Greg Hrinya, Editor03.12.21

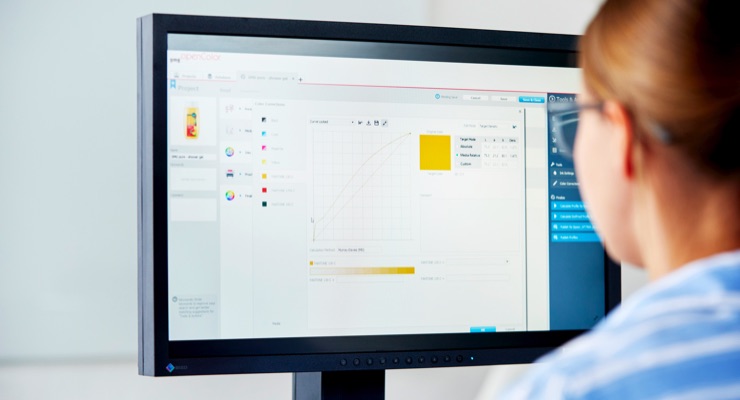

Automation and integration characterize the day-to-day in print production. With GMG's color management, print data is now automatically converted and optimally prepared for various printing technologies. The new connection options from GMG OpenColor allow for even more extensive process optimization.

GMG OpenColor has been designed to reliably guarantee accurate color reproduction. Thanks to the extended interface, the GMG OpenColor libraries are now available to many other providers, such as the company Colorware with MeasureColor – the solution for print quality control – which is now on board.

GMG is very pleased with the cooperation, it says. The values that MeasureColor uses as a target for print production now match the proofing color definitions of GMG OpenColor. That ensures the proof is matched with ease – and, as a result, customer's expectations are met instantly. Make-ready and approval are much faster.

Ruud Wentrup, managing director of MeasureColor developer Colorware, says, "Thanks to the new collaboration, it is finally possible to close the gap between prepress and the printing press. We are happy about the new possibilities of data exchange. That way, we can avoid many mistakes, produce less waste and obtain more precise colors. Trial-and-error is finally history and the printing process is accelerated sustainably."

"The main requirements of our customers are automation and, of course, complete control over print quality," adds Peter Schöffler, product manager at GMG. "Both expectations are met with the new addition. As the library for spectral color information, GMG OpenColor is the central hub of automated color management in prepress. In connection with MeasureColor, results match across the board: increased productivity and extended print capacity thanks to shorter makeready times."

GMG OpenColor has been designed to reliably guarantee accurate color reproduction. Thanks to the extended interface, the GMG OpenColor libraries are now available to many other providers, such as the company Colorware with MeasureColor – the solution for print quality control – which is now on board.

GMG is very pleased with the cooperation, it says. The values that MeasureColor uses as a target for print production now match the proofing color definitions of GMG OpenColor. That ensures the proof is matched with ease – and, as a result, customer's expectations are met instantly. Make-ready and approval are much faster.

Ruud Wentrup, managing director of MeasureColor developer Colorware, says, "Thanks to the new collaboration, it is finally possible to close the gap between prepress and the printing press. We are happy about the new possibilities of data exchange. That way, we can avoid many mistakes, produce less waste and obtain more precise colors. Trial-and-error is finally history and the printing process is accelerated sustainably."

"The main requirements of our customers are automation and, of course, complete control over print quality," adds Peter Schöffler, product manager at GMG. "Both expectations are met with the new addition. As the library for spectral color information, GMG OpenColor is the central hub of automated color management in prepress. In connection with MeasureColor, results match across the board: increased productivity and extended print capacity thanks to shorter makeready times."