Sean Skelly11.20.15

Have you ever heard someone proclaim proudly, “This ain’t my first rodeo?” This person wants you to know that he or she has acquired relevant experience – often with the scars to prove it – that allows him or her to confidently make intelligent decisions based on hard-earned past learnings. Often, this is true, but unfortunately, this phrase can be famous last words when applied to a complex, infrequent transaction, like the purchase of a digital press. This article explores the risks associated with sacrificing a solid decision-making process for one that is based on instincts, and suggests a purchasing framework for buying future digital presses.

The Value of Experience

For most converters new to digital, the selection of their first press required them to go through an accelerated technology education and a comprehensive product evaluation process. Typically, this consisted of meticulously testing samples, staring endlessly under loupes to examine image quality, experimenting with a myriad of substrates and coatings, and, of course, navigating the “market-speak” of eager equipment vendors. It can be both exhausting, yet exhilarating, as they finalize this major capital purchase that can potentially transform their printing business.

When the time comes to buy their next digital press, some converters may be quick to think,“This ain’t my first digital press!” And to some degree, they are right. Their readiness for this subsequent round of purchasing puts them light years ahead of where they were for digital press #1.

Much like riding a bucking bronco (which some installations actually feel like), the most valuable and lasting lessons come from “getting on and riding,” not just reading about or observing digital label printing. Without question, experience in evaluating, acquiring, installing and operating a digital press is invaluable input for subsequent press purchases.

One Good Ride Doesn’t Create a Cowboy

But business danger lurks if a converter is overconfident in blindly reusing what they learned at their “first digital printing press rodeo.” They may be under the illusion that they are now experts in the vendor selection process, and can just go default to auto pilot for the new digital press evaluation. This is based on one very faulty premise: that the circumstances surrounding their first purchase are identical to the circumstances governing the current evaluation project. Nothing could be further from the truth!

For starters, significant and dramatic progress has been made in digital label and package printing, both in raw technology capabilities as well as in the variety of product choices. In recent years, the number of vendors has exploded, with each one offering unique value propositions based on integrating different combinations of printheads, inks, transports, prepress software and finishing equipment. This is no surprise to anyone who monitors the annual slew of new digital press announcements that come out every fall at Labelexpo, including most recently in Brussels.

Even more important than the ever-changing digital equipment landscape is something much more controllable: the converters’ own rationale for buying a new press, and their purchasing strategy when adding that capital asset. It is this strategy validation that is often skipped when a major, new purchasing project is undertaken after a converter has become a digital “expert.”

Capacity (More Horses) versus Capability (Different Horses)

When it’s time to add another press to a converter’s operation, the underlying question usually is: “What do I need: more capacity or more capability?” Of course, the answer is always a little of both. Revenue growth can come from volume increases in the labels you currently produce, or from diversifying your operation by participating in untapped label markets. In either case, an investment in an expensive piece of capital equipment is required, so it’s not always feasible to “pick both” – priorities have to be set, and at least in the near term, only one piece of equipment can be bought.

Note that the functional leaders within the firm will typically have strong opinions about which “horse” decision the firm should pursue. Sales wants to say “Yes” to all possible label selling opportunities, so they are generally unconcerned about proliferating the number of digital presses so long as it will help them to close more deals. On the other hand, Operations often wants to limit the overall number of unique press vendors, thus simplifying the manufacturing process and reducing the burden on Purchasing’s vendor management function.

Regardless of how the capacity/capability question is answered, another important question must be immediately addressed by the top management of the company. For the new digital press that will be purchased, should a Best of Breed approach be pursued, or would equipment standardization in the form of a Single Source strategy be wiser?

Best of Breed

A Best of Breed approach has traditionally been applied to enterprise software systems, where instead of buying a fully integrated MIS system from one vendor, a business buys the “best” individual modules from multiple vendors and integrates them itself. The concept when applied to digital printing presses consists of scanning the market for the most advanced product available, with little or no consideration given to the incumbent press currently in the factory.

The word “Best” can only truly be understood in the context of the individual business’ needs. Is the fastest press the best? Maybe the press with the highest native resolution? Or is it the one with the lowest cost of ownership? Simply put, “Best” is the digital press that outperforms all the others in meeting the business’ highest priority needs.

For example, two converters with differing participation strategies are likely to come to different conclusions of “Best” if they were to do such a market scan. One converter may need to produce clear labels, so a press that offers white ink opacity would be a highly desired feature. In contrast, the second converter may have customers with very demanding color requirements, so they may prioritize color gamut higher and give higher scores to 8–color printing presses. Both of the presses selected are “Best” for the respective converters. Below are some of the key benefits offered by a Best of Breed purchasing model.

De-risks commercial reliance on a single supplier: Single sourcing of key products or components can cripple your business as you might face potential disruption if your press manufacturer undergoes extensive technical, legal or financial problems. A lone printing press in your operation is by definition “single–sourced,” and can only be de-risked by developing robust contingency plans (e.g., outsourcing work to other digitally-capable converters). Although it can be quite challenging to manage multiple, competing $1 million press vendors, the diversification of supplier risk is something that you may want to consider when it’s time to invest in your second or third press.

Targets specific growth areas: Often, label manufacturers have a core competency in one type of market, but are looking to grow the business by expanding into other areas. Consider a company that manufactures 80% of its labels for the food and beverage industry. To diversify the business, it may want to pursue a different market, perhaps the durables segment. If their current press is not suitable because its ink will not withstand harsh environments, a new vendor’s press may solve this problem.

Avoids technology obsolescence: New technologies are continually being developed by component suppliers, putting relentless pressure on digital press manufacturers to incorporate these innovations as quickly as possible. Higher resolution printheads, more powerful lasers and innovative ink formulations are just three examples of must-have features in next generation digital presses. But multi-year printer development cycles don’t allow vendors to just plug-&-play alternative technologies, so converters often have to engage multiple vendors if they want the latest and greatest.

Provides negotiating alternative: Shopping around when acquiring a new digital press can certainly offer some advantages for negotiating the best discounts. Vendors are always aggressively looking for ways to attract new customers, especially if they can lure them away from the incumbent. At a minimum, exploring alternatives to your current digital press vendor will keep the latter from becoming too complacent and taking you for granted as a customer.

Single Source

Converters who emphasize sticking with the same vendor fall under the category of a Single Source strategy. Although they certainly have specific speed, resolution and other performance requirements when buying a digital press, they tend to give extra weight to products from their existing vendor. Ideally, their current supplier would also be the objective Best of Breed, but even if it isn’t, the converter might relax their requirements to “good enough” in exchange for the benefits associated with working with a single vendor.

Note that even many first time press buyers employ a Single Source strategy when buying their first digital press by turning to their trusted flexo manufacturer, whom they have often purchased many, many analog label presses. Until recently, this wasn’t always possible as many flexo vendors did not offer a digital solution, but that has changed dramatically in the past couple of years.

This is definitely a valid approach, but converters should be cautious as their experience with the well-established analog products from a flexo vendor might be completely different than with the digital portfolio, which is very much in the early stages of R&D. Digital is still a relatively new technology, and although it has made great strides in production-worthiness, it is not as battle-proven as analog equipment in service over many decades, even if it is from the same supplier. Below are some of the key benefits offered by a Single Source purchasing model:

Provides volume-based negotiating power: By working closely with the same vendor on repeat purchases, a converter can often obtain better pricing than a one-off opportunistic buyer. This negotiating power can be further enhanced when buying multiple machines at one time, often leading to a sizable discount on a million-dollar or more purchase. This ability to strike a deal can extend to auxiliary items, such as inks, service and parts. In the long term, this can substantially reduce the overall operating costs of your equipment.

Allows early access to next generation products: Beyond pricing, building a long-term relationship with a press vendor can result in an advantageous position whereby you as a converter may get advanced information on upcoming products. Often, vendors will want to collaborate with you on beta testing as well as highlight you in marketing case studies. This allows you to influence and stay ahead of the curve on new technologies from that vendor, while getting your company’s name promoted for free.

Leverages training and established workflow: Adoption of new capital equipment is usually the start of a long process before you master the nuances of the product. By doubling down on a particular vendors’ digital press technology, you usually will be able to leverage 60–90% of the training, workflow, spare parts, ink and maintenance know-how, resulting in your team being able to efficiently onboard that machine more quickly.

Fosters a true, strategic partnership: The rarest, yet most valuable, benefit of a Single Source strategy is the creation of a collaborative partnership. When achieved, candid talk about the most important aspects of your respective businesses can be constructively discussed. This includes direction on your product and technology roadmaps, market participation strategies, acquisition plans, operational objectives and more.

If you have an intimate business relationship with your press manufacturer, you can explore these plans together. Alternatively, if you are just a tire-kicker that is looking for the best deal from any vendor, then they will not be able to provide you with useful guidance.

Conclusion

The sheer cost of a digital press makes it seemingly impractical to adopt any strategy other than a Single Source approach, and initially, this is true. But very few, if any, converters will end up only owning a single digital press during the life of their business. Instead, as digital printing grows to meet demand for SKU proliferation, personalization and short-run jobs, converters will expand beyond their first presses.

As converters start investing in digital press #2, #3 and more, they should undertake a systematic Best of Breed or Single Source strategy that is aligned with the objectives of their business. Both these strategies have merit when it comes to expanding in-house digital printing assets, and it may even be possible to adopt a hybrid strategy that finds an optimal set of the “Few Best.”

Converters will be well-served by following the systematic, professional strategies described above for adding digital printing assets to their facility. At the same time, they need to resist relying on their instincts alone by making the statement, “This ain’t my first rodeo OR my first digital press,” or else they might find themselves riding the “wrong horse,” and the wrong digital press vendor.

About the author: Sean Skelly provides thought leadership to the label and packaging industries on market dynamics, acquisitions, technology adoption and implementation best practices. Sean can be reached at skelly@yahoo.com.

While digital inkjet technology made headlines in 2015, the two leaders in toner-based, electrophotographic (EP) digital label printing technology – HP Indigo and Xeikon – continue to innovate. HP Indigo, in terms of its overall install base, remains the leading digital printing platform in the label industry. Xeikon, the clear #2 OEM in the space, recently announced that its labels and packaging division represents an estimated 58% of its revenues by the end of 2015, validating a decision to spend a signifcant amount of focus on the market.

Both companies continue to make strides, and continue to adapt to the evolving demands of the industry for speed, quality and flexibility.

New features for HP Indigo WS6800

HP Indigo recently unveiled new product features, upgrade packages and software enhancements for its WS6800 digital label press.

Alon Bar-Shany presents at Labelexpo Europe 2015.

“With mounting pressure from brands to deliver differentiated, high-quality labels and packaging at faster and faster turnaround times, converters and PSPs are constantly looking for new avenues for growth and expansion,” says Alon Bar-Shany, vice president and general manager, Indigo Division, HP. “New HP Indigo cross-portfolio innovations, including breakthrough color management and higher productivity and versatility, allow our customers to remain a step ahead of the market, time and time again.”

For the WS6800, the company’s latest press for the digital label market, new features include the Color Automation Package, a digital color matching system that uses the press’ inline spectrophotometer and new Esko-powered HP Indigo Labels and Packaging Print Server capabilities. The package offers converters a quick and easy process to match brand spot colors from the first label to the last.

Other developments include: a new HP ElectroInk Fade Resistant Ink set enables high-value applications with high lightfastness for use outdoors; enhanced media versatility, ease of use, and lower cost of operation with the new Michelman DP680 Primer; integration with industry-leading digital workflow solutions, including Web-to-print solutions designed for labels and packaging product ordering, as well as new proofing, prepress and automation tools; and HP SmartStream Designer integration with security solutions to create microtext variable data printing (VDP), anti-counterfeit QR codes, dynamic guilloche, and end-to-end track and trace solutions.

The HP Indigo WS6000 digital press series now boasts installations in more than 60 countries, with an installed base nearly doubling over the past two years, Bar-Shany says.

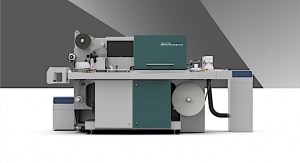

Cheetah technology powers the Xeikon CX3

The CX3 is powered Cheetah technology.

Xeikon’s latest digital label press is the CX3. Based on its Cheetah technology, the Xeikon CX3 has a top speed of 98 fpm, which is 56% faster than any other model in the current Xeikon press portfolio. The 1200 x 3600 dpi resolution press is dedicated solely to the production of pressure sensitive labels. “It offers all the renowned benefits that make the Xeikon 3000 Series unique, including the use of dry toners that meet FDA regulations for food contact and the ability to print opaque white toner in one pass,” says Filip Weymans, Xeikon’s director of segment marketing.

Cheetah technology also enables printing on a variety of heat-sensitive substrates due to the incorporation of Xeikon’s ICE toner technology, which requires a much lower fusing temperature than typical toner-based presses. Weymans says, “Xeikon presses are based on dry toner electrophotography. This enables the use of conventional substrates that do not have to be pre-treated. Extremely high toner lightfastness and truly eco-friendly printing (no VOCs) are some of the other industry leading features of the Xeikon presses for digital label and package printing.”

The CX3 press offers easy integration of third-party workflow software as well as converting/finishing solutions and incorporates professional color management capabilities. In addition to the standard CMYK + White, the fifth station on the Xeikon CX3 can be used to print gamut expansion colors or security toner. Media weights range from 40 gsm to 350 gsm.

The most recent Cheetah installation, and the second overall in the US, was at Action Packaging in Ellington, Connecticut, where CEO Douglas Rice commented: “The Xeikon CX3 is doing exactly what Xeikon stated it would do. We have it running non-stop during one full shift with zero downtime. With our demanding business model, focused on rapid delivery of high quality product, we would be in trouble without its capabilities.”

The Value of Experience

For most converters new to digital, the selection of their first press required them to go through an accelerated technology education and a comprehensive product evaluation process. Typically, this consisted of meticulously testing samples, staring endlessly under loupes to examine image quality, experimenting with a myriad of substrates and coatings, and, of course, navigating the “market-speak” of eager equipment vendors. It can be both exhausting, yet exhilarating, as they finalize this major capital purchase that can potentially transform their printing business.

When the time comes to buy their next digital press, some converters may be quick to think,“This ain’t my first digital press!” And to some degree, they are right. Their readiness for this subsequent round of purchasing puts them light years ahead of where they were for digital press #1.

Much like riding a bucking bronco (which some installations actually feel like), the most valuable and lasting lessons come from “getting on and riding,” not just reading about or observing digital label printing. Without question, experience in evaluating, acquiring, installing and operating a digital press is invaluable input for subsequent press purchases.

One Good Ride Doesn’t Create a Cowboy

But business danger lurks if a converter is overconfident in blindly reusing what they learned at their “first digital printing press rodeo.” They may be under the illusion that they are now experts in the vendor selection process, and can just go default to auto pilot for the new digital press evaluation. This is based on one very faulty premise: that the circumstances surrounding their first purchase are identical to the circumstances governing the current evaluation project. Nothing could be further from the truth!

For starters, significant and dramatic progress has been made in digital label and package printing, both in raw technology capabilities as well as in the variety of product choices. In recent years, the number of vendors has exploded, with each one offering unique value propositions based on integrating different combinations of printheads, inks, transports, prepress software and finishing equipment. This is no surprise to anyone who monitors the annual slew of new digital press announcements that come out every fall at Labelexpo, including most recently in Brussels.

Even more important than the ever-changing digital equipment landscape is something much more controllable: the converters’ own rationale for buying a new press, and their purchasing strategy when adding that capital asset. It is this strategy validation that is often skipped when a major, new purchasing project is undertaken after a converter has become a digital “expert.”

Capacity (More Horses) versus Capability (Different Horses)

When it’s time to add another press to a converter’s operation, the underlying question usually is: “What do I need: more capacity or more capability?” Of course, the answer is always a little of both. Revenue growth can come from volume increases in the labels you currently produce, or from diversifying your operation by participating in untapped label markets. In either case, an investment in an expensive piece of capital equipment is required, so it’s not always feasible to “pick both” – priorities have to be set, and at least in the near term, only one piece of equipment can be bought.

Note that the functional leaders within the firm will typically have strong opinions about which “horse” decision the firm should pursue. Sales wants to say “Yes” to all possible label selling opportunities, so they are generally unconcerned about proliferating the number of digital presses so long as it will help them to close more deals. On the other hand, Operations often wants to limit the overall number of unique press vendors, thus simplifying the manufacturing process and reducing the burden on Purchasing’s vendor management function.

Regardless of how the capacity/capability question is answered, another important question must be immediately addressed by the top management of the company. For the new digital press that will be purchased, should a Best of Breed approach be pursued, or would equipment standardization in the form of a Single Source strategy be wiser?

Best of Breed

A Best of Breed approach has traditionally been applied to enterprise software systems, where instead of buying a fully integrated MIS system from one vendor, a business buys the “best” individual modules from multiple vendors and integrates them itself. The concept when applied to digital printing presses consists of scanning the market for the most advanced product available, with little or no consideration given to the incumbent press currently in the factory.

The word “Best” can only truly be understood in the context of the individual business’ needs. Is the fastest press the best? Maybe the press with the highest native resolution? Or is it the one with the lowest cost of ownership? Simply put, “Best” is the digital press that outperforms all the others in meeting the business’ highest priority needs.

For example, two converters with differing participation strategies are likely to come to different conclusions of “Best” if they were to do such a market scan. One converter may need to produce clear labels, so a press that offers white ink opacity would be a highly desired feature. In contrast, the second converter may have customers with very demanding color requirements, so they may prioritize color gamut higher and give higher scores to 8–color printing presses. Both of the presses selected are “Best” for the respective converters. Below are some of the key benefits offered by a Best of Breed purchasing model.

De-risks commercial reliance on a single supplier: Single sourcing of key products or components can cripple your business as you might face potential disruption if your press manufacturer undergoes extensive technical, legal or financial problems. A lone printing press in your operation is by definition “single–sourced,” and can only be de-risked by developing robust contingency plans (e.g., outsourcing work to other digitally-capable converters). Although it can be quite challenging to manage multiple, competing $1 million press vendors, the diversification of supplier risk is something that you may want to consider when it’s time to invest in your second or third press.

Targets specific growth areas: Often, label manufacturers have a core competency in one type of market, but are looking to grow the business by expanding into other areas. Consider a company that manufactures 80% of its labels for the food and beverage industry. To diversify the business, it may want to pursue a different market, perhaps the durables segment. If their current press is not suitable because its ink will not withstand harsh environments, a new vendor’s press may solve this problem.

Avoids technology obsolescence: New technologies are continually being developed by component suppliers, putting relentless pressure on digital press manufacturers to incorporate these innovations as quickly as possible. Higher resolution printheads, more powerful lasers and innovative ink formulations are just three examples of must-have features in next generation digital presses. But multi-year printer development cycles don’t allow vendors to just plug-&-play alternative technologies, so converters often have to engage multiple vendors if they want the latest and greatest.

Provides negotiating alternative: Shopping around when acquiring a new digital press can certainly offer some advantages for negotiating the best discounts. Vendors are always aggressively looking for ways to attract new customers, especially if they can lure them away from the incumbent. At a minimum, exploring alternatives to your current digital press vendor will keep the latter from becoming too complacent and taking you for granted as a customer.

Single Source

Converters who emphasize sticking with the same vendor fall under the category of a Single Source strategy. Although they certainly have specific speed, resolution and other performance requirements when buying a digital press, they tend to give extra weight to products from their existing vendor. Ideally, their current supplier would also be the objective Best of Breed, but even if it isn’t, the converter might relax their requirements to “good enough” in exchange for the benefits associated with working with a single vendor.

Note that even many first time press buyers employ a Single Source strategy when buying their first digital press by turning to their trusted flexo manufacturer, whom they have often purchased many, many analog label presses. Until recently, this wasn’t always possible as many flexo vendors did not offer a digital solution, but that has changed dramatically in the past couple of years.

This is definitely a valid approach, but converters should be cautious as their experience with the well-established analog products from a flexo vendor might be completely different than with the digital portfolio, which is very much in the early stages of R&D. Digital is still a relatively new technology, and although it has made great strides in production-worthiness, it is not as battle-proven as analog equipment in service over many decades, even if it is from the same supplier. Below are some of the key benefits offered by a Single Source purchasing model:

Provides volume-based negotiating power: By working closely with the same vendor on repeat purchases, a converter can often obtain better pricing than a one-off opportunistic buyer. This negotiating power can be further enhanced when buying multiple machines at one time, often leading to a sizable discount on a million-dollar or more purchase. This ability to strike a deal can extend to auxiliary items, such as inks, service and parts. In the long term, this can substantially reduce the overall operating costs of your equipment.

Allows early access to next generation products: Beyond pricing, building a long-term relationship with a press vendor can result in an advantageous position whereby you as a converter may get advanced information on upcoming products. Often, vendors will want to collaborate with you on beta testing as well as highlight you in marketing case studies. This allows you to influence and stay ahead of the curve on new technologies from that vendor, while getting your company’s name promoted for free.

Leverages training and established workflow: Adoption of new capital equipment is usually the start of a long process before you master the nuances of the product. By doubling down on a particular vendors’ digital press technology, you usually will be able to leverage 60–90% of the training, workflow, spare parts, ink and maintenance know-how, resulting in your team being able to efficiently onboard that machine more quickly.

Fosters a true, strategic partnership: The rarest, yet most valuable, benefit of a Single Source strategy is the creation of a collaborative partnership. When achieved, candid talk about the most important aspects of your respective businesses can be constructively discussed. This includes direction on your product and technology roadmaps, market participation strategies, acquisition plans, operational objectives and more.

If you have an intimate business relationship with your press manufacturer, you can explore these plans together. Alternatively, if you are just a tire-kicker that is looking for the best deal from any vendor, then they will not be able to provide you with useful guidance.

Conclusion

The sheer cost of a digital press makes it seemingly impractical to adopt any strategy other than a Single Source approach, and initially, this is true. But very few, if any, converters will end up only owning a single digital press during the life of their business. Instead, as digital printing grows to meet demand for SKU proliferation, personalization and short-run jobs, converters will expand beyond their first presses.

As converters start investing in digital press #2, #3 and more, they should undertake a systematic Best of Breed or Single Source strategy that is aligned with the objectives of their business. Both these strategies have merit when it comes to expanding in-house digital printing assets, and it may even be possible to adopt a hybrid strategy that finds an optimal set of the “Few Best.”

Converters will be well-served by following the systematic, professional strategies described above for adding digital printing assets to their facility. At the same time, they need to resist relying on their instincts alone by making the statement, “This ain’t my first rodeo OR my first digital press,” or else they might find themselves riding the “wrong horse,” and the wrong digital press vendor.

About the author: Sean Skelly provides thought leadership to the label and packaging industries on market dynamics, acquisitions, technology adoption and implementation best practices. Sean can be reached at skelly@yahoo.com.

While digital inkjet technology made headlines in 2015, the two leaders in toner-based, electrophotographic (EP) digital label printing technology – HP Indigo and Xeikon – continue to innovate. HP Indigo, in terms of its overall install base, remains the leading digital printing platform in the label industry. Xeikon, the clear #2 OEM in the space, recently announced that its labels and packaging division represents an estimated 58% of its revenues by the end of 2015, validating a decision to spend a signifcant amount of focus on the market.

Both companies continue to make strides, and continue to adapt to the evolving demands of the industry for speed, quality and flexibility.

New features for HP Indigo WS6800

HP Indigo recently unveiled new product features, upgrade packages and software enhancements for its WS6800 digital label press.

Alon Bar-Shany presents at Labelexpo Europe 2015.

For the WS6800, the company’s latest press for the digital label market, new features include the Color Automation Package, a digital color matching system that uses the press’ inline spectrophotometer and new Esko-powered HP Indigo Labels and Packaging Print Server capabilities. The package offers converters a quick and easy process to match brand spot colors from the first label to the last.

Other developments include: a new HP ElectroInk Fade Resistant Ink set enables high-value applications with high lightfastness for use outdoors; enhanced media versatility, ease of use, and lower cost of operation with the new Michelman DP680 Primer; integration with industry-leading digital workflow solutions, including Web-to-print solutions designed for labels and packaging product ordering, as well as new proofing, prepress and automation tools; and HP SmartStream Designer integration with security solutions to create microtext variable data printing (VDP), anti-counterfeit QR codes, dynamic guilloche, and end-to-end track and trace solutions.

The HP Indigo WS6000 digital press series now boasts installations in more than 60 countries, with an installed base nearly doubling over the past two years, Bar-Shany says.

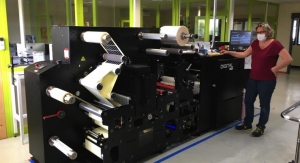

Cheetah technology powers the Xeikon CX3

The CX3 is powered Cheetah technology.

Cheetah technology also enables printing on a variety of heat-sensitive substrates due to the incorporation of Xeikon’s ICE toner technology, which requires a much lower fusing temperature than typical toner-based presses. Weymans says, “Xeikon presses are based on dry toner electrophotography. This enables the use of conventional substrates that do not have to be pre-treated. Extremely high toner lightfastness and truly eco-friendly printing (no VOCs) are some of the other industry leading features of the Xeikon presses for digital label and package printing.”

The CX3 press offers easy integration of third-party workflow software as well as converting/finishing solutions and incorporates professional color management capabilities. In addition to the standard CMYK + White, the fifth station on the Xeikon CX3 can be used to print gamut expansion colors or security toner. Media weights range from 40 gsm to 350 gsm.

The most recent Cheetah installation, and the second overall in the US, was at Action Packaging in Ellington, Connecticut, where CEO Douglas Rice commented: “The Xeikon CX3 is doing exactly what Xeikon stated it would do. We have it running non-stop during one full shift with zero downtime. With our demanding business model, focused on rapid delivery of high quality product, we would be in trouble without its capabilities.”