Steve Katz, Editor11.20.15

Labelexpo Europe reported record-breaking results as it posted new visitor, exhibitor and exhibition space figures for its 2015 edition. Held at Brussels Expo September 29 through October 2, the show enjoyed its largest edition as it marked its 35th anniversary.

Attracting 35,739 visitors, attendance figures were up 12.4% on 2013’s total of 31,795. Visitors came from 146 countries, with most attending from Germany, France, Italy, Belgium and the UK. The show also posted an increase in visitors from outside Europe with 19.6% of the total visitors traveling from elsewhere including Asia, North and South America and Africa. Covering 34,566 square meters, the show’s footprint also increased by 11.65% over 2013, while exhibitor numbers rose from 600 to just over 650.

Held every two years, Labelexpo Europe is the world’s largest event for the label and package printing industry. Dominated by new product launches, the show again saw many major new developments being unveiled including some modular hybrid digital converting systems from several of the industry’s leading press manufacturers. Digital was a hot topic, with more than 50 exhibitors showcasing digital printing equipment – there was seemingly something for every budget and scale.

Labelexpo Europe 2015 also included several new feature areas. The Packprint Workshop was well attended, with live press demonstrations given by Xeikon using its 3500 for digital folding cartons and Nilpeter showing its FA* flexo press for flexible packaging applications. The Smart Packaging Lab covered some current developments in active and intelligent packaging. The show also hosted the first Linerless Trail, which promoted the benefits of linerless labels. Lisa Milburn, managing director of the Labelexpo Global Series, commented: “We would like to thank everyone who took part in this year’s show. The feedback has been genuinely phenomenal, and our exhibitors have been extremely pleased with many of the press manufacturers experiencing record sales and lead generation. The main trends coming out of this year’s show are the continued move to package printing as we see more manufacturers bringing short run production printing presses, which backs up our strategy going forward, and the ongoing dominance of digital as more and more hybrid digital printing presses flood into the marketplace.”

On the show floor

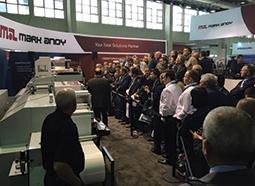

Calling the show a “resounding success,” Mark Andy showcased a broad range of presses in Brussels. The new Digital Series, a hybrid system, displayed a robust integration of flexo and digital printing, foil stamping and converting with multiple die changes. The Digital Series ran at 225 fpm (74 mpm), making it one of the fastest inkjet performers, with job changes in only 10 minutes, including a substrate change. Also at the Mark Andy booth, the new Performance Series P4 made its global debut. Visitors were able to see how the platform can adapt to the varied tooling available in the industry, and advance converters’ productivity with full servo technology.

Mark Andy demos its Digital Series

Five machines had been sold prior to the show, and Mark Andy is predicting sales activity will continue to be strong in the months to come. Commenting on the event, CEO Kevin Wilken said: “This year’s Labelexpo was tremendous for Mark Andy. Our Digital Series was an impressive front-runner to the many digital options shown at the exhibition, and so many customers gave us positive feedback about its speed, quality and versatility. This just reaffirms that our platform and technology are on target, and reaching our goal of driving productivity and profitability for the converter. I’m very proud of the dedicated team that has envisioned the right digital solution for the future.”

UPM Raflatac introduced its Vanish range of ultra-thin, clear PET label faces to the European market. At 23-microns, these thin and robust materials featuring a no-label look are designed for rendering innovative, seamless and high quality imagery. For food labeling on rigid plastic and glass packaging, Vanish labels allow consumers an excellent view of the product together with the brand, instilling the confidence to buy. For beverage labeling, UPM Raflatac touted Vanish as a suitable replacement for screen-printed bottles and a preferred choice for cans. “Vanish films are a tremendous step forward in seamless ‘no-label-look’ labeling with support for highest quality and innovative graphic design,” said Stefano Pistoni, end-use manager at UPM Raflatac EMEIA. “We’re leveraging the latest material advances for packaging material reductions and higher productivity while offering brands a fresh level of differentiation and enhanced perception of quality.”

Innovation with lasers from Martin Automatic

Martin Automatic displayed two of the company’s most popular machines for the narrow web market, the MBS automatic unwind butt splicer, and the LRD turret rewinder. Both machines, which are designed and built with the rugged simplicity required for reliable performance in today’s hardworking commercial environments, feature the latest software and operator interface that moves them towards being a “set and forget” stage in the production cycle. One innovation on the MBS that caught the eye was the “laser assist package.” which provides an optical guide for operators when preparing a splice. Available on new machines and as a retrofit, the laser beam aligns the web edge with the splice tape for more accurate positioning on the reverse side of the substrate. According to Martin’s vice president, Gavin Rittmeyer, “The laser assist package typifies the way that we continue to innovate and bring practical solutions to the market that improve productivity and show a fast ROI for the converter.” Also attracting attention was the space-saving stacked festoon accumulator on the MBS splicer. Designed to facilitate installation where floor space is in short supply, it is one of a number of tailor-made configurations offered by Martin to converters who need the added productivity of automation, but have an already crowded production area.

AB Graphic International recorded its busiest Labelexpo ever, reporting numerous orders from customers worldwide, with particular focus on automation features. “The trend for automation continues and customers were very impressed with our auto Plate Load, Autoslit and auto Iscore,” said Tony Bell, sales director, adding that the company took many high value orders for the Digicon Series 3, the new

AB Graphic International

Digicon-Lite 3 and the German-manufactured SRI machines. Bell also stressed there was keen interest in AB Graphic’s laser cutting system, which at the show was changing jobs on the fly and also producing a 900mm long “rocket” that can’t be printed or cut on conventional machines due to repeat length.

Sun Chemical debuted its Polare ink dispenser, adapted specifically for the demands of the label and narrow web market. Polare is a versatile and fully automated ink dispenser, optimized to deliver the exact amount of ink required, especially for the use of lower volume spot inks, thus minimizing waste and limiting inventory while maximizing production and cost efficiencies. Catering to low viscosity inks such as water-based or UV flexo, as well as high viscosity UV offset inks directly from their original containers, Polare enables efficient on-site blending of special colors, offering a cost-effective and time-efficient alternative to manual blending for on-demand availability while allowing the reuse of press returns. It also gives printers complete control over the workflow by eliminating the need to order specialty colors, therefore reducing lead times to further increase production efficiency.

Xeikon launched the CX3, the first press featuring its Cheetah technology, and the entire stand had a Cheetah theme in its honor. “We

Xeikon’s new Cheetah-powered CX3

are very pleased with the market reception to this exciting technology,” said Filip Weymans, Xeikon’s director segment Labels & Packaging. “With the addition of the Xeikon CX3, we now have six digital label presses, the largest digital label printing portfolio in the industry. And the industry is excited about the Xeikon CX3 as well – by the end of the year, we will have sold 20 units.” Visitors to the Xeikon booth also learned about Fusion Technology, a concept based on the promise of fully automated, unattended label and packaging production from customer order to delivery. Explained Weymans, “Fusion Technology combines full color production printing with digital embellishment of labels and packaging in a single, one-pass and fully digital production process. It will consist of a series of embellishment modules released over time that are not just put inline with the press, but are components of an entirely new modular system with the digital front-end taking care of prepress, data processing, color management and press operation as well as full control and operation of all modules without manual intervention.” Potential digital embellishment modules include hot/cold foiling; screen prints; matte, gloss and structured flood and spot varnish and a digital Braille module.

Bluestar Silicones launched several new products in its Silcolease range and showcased the entire product family, including some new members. Among the new products is Silcolease POLY 371, a polymer that combines excellent controlled release at low speeds, minimizing the need for high doses of RCA while delivering easy high-speed delamination of labels. Also, Silcolease XL 315 has been designed to complement this new polymer perfectly and gives robust long-lasting anchorage and offers fast cure.

Label Traxx gave an exclusive preview of its MIS software Version 8 at Labelexpo. The release marks the launch of three newly-anticipated modules, as well as a host of other new features. “The new modules have been developed to address key customer and industry demands,” explained Label Traxx president Ken Meinhardt. “We are helping our customers face the challenges of a modern business. They need instant access to accurate data in a format that is meaningful, and they need to be able to share that data with other software systems.” Version 8 features include the new API module, which enables the sharing of data with many other systems that support HTTP and SOAP protocols. This integration could be a simple request of information from Label Traxx or a complicated automatic entry. The API module can be used to link to CRM systems like salesforce.com or shipping manifest and labeling software.

GEW introduced ArcLED hybrid UV technology, which enables an investment in an Arc lamp system now to be upgraded later with LEDs using the same lamphead casing and the same power supply and control. With ArcLED technology, the printer simply adds LED cassettes, connects water-cooling and the Rhino ArcLED power supply automatically recognizes which type of cassette is installed in the machine and then on the same press seamlessly switches the power supply. “ArcLED gives the operator maximum freedom and flexibility and will thereby avoid getting locked in to one type of curing technology,” the company says.

Avery Dennison stressed sustainability

Avery Dennison launched at Labelexpo TrueCut, a new adhesive technology specifically for paper. The technology enables major enhancements to conversion speed and adheres better on both cardboard and during low temperature applications. This results in a strong combination of benefits for converters who are looking for superb on-press performance and for end users requiring the broadest possible window of applications. Jan ‘t Hart, global director, explained, “The adhesive gives up to 100% higher conversion speed compared with industry standards and can minimize or sometimes completely eliminate setup time between rolls. Sustainability was also in the spotlight with the introduction of two bio-based polyethylene label films. The new products feature a facestock that includes more than 80% renewable content and offers brand owners the opportunity to meet their target on renewable resources in packaging, while continuing to benefit from the functionality and performance of a regular polyethylene label. Xander van der Vlies, sustainability director at Avery Dennison Materials Group Europe, said, “With our expanding product range of sustainable label materials – which now includes these bio-based PE label films – we can support converters who want to fulfill brand owners’ needs for packaging from renewable resources, while also helping them to provide a differentiating product and drive sales in a fast-growing segment.” The bio-based PE self-adhesive laminates are available in a white and a clear version.

Kocher + Beck presented three new GapMaster systems. The new launches include GapMaster AM (autoMove), designed for continuous, ultra-precise measurement of the gap between the magnetic and the anvil cylinder with motorized, microprocessor-controlled readjustment of the gap as per user input following alterations to the gap. This enables a uniform cutting result to be achieved even in materials with extremely thin liners, unaffected by external influences and also at high web speeds. Also introduced was the GapMaster FR (Free) for cutting units both with and without support roller reinforced journals and bearings. This means that cutting forces are absorbed directly by the side wall bearing assembly. GapMaster Magnetic is also available as a magnetic cylinder, and is suitable for machines with fixed (intermittent) magnetic cylinder circumference, or embossing cylinders with magnetic positive/negative dies.

Nilpeter’s Panorama demonstrations drew large crowds

Nilpeter saw Labelexpo in Brussels as the perfect platform for the launch of its new digital solution, Panorama, which combines the DP-3 digital UV inkjet press with an inline converting system, including a Quick-Change Die unit and smart stripping unit. “Nilpeter is best known for flexo, offset and combination presses,” said COO Peter Eriksen. “By only displaying the Panorama line at this year’s Labelexpo, we’re showing our commitment to this new digital product line.” Panorama has a maximum printing width of 322 mm (12.67") on a 350 mm wide web. It prints at up to 50 mpm (164 fpm) on a variety of paper and filmic substrates from 90 to 350 microns. The name Panorama reflects the wide range of converting and finishing options available. It uses Nilpeter’s web handling and converting technology based on adapted modules, including QC-Die, a smart stripping unit, and hot/cold foiling. Panorama uses Kyocera piezo printheads. With a resolution of 600 dpi. the piezo printheads offer four-level greyscale imaging, while a minimum droplet size of three picoliters provides small-dot halftones to achieve near-offset quality of reproduction.

RotoMetrics celebrates its MLC acquisition

RotoMetrics made headlines at Labelexpo with the surprise announcement of the acquisition of MLC, Brazil’s leading supplier of rotary and flexible dies to the country’s label printing market. MLC, based in Sao Paolo, has 70 employees. The move expands RotoMetrics’ global footprint while establishing a South American manufacturing base to meet the demands of the converting industry worldwide. “MLC offers the opportunity for RotoMetrics to better serve Latin American customers from a strong operating platform strategically located in the region,” said Robert Spiller, president and CEO of RotoMetrics.

With a new brand image, Gallus exhibited over an area of more than 1,200 square meters and presented over 40 live demonstrations to visitor numbers in excess of 9,500 people over the four-day event. Highlighting the booth was the market launch of the

Gallus unveiled its DCS 340

Gallus DCS 340, an industrial digital label printing system. Michael Ring, the new head of digital printing sales at Gallus, explained, “We deliver quality that matches that of offset printing. The DCS 340 achieves a visual resolution of 2400 x 2400 dpi thanks to a physical resolution of 1200 x 1200 dpi with a droplet size of just 2 picoliters. Very small fonts and fine lines are printed precisely and with sharp edges, and vignettes down to 0% can be printed without tonal value jumps.” The eight-color printing system (white, YMCK, GOV) of the DCS 340 extends the color gamut beyond the pure CMYK scale without having to switch to additional Pantone and spot colors. In addition, the system’s finishing capabilities were showcased during a live printing demonstration of a chewing gum label. Visitors were able to see the label – which was embellished with two different cold foils, one overprinted and one downstream from the digital printing unit (DPU) – produced all the way from the PDF to the finished diecut product in a single pass.

MPS

MPS featured the EF Neo, its new generation EF flexo press. The EF Neo was presented and demonstrated for the first time at the MPS stand, alongside the new hybrid EF SYMJET press for conventional and digital printing and the EB narrow web label press. Built with the standard EF platform, but with a new, more modern design, the new EF Neo flexo press has been enhanced with new software with close loop print pressure setting solutions and an improved operator interface. “This press re-design reflects MPS’ focus on the operator,” said Bert van den Brink, technical director for MPS. “Regardless of their skill level, our user-friendly press technology enables them to maximize productivity and deliver the best printing results.”

MPS partnered with leading suppliers to develop several new technology solutions for the EF Neo: a new fully automated Quick-Change die unit for faster job changeovers, developed with Kocher + Beck, an AVT PrescoNW system for the fully automated process of pressure settings on the print stations, and the “future-ready” GEW hybrid UV/LED drying system.

Prati presented its latest machinery, including the new Jupiter WF slitter inspection rewinder. Jupiter cuts time and overhead from every process by implementing fully automated quality control and corrective action via software. The WF system enables converters to streamline production, improve efficiency, reliability and quality, reducing the risk of human error. Moreover, the machine can be fitted with all camera brands. According to Sales & Marketing Director Chiara Prati, Digifast One was ultimately the major attraction on the booth. “Visitors were impressed by the remarkable processing speeds and minimal setup time between jobs,” she said.

Omet

Omet showcased the iFlex 370mm (14") label press for the first time at a show. The press features iLight, a laser-assisted pre-register system, Quick Change Die Cutting by means of a trolley for the slide in/out of the heavy diecutting cylinders. Also, Omet said, iVision, a camera-assisted system for the immediate setup of perfect register, impressed the public and showed how simplicity can be a key to success. Next to iFlex, the XFlex X6 Offset, flexo + offset with sleeves hybrid press was also on display. The XFlex X6 Offset mixes flexo and rotary offset in 530mm (21") width whose multi-technology and multi-application approach can handle medium to large volumes of filmic labels, shrink sleeves, IML labels, flexible packaging and cartons in a single pass. Omet also presented the XFlex X6 Digital with flexo + digital JetPlus combination press to satisfy needs of short run printing and heavy job rotation.

The main attraction at the Erhardt+Leimer booth was its new 100% print inspection system, SmartScan. “It seemed like it was just what the industry had been waiting for,” said Alexander Thomalla, product manager at Erhardt+Leimer. “The system makes it affordable even for small printing houses to offer 100% inspection. It also comprises a 100% print monitoring function with a zoom, splice detection and the detection of missing labels and unremoved matrix. Like a modular system, the customer chooses the functions they need.” The company also showcased the ELCLEAN contact web cleaner, which features a drawer system that allows an adhesive layer to be pulled off quickly and easily from the adhesive roller and the adhesive or rubber roller to be exchanged in a straightforward manner.

At Labelexpo, acpo showcased new products, including a laser printable overlaminate which allows store owners to print variable data on shelf markers using traditional desktop printers; flexible packaging products including heat sealable laminates in clear and matte finishes; and, perhaps most notably, a non-detectable security system (INDSS) overlaminate. Touted by acpo as the first integrated non-detectable security system (INDSS) in the selfwound overlaminate industry, acpo’s INDS system offers the end user the opportunity to use a premium lamination on their label, while ensuring a high level of counterfeit security. The INDS system is built into the product and cannot be detected by means other than the user friendly system provided by acpo. The system offers the product manufacturer the ability to verify the authenticity of their product right on the shelf without disruption to the business. Other applications could include the use of the INDS system to differentiate between manufacturing locations.

Colordyne Technologies demonstrated improvements in print speed on its 3600 Series Production Class platforms. The press at the Colordyne booth featured a new Enhanced Efficiency Mode that runs at 325 fpm (99 mpm) at 1600 x 1175 dpi, in comparison to the 275 fpm (84 mpm) at 1600 x 1375 dpi. “We have nearly doubled our speed in the last 18 months,” said Gary Falconbridge, president. The increase in speed is made possible through a minimal reduction in print resolution in the web direction, allowing for nozzles to be fired faster through the Memjet printhead. Also on display was Colordyne’s newly launched 2600 Series Mini Press, which prints short run digital labels at 60 feet per minute (18 m/min) at 1600 x 1600 dpi. Show attendees witnessed the Mini Press’s robust, dually supported frame and servo driven web handling system, which allows users to produce longer run lengths, like the Production Class system, but with a smaller footprint.

Allen Datagraph launched three new iTech digital label system products at Labelexpo Europe. The company introduced the ADSI iTech Cypher and the ADSI iTech Spectrum digital label printers and the ADSI iTech Axxis XL digital label finisher. Allen Datagraph is a manufacturer of digital label systems that produce fully finished labels, in any shape without dies, for a fraction of the cost of other digital presses – with low, on-going operational expenses, according to the company. Its digital label systems are used by printers, converters and brand owners to create high-quality labels “on demand.” “As the market for short-run digital labels expands, Allen Datagraph, a pioneer in this market, has been very busy responding to customer requests for solutions that provide higher efficiency and improved business results, with an affordable price point,” explained Michael Elliot, president, Allen Datagraph. “We are expanding our narrow web line of digital label printers to include a new high speed inkjet and an improved LED toner. We are also introducing a new digital label finisher that uses a vacuum system to increase both throughput and uptime. All of these technologies are designed to make converters more profitable.”

Japan-based Lintec, making its Labelexpo debut, featured at its booth bubble-free labelstock technology. This newly developed product is designed to ensure perfect, bubble-free label application. Engineered for easy application, the product provides a release mechanism for volatile gases commonly found with plastics to prevent blisters forming beneath the label. Not only does this ensure a better finish, but it offers faster application and reduces product wastage due to misapplied labels. The product will be available in January 2016 following UL certification.

Sonic Solutions presented at Labelexpo the enhanced Phoenix Series ultrasonic anilox cleaning system. New features include a safer level of ultrasonics – 68 kHz – which allows smaller bubbles to get into the smaller cells of today’s higher line count anilox rolls. In addition, the Phoenix Series’ power generators have been modified to become external, interchangeable and easily replaceable. Safety has also been addressed through fixed thermostat settings and a low-level automatic shut-off feature. The Phoenix Series is a fully customizable anilox cleaning system, now able to accommodate rolls of any size. “No anilox roll is too large for Sonic Solutions,” said company president Joe Walczak. “From three inches to ten feet, from one roll to eight rolls at a time, we can customize a system to meet specific needs. And we’ll do it economically.”

Epson presented the largest range of digital label printers and presses it has shown to date, while unveiling several new products. “Epson offers the broadest selection of label printing solutions to meet the most diverse range of label production needs, compared with any other manufacturer today,” said Mark Elsbernd, North America region sales manager. Elsbernd showed Labelexpo visitors the SurePress L-6034VW incorporating Epson’s PrecisionCore linehead and LED-cured UV ink with inline digital varnish and high-opacity white ink. This single-pass press is ideal for high-quality short-to mid-run jobs, producing labels with outstanding scratch and weather resistance. Epson’s seven-color SurePress L-4033AW, described as the world’s only aqueous inkjet label press, is ideal for high-quality, high-value, short-run label jobs. “This press delivers exceptional print quality on a wide variety of standard label substrates, including clear film and metallic substrates, and without the need for pre-treatments or coatings,” Elsbernd explained.

Harper Corporation of America exhibited both its HIVE (High Imaging Volume Engravings) line of engravings series and its award-winning patented QD ink proofing and flatbed printing system. The HIVE anilox engraving series is designed to deliver high levels of print quality and predictability with an exclusive print performance guarantee. It is supported by the HarperScientific division which features pressroom supplies to address care and maintenance needs and a full line of ink proofer devices for color matching. With the expansion of functional printing into the flexo and gravure markets, Harper’s QD ink proofing and flatbed printing system has become a popular tool. It includes printing features and accessories that minimize the amount of expensive materials necessary to test printed electronic concepts and ideas.

AVT’s booth

For AVT (Advanced Vision Technology), Labelexpo in Brussels marked the first major trade show since its strategic alliance with Erhardt + Leimer (E+L). A new joint portfolio of products, born of AVT’s and E+L’s combined experience and technological skills, were demonstrated for the first time. AVT showcased at its booth its new quality control engine for inkjet digital presses, as well as extended automation solutions such as the Offline Setup tool and SolidProof offline proofing system. Additionally, the show served as the premiere of Helios S Turbo, an inspection system designed to help production lines reach maximum potential through, among other enhancements, increased printing and rewinding speeds. Helios S Turbo utilizes what AVT says is the market’s most modern machine vision technology to help printers get even more from their inspection systems. Incorporating the Turbo system into a line allows operators to rest assured that no print problem will be overlooked, regardless of inspection and production speeds.

Konica Minolta exhibited the bizhub Press C71cf, a digital label press designed for non-self-adhesive and self-adhesive labels, in short-to-mid run lengths. The press runs at 13.5 mpm with a maximum paper width of 330mm and 1200 x 1200dpi resolution. It is intended to fit between entry-level and high-end label printing presses. Customers needing to shift volumes from conventional to digital printing can benefit from the new product. The company also hopes to capitalize on the personalization and customization markets, which are a feature of short-run digital printing.

Big crowds at Bobst (forrmerly Nuova Gidue)

Bobst Group, the company that earlier this year acquired narrow web press manufacturer Nuova Gidue, fearured two new press lines. On display was the new M4 press (430 mm width), what the company describes as “the most effective press for printing labels and flexible packaging with excellent register stability at all speeds.” Also at the Bobst stand was the new M6 press (670 mm width), a dedicated mid-web press for the flexible packaging market. Both presses showed the Digital Automation program in the print cylinder configuration for M4 and in the print sleeve configuration for the M6. During the show, demonstrations feature the “live” exchange of multiple jobs with less than 10 meters of substrate waste and one minute of setup time. Bobst has also confirmed its full commitment to the REVO Project spearheaded by Gidue for seven color extended gamut technology. The REVO partners demonstrated the full process live at Labelexpo Europe, every two hours, with a completely new set of seven extended color gamut plates produced, mounted on printing sleeves and printed live on the Bobst M4 and M6 UV flexo presses.

EFI showed its Jetrion 4950LX LED narrow web press

EFI presented a fully inline LED inkjet digital printing system available with laser cutting and finishing for lean label production. The production line features the 13" (330-mm) wide EFI Jetrion 4950LX LED narrow web press with a white ink module. Plus, EFI demonstrated a faster, 164 fpm (50 mpm) speed, a higher level of throughput that can make digital inkjet label converting an even more useful option as a replacement for flexographic printing. To complement its high-productivity press, EFI featured a new Enterprise Packaging Productivity Suite custom configured to address the needs of three segments: label, flexible packaging and folding carton converting, as well as tighter integration with Esko’s Automation Engine.

At the Durst booth, the company exhibited under its mantra, “Tau 330 – Configure your Digital Future Today.” With more than 50 installations of the Tau 330 UV inkjet press worldwide, Durst’s experts showed visitors how they can individually configure the Tau 330 as a standalone solution, as an industrial scale production system with jumbo roll unit, or as a fully digital production unit with inline finishing. There are three compatible ink sets available for the Tau 330, one each to achieve a screen print- or flexo print-like quality and one to comply with current low migration guidelines, for applications in the pharma and food industries. New at Labelexpo, the Tau 330 E is Durst’s economical alternative and is engineered with particular attention to equipment cost while maintaining print quality and printing speed, allowing small companies to enter into digital label production.

ETI Converting Equipment reports that Labelexpo 2015 was a huge success for the Boucherville, QC, Canada-based company, attracting numerous visitors to the ETI stand.

A demonstration of the Mini-Cohesio equipped with an optional JFlex unit

Labelexpo visitors took the opportunity to find out about the new Mini-Cohesio equipped with an optional JFlex unit. With no fewer than 30 live demonstrations, they were able to see that this flexible equipment, combining two printing processes – flexo and digital – allows them not only to print but also to manufacture finished pressure sensitive labels in one pass at a competitive price. The labels, formed by a 80 gsm high gloss paper and a 18 micron PET liner, were diecut with a Pellicut unit, the ETI-manufactured high speed rotary diecutting system for thin liners.

The Mini-Cohesio is capable of running at 150 mpm (500 fpm) and at 84 mpm (275 fpm) when equipped with the JFlex unit with a high-quality printing of 14 micron dots at 1600 x 1375 dpi.

The Mini-Cohesio equipment allows converters to print in-line or use pre-printed material, then apply the silicone and the adhesive coating on the liner, laminate both web (the facestock and the liner) and diecut in register to obtain a roll of pressure sensitive labels.

“The Mini-Cohesio is certainly the ideal equipment to produce small to long production runs of pressure sensitive labels. Once again, ETI stands out by its innovative concept. With numerous promising contacts, ETI expects a successful year in terms of equipment sales,” said Danielle Brunet, director of special projects, ETI Converting Equipment.

Meech displayed its Hyperion range of anti-static bars at Labelexpo. The company highlighted the ways in which static control technologies can help improve safety and product quality. Meech also exhibited its range of web cleaning systems. “We understand the challenges that this sector faces, and for this reason, we are demonstrating the ways in which our systems can help maintain efficient, safe and productive manufacturing environments,” explained Donald Lewis, business development manager. Meech’s Hyperion static control systems include 971IPS and 929IPS anti-static bars, as well as new additions to the range. The company also featured ancillary enhancements, the distance sensor and feedback system. Also on display was the TakClean and CyClean. TakClean is a contact web cleaner employed within the label printing sector, featuring formulated TransTak elastomer contact cleaning rollers and perforated adhesive rolls, which make it suitable for narrower and slower presses. The CyClean is a compact non-contact system designed to remove and extract contamination. Meech has enhanced the cleaning efficiency of the CyClean to remove contamination to below 1 micron. It is best suited for newer, high speed presses and can handle virtually any substrate.

Fujifilm used Labelexpo as its platform to launch its new water-washable flexo plate, Flenex FW, a photopolymer plate containing a rubber-based compound that is not oxygen sensitive, minimizing the effect oxygen has on the dot shape. As a result, Flenex reduces dot gain and improves ink transfer for cleaner and brighter print results. The plate delivers longer runs for label converters, while producing a consistent 200 lpi at 4,400 dpi, 1% flat top process dot structure for high quality. Improved durability and reduction in plate swell are further benefits offered by the new Flenex FW plate.

Primera Technology

Primera Technology presented at Labelexpo its inkjet-based LX-Series of color label printers, as well as its CX-Series of digital roll-to-roll dry toner-based laser printers. The CX1200 is ideal for service bureaus and a broad range of manufacturers who need to print from just a few labels to tens of thousands of labels at a time. With 2400 dpi print resolution and print speed of five meters per minute, the CX1200 delivers professional full-color print quality along with high-speed production. Primera also showcased the FX1200 Digital Finishing System, designed to be the perfect accessory to the CX1200 Color Label Press. It “finishes” the printed output with several different operations including lamination, digital diecutting, waste matrix removal, slitting and rewinding. Utilizing Primera’s QuadraCut technology, virtually any size and shape of label can be produced including complicated contour cuts, without the need to purchase rotary or flat dies.

Flint Group Narrow Web and Flint Group Flexographic Products jointly displayed their most recent innovations, including the new nyloflex FTF Digital plate. It provides flat top dots by processing the plate like any standard digital plate, but a special, textured plate surface eliminates the need for time consuming surface screening and provides an even ink laydown and increased solid ink density with a standard resolution of 2400 or 2540 dpi. Thus, it allows achieving a significant reduction in complexity and efficiency gain in prepress and plate making. In 2014, Flint Group introduced the nyloflex NEF Digital, a flexo plate specially designed for the nyloflex NExT exposure technology, for efficient creation of flat top dots and reproduction of surface screenings. “The customers’ feedback over the last months has confirmed that nyloflex NEF Digital, in combination with nyloflex NExT, enables label printers to exploit the full potential of this exposure technology,” said Dana Contineanu, product manager, nyloflex. “And although the nyloflex NEF Digital plate is designed for the high-output UV LED exposure, when exposed with regular tube light units, it provides additional benefits compared to other digital plates.”

Labelexpo Europe provided Phoseon Technology the opportunity to showcase its new UV LED retrofit solution for flexographic printing, along with a wide array of existing solutions for the label market. The company displayed UV LED technology that delivers rugged, high-performance solutions for narrow-web applications. “Phoseon is extending its UV LED leadership with narrow web and digital printer OEMs by adding fully integrated solutions for the retrofit market. The simple building-block installation kit allows converters to modify their presses a station at a time,” stated Rob Karsten, Phoseon regional director of EMEA. “Phoseon’s UV LED technology allows new revenue opportunities while also saving energy and eliminating replacement part costs. The time is now for leading converters to take full advantage of the proven, reliable UV LED solution from Phoseon and not wait for the marketing hype of future proofing.”

HP Indigo showcased its labels and packaging portfolio innovation, including new product features and upgrade packages, software enhancements for mass customization as well as new financing options. These new innovations allow more customers to capitalize on the growing digital opportunity in a market where they are already achieving 30% page growth year over year. “With mounting pressure from brands to deliver differentiated, high-quality labels and packaging at faster and faster turnaround times, converters and PSPs are constantly looking for new avenues for growth and expansion,” said Alon Bar-Shany, vice president and general manager, Indigo Division. HP demonstrated at the show new features of the HP Indigo WS6800 digital press, which boost color capabilities and productivity. The Color Automation Package uses the press’ inline spectrophotometer and new HP Indigo Labels & Packaging Print Server capabilities powered by Esko, in offering converters a quick and easy process to match brand spot colors from the first label to the last.

Esko displayed its full range of prepress products at Labelexpo, and In addition to its own exhibit, the company highlighted its position as a market-leading innovator in label design, prepress, workflow and printing solutions through its presence at an impressive number of industry partners stands. “Through our extensive partner network, we gain an unparalleled view of industry trends and realities, allowing us to help customers future-proof their businesses by delivering stronger solutions that open the door to new opportunities and improved profitability,” said Philippe Adam, vice president of global marketing at Esko. “These relationships also lead to further development of our solutions, improving the breadth and depth of our offerings in compliance with open standards and by linking to industry partners that are leaders in their respective domains.”

Domino Digital Printing Solutions announced the launch of the N610i integration module, forming part of a digital hybrid solution, all based on its 7-color digital label press. Booth visitors viewed firsthand the new N610i variant, integrated with an AB Graphic Digicon 3, including flexo, varnishing, laminating and diecutting stations. Philip Easton, director of Domino’s Digital Printing Solutions Division, said: “The new N610i inkjet integration module enables our customers to configure a digital hybrid press that meets their business needs now but offers significant flexibility to reconfigure the line for future requirements. Customers now have the option to purchase the N610i either as a standalone digital press, with inline finishing, or as part of a hybrid machine including flexo, screen and foiling stations in different positions in the line,” explained Easton. “The modularity of this solution also allows the customer the ability to reconfigure the machine to suit their future changing needs and is equipped to respond to new incoming jobs.”

PC Industries released the newest version of the Guardian LSI inspection system. To help showcase this system’s ease of use, the company developed an interactive walkthrough of the updated version. The entry-level full web inspection solution now features updated software and is designed for companies that don’t need to worry about tiny defects. The system provides everything needed for typical defects, missing labels and unremoved matrix detection. The Guardian LSI is suitable for growing companies because it provides an affordable way to move up from sampling web viewers to full web inspection. For companies looking to upgrade further at a later date, the Guardian LSI is part of PC Industries’ trade-in program, which provides a way to upgrade from basic inspection to a more powerful inspection system like the Guardian PQV.

INX International Ink Co. held demonstrations of the NW210 inkjet UV digital narrow web press. Since being introduced to the marketplace at the 2014 show in Chicago, reaction to the NW210 inkjet UV digital narrow web press has been favorable. “The NW210 press continues to perform as well as we expected,” said Rick Clendenning, president and CEO of INX International Ink. “It is the ideal vehicle for many label converters, direct mail and packaging printers who are looking to get involved with inkjet digital printing. The NW210 is hard to match with its technology and efficiency. The automated and accurate cutting paths make for extremely fast job changeovers and more work getting done every day. It also is 50% wider than our NW140 press. Couple those advantages with the types of inks that we are showcasing, and I think we have everything in the booth that printers attending Labelexpo need for their operations.”

Ritrama presented its latest and comprehensive range of products for wine and spirits labeling, which includes an array of FSC papers and special films with different textures specifically developed for this segment. The product portfolio is designed to enhance the appearance of the most prestigious wine bottles with a variety of natural papers such as laid, textured or embossed; white or ivory colors; matte and white finishes; and gloss coated and bright metalized papers, as well as clear films for a no-label look. The company also exhibited its Barrier Range, with extreme wet and water resistance properties, recommended for bottles that are to remain immersed in wet and cold conditions such as white wine and champagne bottles.

DuPont Packaging Graphics featured its new DuPont Cyrel FAST DFUV flexographic printing plate, designed for superior print results when used with ultraviolet (UV) curable inks. The new plate improves solid ink density, reduces waste, saves time and cost in many applications - including high end substrates such as pressure sensitive and self-adhesive labels, shrink wrap and wraparound labels, tickets, tags and boards. Cyrel DFUV is a thermal process plate that comes to color quickly and prints smooth and dense solids, without compromising dot gain, highlights and resolution.

Schobertechnologies featured RSM-Digi/Varicut, a new vector technology for the converting of digitally printed flexible packaging material into IML. The system combines continuous and vector rotary diecutting in re-registration mode, resulting in the processing of a wide range of formats with a single tool. In fully modular design, the RSM-Digi/Varicut is designed to convert web widths up to 770mm, and with repeat or format length of up to 1,150mm. The standard configuration includes an M-Stack delivery system.

Wink showcased at its booth the easy and flexible handling ability of its Gap Control adjustable anvil cylinder. “It is very simple and flexible to operate,” explained Andre Gysbers, marketing director for Wink. The unit has two control knobs on its frame which adjust the gap individually for the drive and operator side in order to compensate one-sided wear, inaccuracies in the cutting tool, as well as fluctuations in material thickness. “The adjustment steps are less than a micron, so that even the smallest corrections can be made,” said Gysbers. “Adjustment is possible both at a standstill and when the machine is running.” The advantages of GapControl compared to other systems are mainly rooted in its particularly high stability. “Thanks to its special construction, the GapControl can overcome the limitations of conventional adjustable systems. This means that cutting through is possible with no problems, and even at high production speeds the cylinder shows no resonance or vibration problems. The special construction also ensures that the system is extremely low-maintenance. Also, the GapControl unit can be installed in the diecutting unit very easily, as well as removed when necessary. “This is the absolute best machine of its kind in the industry,” concluded Gysbers. “The show has been very busy, with visitors to our stand showing great interest in Wink technology.”

Mühlbauer presented at Labelexpo its new Light series, the CL Light and PL Light, machinery designed to meet the demands for RFID and NFC products that include special printed features, serialization printing and unique encoding. The CL Light has a cost efficient design together with a high flexibility in output configurations: dry inlay, wet inlay, smart labels and tickets, from reel-to-single or from reel-to-reel – all in one modular system. With this technology, all processes are in one system: reel-to-reel antenna web handling, label or ticket lamination, diecutting as well as output testing. The system has a throughput of up to 10 mpm for semi-rotary cutting and of up to 30 mpm for rotary cutting. With an optimized changeover time between different products paired with lowest tooling costs, this converting system is suited for short run production with smaller lot sizes and at the same time fast-changing applications.

Spartanics

Laser diecutting specialist Spartanics had a presence in five separate exhibits at Labelexpo Europe, including the Smart Packaging Lab. At the Spartanics booth, the L350 Laser Die Cutting System was running on-demand demonstrations. The system is able to be configured as roll-to-roll, roll-to-sheet, sheet-to-sheet or a combination roll/sheet unit. Throughout the show, Labelexpo attendees were encouraged to stop by the Spartanics Stand with their actual label projects on hand. Durst Imaging Technology showcased at its booth the Tau 330 LFS running inline with the Spartanics X350 Laser Module. This high-powered Spartanics laser is capable of cutting at speeds inline exceeding 50 meters per minute. INX International ran the NW210-E UV Inkjet Digital Narrow Web Press featuring the Spartanics X210 Laser Die Cutting Module. The complete digital finishing system is capable of cutting at speeds of more than 30 meters per minute. SMAG Graphique had a large Labelexpo presence, with a showcase over 10 converting systems, including the Digital Galaxie Semi-Rotary Converting System complete with a Spartanics X350 Laser Module.

At Labelexpo, tesa tape addressed quick changeover challenges with the introduction of its new plate mounting tape series, tesa Softprint Secure. As the name implies, tesa engineers developed this plate mounting tape in order to hold down plate edges securely, even on small-diameter cylinders, so that presses can keep running. Also, Softprint Secure features a new bonding agent – SNAP-ON adhesive – which allows easy plate mounting and demounting. tesa Softprint is available in 380µm/15 mil thickness in five distinctive degrees of hardness.

At the Electro Optic Labelexpo booth, the company celebrated its 25th year supplying the label industry with diecutting tools. Today Electro-Optic solely specializes in flexible dies, which have become the diecutting technology of choice in the European market and beyond. Discussing the growth and acceptance of flexible dies, Markus Marfurt, president of Electro Optic USA, said it’s been an “evolutionary process.” He emphasized that Electro Optic, as a supplier that is devoted solely to flexible dies, has been a driving force in flexible tools gaining acceptance within the label industry. As part of its 25th anniversary celebration, Electro Optic showcased its Gold Line Special, a product line designed for cutting the most demanding materials on PP/PET liners. “The Gold Line Special offers perfect cutting ability and unmatched height parallelism due to our patented back-grinding process – this gaurantees the best cutting results on ultra-thin liners,” Marfurt said.

Matho demonstrated its complete cutting unit series Cuttopipe, and also introduced the new baler Cuttopress CP-2000. This new baler is designed for mid-size label converters to handle the sticky waste from up to five presses and pack it together to a highly compact bale. “The concept offers a lot of benefits to handle the waste in an efficient way,” said sales manager Matthias Thor. During the show, PakMarkas from Lithuania ordered a CP-6000 waste extraction system for the removal of matrix waset from five printing presses and six edge trim machines.

KTI featured its recently developed turret rewinder with a smaller footprint and increased production speeds to meet additional customer needs. This machine, named the Mustang Series Turret Rewinder for its speed and durability, offers many additional features to KTI’s KR Series Turret Rewinder and is ideal for running pressure sensitive paper labelstock. The Mustang Series Turret Rewinder has four spindles and is available in web widths up to 20" (508mm), roll diameter up to 12" (304mm), speeds up to 750 fpm (228 mpm) and can run cores ranging from .75" to 3" (19mm to 76mm). Standard features include PLC touch screen controls, servo motor driven spindles, integrated dancer for superior web control, tapered winding tension and remote diagnostics.

In introducing its new Gemini machine series, laser cutting specialist Cartes showcased its Invisible Laser Cutting (ILC) system. The system allows the ability to convert dark color printed labels while avoiding the white line edges caused by laser cutting temperature. Also featured during the show was Cartes’ top-end line GT360 with semi-rotary diecutting unit. This brought to life a new concept showcasing the ability to use magnetic dies to produce labels at different lengths. Thanks to the Image Distortion System (IDS), it is now possible to re-use preexisting dies created for specifics cylinders, even worn, to diecut different lengths. The IDS allows the customer to widen and narrow multiple label lengths up to 20% from the original die, always keeping label interspaces constant.

Making its Labelexpo debut, Sappi Speciality Papers featured its Algro Sol line of silicone base papers featuring low silicone consumption – 25% lower than other standard carrier papers currently available on the market, according to Sappi, which ensures excellent removal of the self-adhesive films from the siliconized carrier paper and results in significant cost savings. Sappi also promoted at the show the increased production capacities at its Alfeld Mill as a result of the recent PM2 rebuild. This ensures a long-term and sustainable supply of Sappi material in a dynamically changing marketplace, also expanding its reach to the Americas and Asia.

BST eltromat and the prepress specialist and platemaker COE (Carl Ostermann Erben GmbH) jointly showed how label manufacturers can achieve previously unknown production reliability when it comes to color fidelity in flexo printing. In this context, close cooperation between prepress, printing and inline spectral color measurement enables them to reliably and conveniently achieve the color values specified by customers, and to keep them dependably stable during production. The key to this is a user interface between the prepress workflow from COE and the solution from BST eltromat for inline spectral color measurement, which is designed to significantly simplify and accelerate press setup.

Frimpeks, a global manufacturer of self-adhesive laminates and inks, showcased recent developments in substrates for the digital media market, along with new UV ink solutions such as low migration products. Emre Sayer, managing director, said, “Labelexpo Europe 2015 was probably the most successful exhibition in the history of the Frimpeks organization. We had inquiries for our self-adhesive laminates and inks from over 75 countries and were fortunate to see our stand full for the four days of the exhibition. Interest in the growth of our organization, that now has full global reach, was incredible. Our new plant in the UK generated particularly high levels of interest from both UK and North European label printers who see the benefit of acrylic adhesive laminate production in the UK. This, combined with our existing hot melt plant in Germany, allows us to provide the full range of self-adhesive materials to North Europe and beyond on a next day basis. Furthermore, there was great interest in our new product developments including microspheric ultra removable adhesives, holographic security materials and our latest range of linerless materials.”

H.B. Fuller launched a new water-based pressure sensitive adhesive named Fulltak SE 8301. Formulated using proprietary polymer technology, it helps beverage producers efficiently remove PSA labels during the label wash-off process of returnable bottles. Fulltak SE 8301 connects ideal coating, drying and conversion performance for the labelstock producer with optimum labeling performance and clean label removal for the beverage producer. Intricately designed PSA labels can be efficiently applied to glass bottles. Under typical conditions, Fulltak SE 8301 delivers two hours of ice-water resistance, thus maintaining brand integrity during use. Stuart Jenkinson, business director, said, “We continue to match product and process innovations to our customers’ critical needs. Fulltak SE 8301 enables label producers to efficiently manufacture high performance PSA paper labels that deliver the value-added benefit of clean label wash-off from returnable bottles.”

Eckart featured at Labelexpo the Ultrastar FP-8230, a UV-curing flexo ink based on Metalure technology. The product is the first Eckart ink to create real mirror effects with UV flexo printing. “The new ink is designed to meet the requirements of the pressure sensitive industry,” said Katrin Danzer, business development communications, Eckart. “Nevertheless, FP-8230 is suitable also for other UV flexo applications such as folding cartons and wet-glue labels.” A key advantage of the ink is in its ability to replace foil stamping or metalized substrates.

The Kodak stand featured a wide range of products across flexo, letterpress, offset and digital printing technologies. “Labelexpo Europe is the world’s largest event for the label and package printing industry and a great opportunity for us to spend time understanding how we can help customers become even more successful,” said Chris Payne, general manager, Flexo Packaging Business, Kodak. “Kodak’s focus is to provide technology that helps brands market their products more successfully while driving automation and cost savings in the production process. The latest developments for our industry-leading Kodak Flexcel NX System, high speed inkjet digital solutions and production workflow do just that and we are excited to showcase them at Labelexpo.”

Delta ModTech showcased its machinery designed with flexibility in mind. The company featured at its booth its engineering expertise in designing, building and integrating manufacturing systems for a variety applications. “We use our proven modules and extensive process know-how to develop a system that meets your specific requirements, improves profitability and reduces risk,” said Mike Huss, business development for Minnesota, USA-based Delta ModTech. Huss reported an active Labelexpo 2015, and for the company, he said it was the best one it has participated in to date. Delta ModTech machinery features Human Machine Interface (HMI) touch screen, which includes a graphic representation of the machine, allowing access to each module by simply touching the screen. The HMI also includes alarm monitoring, batch counters, user security setting and help screens.

Mondi Advanced Materials promoted its capability as a producer of film and release liner materials. Mondi not only supplies standard as well as speciality polyolefin-based films for label facestock, but also offers high-quality customized release liners. With processing speeds for self-adhesive labels steadily increasing, Mondi said it meets the evolving requirements through ongoing product and process development, customer partnerships and skilled technical product support. “The combination of Mondi Advanced Materials global production network and the newly set up sales organization guarantees expert know-how and service in every region and at the same time close to its customers,” the company said.

Siegwerk welcomed visitors to its booth offering them the “red carpet for your products.” The new products featured included the printing ink series in the Sicura “Nutri” family – for safe UV printing on food packaging and labels; the high quality, uncomplicated Sicura series for non-food packaging and labels; and FastMatch: a simple and accurate formulation tool for mixed colors. Siegwerk also exhbited Sicura Nutri Waterless, the first real UV-waterless ink range for standard and anilox printing units.

Dantex launched the PicoColour II high-speed UV inkjet digital label press. The press has been developed by the Dantex Digital team, together with JF Machines Limited, now a part of the Dantex Group. Richard Danon, Dantex Group Chairman, said, “We are really delighted with our new partnership with JFM, and very much look forward to working together. This acquisition has brought Dantex the expertise necessary to be able to build state of the art label printing presses using high-speed UV inkjet technology. The PicoColour II at 210mm is our first offering. Press manufacturing is based at our premises in the Leeds/Bradford area, which has a long history of working with the printing industry. We are very excited about the prospects ahead, as we blend the considerable talents and technology of Dantex with those of JFM.”

IST Metz launched MBS, a curing system where housing either a UV lamp or LED technology can be used. The MBS unit can simply be inserted into the machine; all supply connections engage automatically. This enables users to change easily from operation with a UV lamp to UV LEDs. Thanks to the removable internal housing, all components in the unit can be accessed easily and without screws. The MBS range is available in three versions – an air-cooled system with UV lamp and facility for a subsequent upgrade to LED, an air-cooled system with UV LEDs and facility for a subsequent upgrade to UV lamp, and an air-cooled hybrid version featuring both technologies, which can be used interchangeably in the printing press as required.

SunJet, the global inkjet division of Sun Chemical, presented at Labelexpo its next generation single pass inkjet inks designed for optimal output in a range of narrow web, label and packaging applications.SunJet demonstrated at its booth the latest technical advances to its award-winning UV curing low migration Etijet range for narrow web and labels and Amphora inks for general packaging applications. First introduced to the market at Labelexpo 2013, SunJet has used its understanding of single pass inkjet technology to drive its inks forward to deliver optimum performance, quality and efficiency. Both ink ranges are fully compatible with new generation printheads and are suitable for use in a wide range of food and sensitive product packaging applications.

Afinia Label presented its L801 Color Label Printer and R635 Laser Label Printer. Also, a mini digital label press (DLP-2000), finishing system (DLF-1000), and a new label applicator (A300) were shown.“We had very strong showing at Labelexpo Europe this year,” said Scott Coates, Afinia Label UK’s business development manager. “When combined, we have the industry’s fastest and least cost end-to-end label solution.” The Afinia Label L801 Color Label Printer is powered by Memjet technology, which gives it a print speed of 60 feet per minute and an ink cost of less than three cents for a 4" x 6" label with 75% coverage. The L801 supports three print modes: Roll to Roll, Roll to Cut, Print & Hold.

Tri-Tronics introduced at Labelexpo what it touted as the first ultrasonic clear label sensor with a high performance OLED onboard display. Users are provided with an unprecedented view of the sensor’s performance, options, program modes, and helpful simple instructions. The new sensor displays a home screen, quick set and a scope that provides users with complete confidence in initial setup and worry free performances. Features and benefits include visual confirmation, confident setup, one button autoset (gap set), “tweak-able” (momentary up/down adjustment), available timers and delays, cable and connector versions (m12 and m8), and durable and robust housing. The new sensors are compatible with existing mounting configurations

ITW Dynatec showed Labelexpo Europe its comprehensive lineup of hotmelt systems for precise application onto tapes and labels. According to the company, its hot melt systems are simple to operate and highly customizable to meet a broad range of label and tape requirements. The company showed a coating system with the new TwinCoat Application Technology, which offers the possibility to create an adhesive film with two different surfaces. TwinCoat is a non-contact, metered slot die applicator that has the ability to split the required amount of adhesive into two layers, with different characteristics, and to apply them simultaneously on a substrate. This innovation allows two layers to be combined in one, using just one applicator and with only one production step, creating adhesive films with a dual characteristic. The results are high transparency and streak-free.

Dow Corning launched a new water-based silicone emulsion at Labelexpo. The Syl-Off EM 7945 coating has been developed for off-line coating of polyethylene terephthalate (PET) films. Dow said it is a more sustainable and safer alternative to solvent-based release coatings, which it can replace without incurring additional costs. The new emulsion is designed to deliver higher performance versus traditional release coatings, including faster cure, superior anchorage, lower release force and excellent aesthetics.

IPT digital’s JFlex 870 & JFlex 1700 digital label conversion systems made their European debut at the show. The systems are designed to enable label converters to turn an existing analog press into a high-speed digital printing platform. Using Memjet inkjet technology, the drop-on-demand thermal inkjet unit has four print heads printing CMYK with an optional fifth print head for spot color. Each print head contains 70,400 print nozzles firing three billion dots per second/12.4 kHz. The result is 275 feet per minute of 8.69 or 17" wide print, with a 1600 x 1375 dpi resolution. The JFlex 870 and JFlex 1700 digital label conversion systems are engineered and manufactured by RDP Marathon of Montreal, Canada.

Codimag showed two versions of its Aniflo press technology and performed AnifloLive demos throughout the show.The VIVA 340 evolution is the brand new reel-to-reel version of the VIVA340 Aniflo press. It runs with fixed inks in 4C or 6C expanded gamut to avoid wash-ups and leaves all the time-consuming converting features to an off-line finishing system. Aniflo predictability allows matching the proof right away and advanced automated features, such as the new CODIReg fully automatic register system, reduce make ready and waste.According to Codimag, this makes the VIVA340 a real alternative to digital. To show the efficiency of the press, Codimag offered visitors the chance to run their own jobs live during the exhibition.

Grafotronic demonstrated its new DCL series, a fully modular digital finishing machine. The machine includes the Grafotronic designed nonstop printing and finishing system and the combined semi-rotary/rotary diecutting unit. Each module works independently and the machine is fully upgradeable in the future. The DCL is also equipped with rotary mode for high speed production of blanks in 220 mpm or pre-printed labels in 180 mpm. The DCL’s many options include: cold foil/laminations,front and back flexo printing, a new non-stop buffer, a nonstop semi-turrett rewind with auto-cut and auto-start. “Digital printing machines are getting faster and there is a growing demand for fast and flexible finishing solutions,”commented Gabriele Gerbella, international sales manager at Grafotronic.

Numerous on-site sales

Adamtec, a Valencia, Spain-based label manufacturer, purchased a six-station SPGPrints DSI digital UV-inkjet press to meet the demand for short production runs from customers in the food, chemical and automotive industries. The 13" (330mm) press features the standard CMYK, white and a digital primer. Jaume Crespo, general manager at Adamtec, commented, “From the trial results, and the support from SPGPrints’ technical people, it was clear that DSI could give us the flexibility to offer variable data and the quality to deliver the consistency and high-impact branding solutions on which our brand and customers depend. Another influencing factor was the performance of SPGPrints’ inks, which give us an opacity equivalent to screen-printing and strong resistance needed for industrial situations.” TheDSI press features as standard intermittent LED pinning between each color station to ensure immediate curing and ink stability at fast speeds, and a chill drum to stabilize film substrates. This feature is of great benefit to Adamtec, which supplies high quantities of PP labels to the food and chemical industries.

SPGPrints’ DSI UV inkjet press

With the addition of the DSI press, which will be installed in December, Adamtec showed its commitment to deliver quality labels to its customers. Adamtec will continue to deliver longer production runs with its two existing flexo presses. Crespo says: ‘With the acquisition of the SPGPrints’ DSI UV-inkjet press, we will be able to print individualized labels in the same production run, which we believe it is great value to our customers, and therefore a strong growth area for us. Our automotive customers, for instance, are seeking serialized battery labels and the ability to tailor information for each region. The DSI press will enable us to adapt label designs at short notice, and schedule these jobs with minimal material waste or setup time.”

Bas Hoijtink, commercial manager graphics at SPGPrints, said the company had a grand total of eight system sales at the show. “The DSI UV-inkjet system has proven to be the platform for system cost savings through variable data printing and high-impact graphics that drive point-of sale brand success for label printers in Europe and America. With our live demonstrations of customer-commissioned jobs, visitors had a first-hand appreciation of the flexibility, quality and substrate versatility offered by the technology – and an idea of the high-level support that is essential for successfully integrating a digital print workflow,” Hoitjink said.

Sweden’s Jodi Etiketter ordered at Labelexpo a Xeikon CX3 digital label press, while Finish operation Tarratuote Oy, opted for the Xeikon 3030Plus system. “It is great to see just how label specialists are benefitting from our broadest portfolio of solutions to date,” said Filip Weymans, Xeikon’s director segment marketing. “It is also indicative of how varied production demands are – from short to long runs – and how operations need to ensure they can meet their customers’ demand cost effectively, efficiently and to a very high quality.” Jodi Etiketter specializes in self-adhesive labels and a variety of specialty labels. The company decided to invest in the Xeikon CX3 with a digital finishing line. It will be fully equipped with roll-to-roll capabilities as well as inline converting with a new DC330. Tarratuote Oy, based in Tampere, Finland, ordered a Xeikon 3030Plus system with MiniDcoat post-press line and the latest Xeikon X-800 digital front-end workflow.

UK-based The Label Makers (TLM) purchased its second Tau 330 UV inkjet press at Labelexpo. David Webster, managing director and owner, along with Zenna Parfaniuk, The Label Makers’ director, finalized the purchase at the Durst stand at the Brussels Expo. TLM made its first Tau 330 purchase in early 2013. Running the press multiple shifts, they have moved a lot of flexo and screen printing jobs to the 330. The new TLM press on order is a 7-color machine equipped with a chill roller. The Durst Tau 330 is a digital UV inkjet print system with a print speed of 48 meters per minute. “In contrast to this industrial scale end-to-end set up, showgoers were also extremely interested in our introduction of the Tau 330 E at Labelexpo, which paves the way for small- and medium-sized companies to enter into digital production. Digital production in the label and package printing segment is a reality and we are making it happen,” said Durst’s Helmut Munter.

At Labelexpo Europe, representatives from Epson America, Inc. announced that Graphic Image Label, a custom prime label printer serving small companies to multinational businesses, purchased the Epson SurePress L-4033AW as a key part of the company’s expansion into the United States. With operations in Mexico and the United States, Graphic Image Label installed the SurePress in its new San Diego, CA, USA, facility to produce high-quality pressure sensitive and self-adhesive prime labels for wine makers and small gourmet food, health and beauty, electronics, and industrial manufacturers. “For almost 20 years, we have been committed to producing high quality labels that exceed our client’s production standards,” said Carlos Garmendia, CEO, Graphic Image Label. “The Epson SurePress produces outstanding results for our pressure-sensitive labels while keeping production costs, maintenance costs and set-up times as low as possible.”

FFEI Ltd announced at Labelexpo the sale of two Graphium presses to Saudi Plastics Factory (SPF), a leading Saudi Arabian producer of plastic containers and packaging. Graphium is a digital hybrid, five color UV inkjet press including white integrated with inline flexo and finishing stations. Fawaz al Kaaki, president and managing director of SPF said, “We chose to invest in Graphium hybrid digital printers in order to better serve our customers. They will now be able to print PVC labels and apply them to their plastic containers – faster and more efficiently.” FFEI said Graphium is the first press to be configured with two pre-digital flexo stations, a six color inkjet digital system, two post digital flexo stations with foiling and Edale’s new hybrid semi/full rotary diecutting system.

Concluded Doug Jones, vice president of global marketing for anilox supplier Apex International: “We enjoyed our most successful Labelexpo to date, eclipsing all previously established metrics in terms of booth visitors, generated leads and orders written onsite. We want to thank all of our friends and partners for making Labelexpo Europe 2015 our best ever.”

Over 500 guests gathered at the prestigious Label Industry Global Awards ceremony in Brussels to find out which of the finalist companies would walk away with coveted label industry awards. The 12th annual awards event was held September 29 at Brussels Expo as part of Labelexpo Europe 2015.

Kurt Walker, FINAT’s former president was presented with the esteemed R. Stanton Avery Lifetime Achievement Award. Sponsored by Avery Dennison, the award is given to an individual who has made a substantial and key contribution to the label industry over a minimum of 25 years. Walker received the award in recognition of his work with FINAT and in driving innovation and best practices throughout the international label community. He joins the industry’s echelons with previous winners including Suzanne Zaccone of GSI Technologies, Tomas Rink of Ritrama, RotoMetrics’ Steve Lee, Helmut Schreiner, Nilpeter’s Lars Eriksen and FLEXcon’s Neil McDonough.

Kurt Walker, FINAT’s former president was presented with the esteemed R. Stanton Avery Lifetime Achievement Award. Sponsored by Avery Dennison, the award is given to an individual who has made a substantial and key contribution to the label industry over a minimum of 25 years. Walker received the award in recognition of his work with FINAT and in driving innovation and best practices throughout the international label community. He joins the industry’s echelons with previous winners including Suzanne Zaccone of GSI Technologies, Tomas Rink of Ritrama, RotoMetrics’ Steve Lee, Helmut Schreiner, Nilpeter’s Lars Eriksen and FLEXcon’s Neil McDonough.

HP Indigo was revealed as the winner of the Award for Innovation (for companies with more than 300 employees), sponsored by Flint Group Narrow Web. HP Indigo won for its work in developing its HP SmartStream Mosaic software. Started by a request from Coca-Cola Israel to create a unique variable product with shelf appeal following the success of the Share a Coke campaign, HP Indigo has delivered the ability to create millions of unique images and designs on labels and packaging from seed patterns using an innovative graphics algorithm.

The Award for Innovation (for companies with up to 300 employees), sponsored by Flint Group Narrow Web went to joint recipients GEW and Lake Image Systems. GEW impressed the judges with its RHINO electronic power supply which has been developed to enable the lowest possible operating cost for a UV-curing system, operating at 95% energy efficiency to provide low energy consumption and a reduced environmental footprint. The system lowers both a printer’s carbon footprint and its utility bill.

Lake Image Systems was honored for developing MaxScan, its latest addition to the Discovery MultiScan family. Based on contact scanning technology, MaxScan provides key benefits over traditional line scan camera technology, such as uniform 600 dpi inspection resolution and virtually no angular variation, to provide label converters with tools to accurately detect print defects without the need for expensive additional rollers, re-designed web paths or complex optical assemblies.

Lake Image Systems was honored for developing MaxScan, its latest addition to the Discovery MultiScan family. Based on contact scanning technology, MaxScan provides key benefits over traditional line scan camera technology, such as uniform 600 dpi inspection resolution and virtually no angular variation, to provide label converters with tools to accurately detect print defects without the need for expensive additional rollers, re-designed web paths or complex optical assemblies.

Lintec was announced as the winner of the Award for Sustainability, sponsored by Xeikon. Lintec has developed a new label facestock, KP5000, which uses the world’s highest percentage (80%) of recycled PET pellets. The new face material, which has physical features equivalent to virgin PET films and has a lower production cost than other recycled materials, is produced from mechanically recycled PET bottles as the raw material.

Mike Fairley, chair of the judges, commented: “Choosing winners from such an impressive list of companies was always going to be difficult and all of our winners and finalists truly deserve our utmost admiration and congratulations. The awards are designed to showcase the depth and best of talent and achievement across the global label industry and all of this year’s entrants demonstrated enormous innovation, best practice and inspiring work. The awards go some way towards shining a light on the significant dedication, commitment and excellence going on each and every day in this exciting and dynamic sector.”

Attracting 35,739 visitors, attendance figures were up 12.4% on 2013’s total of 31,795. Visitors came from 146 countries, with most attending from Germany, France, Italy, Belgium and the UK. The show also posted an increase in visitors from outside Europe with 19.6% of the total visitors traveling from elsewhere including Asia, North and South America and Africa. Covering 34,566 square meters, the show’s footprint also increased by 11.65% over 2013, while exhibitor numbers rose from 600 to just over 650.

Held every two years, Labelexpo Europe is the world’s largest event for the label and package printing industry. Dominated by new product launches, the show again saw many major new developments being unveiled including some modular hybrid digital converting systems from several of the industry’s leading press manufacturers. Digital was a hot topic, with more than 50 exhibitors showcasing digital printing equipment – there was seemingly something for every budget and scale.

Labelexpo Europe 2015 also included several new feature areas. The Packprint Workshop was well attended, with live press demonstrations given by Xeikon using its 3500 for digital folding cartons and Nilpeter showing its FA* flexo press for flexible packaging applications. The Smart Packaging Lab covered some current developments in active and intelligent packaging. The show also hosted the first Linerless Trail, which promoted the benefits of linerless labels. Lisa Milburn, managing director of the Labelexpo Global Series, commented: “We would like to thank everyone who took part in this year’s show. The feedback has been genuinely phenomenal, and our exhibitors have been extremely pleased with many of the press manufacturers experiencing record sales and lead generation. The main trends coming out of this year’s show are the continued move to package printing as we see more manufacturers bringing short run production printing presses, which backs up our strategy going forward, and the ongoing dominance of digital as more and more hybrid digital printing presses flood into the marketplace.”

On the show floor