customers with the benefits of digital printing, as well as enhanced durability and fast speeds, by using aqueous pigment inkjet technology. The digital workflow adds the flexibility to change designs on the fly, print on demand, implement variable data and make color alterations without changing inks, plates, or tooling. Plus, using an aqueous pigment-based inkjet ink provides greater substrate compatibility than previous aqueous inkjet technologies.

“The ArrowJet Aqua 330R is the first USA-manufactured, roll-to-roll press with an integrated ChromaPlex LT inkjet print engine from Colordyne,” says Shaan Patel, business development manager of Arrow Systems. “The impressive speeds and capabilities of the system offer several benefits, including improving production efficiency, reducing run costs and providing exceptional resolution. Designed with the end user in mind, the modularity of the ArrowJet Aqua 330R gives customers the flexibility to tailor the press to their specific market and application needs.”

The new press offers high resolution, up to 1600 x 1600 dpi, and print speeds up to 150 fpm (50 m/m). The ArrowJet Aqua 330R can be configured for either off-line operation, or paired with various inline finishing options, including both laser diecutting and traditional analog finishing. Fast speeds and low ink costs allow this system to provide one of the highest production rates and lowest print costs in digital narrow web label printing.

“We are excited to work with Arrow Systems, as a Strategic Integration Partner of our ChromaPlex LT print engine,” states Taylor Buckthorpe, director of sales at Colordyne. “With the integration of our aqueous pigment inkjet engine, the ArrowJet Aqua 330R is compatible with a wide range of applications to add greater value to customers’ businesses.”

The ArrowJet Aqua 330R features a large unwind and rewind with capacity up to standard 20" rolls, an inline edge guide, inline IR curing, and an integrated RIP software for precise color matching and variable data printing. The modularity of the print engine technology offers the ability to stitch multiple printheads together for wider print widths. Arrow Systems is currently working on a 17’’ model for the flexible packaging market and will be looking at other custom widths for customers in various industries around the world.