Steve Katz, Associate Editor01.26.22

Static electricity could be a hair-raising experience for label converters. Thankfully, there are suppliers to the label industry dedicated to controlling this scientific phenomenon that can wreak havoc on a print run. We caught up with some of the industry’s leading suppliers, who discuss the latest industry trends and their effect on static, as well as the products they offer that address static control challenges.

Static Clean International

Julianne Ouellet, director of marketing at Static Clean International, points out that the speed of webs have increased, resolutions and tolerances are much tighter, print quality demand has improved, and all are impacted by static electricity.

Addressing the negative impact static can have on a print run, Static Clean International offers long-range and high-speed static eliminators (4103 and 4203) that are popular and effective in labeling applications/processes for the food, drink, pharmaceutical, medical and FMCG (Fast Moving Consumer Goods) sectors.

“Due to their small profile, these static eliminators are ideal for mounting on machines where space is sometimes at a premium. The Model 4203 long range bars that work up to 30" away are well-suited for roll-to-sheet and roll-to-roll presses,” explains Ouellet.

She adds, “Technology is always changing for the label industry, and the static control industry will follow the trends. The medical device and pharma industries not only require a quality label, but ones that are particle-free. It is a fact that if static is controlled on the press, less particles will be attracted to the process. The future is bright for static control and static control products in the label and converting industry. In today’s marketplace, there is a heavy focus on everything being static ‘clean’ and ‘particulate-free.’ Controlling static that causes particles to ‘stick’ to materials – such as plastic packaging or labels – is relevant to the new norm and standards that the printing industry demands. High reject rates will occur if static electricity is not controlled on the press.”

At Static Clean International, one of the latest developments in the works is a static bar that can work at even higher speeds and up to five feet from the web. “While these improvements are great to implement at unwind and rewind rolls, in time it will have promise for use in other areas such as before print stations and after corona treatment,” she says, concluding, “Static Clean is always creating and exploring ways to create products that keep up with evolving industry demands.”

Simco-Ion

“For the label printer, static control and web cleaning often go hand in hand,” says Gabby Lockwood, marketing communications specialist at Simco-Ion.

The company has seen a spike in demand from OEMs, especially those with a digital hybrid press offering. “These presses require proven, reliable, and cost-effective static elimination and web cleaning technology to continue to run profitably, day after day,” Lockwood says, noting that 2021 saw a marked increase in the sale of Teknek contact cleaners and the Simco-Ion IQ Easy static bars into the narrow web printing market segment.

“One of the drivers of this is that digital printheads require a clean substrate to continually deliver precise printing results. OEMs are focused on delivering a clean sheet into the printhead as daily accumulation of visible and non-visible particulate on the printing heads results in costly inefficiencies and waste. Invisible particles, trapped by the boundary layer of air on the moving web, continue to bedevil non-contact and touchless systems because, regardless of their design, they struggle to consistently break the boundary layer of air to remove 95%+ of the sub 10 micron particles.

“Teknek, contact cleaning specialists, smash the boundary level of air, guaranteeing consistent cleaning results across a variety of web speeds, thicknesses and tensions,” Lockwood says. “Teknek continues to grow because it uniquely provides a variety of in-house designed elastomers, focused on the surface to be cleaned, and when the Teknek cleaning roll is paired with the proprietary Teknek adhesive, the result is the world famous Teknek Cleaning Core.”

According to Lockwood, the Teknek Cleaning Core has proven to be able to remove dry unattached particles down to <1 micron. Lockwood explains, “The core works continuously to clean the entire web by gently contacting the web, such that the cleaning roll lifts the contaminate off the web and the Teknek adhesive refreshes the cleaning roll.”

For static elimination, narrow web converters can look to Simco-Ion. The design of its Easy Bar allows the high output power supply to make the most out of the return signal from the web to maximize ionization performance, unlike competitive offerings, which require separate ground connections to the bar to protect their power supply. Additionally, the bar has no pins to replace, no air requirement, is purpose-built for converting, comes with worldwide support, and is scalable up to what the company says is a state-of-the-art Industry 4.0 monitored system via the Simco-Ion Control Station. “This is why the blue of the Easy Bar continues to be the most recognizable OEM static bar at every converting show,” Lockwood says.

Recently, the Easy Bar family added a new member, the Easy LP. The Easy LP provides the same level of class leading performance but in a smaller package, .75" tall, and with a flat mounting kit so that it fits in the tightest of spaces. With an output tuning for 1-4" from the target, Simco-Ion says it is ideal for difficult applications, and whether the target charge is 20kv or 500V this bar will successfully drive both to zero.

Finally, for customers who want to eliminate long cable runs and don’t want the security issues posed by another IP address, Simco-Ion introduced the IQ Power Wireless Link via Industrial Bluetooth for use with the Control Station. With line of sight range of 200’ this system allows for constant contact with all IQ Power static eliminators, including Fantom blowers and sensor bars without complicated and expensive cable installation. The wireless hub is powered by a 24V connection, and thus can be mounted in difficult to access areas, for example on a turret, to allow communication with bars mounted on the winder.

Meech international

“There are several different static-related issues found at label converters,” states Matt Fyffe, vice president and general manager at Meech International. “Traditionally, a majority of these problems deal with print quality. Static electricity attracts dust and debris to the web, which can result in poor quality and high reject rates.”

With an increasing number of label converters going digital and also printing on film and coated stocks, Fyffe is noticing much higher demand for static control products. He says, “Digital printheads are especially susceptible to static issues. A high static charge on the web can actually repel the ink droplets from the digital printer. The repelled ink droplets will then gum up the printhead and will require more frequent cleaning. In extreme cases, high charges can actually cause permanent damage to the printheads.”

According to Fyffe, label converters today must be more adaptable and quick to change in order to compete. “This means they need to be able to print and convert various substrates at a moment’s notice with quick changeover. Therefore, they need static control and web cleaning systems that can be used on multiple substrates without requiring time to reset the controls.”

The systems provided by Meech require very little, if any, service and input from the operators, Fyffe says, adding, “They adjust themselves to maintain optimum performance.”

Fyffe points out that tacky roller web cleaners are the most popular form of web cleaning systems in the label converter market as they are fairly inexpensive and easy to install. “However,” he says, “there is a consumable cost involved, and they require regular maintenance and constant operator supervision.”

Meech has recently developed a fan driven non-contact web cleaning system for the narrow web industry as an upgrade to the tacky roller systems of old. The CyClean-R system from Meech boasts several advantages over tacky rollers, including no ongoing consumable costs; very little maintenance required; operation does not affect the web path; the ability to run at very low tensions; easy to install over an existing roller; flexibility to run on any substrate, including paper, film or foil; and full press integration.

The SmartControl Touch is a static control product from Meech that Fyffe is excited about. It allows the user to monitor, control and adjust the performance of multiple connected comparable Hyperion ionizing bars and sensors via the integrated touchscreen or remotely via a mobile phone, tablet or remote desktop.

“This means that at all times, the performance of the connected equipment may be monitored and optimized to achieve the best results, according to the application,” Fyffe says. “The ionizing equipment’s performance is easily tracked by the SmartControl Touch, which uses Meech’s Ion Current Monitoring Technology, allowing the user to monitor the ionizing performance. With the ability to connect six bars directly and an additional 24 bars using two expansion units (sold separately), SmartControl delivers exceptional central control.”

TAKK Industries

Terrance Clark, sales manager for TAKK Industries, notes several problems that static electricity can cause in label converting, chief among them are print quality related defects. He says, “Static electricity is prone to result in repulsion or attraction of ink to a substrate’s surface. In the case of repulsion of ink droplets or dots, a printer likely would see ink smears, fuzzy characters or print hickies that negatively impact production of high-quality printed labels.”

When it comes to the label industry’s major trend – digital printing – Clark points out, “Conversely, static electricity attraction effects in digital printing can cause ink to expand out in what should be white space of a label or cause dropout of incorrect colors during printing from the digital printhead. These static issues create unacceptable prints, causing wasted production time, ink and substrates, and considerable labor and re-work costs.”

Clark emphasizes that label converters continue to be laser focused on producing the best products with improved profit margins. “In pursuit of this goal, many savvy printers are looking for next generation static control technologies,” he says. “These automatically adjusting ionizers (static eliminators) have very high capabilities and versatility to match the unique, ever-evolving parameters that today’s leading label converters must have to deliver and meet their customers’ expectations.”

To meet these evolving converter needs, TAKK Industries brought to market its “Reactive Intelligence” static elimination technology in its NEOS series static eliminators.

“The NEOS, in addition to its exceptional static elimination capabilities, also continuously adjusts both its static elimination power and ion output to match the exact needs of the application,” Clark explains. “It can be installed at short or exceptionally long distances of up to 60-plus inches to accommodate changing diameter rolls or challenging space situations. The NEOS’ technology easily dovetails with today’s leading-edge PLC/HMI interfaces for instant status information about the unit’s operation, in addition to local status indicators on the NEOS bar.”

According to Clark, TAKK Industries’ NEOS Series Static Control Technology is fast becoming the comprehensive, fool-proof static control solution that meets the demands of label converters. “The NEOS Series is a new evolution in smart static controls, providing exceptional capabilities such as using ‘Reactive Intelligence’ that detects and delivers the exact amount of ionization required, thus maintaining consistent control of static.”

Models from the NEOS series eliminate static charges at distances up to 60" and speeds up to 4,500 fpm without air.

TAKK recently introduced its 3024 Compact and 3024 Ultra DC Static Eliminators. These units are specially designed and suited for both OEM machinery and end users where there are tight constraints for mounting on digital or conventional label presses, tabletop winders, and related production machinery requiring high performance static elimination performance in a compact size. The 3024 has a built-in power supply and LED indicators that provide local and remote status for the ionizer bar. The 3024 Ultra and Compact are highly suited for narrow web labels, sleeves and tapes.

By Fabrizio Mandingorra, PPG global segment manager, Teslin Products, Labels and Graphics

Three significant problems caused by static electricity in the workplace include electrostatic attraction and repulsion, shocks to operators, and fire risk. Electrostatic attraction/repulsion is one of the most widespread issues in the plastics, packaging and paper industries, and can result in product issues such as sticking, repelling each other, and attracting dust. All of these elements ultimately lead to loss of productivity and profits. Fire risk is critically important in industries where solvent materials are used. Static charge on material can cause a spark discharge, which can ignite the solvent and create a fire.

When labels are processed through digital laser printers, they are charged through an electrostatic process that causes print toner to adhere to the label surface. When printed labels are peeled, that action can generate static charge (tribocharging), which has the potential to ignite vapors in industrial environments in which chemicals, solvents and flammable materials are present.

In 2017, an employee working at a global paint and coating manufacturer was filling 5-gallon pails of primer using an automated filling device. As pails were filled, the employee sealed the lids and applied a vinyl self-adhesive label to each pail, discarding the label backing into a wheeled trash bin nearby.

While mopping the floor with a cleaning solution, the employee contacted the wheel of the cart with the mop head, generating a static spark that jumped from the wheel and ignited the solvent in the cleaning solution, setting the mop head on fire. Although the fire was quickly extinguished, an investigation later determined that the voltage from the wheeled trash bin was generated by the electrostatically charged label backings it contained.

After making this determination, the paint manufacturer immediately engaged its label management vendor and an independent testing center to identify the labelstocks that would generate the lowest amount of electrostatic voltage during label application.

The company turned to a process safety management firm that helps businesses in preventing explosions, fires and accidental material releases to conduct static testing of PPG Teslin substrate, vinyl and PET label materials.

First, a label peel test was conducted to determine the electrostatic charge buildup when an electrically-isolated label set is peeled off from its backing and placed in a Faraday Cage under different conditions of relative humidity. The specific charge density calculated was then compared with maximum surface charge density (charge per unit area of 2.7x10-5 Coulomb/m2) in free space.

When peeled from their backings, vinyl labels can become electrostatically charged to 29% of the maximum charge density possible (2.7x10-5 C/m2) at ambient humidity environments, and PET labels can become charged to 30%. The same test of Teslin labels showed that they only become electrostatically charged to 0.065%. The charge on both the vinyl and PET labels can give rise to incendive electrostatic discharges under ambient and low relative humidity conditions.

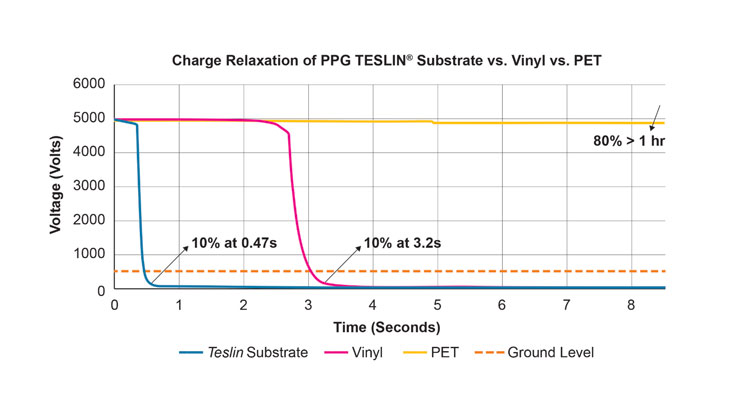

A second test comparing charge relaxation (decay) time of Teslin substrate, vinyl and PET was conducted to measure the time needed to dissipate the electrostatic charge from the surface of the materials to ground (earth).

At 71% relative humidity, in less than 0.5 seconds, Teslin substrate dissipated more than 90% of its starting charge of 5000V. Both PET and vinyl held approximately 100% of their starting charge of 5000V over the same amount of time and showed minimal tendency to dissipate their charge. Although vinyl eventually dissipates its charge, it takes more than three seconds and does not meet the static dissipative definition of an electrostatic material.

This test was performed in accordance with MIL-STD-3010C, test method 4046. Based on the results of the testing, the paint manufacturer selected Teslin labelstock for its ability to dissipate static and accommodate laser printing. The third-party testing supported the safety benefits gained by switching to Teslin labels, and showed that vinyl and PET labels are highly chargeable and pose a significant safety threat. By switching to Teslin labelstock, the company increased worker safety and diminished the risk of fire by reducing static during label-peeling and application in its production facilities.

Static Clean International

Julianne Ouellet, director of marketing at Static Clean International, points out that the speed of webs have increased, resolutions and tolerances are much tighter, print quality demand has improved, and all are impacted by static electricity.

Addressing the negative impact static can have on a print run, Static Clean International offers long-range and high-speed static eliminators (4103 and 4203) that are popular and effective in labeling applications/processes for the food, drink, pharmaceutical, medical and FMCG (Fast Moving Consumer Goods) sectors.

“Due to their small profile, these static eliminators are ideal for mounting on machines where space is sometimes at a premium. The Model 4203 long range bars that work up to 30" away are well-suited for roll-to-sheet and roll-to-roll presses,” explains Ouellet.

She adds, “Technology is always changing for the label industry, and the static control industry will follow the trends. The medical device and pharma industries not only require a quality label, but ones that are particle-free. It is a fact that if static is controlled on the press, less particles will be attracted to the process. The future is bright for static control and static control products in the label and converting industry. In today’s marketplace, there is a heavy focus on everything being static ‘clean’ and ‘particulate-free.’ Controlling static that causes particles to ‘stick’ to materials – such as plastic packaging or labels – is relevant to the new norm and standards that the printing industry demands. High reject rates will occur if static electricity is not controlled on the press.”

At Static Clean International, one of the latest developments in the works is a static bar that can work at even higher speeds and up to five feet from the web. “While these improvements are great to implement at unwind and rewind rolls, in time it will have promise for use in other areas such as before print stations and after corona treatment,” she says, concluding, “Static Clean is always creating and exploring ways to create products that keep up with evolving industry demands.”

Simco-Ion

“For the label printer, static control and web cleaning often go hand in hand,” says Gabby Lockwood, marketing communications specialist at Simco-Ion.

The company has seen a spike in demand from OEMs, especially those with a digital hybrid press offering. “These presses require proven, reliable, and cost-effective static elimination and web cleaning technology to continue to run profitably, day after day,” Lockwood says, noting that 2021 saw a marked increase in the sale of Teknek contact cleaners and the Simco-Ion IQ Easy static bars into the narrow web printing market segment.

“One of the drivers of this is that digital printheads require a clean substrate to continually deliver precise printing results. OEMs are focused on delivering a clean sheet into the printhead as daily accumulation of visible and non-visible particulate on the printing heads results in costly inefficiencies and waste. Invisible particles, trapped by the boundary layer of air on the moving web, continue to bedevil non-contact and touchless systems because, regardless of their design, they struggle to consistently break the boundary layer of air to remove 95%+ of the sub 10 micron particles.

“Teknek, contact cleaning specialists, smash the boundary level of air, guaranteeing consistent cleaning results across a variety of web speeds, thicknesses and tensions,” Lockwood says. “Teknek continues to grow because it uniquely provides a variety of in-house designed elastomers, focused on the surface to be cleaned, and when the Teknek cleaning roll is paired with the proprietary Teknek adhesive, the result is the world famous Teknek Cleaning Core.”

According to Lockwood, the Teknek Cleaning Core has proven to be able to remove dry unattached particles down to <1 micron. Lockwood explains, “The core works continuously to clean the entire web by gently contacting the web, such that the cleaning roll lifts the contaminate off the web and the Teknek adhesive refreshes the cleaning roll.”

For static elimination, narrow web converters can look to Simco-Ion. The design of its Easy Bar allows the high output power supply to make the most out of the return signal from the web to maximize ionization performance, unlike competitive offerings, which require separate ground connections to the bar to protect their power supply. Additionally, the bar has no pins to replace, no air requirement, is purpose-built for converting, comes with worldwide support, and is scalable up to what the company says is a state-of-the-art Industry 4.0 monitored system via the Simco-Ion Control Station. “This is why the blue of the Easy Bar continues to be the most recognizable OEM static bar at every converting show,” Lockwood says.

Recently, the Easy Bar family added a new member, the Easy LP. The Easy LP provides the same level of class leading performance but in a smaller package, .75" tall, and with a flat mounting kit so that it fits in the tightest of spaces. With an output tuning for 1-4" from the target, Simco-Ion says it is ideal for difficult applications, and whether the target charge is 20kv or 500V this bar will successfully drive both to zero.

Finally, for customers who want to eliminate long cable runs and don’t want the security issues posed by another IP address, Simco-Ion introduced the IQ Power Wireless Link via Industrial Bluetooth for use with the Control Station. With line of sight range of 200’ this system allows for constant contact with all IQ Power static eliminators, including Fantom blowers and sensor bars without complicated and expensive cable installation. The wireless hub is powered by a 24V connection, and thus can be mounted in difficult to access areas, for example on a turret, to allow communication with bars mounted on the winder.

Meech international

“There are several different static-related issues found at label converters,” states Matt Fyffe, vice president and general manager at Meech International. “Traditionally, a majority of these problems deal with print quality. Static electricity attracts dust and debris to the web, which can result in poor quality and high reject rates.”

With an increasing number of label converters going digital and also printing on film and coated stocks, Fyffe is noticing much higher demand for static control products. He says, “Digital printheads are especially susceptible to static issues. A high static charge on the web can actually repel the ink droplets from the digital printer. The repelled ink droplets will then gum up the printhead and will require more frequent cleaning. In extreme cases, high charges can actually cause permanent damage to the printheads.”

According to Fyffe, label converters today must be more adaptable and quick to change in order to compete. “This means they need to be able to print and convert various substrates at a moment’s notice with quick changeover. Therefore, they need static control and web cleaning systems that can be used on multiple substrates without requiring time to reset the controls.”

The systems provided by Meech require very little, if any, service and input from the operators, Fyffe says, adding, “They adjust themselves to maintain optimum performance.”

Fyffe points out that tacky roller web cleaners are the most popular form of web cleaning systems in the label converter market as they are fairly inexpensive and easy to install. “However,” he says, “there is a consumable cost involved, and they require regular maintenance and constant operator supervision.”

Meech has recently developed a fan driven non-contact web cleaning system for the narrow web industry as an upgrade to the tacky roller systems of old. The CyClean-R system from Meech boasts several advantages over tacky rollers, including no ongoing consumable costs; very little maintenance required; operation does not affect the web path; the ability to run at very low tensions; easy to install over an existing roller; flexibility to run on any substrate, including paper, film or foil; and full press integration.

The SmartControl Touch is a static control product from Meech that Fyffe is excited about. It allows the user to monitor, control and adjust the performance of multiple connected comparable Hyperion ionizing bars and sensors via the integrated touchscreen or remotely via a mobile phone, tablet or remote desktop.

“This means that at all times, the performance of the connected equipment may be monitored and optimized to achieve the best results, according to the application,” Fyffe says. “The ionizing equipment’s performance is easily tracked by the SmartControl Touch, which uses Meech’s Ion Current Monitoring Technology, allowing the user to monitor the ionizing performance. With the ability to connect six bars directly and an additional 24 bars using two expansion units (sold separately), SmartControl delivers exceptional central control.”

TAKK Industries

Terrance Clark, sales manager for TAKK Industries, notes several problems that static electricity can cause in label converting, chief among them are print quality related defects. He says, “Static electricity is prone to result in repulsion or attraction of ink to a substrate’s surface. In the case of repulsion of ink droplets or dots, a printer likely would see ink smears, fuzzy characters or print hickies that negatively impact production of high-quality printed labels.”

When it comes to the label industry’s major trend – digital printing – Clark points out, “Conversely, static electricity attraction effects in digital printing can cause ink to expand out in what should be white space of a label or cause dropout of incorrect colors during printing from the digital printhead. These static issues create unacceptable prints, causing wasted production time, ink and substrates, and considerable labor and re-work costs.”

Clark emphasizes that label converters continue to be laser focused on producing the best products with improved profit margins. “In pursuit of this goal, many savvy printers are looking for next generation static control technologies,” he says. “These automatically adjusting ionizers (static eliminators) have very high capabilities and versatility to match the unique, ever-evolving parameters that today’s leading label converters must have to deliver and meet their customers’ expectations.”

To meet these evolving converter needs, TAKK Industries brought to market its “Reactive Intelligence” static elimination technology in its NEOS series static eliminators.

“The NEOS, in addition to its exceptional static elimination capabilities, also continuously adjusts both its static elimination power and ion output to match the exact needs of the application,” Clark explains. “It can be installed at short or exceptionally long distances of up to 60-plus inches to accommodate changing diameter rolls or challenging space situations. The NEOS’ technology easily dovetails with today’s leading-edge PLC/HMI interfaces for instant status information about the unit’s operation, in addition to local status indicators on the NEOS bar.”

According to Clark, TAKK Industries’ NEOS Series Static Control Technology is fast becoming the comprehensive, fool-proof static control solution that meets the demands of label converters. “The NEOS Series is a new evolution in smart static controls, providing exceptional capabilities such as using ‘Reactive Intelligence’ that detects and delivers the exact amount of ionization required, thus maintaining consistent control of static.”

Models from the NEOS series eliminate static charges at distances up to 60" and speeds up to 4,500 fpm without air.

TAKK recently introduced its 3024 Compact and 3024 Ultra DC Static Eliminators. These units are specially designed and suited for both OEM machinery and end users where there are tight constraints for mounting on digital or conventional label presses, tabletop winders, and related production machinery requiring high performance static elimination performance in a compact size. The 3024 has a built-in power supply and LED indicators that provide local and remote status for the ionizer bar. The 3024 Ultra and Compact are highly suited for narrow web labels, sleeves and tapes.

By Fabrizio Mandingorra, PPG global segment manager, Teslin Products, Labels and Graphics

Three significant problems caused by static electricity in the workplace include electrostatic attraction and repulsion, shocks to operators, and fire risk. Electrostatic attraction/repulsion is one of the most widespread issues in the plastics, packaging and paper industries, and can result in product issues such as sticking, repelling each other, and attracting dust. All of these elements ultimately lead to loss of productivity and profits. Fire risk is critically important in industries where solvent materials are used. Static charge on material can cause a spark discharge, which can ignite the solvent and create a fire.

When labels are processed through digital laser printers, they are charged through an electrostatic process that causes print toner to adhere to the label surface. When printed labels are peeled, that action can generate static charge (tribocharging), which has the potential to ignite vapors in industrial environments in which chemicals, solvents and flammable materials are present.

In 2017, an employee working at a global paint and coating manufacturer was filling 5-gallon pails of primer using an automated filling device. As pails were filled, the employee sealed the lids and applied a vinyl self-adhesive label to each pail, discarding the label backing into a wheeled trash bin nearby.

While mopping the floor with a cleaning solution, the employee contacted the wheel of the cart with the mop head, generating a static spark that jumped from the wheel and ignited the solvent in the cleaning solution, setting the mop head on fire. Although the fire was quickly extinguished, an investigation later determined that the voltage from the wheeled trash bin was generated by the electrostatically charged label backings it contained.

After making this determination, the paint manufacturer immediately engaged its label management vendor and an independent testing center to identify the labelstocks that would generate the lowest amount of electrostatic voltage during label application.

The company turned to a process safety management firm that helps businesses in preventing explosions, fires and accidental material releases to conduct static testing of PPG Teslin substrate, vinyl and PET label materials.

First, a label peel test was conducted to determine the electrostatic charge buildup when an electrically-isolated label set is peeled off from its backing and placed in a Faraday Cage under different conditions of relative humidity. The specific charge density calculated was then compared with maximum surface charge density (charge per unit area of 2.7x10-5 Coulomb/m2) in free space.

When peeled from their backings, vinyl labels can become electrostatically charged to 29% of the maximum charge density possible (2.7x10-5 C/m2) at ambient humidity environments, and PET labels can become charged to 30%. The same test of Teslin labels showed that they only become electrostatically charged to 0.065%. The charge on both the vinyl and PET labels can give rise to incendive electrostatic discharges under ambient and low relative humidity conditions.

A second test comparing charge relaxation (decay) time of Teslin substrate, vinyl and PET was conducted to measure the time needed to dissipate the electrostatic charge from the surface of the materials to ground (earth).

At 71% relative humidity, in less than 0.5 seconds, Teslin substrate dissipated more than 90% of its starting charge of 5000V. Both PET and vinyl held approximately 100% of their starting charge of 5000V over the same amount of time and showed minimal tendency to dissipate their charge. Although vinyl eventually dissipates its charge, it takes more than three seconds and does not meet the static dissipative definition of an electrostatic material.

This test was performed in accordance with MIL-STD-3010C, test method 4046. Based on the results of the testing, the paint manufacturer selected Teslin labelstock for its ability to dissipate static and accommodate laser printing. The third-party testing supported the safety benefits gained by switching to Teslin labels, and showed that vinyl and PET labels are highly chargeable and pose a significant safety threat. By switching to Teslin labelstock, the company increased worker safety and diminished the risk of fire by reducing static during label-peeling and application in its production facilities.