Steve Katz, Editor09.07.16

The vast majority of the global label printing market is still produced via the flexographic printing process. While digital printing technology is the current buzz in the label and packaging printing industry – and its inroads are noteworthy – it’s still accounting for just a small slice of the overall pie. Market research firm LPC, Inc. estimates that in North America, digital makes up just over 9% of the region’s printed labels. (For more on this, turn to page 68.)

Flexo is still the dominating force in the label market, and in order for it to remain that way, its key innovators – the press manufacturers – are developing machinery that’s easier to operate while making continuous advancements in the press’s ability to produce high quality labels.

Today’s flexo presses are more productive than ever in every facet of the label converting process. Here’s a look at the latest developments from the industry’s leading manufacturers, as well as insights into what’s driving innovation as flexo forges into the future.

Mark Andy

Productivity can be measured by such metrics as job changeover time, setup waste, run waste, run speed and unplanned downtime. And for St. Louis, MO-based Mark Andy, “Quick Change” has been realized in many press designs for all functions of the press, including web tensioning, inking, plate change, die change, matrix setup and more.

According to John Howard, director of product management, Mark Andy, several innovative designs have been introduced recently which either passively or actively set ink and impression on a job change. “Automated register systems quickly get the job in register which minimizes setup waste. Die station designs allow a die to be changed out in about 30 seconds. Overall, presses have been designed to run faster, and the systems that support printing and converting also have become capable of higher speeds, such as hot air drying and matrix stripping,” he explains, adding, “And presses are much more reliable – unplanned downtime is reduced through higher precision mechanisms and more reliable electronics.”

Developing presses that are easier to operate is another driver for Mark Andy innovation. Howard says, “Whether it’s a sleeve or cylinder press, the operator can quickly and easily change a plate. An inking system now can be a one-motion lock up, and controls are ergonomically designed. Also, die changes can be accomplished with no lifting while decorating functions can be mounted on a rail system and easily moved around. So, with less effort, an operator can achieve a high level of quality – consistently – and run at a high production speed. This ultimately generates more saleable product at a lower cost, both of which drive profit.”

Mark Andy’s flexo press developments have been influenced by the company’s digital product – the Mark Andy Digital Series. Explains Howard: “The nature of web handling is more demanding on the digital side; tension control and uniform displacement are keys to tight color-to-color fit in digital. Also, digital press manufacturing controls – idlers, transmission error, tension control, etc. – have transferred to the analog flexo side, thus improving register there.

“Additionally, the trend of decreasing run lengths requires setups to be faster and easier and a lot of design effort has been devoted to enabling a ‘pit stop’ changeover,” Howard adds. “Faster speeds have driven advancements in hot air drying and UV curing. UV LED curing provides benefits in productivity, speed and energy efficiency.”

Another trend leading to new Mark Andy press technology is that of running filmic labels and flexible packaging on narrow web inline presses. Howards notes that filmic substrates are more sensitive to heat and cannot be tensioned like paper or PS substrates. He says, “Web transport without wrinkling or register problems requires specific machine solutions.”

With regard to specific solutions, Mark Andy’s Performance Series has continually evolved to meet converters’ changing needs. The Performance Series comprises four models: P3, P4, P5 and P7. The P4 is servo-driven and is designed to accept “legacy” shafted plate rolls (such as from the Mark Andy 2200). “For converters with large inventories of shafted plate rolls, the P4 brings substantial productivity improvements compared to older technology presses,” Howard says.

The P3, P5 and P7 feature bearered plate roll design, wherein cams at the impression and anilox radii set the position of the plate roll whose bearer diameter emulates the plate roll diameter. “The advantage of the bearer plate roll capture is the accurate and repeatable positioning of the plate roll, which results in the correct impression,” Howard explains.

All Performance Series models have very fast setup and low waste, and ink and impression need no adjustment on a job change unless the substrate changes. Inking setup is a fluid “load-and-lock” motion. “Performance Series presses have exceptionally good color-to-color register and image fit capabilities,” Howard adds. “And web displacement and plate roll angular positioning are extremely precise through motion control. Highly analytical techniques are used to ensure mechanical components are not introducing unacceptable periodic transmission errors. An optional mark-to-mark register control enables automatic registration setup and running register control without operator intervention.”

Rail systems are available on all Performance Series models and rail mounted functions include rotary screen, cold foil, lamination, waste windup and more. Rotary hot foil and rotary screen are also available as cassettes. Performance Series presses can be equipped with hot air drying, UV Hg curing, and UV LED curing, including Mark Andy’s ProLED, a solution with irradiance levels up to 25 watts per square cenitmeter. These solutions can be had in combination as well.

Converting components on the Performance series include vertical slot diecutting, Mark Andy’s Quick Change Die Cut (QCDC) technology which enables a fast and easy die change, sheeting, rewinding and other specialized solutions. The latest design features modular configurability of various functional heads mounted on common bases.

The press platform is also very flexible, designed to accept vision and defect detection solutions from any OEM. The P3, P5 and P7 models range from mechanical gear-driven (P3) to full servo with multi-axis servo drives per print station (P7).

Nilpeter

Paul Teachout, vice president of sales and marketing at Nilpeter USA in Cincinnati, OH, points out that over the last decade there has been a dramatic change in narrow web flexo press design, and the changing workforce is playing a role in press evolution. “Automation and smart controls have taken over to engage the younger generation,” he says, noting that Millennials are now the largest workforce in the world.

In addition to attracting the next generation of press operators, Teachout stresses that new machinery is also designed to produce packaging for the current end user. He says, “Today’s presses offer fully automated drives and wireless operation. They are designed and built to prepare for the next level of dynamic packaging that will offer direct package interaction with the consumer.”

Automation is not only on the drive side of the machine, but now carried over to the operator side. “With the most sophisticated press designs of today, you no longer see knobs and gears,” Teachout says. “All operator functions are now controlled by servo motors, thus all positional data can be saved and recalled for future use. If you’re turning a knob to position a gear-driven cylinder, you are running outdated equipment. Current press designs are smart and interactive, tablet controlled and intuitive to operate. The Millennials want faster, better and easier and that’s exactly what we gave them.”

Nilpeter’s press innovation is in-line with many emerging printing technologies, such as expanded gamut. “The expanded gamut process consists of CMYK plus orange, green and violet. With this fixed color pallete you can now achieve upwards of 85% of PMS spot colors with no changes in press set-up. This greatly reduces the need for wash-up and make-ready related downtime. With the level of automation today, gearless plate sleeves and total job save and recall, the expanded gamut process allows new narrow web press designs to directly compete with digital. This is where the science of flexography is applied to high level automation, creating the print shop of tomorrow,” Teachout says.

For Nilpeter, what has allowed the company to maintain its growth trajectory, is the opportunity to entertain new market trends while maintaining its current market position. And this is due to significant advances in flexograohy. “The flexo process,” Teachout says, “can now compete with any other print media – offset and gravure no longer have a stranglehold on high quality printing. Flexo is as good or better than these processes. It provides the opportunity to deliver a high quality printed image, on a variety of substrates that include very cost-effective decorative embellishments – all inline in one pass. Flexo is still the most productive way to deliver a final solution. As more and more rigid and flexible applications turn to flexo, it creates more and more opportunities for inline narrow web press offerings.”

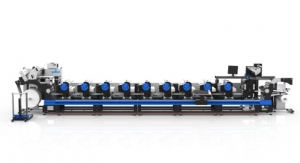

The latest press offering from Nilpeter is the FA-4*, a fully automated platform from unwind to rewind, with no air clutches, no magnetic particle brakes, no line shafts and no expensive plate roll gears and bearings. Describes Teachout, “It is a triple axis servo design. That means the anilox, impression roll and gearless plate sleeve are all directly driven by independent servo motors. There are four more motors on the operator side that control all printing functions – no more knobs to turn or mechanical parts to maintain. No more plate rolls, gears, bearings or expensive plate tooling to purchase. Just lightweight composite sleeves fully controlled by automation.

“All this allows for direct save and recall of all jobs for future production,” Teachout says. “A simple recall, sleeve change, and then hit the run button – and the first label will be a duplicate to the one you ran last.”

The web transportation system of the FA-4* allows for constant tension control and, Teachout stresses, more importantly, constant temperature control. “Without these you have no register control,” he explains. “Nilpeter presses have no match to web handling and transportation which allows processes like expanded gamut to excel. The CleanInking systems allow for the most precise ink metering available – another crucial element in extended gamut printing and maintaining color values through speed changes. There is no ink pan, no meter roll and no hydraulic effect during speed changes to affect color density or hue. It is a true one piece quick-change solution where ink can even be stored offline with no need to clean up.”

All these automation and quick change features are exactly why Nilpeter has branded them “Clean Hand Technology” solutions. “The FA-4* is a next generation machine designed to meet the needs of tomorrow’s converter and dynamic packaging solutions. It addresses the challenges of our changing workforce, streamlines our production operations and utilizes current scientific approaches to decrease our waste and downtime and increase converter profitability.”

Omet

Omet, the Italy-based press manufacturer for labels and flexible packaging, recently showcased its iFlex flexo label press at an Open House at its new North American headquarters in Elk Grove Village, IL, USA. During the event, an 8-color iFlex with cold foil ran the jobs at 14.5" web widths. The press demonstration showed how Omet sees the iFlex filling a gap in the flexo label press market, providing medium-to-large label converters a one-pass option for just-in-time deliveries. According to Omet, the press is suitable for self-adhesive labels and can meet a growing need in the beer and drinks markets, in particular.

The iFlex press features iLight, a pre-register alignment aid for the print cylinders, and iVision, which features a smart camera for instant register correction. The iVision unit includes a display in the middle of the press for register control. In addition, iFlex can operate at speeds up to 630 fpm (190 m/m). “This is the easiest and smartest way to set up a new job, thanks to the new exclusive features that have been installed on the iFlex,” explains Bill Mulligan, sales manager for the Northeast region, Omet Americas.

“One of the most unique features on this press is iLight,” he adds. “It is the first ever laser application on a flexo printing press. It is a guiding light for instant print cylinder re-registration, and the operator just needs to follow the light of the laser and replace the cylinder in the correct position, simply by matching the laser beam. It is an extremely simple operation.”

The iVision’s scanned images reach the central display, where the register is manually set prior to the job reaching the end of the line. “With iVision, the operator can achieve perfect register for all of the colors on the machine, which means less waste and less downtime,” says Mulligan.

Ease of use is a key selling point of the iFlex. Mulligan adds, “These simple operations can be carried out by anyone, even if they do not know the first thing about running a flexo printing presses.”

During the Open House, Omet’s demo illustrated a quick job changeover from one label job to another while showing special effects capabilities. The press is equipped for cold foil, varnish, laminated effects and creative diecutting. “The operator just needs to open the diecutting station and take the Easy Change Cart – while the press is running – and quickly insert it by means of a simple sliding device,” explains Mulligan, adding, “An operation that used to take 15 to 20 minutes now takes less than a minute.”

Omet Americas opened its new, larger facility in the Chicago area to meet growing demand in the North American market. According to the company, North American sales doubled in 2015, where it originally opened its doors in 2011.

Gallus

A prototype of a new generation Gallus press will be unveiled at Gallus Innovation Days in Switzerland, which runs from September 20-22 at company headquarters in St. Gallen. Gallus anticipates the event to attract about 1,000 visitors from all over the world.

According to Matthias Marx, head of corporate communications at Gallus, the new generation of label press to be unveiled is equipped with flexo printing units and features an innovative new construction which can be configured to a customer’s requirements in terms of the level of automation or web width. Gallus will launch the first series machines with a width of 440 mm (17").

“The future modular platform principle will make it possible to configure everything from basic models to fully equipped versions with varying degrees of automation, all to the known Gallus quality level,” Marx says.

With its maximum speed of 200 m/m and extremely short setup times, these printing presses are the fastest narrow-web machines that Gallus has ever built. “Our engineers paid particular attention to achieving the highest possible level of productivity, using features such as precise register accuracy regardless of speed, extremely straightforward operation even at low levels of automation, a very short web path from printing unit to printing unit, and exceptionally easy changeovers. The first deliveries of these new machines are scheduled for the second quarter of 2017,” says Marx, adding, “Gallus Innovation Days are always popular and we believe this time around the new machine platform will inspire our customers from all over the world.”

MPS

To Dutch press manufacturer MPS, the future of flexo rests on full press automation. Kees Nijenhuis is vice president of MPS Systems North America Inc. in Green Bay, WI, USA, where MPS presses are assembled for the North American market. He emphasizes that automation is not only about whether or not the press is servo-driven or equipped with automated registration systems. “The crucial question and missing link is whether also the print pressure settings are automated, thereby automating all press settings and completely eliminating manual and non-intelligent adjustments,” Nijenhuis says.

In 2008 MPS launched Automated Print Control (APC), a servo adjustment technology automating all print pressure settings. Today MPS is working with partner suppliers and converters to develop further possibilities that can be linked to Automated Print Control. “These automation developments have three main advantages,” explains Nijenhuis. “First of all, it allows you to meet the increasingly high level of quality standards. Automated print pressures settings allow for controlled pressure settings based on objective numbers instead of a subjective value of a manual knob. Furthermore, thanks to the development of AVT’s Presco technology, inspection cameras can be used to measure the actual dot gain where this information is sent back in a closed-loop to the servo adjustment motors, automatically correcting the print pressure to the perfect setting.

“Second, it allows you to improve productivity to a best-in-class level,” Nijenhuis adds. “Job memory offers the ability to use a material calibration database and it allows printers the ability to save and recall print pressure settings of repeat jobs, significantly reducing setup waste and time. Also, a fully automated press can be linked to any Management Information System (MIS), workflow system, inspection system or post-press system, thereby monitoring and controlling press performance and optimizing the interaction of the press with other parts of your logistical system.” In order to achieve this, MPS developed a special software connectivity platform, called “connect.16”.

The third, and to Nijenhuis perhaps the most important advantage, has to do with tomorrow’s press operator. “It is becoming harder and harder to find and keep skilled and experienced press operators,” he says. “Press automation has changed flexo printing printing from being an art to being more of a science. This allows tomorrow’s press operators with less and less printing skills and more and more automation skills to also be motivated and achieve maximum print quality and productivity.”

The MPS EF press is the company’s flagship multi-substrate flexo press, especially designed for label production and flexible packaging printing. The press features UV, hot-air and LED drying technology, allowing users to print on a wide variety of substrates including thin film, paper, cartonboard, shrink sleeves, in-mold, tube and flexible packaging.

The EF press can be configured with new “future-proof” technological solutions for the highest level of productivity, Nijenhuis says, such as a fully automated Quick Change Die unit, a hybrid UV/LED drying system and a system for fully automated processing of pressure settings. The EF offers a choice of either plate rolls or print sleeves.

Flexo is still the dominating force in the label market, and in order for it to remain that way, its key innovators – the press manufacturers – are developing machinery that’s easier to operate while making continuous advancements in the press’s ability to produce high quality labels.

Today’s flexo presses are more productive than ever in every facet of the label converting process. Here’s a look at the latest developments from the industry’s leading manufacturers, as well as insights into what’s driving innovation as flexo forges into the future.

Mark Andy

Productivity can be measured by such metrics as job changeover time, setup waste, run waste, run speed and unplanned downtime. And for St. Louis, MO-based Mark Andy, “Quick Change” has been realized in many press designs for all functions of the press, including web tensioning, inking, plate change, die change, matrix setup and more.

According to John Howard, director of product management, Mark Andy, several innovative designs have been introduced recently which either passively or actively set ink and impression on a job change. “Automated register systems quickly get the job in register which minimizes setup waste. Die station designs allow a die to be changed out in about 30 seconds. Overall, presses have been designed to run faster, and the systems that support printing and converting also have become capable of higher speeds, such as hot air drying and matrix stripping,” he explains, adding, “And presses are much more reliable – unplanned downtime is reduced through higher precision mechanisms and more reliable electronics.”

Developing presses that are easier to operate is another driver for Mark Andy innovation. Howard says, “Whether it’s a sleeve or cylinder press, the operator can quickly and easily change a plate. An inking system now can be a one-motion lock up, and controls are ergonomically designed. Also, die changes can be accomplished with no lifting while decorating functions can be mounted on a rail system and easily moved around. So, with less effort, an operator can achieve a high level of quality – consistently – and run at a high production speed. This ultimately generates more saleable product at a lower cost, both of which drive profit.”

Mark Andy’s flexo press developments have been influenced by the company’s digital product – the Mark Andy Digital Series. Explains Howard: “The nature of web handling is more demanding on the digital side; tension control and uniform displacement are keys to tight color-to-color fit in digital. Also, digital press manufacturing controls – idlers, transmission error, tension control, etc. – have transferred to the analog flexo side, thus improving register there.

“Additionally, the trend of decreasing run lengths requires setups to be faster and easier and a lot of design effort has been devoted to enabling a ‘pit stop’ changeover,” Howard adds. “Faster speeds have driven advancements in hot air drying and UV curing. UV LED curing provides benefits in productivity, speed and energy efficiency.”

Another trend leading to new Mark Andy press technology is that of running filmic labels and flexible packaging on narrow web inline presses. Howards notes that filmic substrates are more sensitive to heat and cannot be tensioned like paper or PS substrates. He says, “Web transport without wrinkling or register problems requires specific machine solutions.”

With regard to specific solutions, Mark Andy’s Performance Series has continually evolved to meet converters’ changing needs. The Performance Series comprises four models: P3, P4, P5 and P7. The P4 is servo-driven and is designed to accept “legacy” shafted plate rolls (such as from the Mark Andy 2200). “For converters with large inventories of shafted plate rolls, the P4 brings substantial productivity improvements compared to older technology presses,” Howard says.

The P3, P5 and P7 feature bearered plate roll design, wherein cams at the impression and anilox radii set the position of the plate roll whose bearer diameter emulates the plate roll diameter. “The advantage of the bearer plate roll capture is the accurate and repeatable positioning of the plate roll, which results in the correct impression,” Howard explains.

All Performance Series models have very fast setup and low waste, and ink and impression need no adjustment on a job change unless the substrate changes. Inking setup is a fluid “load-and-lock” motion. “Performance Series presses have exceptionally good color-to-color register and image fit capabilities,” Howard adds. “And web displacement and plate roll angular positioning are extremely precise through motion control. Highly analytical techniques are used to ensure mechanical components are not introducing unacceptable periodic transmission errors. An optional mark-to-mark register control enables automatic registration setup and running register control without operator intervention.”

Rail systems are available on all Performance Series models and rail mounted functions include rotary screen, cold foil, lamination, waste windup and more. Rotary hot foil and rotary screen are also available as cassettes. Performance Series presses can be equipped with hot air drying, UV Hg curing, and UV LED curing, including Mark Andy’s ProLED, a solution with irradiance levels up to 25 watts per square cenitmeter. These solutions can be had in combination as well.

Converting components on the Performance series include vertical slot diecutting, Mark Andy’s Quick Change Die Cut (QCDC) technology which enables a fast and easy die change, sheeting, rewinding and other specialized solutions. The latest design features modular configurability of various functional heads mounted on common bases.

The press platform is also very flexible, designed to accept vision and defect detection solutions from any OEM. The P3, P5 and P7 models range from mechanical gear-driven (P3) to full servo with multi-axis servo drives per print station (P7).

Nilpeter

Paul Teachout, vice president of sales and marketing at Nilpeter USA in Cincinnati, OH, points out that over the last decade there has been a dramatic change in narrow web flexo press design, and the changing workforce is playing a role in press evolution. “Automation and smart controls have taken over to engage the younger generation,” he says, noting that Millennials are now the largest workforce in the world.

In addition to attracting the next generation of press operators, Teachout stresses that new machinery is also designed to produce packaging for the current end user. He says, “Today’s presses offer fully automated drives and wireless operation. They are designed and built to prepare for the next level of dynamic packaging that will offer direct package interaction with the consumer.”

Automation is not only on the drive side of the machine, but now carried over to the operator side. “With the most sophisticated press designs of today, you no longer see knobs and gears,” Teachout says. “All operator functions are now controlled by servo motors, thus all positional data can be saved and recalled for future use. If you’re turning a knob to position a gear-driven cylinder, you are running outdated equipment. Current press designs are smart and interactive, tablet controlled and intuitive to operate. The Millennials want faster, better and easier and that’s exactly what we gave them.”

Nilpeter’s press innovation is in-line with many emerging printing technologies, such as expanded gamut. “The expanded gamut process consists of CMYK plus orange, green and violet. With this fixed color pallete you can now achieve upwards of 85% of PMS spot colors with no changes in press set-up. This greatly reduces the need for wash-up and make-ready related downtime. With the level of automation today, gearless plate sleeves and total job save and recall, the expanded gamut process allows new narrow web press designs to directly compete with digital. This is where the science of flexography is applied to high level automation, creating the print shop of tomorrow,” Teachout says.

For Nilpeter, what has allowed the company to maintain its growth trajectory, is the opportunity to entertain new market trends while maintaining its current market position. And this is due to significant advances in flexograohy. “The flexo process,” Teachout says, “can now compete with any other print media – offset and gravure no longer have a stranglehold on high quality printing. Flexo is as good or better than these processes. It provides the opportunity to deliver a high quality printed image, on a variety of substrates that include very cost-effective decorative embellishments – all inline in one pass. Flexo is still the most productive way to deliver a final solution. As more and more rigid and flexible applications turn to flexo, it creates more and more opportunities for inline narrow web press offerings.”

The latest press offering from Nilpeter is the FA-4*, a fully automated platform from unwind to rewind, with no air clutches, no magnetic particle brakes, no line shafts and no expensive plate roll gears and bearings. Describes Teachout, “It is a triple axis servo design. That means the anilox, impression roll and gearless plate sleeve are all directly driven by independent servo motors. There are four more motors on the operator side that control all printing functions – no more knobs to turn or mechanical parts to maintain. No more plate rolls, gears, bearings or expensive plate tooling to purchase. Just lightweight composite sleeves fully controlled by automation.

“All this allows for direct save and recall of all jobs for future production,” Teachout says. “A simple recall, sleeve change, and then hit the run button – and the first label will be a duplicate to the one you ran last.”

The web transportation system of the FA-4* allows for constant tension control and, Teachout stresses, more importantly, constant temperature control. “Without these you have no register control,” he explains. “Nilpeter presses have no match to web handling and transportation which allows processes like expanded gamut to excel. The CleanInking systems allow for the most precise ink metering available – another crucial element in extended gamut printing and maintaining color values through speed changes. There is no ink pan, no meter roll and no hydraulic effect during speed changes to affect color density or hue. It is a true one piece quick-change solution where ink can even be stored offline with no need to clean up.”

All these automation and quick change features are exactly why Nilpeter has branded them “Clean Hand Technology” solutions. “The FA-4* is a next generation machine designed to meet the needs of tomorrow’s converter and dynamic packaging solutions. It addresses the challenges of our changing workforce, streamlines our production operations and utilizes current scientific approaches to decrease our waste and downtime and increase converter profitability.”

Omet

Omet, the Italy-based press manufacturer for labels and flexible packaging, recently showcased its iFlex flexo label press at an Open House at its new North American headquarters in Elk Grove Village, IL, USA. During the event, an 8-color iFlex with cold foil ran the jobs at 14.5" web widths. The press demonstration showed how Omet sees the iFlex filling a gap in the flexo label press market, providing medium-to-large label converters a one-pass option for just-in-time deliveries. According to Omet, the press is suitable for self-adhesive labels and can meet a growing need in the beer and drinks markets, in particular.

The iFlex press features iLight, a pre-register alignment aid for the print cylinders, and iVision, which features a smart camera for instant register correction. The iVision unit includes a display in the middle of the press for register control. In addition, iFlex can operate at speeds up to 630 fpm (190 m/m). “This is the easiest and smartest way to set up a new job, thanks to the new exclusive features that have been installed on the iFlex,” explains Bill Mulligan, sales manager for the Northeast region, Omet Americas.

“One of the most unique features on this press is iLight,” he adds. “It is the first ever laser application on a flexo printing press. It is a guiding light for instant print cylinder re-registration, and the operator just needs to follow the light of the laser and replace the cylinder in the correct position, simply by matching the laser beam. It is an extremely simple operation.”

The iVision’s scanned images reach the central display, where the register is manually set prior to the job reaching the end of the line. “With iVision, the operator can achieve perfect register for all of the colors on the machine, which means less waste and less downtime,” says Mulligan.

Ease of use is a key selling point of the iFlex. Mulligan adds, “These simple operations can be carried out by anyone, even if they do not know the first thing about running a flexo printing presses.”

During the Open House, Omet’s demo illustrated a quick job changeover from one label job to another while showing special effects capabilities. The press is equipped for cold foil, varnish, laminated effects and creative diecutting. “The operator just needs to open the diecutting station and take the Easy Change Cart – while the press is running – and quickly insert it by means of a simple sliding device,” explains Mulligan, adding, “An operation that used to take 15 to 20 minutes now takes less than a minute.”

Omet Americas opened its new, larger facility in the Chicago area to meet growing demand in the North American market. According to the company, North American sales doubled in 2015, where it originally opened its doors in 2011.

Gallus

A prototype of a new generation Gallus press will be unveiled at Gallus Innovation Days in Switzerland, which runs from September 20-22 at company headquarters in St. Gallen. Gallus anticipates the event to attract about 1,000 visitors from all over the world.

According to Matthias Marx, head of corporate communications at Gallus, the new generation of label press to be unveiled is equipped with flexo printing units and features an innovative new construction which can be configured to a customer’s requirements in terms of the level of automation or web width. Gallus will launch the first series machines with a width of 440 mm (17").

“The future modular platform principle will make it possible to configure everything from basic models to fully equipped versions with varying degrees of automation, all to the known Gallus quality level,” Marx says.

With its maximum speed of 200 m/m and extremely short setup times, these printing presses are the fastest narrow-web machines that Gallus has ever built. “Our engineers paid particular attention to achieving the highest possible level of productivity, using features such as precise register accuracy regardless of speed, extremely straightforward operation even at low levels of automation, a very short web path from printing unit to printing unit, and exceptionally easy changeovers. The first deliveries of these new machines are scheduled for the second quarter of 2017,” says Marx, adding, “Gallus Innovation Days are always popular and we believe this time around the new machine platform will inspire our customers from all over the world.”

MPS

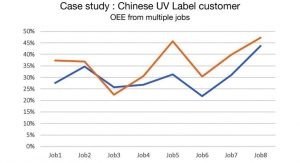

To Dutch press manufacturer MPS, the future of flexo rests on full press automation. Kees Nijenhuis is vice president of MPS Systems North America Inc. in Green Bay, WI, USA, where MPS presses are assembled for the North American market. He emphasizes that automation is not only about whether or not the press is servo-driven or equipped with automated registration systems. “The crucial question and missing link is whether also the print pressure settings are automated, thereby automating all press settings and completely eliminating manual and non-intelligent adjustments,” Nijenhuis says.

In 2008 MPS launched Automated Print Control (APC), a servo adjustment technology automating all print pressure settings. Today MPS is working with partner suppliers and converters to develop further possibilities that can be linked to Automated Print Control. “These automation developments have three main advantages,” explains Nijenhuis. “First of all, it allows you to meet the increasingly high level of quality standards. Automated print pressures settings allow for controlled pressure settings based on objective numbers instead of a subjective value of a manual knob. Furthermore, thanks to the development of AVT’s Presco technology, inspection cameras can be used to measure the actual dot gain where this information is sent back in a closed-loop to the servo adjustment motors, automatically correcting the print pressure to the perfect setting.

“Second, it allows you to improve productivity to a best-in-class level,” Nijenhuis adds. “Job memory offers the ability to use a material calibration database and it allows printers the ability to save and recall print pressure settings of repeat jobs, significantly reducing setup waste and time. Also, a fully automated press can be linked to any Management Information System (MIS), workflow system, inspection system or post-press system, thereby monitoring and controlling press performance and optimizing the interaction of the press with other parts of your logistical system.” In order to achieve this, MPS developed a special software connectivity platform, called “connect.16”.

The third, and to Nijenhuis perhaps the most important advantage, has to do with tomorrow’s press operator. “It is becoming harder and harder to find and keep skilled and experienced press operators,” he says. “Press automation has changed flexo printing printing from being an art to being more of a science. This allows tomorrow’s press operators with less and less printing skills and more and more automation skills to also be motivated and achieve maximum print quality and productivity.”

The MPS EF press is the company’s flagship multi-substrate flexo press, especially designed for label production and flexible packaging printing. The press features UV, hot-air and LED drying technology, allowing users to print on a wide variety of substrates including thin film, paper, cartonboard, shrink sleeves, in-mold, tube and flexible packaging.

The EF press can be configured with new “future-proof” technological solutions for the highest level of productivity, Nijenhuis says, such as a fully automated Quick Change Die unit, a hybrid UV/LED drying system and a system for fully automated processing of pressure settings. The EF offers a choice of either plate rolls or print sleeves.