Greg Hrinya, Editor05.30.23

35 Ontario Street

Stratford, CT, USA 06615

www.penmar-industries.com

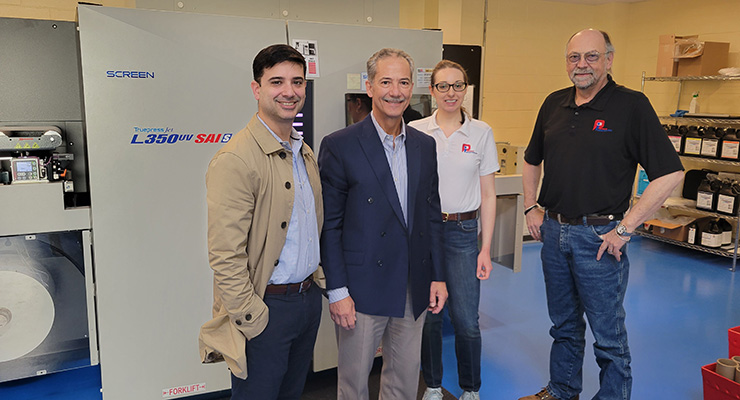

As Rick Cipot, operations and general manager, says, Penmar Industries is a “small company with a big impact.” Under the leadership of Ed Rodriguez, his son, Eddy, and Cipot, this Connecticut-based converter has experienced significant growth – and they’re poised for more, both organically and through M&A. Penmar has just installed a digital press, continues to expand to new markets, and has its eye set on the next wave of technology in order to live up to a mantra built on change.

Change has been a constant throughout Penmar’s storied history. James Penders and Phillip Marchese established the company in 1964. These natural born salesmen boasted a knack for filling needs in the marketplace. Not only did they target labels and packaging, but they answered another customer challenge: serving as a part-owner of SpecTape, a business in Erlanger, KY, USA, that manufactures and converts pressure sensitive tapes.

“The company was built on the philosophy of someone coming in and asking, ‘Can you do this?’” says Ed. “The immediate answers are, ‘Yes, we can,’ and ‘We’ll figure it out.’ Years ago, a customer came to Jim and said, ‘We’re buying stickers from this company. Is this something you can do?’ He turned around and said, ‘Yes, we can.’ So that was our foray into the printing of labels and prompted our investment in our first flexo machine – a one-color press.”

Rodriguez, president, was a fast learner, who took the job one day at a time. He leaned on the label industry, his customers, and Cipot to gain his footing. “Industry organizations, such as FLAG (Flexo Label Advantage Group), were very helpful. I went to all the industry meetings to talk about the business and learn about the business, and then I spoke with our customers. Customers are the best educators you could possibly find.”

Ed took his cue from the company’s original owners, as he was always open to change and fervently growing the business. “One of our core competencies as a company is we’ve always changed who we are,” says Rodriguez. “We keep evolving and changing so we can always be at the leading edge while delivering value to our customers the best that we can. That has been one of the values all along – embrace change. Change is a good thing, and it started with our founders.”

Penmar evolved from a packaging company that produced labels, to a label company that now also provides packaging solutions.

Penmar is constantly evaluating the marketplace, looking to see where it can add value for its customers. “We’ve got relationships with some incredible Fortune 200 companies, but you can’t just sit back and hope they’re going to stay with your forever,” says Rick. “You need to position yourself to be ahead of the curve for the next change. As long as you have that relationship with your customers, then you know which direction they’re going, and you can prepare yourself for that with the latest technology and the best customer service.”

“We exist for one reason and one reason only – to serve our customers; and we want to do it better than anyone else,” adds Ed.

To better serve its customers, Penmar Industries added to its printing footprint in 2022 with a Screen digital inkjet press and finishing equipment from Grafotronic. The equipment accompanies four Webtron flexo presses. Penmar has also established partnerships with key suppliers. Acucote, now part of Fedrigoni, Avery Dennison and 3M were instrumental as Penmar navigated supply chain challenges. Plus, RotoMetrics, a Maxcess company, has been a key partner for more than two decades.

“Our combination of printing and finishing equipment does not exist in the world,” states Ed. “We’ve added some unique technologies that were created specifically for us, which brings us capabilities no one else has.”

“We’ve partnered with a number of different companies,” notes Rick. “To me, relationships are very, very important, and it goes back and forth. For example, I’ve been working with RotoMetrics since I started this job. If you don’t have the relationships, you’re not going to go very far in this business – or any business for that matter.”

Penmar currently operates out of a 15,000 square-foot facility in Stratford, CT. The leadership triumvirate of Ed and Eddy, who today serves as vice president of finance, along with Cipot, preside over a dedicated team of 15 employees.

While standalone digital and hybrid were both viable technologies, the former met the company’s timeline. “I happen to be of the philosophy that if I’m preaching to the choir, I’d like to have my pews filled before I build a church,” explains Ed. “Others will build a church and then fill it with people, and they can be very successful with that strategy. But if I bring in hybrid technology, that would be building a church without the people.

“I wanted to make sure we have the business demand for that technology. So, we decided to go with the digital press to build capacity to an extent, where in the future I can justify bringing in a hybrid press, and we can expand into hybrid more easily,” he says.

Eddy and Rick subsequently embarked on the task of finding the ideal digital partner. Rick had spent nearly half a decade keeping tabs on the latest product launches and technological advances, but Penmar still had empty pews. As the company began expanding into new markets, with a greater emphasis on food and beverage, the demand emerged. Plus, customers were requesting variable data with their labels.

“Eddy and Rick spent an awful lot of time really researching and focusing on the technology we should have,” recalls Ed. “They were involved with the planning, strategy and making sure our customer pipeline was filled.”

“Ed came to me with a blank check and said, ‘Go for it,’ which was scary as heck to me,” says Rick. “I was scared because I was spending money that wasn’t my money, and Ed wasn’t looking over my shoulder. He trusted me and pretty much gave me carte blanche. So, I started doing my research and making calls. The more I started understanding Screen and their technology, the more I got interested in their process. So, I started talking with them and getting samples. I also needed to look at finishing equipment, and my Screen rep suggested I speak with Grafotronic.”

Penmar entered the digital world with the Screen Truepress Jet L350 UV SAI S digital label press and the Grafotronic CF2. Both equipment manufacturers presented Rick with the opportunity to customize the machinery specifically to Penmar’s needs and wishes, and the modular nature of the units allow growth alongside the label converter.

“One of the great aspects of Grafotronic was they were not selling me an off-the-shelf piece of equipment,” says Rick. “They were giving me the opportunity to be as creative as I wanted to be in designing it for Penmar. Whether you’re a pizza shop or IBM, the goal remains the same: What can you offer us that someone else can’t? And I do that with suppliers.

“Digital printing has made huge advancements in the last three years,” adds Rick. “Screen, in my opinion, pretty much left everyone in the background. When I go in there and take that machine apart, you can see the quality of the product. I can call that a press. To me, it’s the best system out there, since we’re getting true colors. The gamut of colors we’re able to run is amazing. Screen is very meticulous with their quality of color, and we’re very meticulous about that, as well. After we ran our first test with Screen, I realized this was the equipment we need. We haven’t had any downtime on the press, and Screen’s attention to detail is something I’ve never experienced before.”

The marriage of Screen and Grafotronic has been a fruitful one for Penmar. Rick spent countless hours working with Grafotronic’s engineering team in Poland in order to fine-tune a machine that would produce the kind of eye-catching labels Penmar’s customers have come to expect.

“With Screen, I was able to design a piece of equipment that can push the limits of what a digital press can do,” adds Rick. “Then I can carry that work over to the Grafotronic CF2, and that’s been a game-changer for us. We’ve been able to get really creative with the types of labels we can produce, and our customers are really excited about what we can offer them without charging exorbitant prices for a project, which is really important.”

promoting quality.

“For us, it’s all about relationships, and I deal with those every day with my team,” explains Rick. “Rarely do I use the word employees because we’re all on a level playing field as far as I’m concerned – and I want to keep it that way. Anyone in this building can stop a job at any time if they think something’s wrong, and I mean anybody. I would much rather call a customer today and tell them a job is going to ship late than for them to call me in three days with a problem. That’s not the way we do things. A job might get as far as rewind when the operator thinks something isn’t right. That’s perfect, because that tells me the team is paying attention, and I love them questioning something I did. That’s the way things should be done, and I’m proud of these folks. At the end of the day, they’re contributing to our success. When you have a team that knows that their job is just as important as the next person’s job, and we’re all on the same level, that goes a long, long way. Our production meetings are a two-way conversation, and that’s what I want.”

“Teamwork is very important to us, and everyone owns quality here,” adds Ed. “There is no two ways about that. If someone is walking around the facility and they see something that might not look quite right for a customer, they have the responsibility of stopping the process right there to make sure that the process is right. Everyone owns quality, and it’s not one person’s responsibility, it’s everyone’s responsibility. That’s part of the communication that’s so important here at Penmar. Everyone is valued for how they add value to our team, and that is all part of our culture.”

“If someone comes walking into our shop, you’re going to see the most diverse team ever,” Rick adds. “It’s amazing what we’ve assembled here. The talent is absolutely incredible.”

Penmar’s leadership has lauded the team members for their commitment to the company throughout a trying few years. From the pandemic to ongoing supply chain challenges, the team has answered the call. A big part of that success has been the cross-training of employees throughout the facility. All operations target efficiency.

“Our idea of acquisition is to grow our capabilities, our competencies, our geographic reach, and our customer base,” remarks Ed. “The idea is not to look at Connecticut – anywhere is fine as long as we’re increasing our capabilities and the expansion adds value to the portfolio to better serve our customers.

“M&A is part of our long-term strategy, so we’re going to continue in that direction,” adds Ed. “We’ve been actively exploring acquisitions for the last 4-5 years, and we’ve gotten close a few times. Right now, the M&A process continues. There are a variety of options that are extremely attractive. We are currently looking at some active options, but until everything is signed you just never know.”

Eddy joined Penmar to help drive growth, specifically in the acquisition realm. “Eddy has dealt with some of the major accounting firms in the world doing internal auditing,” explains Ed. “We were trying to figure out how to really grow this company, because organic growth is not good enough. That’s when we decided to go into a merger and acquisition focus. I needed someone with a lot of experience in accounting, someone who can look at the books and sort out the numbers, and he has all that real-world experience. On top of which, he has a Master’s of Finance and an MBA, as well. He’s also a CPA, so this was the kind of person I’d be looking to hire. I asked him if this was something he wanted to do, and he said yes.”

Penmar’s future growth will also be built around sustainability. The company has switched exclusively to water-based inks – eliminating all solvent-based inks – and converted to solar power with panels

on its roof.

“One of my biggest goals when we moved into this facility was not only to make it a better environment for production, but also to be conscious of the community and our environmental footprint,” says Rick. “One of the first steps was getting rid of solvent inks and going with water-based inks.”

Not only has the company’s sustainability focus been good for the environment, but the moves have also made sound business sense. “Today I am able to generate enough energy to run the company with solar panels,” states Ed. “Every single light bulb in this facility has been changed to promote sustainability – every single one. Plus, in two years, we’ll be making money generating energy on our own. So far, we’ve saved nearly two-thirds of our yearly electricity bill, so it’s a win-win. Every time a customer wants to know about our sustainability story, they get very excited about what we’ve done and the results we’ve achieved. This, in turn, has solidified our relationship with those customers who really value sustainability.”

Stratford, CT, USA 06615

www.penmar-industries.com

As Rick Cipot, operations and general manager, says, Penmar Industries is a “small company with a big impact.” Under the leadership of Ed Rodriguez, his son, Eddy, and Cipot, this Connecticut-based converter has experienced significant growth – and they’re poised for more, both organically and through M&A. Penmar has just installed a digital press, continues to expand to new markets, and has its eye set on the next wave of technology in order to live up to a mantra built on change.

Change has been a constant throughout Penmar’s storied history. James Penders and Phillip Marchese established the company in 1964. These natural born salesmen boasted a knack for filling needs in the marketplace. Not only did they target labels and packaging, but they answered another customer challenge: serving as a part-owner of SpecTape, a business in Erlanger, KY, USA, that manufactures and converts pressure sensitive tapes.

“The company was built on the philosophy of someone coming in and asking, ‘Can you do this?’” says Ed. “The immediate answers are, ‘Yes, we can,’ and ‘We’ll figure it out.’ Years ago, a customer came to Jim and said, ‘We’re buying stickers from this company. Is this something you can do?’ He turned around and said, ‘Yes, we can.’ So that was our foray into the printing of labels and prompted our investment in our first flexo machine – a one-color press.”

Rodriguez, president, was a fast learner, who took the job one day at a time. He leaned on the label industry, his customers, and Cipot to gain his footing. “Industry organizations, such as FLAG (Flexo Label Advantage Group), were very helpful. I went to all the industry meetings to talk about the business and learn about the business, and then I spoke with our customers. Customers are the best educators you could possibly find.”

Ed took his cue from the company’s original owners, as he was always open to change and fervently growing the business. “One of our core competencies as a company is we’ve always changed who we are,” says Rodriguez. “We keep evolving and changing so we can always be at the leading edge while delivering value to our customers the best that we can. That has been one of the values all along – embrace change. Change is a good thing, and it started with our founders.”

Penmar evolved from a packaging company that produced labels, to a label company that now also provides packaging solutions.

Penmar is constantly evaluating the marketplace, looking to see where it can add value for its customers. “We’ve got relationships with some incredible Fortune 200 companies, but you can’t just sit back and hope they’re going to stay with your forever,” says Rick. “You need to position yourself to be ahead of the curve for the next change. As long as you have that relationship with your customers, then you know which direction they’re going, and you can prepare yourself for that with the latest technology and the best customer service.”

“We exist for one reason and one reason only – to serve our customers; and we want to do it better than anyone else,” adds Ed.

To better serve its customers, Penmar Industries added to its printing footprint in 2022 with a Screen digital inkjet press and finishing equipment from Grafotronic. The equipment accompanies four Webtron flexo presses. Penmar has also established partnerships with key suppliers. Acucote, now part of Fedrigoni, Avery Dennison and 3M were instrumental as Penmar navigated supply chain challenges. Plus, RotoMetrics, a Maxcess company, has been a key partner for more than two decades.

“Our combination of printing and finishing equipment does not exist in the world,” states Ed. “We’ve added some unique technologies that were created specifically for us, which brings us capabilities no one else has.”

“We’ve partnered with a number of different companies,” notes Rick. “To me, relationships are very, very important, and it goes back and forth. For example, I’ve been working with RotoMetrics since I started this job. If you don’t have the relationships, you’re not going to go very far in this business – or any business for that matter.”

Penmar currently operates out of a 15,000 square-foot facility in Stratford, CT. The leadership triumvirate of Ed and Eddy, who today serves as vice president of finance, along with Cipot, preside over a dedicated team of 15 employees.

SCREEN TIME

With Penmar constantly analyzing the future of label printing, Ed and Rick realized that digital printing was a necessity for continued growth. Penmar’s booming business and customer demand required additional capacity in the form of the newest equipment. Both Ed and Eddy had been targeting the acquisition of digital printing technology through M&A – acquiring a company with digital already in its portfolio. However, the slowdown in the M&A process spurred Penmar management to explore bringing a new press in-house.While standalone digital and hybrid were both viable technologies, the former met the company’s timeline. “I happen to be of the philosophy that if I’m preaching to the choir, I’d like to have my pews filled before I build a church,” explains Ed. “Others will build a church and then fill it with people, and they can be very successful with that strategy. But if I bring in hybrid technology, that would be building a church without the people.

“I wanted to make sure we have the business demand for that technology. So, we decided to go with the digital press to build capacity to an extent, where in the future I can justify bringing in a hybrid press, and we can expand into hybrid more easily,” he says.

Eddy and Rick subsequently embarked on the task of finding the ideal digital partner. Rick had spent nearly half a decade keeping tabs on the latest product launches and technological advances, but Penmar still had empty pews. As the company began expanding into new markets, with a greater emphasis on food and beverage, the demand emerged. Plus, customers were requesting variable data with their labels.

“Eddy and Rick spent an awful lot of time really researching and focusing on the technology we should have,” recalls Ed. “They were involved with the planning, strategy and making sure our customer pipeline was filled.”

“Ed came to me with a blank check and said, ‘Go for it,’ which was scary as heck to me,” says Rick. “I was scared because I was spending money that wasn’t my money, and Ed wasn’t looking over my shoulder. He trusted me and pretty much gave me carte blanche. So, I started doing my research and making calls. The more I started understanding Screen and their technology, the more I got interested in their process. So, I started talking with them and getting samples. I also needed to look at finishing equipment, and my Screen rep suggested I speak with Grafotronic.”

Penmar entered the digital world with the Screen Truepress Jet L350 UV SAI S digital label press and the Grafotronic CF2. Both equipment manufacturers presented Rick with the opportunity to customize the machinery specifically to Penmar’s needs and wishes, and the modular nature of the units allow growth alongside the label converter.

“One of the great aspects of Grafotronic was they were not selling me an off-the-shelf piece of equipment,” says Rick. “They were giving me the opportunity to be as creative as I wanted to be in designing it for Penmar. Whether you’re a pizza shop or IBM, the goal remains the same: What can you offer us that someone else can’t? And I do that with suppliers.

“Digital printing has made huge advancements in the last three years,” adds Rick. “Screen, in my opinion, pretty much left everyone in the background. When I go in there and take that machine apart, you can see the quality of the product. I can call that a press. To me, it’s the best system out there, since we’re getting true colors. The gamut of colors we’re able to run is amazing. Screen is very meticulous with their quality of color, and we’re very meticulous about that, as well. After we ran our first test with Screen, I realized this was the equipment we need. We haven’t had any downtime on the press, and Screen’s attention to detail is something I’ve never experienced before.”

The marriage of Screen and Grafotronic has been a fruitful one for Penmar. Rick spent countless hours working with Grafotronic’s engineering team in Poland in order to fine-tune a machine that would produce the kind of eye-catching labels Penmar’s customers have come to expect.

“With Screen, I was able to design a piece of equipment that can push the limits of what a digital press can do,” adds Rick. “Then I can carry that work over to the Grafotronic CF2, and that’s been a game-changer for us. We’ve been able to get really creative with the types of labels we can produce, and our customers are really excited about what we can offer them without charging exorbitant prices for a project, which is really important.”

OWNING QUALITY

The latest and greatest equipment will fall short without a dedicated team to run it. Ed and Rick have both preached the importance of Penmar’s dedicated staff, and they have empowered the team to make key decisions in the company’s operations – with an eye onpromoting quality.

“For us, it’s all about relationships, and I deal with those every day with my team,” explains Rick. “Rarely do I use the word employees because we’re all on a level playing field as far as I’m concerned – and I want to keep it that way. Anyone in this building can stop a job at any time if they think something’s wrong, and I mean anybody. I would much rather call a customer today and tell them a job is going to ship late than for them to call me in three days with a problem. That’s not the way we do things. A job might get as far as rewind when the operator thinks something isn’t right. That’s perfect, because that tells me the team is paying attention, and I love them questioning something I did. That’s the way things should be done, and I’m proud of these folks. At the end of the day, they’re contributing to our success. When you have a team that knows that their job is just as important as the next person’s job, and we’re all on the same level, that goes a long, long way. Our production meetings are a two-way conversation, and that’s what I want.”

“Teamwork is very important to us, and everyone owns quality here,” adds Ed. “There is no two ways about that. If someone is walking around the facility and they see something that might not look quite right for a customer, they have the responsibility of stopping the process right there to make sure that the process is right. Everyone owns quality, and it’s not one person’s responsibility, it’s everyone’s responsibility. That’s part of the communication that’s so important here at Penmar. Everyone is valued for how they add value to our team, and that is all part of our culture.”

“If someone comes walking into our shop, you’re going to see the most diverse team ever,” Rick adds. “It’s amazing what we’ve assembled here. The talent is absolutely incredible.”

Penmar’s leadership has lauded the team members for their commitment to the company throughout a trying few years. From the pandemic to ongoing supply chain challenges, the team has answered the call. A big part of that success has been the cross-training of employees throughout the facility. All operations target efficiency.

PLANS FOR GROWTH

Due to the rapid growth at Penmar, Ed and Eddy have targeted M&A as a means of furthering the company’s position in the market. Plus, Penmar could also seek facility expansion as the company grows.“Our idea of acquisition is to grow our capabilities, our competencies, our geographic reach, and our customer base,” remarks Ed. “The idea is not to look at Connecticut – anywhere is fine as long as we’re increasing our capabilities and the expansion adds value to the portfolio to better serve our customers.

“M&A is part of our long-term strategy, so we’re going to continue in that direction,” adds Ed. “We’ve been actively exploring acquisitions for the last 4-5 years, and we’ve gotten close a few times. Right now, the M&A process continues. There are a variety of options that are extremely attractive. We are currently looking at some active options, but until everything is signed you just never know.”

Eddy joined Penmar to help drive growth, specifically in the acquisition realm. “Eddy has dealt with some of the major accounting firms in the world doing internal auditing,” explains Ed. “We were trying to figure out how to really grow this company, because organic growth is not good enough. That’s when we decided to go into a merger and acquisition focus. I needed someone with a lot of experience in accounting, someone who can look at the books and sort out the numbers, and he has all that real-world experience. On top of which, he has a Master’s of Finance and an MBA, as well. He’s also a CPA, so this was the kind of person I’d be looking to hire. I asked him if this was something he wanted to do, and he said yes.”

Penmar’s future growth will also be built around sustainability. The company has switched exclusively to water-based inks – eliminating all solvent-based inks – and converted to solar power with panels

on its roof.

“One of my biggest goals when we moved into this facility was not only to make it a better environment for production, but also to be conscious of the community and our environmental footprint,” says Rick. “One of the first steps was getting rid of solvent inks and going with water-based inks.”

Not only has the company’s sustainability focus been good for the environment, but the moves have also made sound business sense. “Today I am able to generate enough energy to run the company with solar panels,” states Ed. “Every single light bulb in this facility has been changed to promote sustainability – every single one. Plus, in two years, we’ll be making money generating energy on our own. So far, we’ve saved nearly two-thirds of our yearly electricity bill, so it’s a win-win. Every time a customer wants to know about our sustainability story, they get very excited about what we’ve done and the results we’ve achieved. This, in turn, has solidified our relationship with those customers who really value sustainability.”