Greg Hrinya01.28.21

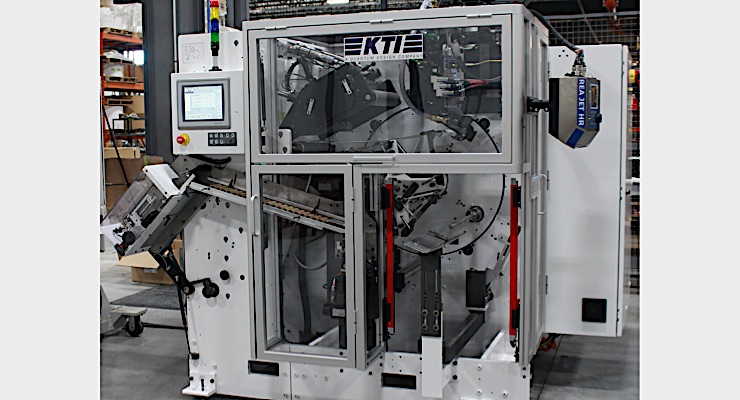

KTI, a global manufacturer of automatic splicers, turret rewinders and other web converting equipment, has completed installation of an MTR Series turret rewinder at Abbott Label in Santa Fe Springs, CA.

Abbott Label, established in 2000, is a Dallas, TX, USA-based label converter with additional locations in Chicago, Los Angeles and Atlanta. Abbott is a trade-only pressure sensitive label converter that has found success through a simple philosophy of putting the customer first. In fact, Abbott's plant locations were chosen strategically to allow the company to ship product anywhere in the country in only two days.

Abbott plans to run thermal transfer, direct thermal and semi-gloss labels on the new turret rewinder. The company was looking for a way to run and finish high volume roll labels while avoiding a secondary step of rewinding. With one of its primary focuses being speed, the MTR will allow Abbott to meet its customer satisfaction goals and deliver orders quickly.

The MTR has increased production speeds, leaving more time for the operator to focus on machine efficiency and package finished rolls. The automatic tail gluer closes rolls, leaving them ready-to-package right off of the machine. With the MTR’s small footprint, it can be seamlessly integrated into most production lines.

Hayden Wier, marketing manager at Abbott Label, says “The research we have done on turret rewinders and the industry has told us that KTI’s MTR Series is a reliable turret rewinder and is supported well, helping make the decision easy for us.”

KTI’s after-sale support is one of Quantum Design’s core values, according to Derek Wheeler, VP of sales, “KTI and Quantum Design take pride in how quickly we strive to turn around service requests. Our preventative maintenance packages and reminders help service our customers before they need us.

“With an in-house automation team and over a dozen controls engineers, Quantum Design and KTI can offer an advantage over competitors in the industry," he adds. "Not only can we ensure the highest level of automation on new machines, but we can help customers maintain their controls with years of support following installation.”

With the successful installation of this turret rewinder, Abbott Label has already ordered a second MTR Series Turret Rewinder to be installed in its Atlanta, GA plant in Spring 2021.

The MTR Series Turret Rewinder has four spindles and is available in web widths up to 22" (558 mm), roll diameters up to 16" (406 mm), speeds up to 750 fpm (228 m/m) and can run cores ranging from .75" to 3" (19 mm to 76 mm). Standard features include PLC touch screen controls, servo motor driven spindles, an integrated dancer for superior web control, tapered winding tension and remote diagnostics.

Optional features available for the MTR Series turret rewinder include a roll closure system with optional print and apply functionality, automatic core loading with adjustable spacing of cores, proprietary core hopper system. Customers can choose from two types of core gluing: an automatic spray glue system with a hot-melt tank and spray nozzle, or the traditional hot-melt glue pot with an optional refill system.

Abbott Label, established in 2000, is a Dallas, TX, USA-based label converter with additional locations in Chicago, Los Angeles and Atlanta. Abbott is a trade-only pressure sensitive label converter that has found success through a simple philosophy of putting the customer first. In fact, Abbott's plant locations were chosen strategically to allow the company to ship product anywhere in the country in only two days.

Abbott plans to run thermal transfer, direct thermal and semi-gloss labels on the new turret rewinder. The company was looking for a way to run and finish high volume roll labels while avoiding a secondary step of rewinding. With one of its primary focuses being speed, the MTR will allow Abbott to meet its customer satisfaction goals and deliver orders quickly.

The MTR has increased production speeds, leaving more time for the operator to focus on machine efficiency and package finished rolls. The automatic tail gluer closes rolls, leaving them ready-to-package right off of the machine. With the MTR’s small footprint, it can be seamlessly integrated into most production lines.

Hayden Wier, marketing manager at Abbott Label, says “The research we have done on turret rewinders and the industry has told us that KTI’s MTR Series is a reliable turret rewinder and is supported well, helping make the decision easy for us.”

KTI’s after-sale support is one of Quantum Design’s core values, according to Derek Wheeler, VP of sales, “KTI and Quantum Design take pride in how quickly we strive to turn around service requests. Our preventative maintenance packages and reminders help service our customers before they need us.

“With an in-house automation team and over a dozen controls engineers, Quantum Design and KTI can offer an advantage over competitors in the industry," he adds. "Not only can we ensure the highest level of automation on new machines, but we can help customers maintain their controls with years of support following installation.”

With the successful installation of this turret rewinder, Abbott Label has already ordered a second MTR Series Turret Rewinder to be installed in its Atlanta, GA plant in Spring 2021.

The MTR Series Turret Rewinder has four spindles and is available in web widths up to 22" (558 mm), roll diameters up to 16" (406 mm), speeds up to 750 fpm (228 m/m) and can run cores ranging from .75" to 3" (19 mm to 76 mm). Standard features include PLC touch screen controls, servo motor driven spindles, an integrated dancer for superior web control, tapered winding tension and remote diagnostics.

Optional features available for the MTR Series turret rewinder include a roll closure system with optional print and apply functionality, automatic core loading with adjustable spacing of cores, proprietary core hopper system. Customers can choose from two types of core gluing: an automatic spray glue system with a hot-melt tank and spray nozzle, or the traditional hot-melt glue pot with an optional refill system.