Greg Hrinya, Associate Editor09.11.17

From converters to their customers, environmentally friendly practices are profoundly affecting the labels and packaging space. One such way that the industry can save – both from sustainable and cost perspectives – involves ultraviolet (UV) light emitting diode (LED) curing.

UV curing technologies have been designed to instantly cure specially formulated inks, coatings and adhesives through polymerization. UV curing can include medium-pressure mercury arc and microwave-powered lamps, as well as LEDs.

According to Phoseon Technology, both arc and microwave curing technologies rely on the vaporization of mercury within a sealed quartz tube containing an inert gas mixture. Mercury emits ultraviolet light when vaporized, while electrodeless lamps utilize microwaves to vaporize the mercury.

Electrode lamps harness a high-voltage arc struck between two electrodes to achieve the same result. When the mercury is vaporized into an extremely high-temperature plasma gas, it emits a spectral output across UVA, UVB, UVC and UVV bands that can be manipulated by introducing metallic additives to the inside of the lamps. When the ink, adhesive or coating formulations are exposed to ultraviolet energy, they are crosslinked into a photopolymer.

UV LEDs, however, are solid-state semiconductors. Compared to conventional lamp technology, LEDs contain no moving parts or mercury plasma gas. In addition, they often operate at temperatures nearly 1/10th of those dealing with conventional lamps.

Martin Kugler, corporate communications for GEW, states that the electricity consumption of a typical mercury arc system is 2,005,000 kWh over a 10-year period. The equivalent UV LED system would consume 950,000 kWh, a reduction of over 50%. In the US, at approximately 12¢/kWh, this equals a savings of $126,000. This is based on an 18" 8-lamp system with chiller, 60% uptime, two shifts per day and six days a week.

“Improvements in conventional reflector geometry have increased intensity at the web by capturing more UV energy and directing it in a true elliptical focus at the web, increasing curing power by 35%, thus reducing energy consumption,” notes Mark Hahn, VP of sales and marketing at AAA Press International. “UV LED curing technology has seen dramatic improvements in output power going from 16W/CM2 to over 30W/CM2, as well as significant improvements in optics design, allowing complete curing at higher line speeds.”

According to AMS Spectral UV – A Baldwin Technology Company, a mercury arc bulb can last 2,000 hours while the chips in an LED UV module can last 20,000 hours or more. This eliminates the need to frequently replace them as part of production maintenance.

“Over the first 20,000 hours of life, a typical LED system will lose about 15-20% of its UV output,” says Kugler. “After 20,000 hours, the LEDs will continue to work but output will degrade more quickly and the probability of LED failure increases. When a single LED fails, the user will not notice, as surrounding LEDs automatically increase in power to accommodate the loss. However, eventually, enough LEDs in a single area will fail and curing results will suffer.”

Stefanie DeBetta Langler, sales and customer service manager at Southern Lamps, explains that life expectancy and cost play a large role in a customer’s decision-making process regarding UV systems. “A typical LED system can cost $102,000 and the replacement lamp is $49,200. LED lamps are predicted to last 10 times as long as an arc lamp, but for 200 times the cost,” she says. “In comparison, a typical arc UV system will cost $28,500 and a lamp will be $258. The system is almost 1/4 of the cost and the lamps are 1/190th of the cost.”

Research and development has played a critical role in the advancement of UV LED curing, which has seen its usage increase over the past decade. “Where UV curing technology has been established for decades, LED UV curing technology for commercial printing applications is something that has proliferated over the past decade,” explains Larisa Shewczyk, marketing lead at AMS Spectral. “LED UV curing technologies now offer higher curing intensities than conventional UV curing can, and their power consumption is significantly lower. The quality of inks available for UV and LED UV curing has greatly improved, in terms of quality and availability.”

Phoseon, which is focused entirely on LED curing, has patented Semiconductor Light Matrix (SLM) technology to encapsulate LEDs, arrays, optics and thermal management to ensure curing performance. Each of these four components is a strictly engineered system that provides maximum UV energy for excellent performance while also increasing long-term robustness for demanding applications.

“When connected to a DC power source, an electric current flows through the semiconductors, dropping electrons into a state of lower energy as they travel from the negative to the positive side of each discrete LED,” says Phoseon. “The energy differential is released from the device in the form of a relatively monochromatic spectral distribution.”

Phoseon offers multiple products for UV LED curing. For use in both commercial and industrial applications, Phoseon products utilize 365nm, 385nm, 395nm and 405nm wavelengths and provide product lines with both air-cooled and water-cooled UV curing systems.

The FireJet family from Phoseon features high capability air-cooled UV LED curing lamps, which have been designed primarily for UV inkjet wide format systems. The line is also capable of curing at high speeds for small, medium and grand format digital printing systems.

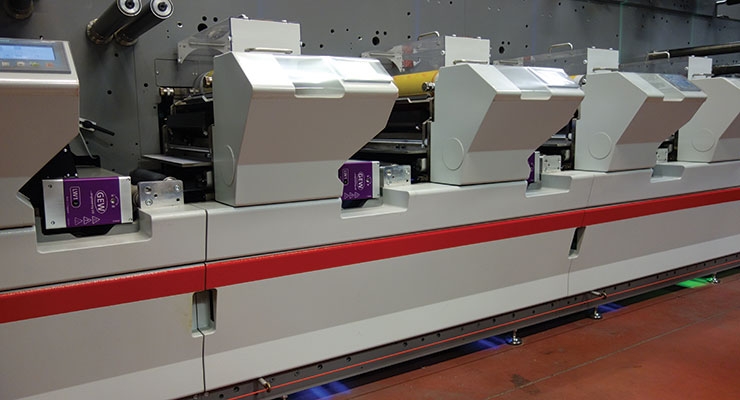

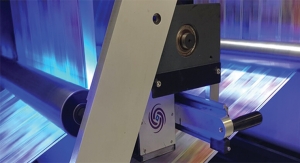

GEW provides its customers with a range of UV curing systems, comprising both LED and hybrid systems together with the associated fully hybrid Rhino ArcLED electronic power supply. Within an ArcLED system, printers are able to operate full hybrid UV curing, working with both mercury arc and LED lamp technology on the same press.

Rhino ArcLED hybrid power supplies from GEW automatically recognize the type of cassette and switch to the correct power, which means both LED UV lampheads and conventional mercury arc lamps can be used with one single power supply and operated with from the same touch control panel.

UV vs. UV LED

According to industry experts, there is a growing trend toward UV LED technology. Converters can print on a variety of substrates at faster speeds, all while decreasing waste and costs.

Energy savings are reported at 50% or more with UV LED curing, and speeds can increase by 20-30%. There is less press downtime, as well. This curing technology allows for a great depth of cure, which improves adhesion. In addition, converters can lay down heavier or denser blacks while offering opaque whites.

“The capital cost for UV LED is higher than for arc lamp UV but the running costs are significantly lower,” says GEW’s Kugler. “Users will have to balance the initial investment against ongoing costs to determine the return on investment. GEW can provide power usage estimates for comparable arc and LED systems tailored to specific requirements. In the meantime, the demand for arc lamps will continue as a low investment alternative for their proven technology and choice of widely available inks.”

“UV LED improves on the existing process by enabling thinner, heat-sensitive substrates while reducing harmful byproducts, such as ozone, and improving workplace safety,” says Phoseon. “Additionally, UV LEDs can be turned on and off instantly and utilize input power efficiently to enable lower operation costs over the application lifetime.”

AMS Spectral’s Shewczyk says that one of UV LED’s main selling points is the lack of ozone production. “Conventional UV curing uses mercury arc bulbs to create UV light – the bulbs contain mercury, and the process produces ozone that needs to be ventilated from pressrooms,” she says. “UV LED curing uses LED chips to generate UV light in a process that does not involve the production of ozone. Not only does this eliminate an environmental hazard, it also eliminates the smell ozone is known for leaving on UV-cured print pieces.”

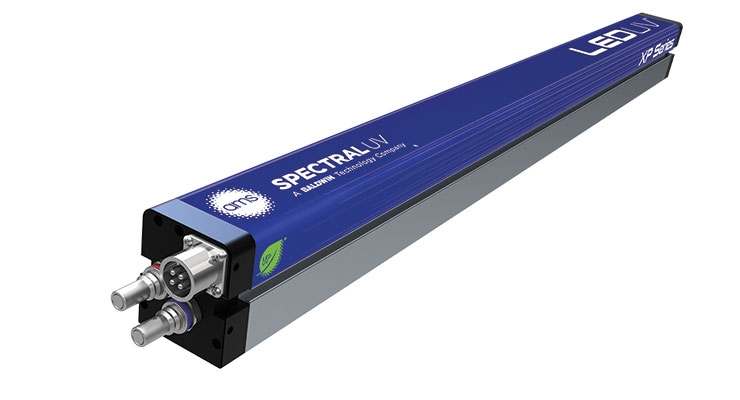

AMS Spectral UV manufactures both conventional UV and UV LED curing technologies for solidifying inks and coatings. AMS Spectral UV’s main LED product lines for label and narrow web printing are the XP Flexo Series and the Label Series. The XP Series curing technology recently received the Intertech Technology Award from Printing Industries of America.

Mike Buystedt, vice president of Flint Group Narrow Web North America, cited the shift in North America at the 2017 FTA Annual Forum. At present, there are over 300 LED lamps installed for narrow web applications. “It’s a totally different paradigm,” said Buystedt. “Our industry has come to accept the downtime related to mercury curing lamps, as that’s been the only option. With LED curing, we don’t have to accept the unnecessary downtime associated to mercury lamp failures and inefficiencies and hazards.”

“We are seeing a great deal of converters investigating UV LED curing technology and some even integrating it in to their machines because very good ink, coating and adhesive chemistry are being offered by a number of suppliers,” says AAA Press International’s Hahn. “There is some governmental pressure worldwide to limit the amount of mercury in new equipment wherever possible, and legislation may be forthcoming to force change toward UV LED technology sometime after the year 2020 in the United States. We are seeing significant improvements in LED power and optics, which should reduce the number of LED’s in the array of each lamp.”

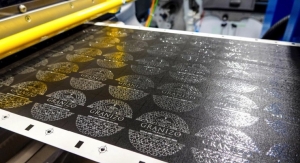

For a multitude of reasons, UV LED curing has seen an exponential rise in recent years, according to Phoseon Technology, as UV LED lamps dramatically improve print quality and capabilities of printing on everything ranging from labels and backlit signs to Braille lettering.

“UV LED curing technology has arrived,” the company says. “It is no longer an emerging technology but an enabling technology – one that is bringing a host of advanced capabilities to screen printing, flexographic and digital printing. These advances and new capabilities are helping industrial, graphics and specialty printing operations be more productive, versatile and energy efficient.

AAA Press manufactures the Lightouch Versiflex Medium Pressure Mercury Vapor UV curing system manufactured in Arlington Heights, IL with more than 4,000 lamp systems in the field. “In the last five years, we have partnered with a leading UV LED manufacturer to integrate this exciting new technology into the Lightouch platform,” says Hahn. “UV LED ink and coating technology has evolved in this timeframe, making this proven technology commercially available to those pioneers that are open to experiencing the outstanding benefits of UV LED curing.”

The results are evident in the market, as many suppliers and converters have made the shift to UV LED. “Lately the market for UV LED curing has grown greatly, since this technology has been fully developed and has largely surpassed the capabilities of conventional UV curing,” says Shewczyk. “More and more printers are opting for UV LED-based solutions because they offer a host of benefits over conventional UV systems.”

Manufacturers have made significant advances to improve lamp quality and lifetime. “Every effort is made to eradicate internal contamination from the lamps,” says Southern Lamps’ Langler. “These processes, along with high-quality component materials and better education around the use and care of the lamps by end users, all mean that lamp lifetimes are increasing. We offer a 1,000-hour warranty on our UV lamps but frequently get positive feedback from customers whose lamps are still going strong and curing at 5,000 hours and beyond.”

Southern Lamps, which offers high-quality UV drying lamps to the printing industry, sees several future trends. “There has, understandably, been a huge amount of interest in UV LED print curing over the past five years, and the technology certainly has its place for some applications,” adds Langler. “What I anticipate is that the benefits of arc UV and the relatively low cost of the systems and lamps mean there will be a strong market for new and replacement lamps for a long time to come.”

Southern Lamps also offers its customers services like holding stock, monthly or quarterly reminders, service and repair for curing/drying equipment, and additional lamps and spare parts, including exposure lamps, infrared drying lamps, and reflectors.

The Ink Factor

When choosing a curing technology, the inks play a significant role. Throughout the years, UV inks have been developed to function more like conventional or water-based inks.

According to Renee Schouten, director of marketing at INX International Ink Co., UV light cures these inks almost instantly. Photo-initiators in the ink react and crosslink or polymerize, forming a dry film. Converters are allowed to work quickly and economically because UV inks cure so quickly.

“UV and UV LED is an enabling technology,” says Jonathan Graunke, VP, UV/EB Technology, at INX International Ink Co. “It allows conventional sheetfed printers to do things they couldn’t do before like print on plastics, produce special effects, and have instant ability to post process. In flexo printing, it allows for more specialty printing and superb product resistance properties while having an ink that remains stable on press, as there is no water and little to no VOCs to cause inks to drift.”

According to Phoseon Technology, UV-compatible ink technologies were limited as far back as 2006. Today, most ink vendors provide solutions for UV LED curing.

“Today, a large number of suppliers have developed flexographic and narrow web inks that work with LED technology,” says Phoseon. “As LED technology has become more powerful and more compatible inks are available, this has resulted in substantial advanced capabilities for UV printing. Material suppliers have responded to the demand and challenge from the printing world to formulate raw materials that absorb energy corresponding to the wavelength of UV LED light sources.”

The benefits of UV-curable inks include fast curing speeds, high print qualities, durability and substrate flexibility. “With UV printing, you can print on almost any surface, whether it is absorbent or not,” explains Schouten. “There are no more double passes through the press, and no more reruns. UV printing allows for high-gloss levels, vibrant colors, an array of coatings and printing that’s crisp and has a sharper finished look. That’s because UV inks tend to sit on top of the printed surface, rather than being absorbed into it.”

In addition, ink is dry the moment it comes off the press, which is helpful when dealing with uncoated papers. Waiting time is eliminated and operators can perform press checks more quickly while moving on to binding and finishing.

Suppliers have developed new resins, monomers, oligomers and photo-initiators to make the entire curing process more effective. “UV inks are rising in popularity for several reasons,” says Schouten. “Water-based inks are cumbersome to dry and solvent-based inks require the removal of part of the solvent – after transfer – which is challenging to dispose of with environmental regulations. Both water-based and solvent-based inks require a drying process, which takes time and also reduces the efficacy of the ink, as ink costs in volume and about 40% of the ink base is lost in drying or curing. That said, UV inks’ usage is still rising and will likely continue.”

UV curing technologies have been designed to instantly cure specially formulated inks, coatings and adhesives through polymerization. UV curing can include medium-pressure mercury arc and microwave-powered lamps, as well as LEDs.

According to Phoseon Technology, both arc and microwave curing technologies rely on the vaporization of mercury within a sealed quartz tube containing an inert gas mixture. Mercury emits ultraviolet light when vaporized, while electrodeless lamps utilize microwaves to vaporize the mercury.

Electrode lamps harness a high-voltage arc struck between two electrodes to achieve the same result. When the mercury is vaporized into an extremely high-temperature plasma gas, it emits a spectral output across UVA, UVB, UVC and UVV bands that can be manipulated by introducing metallic additives to the inside of the lamps. When the ink, adhesive or coating formulations are exposed to ultraviolet energy, they are crosslinked into a photopolymer.

UV LEDs, however, are solid-state semiconductors. Compared to conventional lamp technology, LEDs contain no moving parts or mercury plasma gas. In addition, they often operate at temperatures nearly 1/10th of those dealing with conventional lamps.

Martin Kugler, corporate communications for GEW, states that the electricity consumption of a typical mercury arc system is 2,005,000 kWh over a 10-year period. The equivalent UV LED system would consume 950,000 kWh, a reduction of over 50%. In the US, at approximately 12¢/kWh, this equals a savings of $126,000. This is based on an 18" 8-lamp system with chiller, 60% uptime, two shifts per day and six days a week.

“Improvements in conventional reflector geometry have increased intensity at the web by capturing more UV energy and directing it in a true elliptical focus at the web, increasing curing power by 35%, thus reducing energy consumption,” notes Mark Hahn, VP of sales and marketing at AAA Press International. “UV LED curing technology has seen dramatic improvements in output power going from 16W/CM2 to over 30W/CM2, as well as significant improvements in optics design, allowing complete curing at higher line speeds.”

According to AMS Spectral UV – A Baldwin Technology Company, a mercury arc bulb can last 2,000 hours while the chips in an LED UV module can last 20,000 hours or more. This eliminates the need to frequently replace them as part of production maintenance.

“Over the first 20,000 hours of life, a typical LED system will lose about 15-20% of its UV output,” says Kugler. “After 20,000 hours, the LEDs will continue to work but output will degrade more quickly and the probability of LED failure increases. When a single LED fails, the user will not notice, as surrounding LEDs automatically increase in power to accommodate the loss. However, eventually, enough LEDs in a single area will fail and curing results will suffer.”

Stefanie DeBetta Langler, sales and customer service manager at Southern Lamps, explains that life expectancy and cost play a large role in a customer’s decision-making process regarding UV systems. “A typical LED system can cost $102,000 and the replacement lamp is $49,200. LED lamps are predicted to last 10 times as long as an arc lamp, but for 200 times the cost,” she says. “In comparison, a typical arc UV system will cost $28,500 and a lamp will be $258. The system is almost 1/4 of the cost and the lamps are 1/190th of the cost.”

Research and development has played a critical role in the advancement of UV LED curing, which has seen its usage increase over the past decade. “Where UV curing technology has been established for decades, LED UV curing technology for commercial printing applications is something that has proliferated over the past decade,” explains Larisa Shewczyk, marketing lead at AMS Spectral. “LED UV curing technologies now offer higher curing intensities than conventional UV curing can, and their power consumption is significantly lower. The quality of inks available for UV and LED UV curing has greatly improved, in terms of quality and availability.”

Phoseon, which is focused entirely on LED curing, has patented Semiconductor Light Matrix (SLM) technology to encapsulate LEDs, arrays, optics and thermal management to ensure curing performance. Each of these four components is a strictly engineered system that provides maximum UV energy for excellent performance while also increasing long-term robustness for demanding applications.

“When connected to a DC power source, an electric current flows through the semiconductors, dropping electrons into a state of lower energy as they travel from the negative to the positive side of each discrete LED,” says Phoseon. “The energy differential is released from the device in the form of a relatively monochromatic spectral distribution.”

Phoseon offers multiple products for UV LED curing. For use in both commercial and industrial applications, Phoseon products utilize 365nm, 385nm, 395nm and 405nm wavelengths and provide product lines with both air-cooled and water-cooled UV curing systems.

The FireJet family from Phoseon features high capability air-cooled UV LED curing lamps, which have been designed primarily for UV inkjet wide format systems. The line is also capable of curing at high speeds for small, medium and grand format digital printing systems.

GEW provides its customers with a range of UV curing systems, comprising both LED and hybrid systems together with the associated fully hybrid Rhino ArcLED electronic power supply. Within an ArcLED system, printers are able to operate full hybrid UV curing, working with both mercury arc and LED lamp technology on the same press.

Rhino ArcLED hybrid power supplies from GEW automatically recognize the type of cassette and switch to the correct power, which means both LED UV lampheads and conventional mercury arc lamps can be used with one single power supply and operated with from the same touch control panel.

UV vs. UV LED

According to industry experts, there is a growing trend toward UV LED technology. Converters can print on a variety of substrates at faster speeds, all while decreasing waste and costs.

Energy savings are reported at 50% or more with UV LED curing, and speeds can increase by 20-30%. There is less press downtime, as well. This curing technology allows for a great depth of cure, which improves adhesion. In addition, converters can lay down heavier or denser blacks while offering opaque whites.

“The capital cost for UV LED is higher than for arc lamp UV but the running costs are significantly lower,” says GEW’s Kugler. “Users will have to balance the initial investment against ongoing costs to determine the return on investment. GEW can provide power usage estimates for comparable arc and LED systems tailored to specific requirements. In the meantime, the demand for arc lamps will continue as a low investment alternative for their proven technology and choice of widely available inks.”

“UV LED improves on the existing process by enabling thinner, heat-sensitive substrates while reducing harmful byproducts, such as ozone, and improving workplace safety,” says Phoseon. “Additionally, UV LEDs can be turned on and off instantly and utilize input power efficiently to enable lower operation costs over the application lifetime.”

AMS Spectral’s Shewczyk says that one of UV LED’s main selling points is the lack of ozone production. “Conventional UV curing uses mercury arc bulbs to create UV light – the bulbs contain mercury, and the process produces ozone that needs to be ventilated from pressrooms,” she says. “UV LED curing uses LED chips to generate UV light in a process that does not involve the production of ozone. Not only does this eliminate an environmental hazard, it also eliminates the smell ozone is known for leaving on UV-cured print pieces.”

AMS Spectral UV manufactures both conventional UV and UV LED curing technologies for solidifying inks and coatings. AMS Spectral UV’s main LED product lines for label and narrow web printing are the XP Flexo Series and the Label Series. The XP Series curing technology recently received the Intertech Technology Award from Printing Industries of America.

Mike Buystedt, vice president of Flint Group Narrow Web North America, cited the shift in North America at the 2017 FTA Annual Forum. At present, there are over 300 LED lamps installed for narrow web applications. “It’s a totally different paradigm,” said Buystedt. “Our industry has come to accept the downtime related to mercury curing lamps, as that’s been the only option. With LED curing, we don’t have to accept the unnecessary downtime associated to mercury lamp failures and inefficiencies and hazards.”

“We are seeing a great deal of converters investigating UV LED curing technology and some even integrating it in to their machines because very good ink, coating and adhesive chemistry are being offered by a number of suppliers,” says AAA Press International’s Hahn. “There is some governmental pressure worldwide to limit the amount of mercury in new equipment wherever possible, and legislation may be forthcoming to force change toward UV LED technology sometime after the year 2020 in the United States. We are seeing significant improvements in LED power and optics, which should reduce the number of LED’s in the array of each lamp.”

For a multitude of reasons, UV LED curing has seen an exponential rise in recent years, according to Phoseon Technology, as UV LED lamps dramatically improve print quality and capabilities of printing on everything ranging from labels and backlit signs to Braille lettering.

“UV LED curing technology has arrived,” the company says. “It is no longer an emerging technology but an enabling technology – one that is bringing a host of advanced capabilities to screen printing, flexographic and digital printing. These advances and new capabilities are helping industrial, graphics and specialty printing operations be more productive, versatile and energy efficient.

AAA Press manufactures the Lightouch Versiflex Medium Pressure Mercury Vapor UV curing system manufactured in Arlington Heights, IL with more than 4,000 lamp systems in the field. “In the last five years, we have partnered with a leading UV LED manufacturer to integrate this exciting new technology into the Lightouch platform,” says Hahn. “UV LED ink and coating technology has evolved in this timeframe, making this proven technology commercially available to those pioneers that are open to experiencing the outstanding benefits of UV LED curing.”

The results are evident in the market, as many suppliers and converters have made the shift to UV LED. “Lately the market for UV LED curing has grown greatly, since this technology has been fully developed and has largely surpassed the capabilities of conventional UV curing,” says Shewczyk. “More and more printers are opting for UV LED-based solutions because they offer a host of benefits over conventional UV systems.”

Manufacturers have made significant advances to improve lamp quality and lifetime. “Every effort is made to eradicate internal contamination from the lamps,” says Southern Lamps’ Langler. “These processes, along with high-quality component materials and better education around the use and care of the lamps by end users, all mean that lamp lifetimes are increasing. We offer a 1,000-hour warranty on our UV lamps but frequently get positive feedback from customers whose lamps are still going strong and curing at 5,000 hours and beyond.”

Southern Lamps, which offers high-quality UV drying lamps to the printing industry, sees several future trends. “There has, understandably, been a huge amount of interest in UV LED print curing over the past five years, and the technology certainly has its place for some applications,” adds Langler. “What I anticipate is that the benefits of arc UV and the relatively low cost of the systems and lamps mean there will be a strong market for new and replacement lamps for a long time to come.”

Southern Lamps also offers its customers services like holding stock, monthly or quarterly reminders, service and repair for curing/drying equipment, and additional lamps and spare parts, including exposure lamps, infrared drying lamps, and reflectors.

The Ink Factor

When choosing a curing technology, the inks play a significant role. Throughout the years, UV inks have been developed to function more like conventional or water-based inks.

According to Renee Schouten, director of marketing at INX International Ink Co., UV light cures these inks almost instantly. Photo-initiators in the ink react and crosslink or polymerize, forming a dry film. Converters are allowed to work quickly and economically because UV inks cure so quickly.

“UV and UV LED is an enabling technology,” says Jonathan Graunke, VP, UV/EB Technology, at INX International Ink Co. “It allows conventional sheetfed printers to do things they couldn’t do before like print on plastics, produce special effects, and have instant ability to post process. In flexo printing, it allows for more specialty printing and superb product resistance properties while having an ink that remains stable on press, as there is no water and little to no VOCs to cause inks to drift.”

According to Phoseon Technology, UV-compatible ink technologies were limited as far back as 2006. Today, most ink vendors provide solutions for UV LED curing.

“Today, a large number of suppliers have developed flexographic and narrow web inks that work with LED technology,” says Phoseon. “As LED technology has become more powerful and more compatible inks are available, this has resulted in substantial advanced capabilities for UV printing. Material suppliers have responded to the demand and challenge from the printing world to formulate raw materials that absorb energy corresponding to the wavelength of UV LED light sources.”

The benefits of UV-curable inks include fast curing speeds, high print qualities, durability and substrate flexibility. “With UV printing, you can print on almost any surface, whether it is absorbent or not,” explains Schouten. “There are no more double passes through the press, and no more reruns. UV printing allows for high-gloss levels, vibrant colors, an array of coatings and printing that’s crisp and has a sharper finished look. That’s because UV inks tend to sit on top of the printed surface, rather than being absorbed into it.”

In addition, ink is dry the moment it comes off the press, which is helpful when dealing with uncoated papers. Waiting time is eliminated and operators can perform press checks more quickly while moving on to binding and finishing.

Suppliers have developed new resins, monomers, oligomers and photo-initiators to make the entire curing process more effective. “UV inks are rising in popularity for several reasons,” says Schouten. “Water-based inks are cumbersome to dry and solvent-based inks require the removal of part of the solvent – after transfer – which is challenging to dispose of with environmental regulations. Both water-based and solvent-based inks require a drying process, which takes time and also reduces the efficacy of the ink, as ink costs in volume and about 40% of the ink base is lost in drying or curing. That said, UV inks’ usage is still rising and will likely continue.”