L&NW Staff07.07.20

Last month Domino provided a sneak peek of the new X630i digital aqueous inkjet press with a 42-second video teaser. Domino has just unveiled a full three-minute video providing further details on this digital corrugated press.

Domino's X630i digital aqueous inkjet corrugated press has been developed to help converters grow their digital printing business with entrance into new sectors.

The X630i is a single pass, CMYK water-based digital inkjet press with Domino’s AQ95 ink set, which is Swiss Ordinance and Nestle compliant. The ink utilizes a polymer-based technology enabling printing on a wide range of uncoated and coated stocks, with no pre-coating required. And because it's digital, it continuously prints from one job to the next without the need to stop the press, so converters can change SKUs, images, artwork designs, and personalization with the simple user interface. It translates to less setup, less make-ready, less downtime, and more uptime.

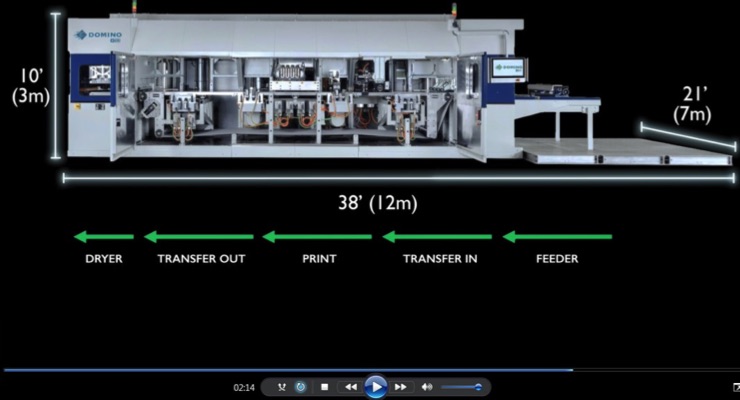

Printing at speeds up to 246 fpm (75 m/m), the X630i touts throughput on a small footprint, measuring only 10’ H x 38’ W x 21’ D. And the X630i utilizes an environmentally friendly production process, allowing converters to do more. From transit packaging to display work and everything in-between, the X630i allows for a wide range of print options to be considered across the brand offering, helping converters to increase margins, improve workflow, and grow their sales opportunities. It offers a lower total cost of ownership, while addressing the needs of converters and brand owners, alike. “This is the new business model for corrugated box printing. The Domino X630i changes everything, taking the corrugated print industry and your business to the next level," the company states.

Brand owners are increasing the number of versions, varieties, sizes, and flavors of products to gain and maintain consumer mindshare, as well as adding personalization to their packaging for greater consumer and brand engagement. They also want to minimize the amount of inventory-on-hand, while having their corrugated packaging supplier provide quick turnaround, on demand.

In parallel, converters are seeing an upward trajectory in this shorter run work, which challenges conventional printing methods in the amount of time it takes for set-up, changeovers, and running production. And converters want to ensure they are addressing the needs of their brand owner customers while running their business successfully and profitably. Digital Printing provides that product.

Domino's X630i digital aqueous inkjet corrugated press has been developed to help converters grow their digital printing business with entrance into new sectors.

The X630i is a single pass, CMYK water-based digital inkjet press with Domino’s AQ95 ink set, which is Swiss Ordinance and Nestle compliant. The ink utilizes a polymer-based technology enabling printing on a wide range of uncoated and coated stocks, with no pre-coating required. And because it's digital, it continuously prints from one job to the next without the need to stop the press, so converters can change SKUs, images, artwork designs, and personalization with the simple user interface. It translates to less setup, less make-ready, less downtime, and more uptime.

Printing at speeds up to 246 fpm (75 m/m), the X630i touts throughput on a small footprint, measuring only 10’ H x 38’ W x 21’ D. And the X630i utilizes an environmentally friendly production process, allowing converters to do more. From transit packaging to display work and everything in-between, the X630i allows for a wide range of print options to be considered across the brand offering, helping converters to increase margins, improve workflow, and grow their sales opportunities. It offers a lower total cost of ownership, while addressing the needs of converters and brand owners, alike. “This is the new business model for corrugated box printing. The Domino X630i changes everything, taking the corrugated print industry and your business to the next level," the company states.

Brand owners are increasing the number of versions, varieties, sizes, and flavors of products to gain and maintain consumer mindshare, as well as adding personalization to their packaging for greater consumer and brand engagement. They also want to minimize the amount of inventory-on-hand, while having their corrugated packaging supplier provide quick turnaround, on demand.

In parallel, converters are seeing an upward trajectory in this shorter run work, which challenges conventional printing methods in the amount of time it takes for set-up, changeovers, and running production. And converters want to ensure they are addressing the needs of their brand owner customers while running their business successfully and profitably. Digital Printing provides that product.