Jack Kenny09.10.18

The laser diecutter for narrow web converting made its debut about 20 years ago at Labelexpo Americas. Presented by the US press maker Comco, it was a squat, free-standing curiosity that drew the attention of converters who pondered its potential impact on what they do for a living.

It took a while, but cutting label shapes using laser beams emerged in later years as a young and growing player with a future in the narrow web industry. How strong a future remained to be seen. The interest is there, certainly, but growth has been gradual. Label converters as a group tend to be cautious in their adoption of new technologies, especially when an age-old practice – in this case solid and flexible metal tooling – does the job well already.

“There is always fear when it comes to totally changing the printing method, and it takes time for converters to understand the benefits of something new, including return on investment,” says Floriana Montella, business development manager for AB Graphic, based in the UK. “Another reason for delay is the price of digital equipment, in some cases undeniably higher than some conventional configurations.” In some countries, she notes, the cost of a label is still so low that it doesn’t justify the purchase of high-tech equipment.

“But there has always been a worldwide interest in laser technology,” she adds, “and during the last 15 years some countries have invested more into digital than others. The USA, Japan, Germany, Brazil and Canada are more open to change than others. And there are those who have already adopted laser cutting because the number of labels they produce is so high that it justifies the investment.”

Tom O’Hara is president of Spartanics, an Illinois-based company that has focused on laser diecutting since its early days. The narrow web market, he says, has largely gotten past the acceptance stage. “My experience in talking with customers is that the technology has been out in the marketplace long enough, performing long enough, that we don’t have to prove the viability of lasers. That was a challenge at the beginning. The driver today is the move to digital. We have a few laser diecutters in conventional flexo converting companies, but the vast majority are with digital operations. What is increasing the market share in double digits for the last few years is the improvement of digital in speed and reliability.”

“We’ve seen continued interest and growth among our label customers,” reports Dave Grenwis, marketing manager at Delta ModTech, a Minnesota-based converting equipment manufacturer. “Some are just getting into laser cutting and others have several laser systems installed. Integration of on-the-fly cut changes, with the use of a bar code reader, is becoming very popular since it allows for longer runs with less changeover. We have also linked machines with printers and laser cutters to ERP systems. With these machines, orders can be entered into an ERP system and the machine will print a bar code on the web that is read by sensor and tells the laser the cut pattern to use.”

“In recent years, the interest of the market in a solution that satisfies the digital concept has been growing significantly. Laser technology is undoubtedly the one that most complements this concept, especially in countries where, to date, it is not possible to have a flexible die in fewer than three or four days,” says Virgilio Micale, director of sales for Cartes, a converting equipment manufacturer based in Italy.

Systems and Components

Laser diecutting systems today are used as standalone units, or inline with inkjet label presses and as a module in an off-line converting system. Arrow Systems, a Niagara Falls-based marketer of converting equipment, offers both. It incorporates Anycut laser cutters, from a Korean manufacturer, into both of its systems, notes sales manager Davis Tiburzi.

“These range from a maximum web width of 8.5" up to our production class models with a maximum web width of 13.5". Laser power options range from 80 watts up to 250 watts. Maximum speeds range from 50 fpm up to 150 fpm (15 to 45 m/m).” All Arrow systems are single laser models. The cost range for its laser modules ranges from $99,000 to $250,000.

Matik, a North American distributor of European converting equipment, supplies laser diecutters from SEI Laser, an Italian manufacturer. According to Matik president Steve Leibin, “SEI’s Labelmaster can be configured to run inline or off-line with a digital press. If label converters have multiple digital presses, then running offline often makes more sense, since the laser diecutter can usually run faster than the digital press. Running inline has challenges due to speed differences, and software integration between the press and laser needs to be finely tuned to account for stops, restarts, speeds and so on.”

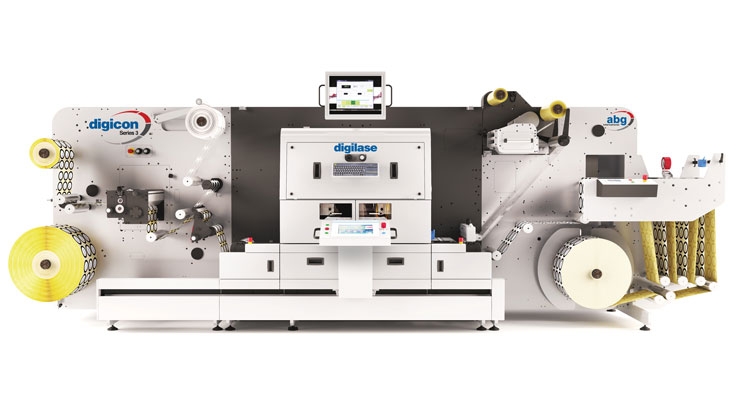

Montella says that the Digilase from AB Graphic is configured with one or two CO2 laser heads of either 200 watts or 400 watts. Speed can reach up to 200 fpm (60 m/m) depending on the job. Unwind, matrix stripping and rewind are standard, but popular options include overlaminating, flexo varnishing and automatic back scoring. The majority of its installed lasers are standalone.

“We recommend that the laser cutting process is separate from other finishing because it’s the only fully automatic process: the operator just needs to load and unload the rolls of substrate,” says Montella. “Most of the work is made in prepress. If the labels are printed and the die line files are made as instructed, then the job is ready.” ABG has also installed machines with both conventional and laser cutting, “But these configurations are quite rare,” Montella adds.

Colordyne Technologies, headquartered in Brookfield, WI, is a manufacturer of digital inkjet label presses and works with LasX to implement a laser cutting system into its printing and converting equipment. Marketing manager Katelyn Bohr says that two of the company’s digital presses include laser cutters. “The 2800 series Mini Laser Pro is a good system for people who are looking to start in digital printing, who might be new to digital or who want a standalone system,” she says. The 3600 series is a complete finishing system that incorporates a laser cutting unit. With a bit of training it’s easy to operate,” she adds. “The 2800 Mini Laser Pro is designed for anyone to use.”

The majority of converters using Colordyne systems are focusing on short runs, Bohr says. “They are doing customization, seasonal products, test markets, changing SKUs. With private branding, there might not be a lot of changes to the artwork, but altering the product information can be costly when using solid dies and waiting for the tooling to be made.”

Spartanics’ laser systems are made to work inline, near line, or off-line. “Of those three, the majority of converters are still doing it off-line,” says O’Hara. “But that might be changing: I think inline is becoming the direction. Both the printing and the finishing from the software perspective is getting better at managing uptime.”

The basic Spartanics’ design is modular, with a single or dual laser head. “Then there are other options that might be needed: spot or flood varnish, laminating, a manual or auto back score unit, slitting, rewinding. What works best in that space is modular, so the converter can basically get the functionality they need and in the order in which they want it to be.” Prices for the modular units start around $250,000, though customized machines featuring many different finishing treatments have reached $750,000.

At Labelexpo Americas this year, Spartanics is introducing its Laser Lite, a lower cost machine. O’Hara says it’s for those who are producing labels satisfactorily at 9 or 18 m/m. The Laser Lite comes with fewer options and will be positioned under $100,000. “But still with all the software functionality,” he adds.

Delta ModTech offers roll-to-roll Edge laser systems, using CO2, IR or UV beam delivery to provide various powers and wavelengths, according to Grenwis. “Lasers can provide a variety of cuts: ablation, kiss cutting, drilling, slitting, perforation, through cuts and slug removal, scoring, reject marking, scribing and sequential numbering,” he says. “The Edge CO2 is the most common with converters due to its flexibility in both product web paths and cutting of various materials. It can be moved to five different positions on the machine, offering countless web path options. It also can be moved up and out of the way, allowing the use of all seven stations on the machine for a conventional diecutting process.”

Delta also has a portable Flex Edge system that can be used inline or off-line with various configurations in both roll-to-roll and sheetfed. It can be bolted inline to an existing Delta machine or run as a standalone unit.

Custom Delta systems can use various beam delivery types and multiple laser heads. “We’ve built machines with up to 18 lasers for a single process,” Grenwis says.

Laser units from Cartes come in standard or customized form. The company produces finishing equipment ranging from simple to complex. “We can configure our systems with or without laser units, and we also produce standalone laser machines,” says Virgilio Micale. Cartes, which has worked for 20 years with an Italian laser manufacturer, markets its Semi-Sealed 350-watt laser that works with fresh gas inside its laser component. The company says that this provides two advantages: “The power of the laser is always constant and at the top of its performance, and the quality of the cut is always the most precise you can get.”

Substrates

Manufacturers and converters agree that most label substrates can safely and functionally be subjected to laser cutting. Here’s a list supplied by Delta ModTech: PSA, polyester, paper, abrasives, cork, foam, rubber, neoprene, silicone, PU, PE, PET, polycarbonate, polyethylene, polypropylene, thin foil, and metal.

The above list includes ablated metals bonded to polyester or similar substrates; and abrasives, adhesives, fabric, paper, plastic, rubber, and textiles.

The main exception is PVC or any other material that contains chlorine. Micale explains, “Polyvinyl chloride is not recommended, since burning this plastic can release chlorine dioxins, which are the most potent synthetic carcinogen ever tested in a laboratory and very dangerous for humans.”

Tiburzi from Arrow points out that certain plastics could be challenging. He says, “Due to the heat of the laser, non-PET film liners (PP and BOPP) have a tendency to react with the laser heat and substrate above. Because the heat tolerances of PP and BOPP are not very high, they are susceptible to distortions or melting from the heat, which may affect the final product.”

Benefits, Challenges

The obvious benefit to laser diecutting is that it eliminates the need for solid or flexible dies, which includes the ordering, the manufacturing and shipping time, the storage, the wear and the sharpening. Make-ready time is minimal.

Low waste is another advantage, thanks to the software that powers the system. Constant improvements are being made to the operating software, which now can incorporate job data of all kinds and, for the past couple of years, enable on-the-fly job changes: Switching from one diecutting pattern to another without hesitation. “There’s no need to stop the machine to change dies between jobs,” says Montella of AB Graphic.

Spartanics’ O’Hara cites ease of operation as a great satisfaction among users. “I cannot think of a customer who doesn’t tell me it’s the most used machine on their floor. Even if they have a die, they’d rather run it on the laser.”

A laser can cut highly intricate shapes, sharp corners, fine contours with pinpoint accuracy and minimal waste, adds Montella. “There are no limits when it comes to creativity, with kiss cutting, engraving, through cutting and bit removal.”

Challenges are common with every process, of course. Some materials are difficult to cut, and lasers might struggle with them. A rotary die usually cuts through any substrate at approximately the same speed; the laser speed will be dependent on the cut pattern. Then there’s the run length: A rotary die can handle a long run because it cuts at a faster rate, and therefore a lower cost.

“Speed is always going to be an issue,” says O’Hara. “Everybody wants to go faster. In the digital world you should be thinking of number of jobs a day, or total turnaround to run a job. If you’re thinking in terms of speed components, you’ll always be disappointed if you compare against conventional diecutting.

“It’s no longer a question of whether laser can do the job,” he adds. “The question is: Is laser too slow? In a large run it is. But with small and medium runs, that’s not true – you will be much faster with digital finishing than with traditional equipment. That’s an education process with customers. They do get it when you run the numbers and demonstrate.”

“As in the adoption of digital printing, the greatest challenge for laser finishing is the fear of the unknown and understanding the business case for a new technology,” says Steve Leibin of Matik.

Leibin continues, “Laser speeds, of course, are related to square inches of cutting required, the intricacy of the cut and the substrate involved, which can also be a limitation in many conventional diecutting applications.”

The concept behind the development of the laser was proposed by Albert Einstein in his 1917 paper Zur Quantentheorie der Strahlung (On the Quantum Theory of Radiation). Over the next four decades, teams of scientists in Europe and North America pursued the concept, producing remarkable developments. In 1958, Bell Labs researchers Charles Townes and Arthur Schawlow filed a patent application for the laser.

The first practical laser was produced two years later. The thing was, nobody knew what to do with it. It was referred to as “a solution looking for a problem.” One early attempt at finding a use for the concentrated light beam showed up in Goldfinger, an early 007 motion picture. Secret agent James Bond (played by the inimitable Sean Connery) was nearly sliced in half – a truly cringeworthy scene – by a crude laser. Nice try, but not much of a market there.

Laser stands for “light amplification by stimulated emission of radiation.” The light is described as coherent and differs from ordinary light by the behavior of its light waves. Compare: A flashlight beam is like a crowd of commuters jostling their way helter-skelter onto a train; a laser beam is like a legion of soldiers marching in lock step. Unless you have a strong scientific bent, that’s all you have to know.

Lasers are everywhere today. They proliferate in science, the military, medicine and just about every industry. They are used for cutting, welding, drilling, marking, surveying, guiding, and shooting the moon. Your eye doctor and dentist use them on you. They live in our home entertainment components, printers and computer mice. We play tag with them. Your cat finds them irresistible.

It took a while, but cutting label shapes using laser beams emerged in later years as a young and growing player with a future in the narrow web industry. How strong a future remained to be seen. The interest is there, certainly, but growth has been gradual. Label converters as a group tend to be cautious in their adoption of new technologies, especially when an age-old practice – in this case solid and flexible metal tooling – does the job well already.

“There is always fear when it comes to totally changing the printing method, and it takes time for converters to understand the benefits of something new, including return on investment,” says Floriana Montella, business development manager for AB Graphic, based in the UK. “Another reason for delay is the price of digital equipment, in some cases undeniably higher than some conventional configurations.” In some countries, she notes, the cost of a label is still so low that it doesn’t justify the purchase of high-tech equipment.

“But there has always been a worldwide interest in laser technology,” she adds, “and during the last 15 years some countries have invested more into digital than others. The USA, Japan, Germany, Brazil and Canada are more open to change than others. And there are those who have already adopted laser cutting because the number of labels they produce is so high that it justifies the investment.”

Tom O’Hara is president of Spartanics, an Illinois-based company that has focused on laser diecutting since its early days. The narrow web market, he says, has largely gotten past the acceptance stage. “My experience in talking with customers is that the technology has been out in the marketplace long enough, performing long enough, that we don’t have to prove the viability of lasers. That was a challenge at the beginning. The driver today is the move to digital. We have a few laser diecutters in conventional flexo converting companies, but the vast majority are with digital operations. What is increasing the market share in double digits for the last few years is the improvement of digital in speed and reliability.”

“We’ve seen continued interest and growth among our label customers,” reports Dave Grenwis, marketing manager at Delta ModTech, a Minnesota-based converting equipment manufacturer. “Some are just getting into laser cutting and others have several laser systems installed. Integration of on-the-fly cut changes, with the use of a bar code reader, is becoming very popular since it allows for longer runs with less changeover. We have also linked machines with printers and laser cutters to ERP systems. With these machines, orders can be entered into an ERP system and the machine will print a bar code on the web that is read by sensor and tells the laser the cut pattern to use.”

“In recent years, the interest of the market in a solution that satisfies the digital concept has been growing significantly. Laser technology is undoubtedly the one that most complements this concept, especially in countries where, to date, it is not possible to have a flexible die in fewer than three or four days,” says Virgilio Micale, director of sales for Cartes, a converting equipment manufacturer based in Italy.

Systems and Components

Laser diecutting systems today are used as standalone units, or inline with inkjet label presses and as a module in an off-line converting system. Arrow Systems, a Niagara Falls-based marketer of converting equipment, offers both. It incorporates Anycut laser cutters, from a Korean manufacturer, into both of its systems, notes sales manager Davis Tiburzi.

“These range from a maximum web width of 8.5" up to our production class models with a maximum web width of 13.5". Laser power options range from 80 watts up to 250 watts. Maximum speeds range from 50 fpm up to 150 fpm (15 to 45 m/m).” All Arrow systems are single laser models. The cost range for its laser modules ranges from $99,000 to $250,000.

Matik, a North American distributor of European converting equipment, supplies laser diecutters from SEI Laser, an Italian manufacturer. According to Matik president Steve Leibin, “SEI’s Labelmaster can be configured to run inline or off-line with a digital press. If label converters have multiple digital presses, then running offline often makes more sense, since the laser diecutter can usually run faster than the digital press. Running inline has challenges due to speed differences, and software integration between the press and laser needs to be finely tuned to account for stops, restarts, speeds and so on.”

Montella says that the Digilase from AB Graphic is configured with one or two CO2 laser heads of either 200 watts or 400 watts. Speed can reach up to 200 fpm (60 m/m) depending on the job. Unwind, matrix stripping and rewind are standard, but popular options include overlaminating, flexo varnishing and automatic back scoring. The majority of its installed lasers are standalone.

“We recommend that the laser cutting process is separate from other finishing because it’s the only fully automatic process: the operator just needs to load and unload the rolls of substrate,” says Montella. “Most of the work is made in prepress. If the labels are printed and the die line files are made as instructed, then the job is ready.” ABG has also installed machines with both conventional and laser cutting, “But these configurations are quite rare,” Montella adds.

Colordyne Technologies, headquartered in Brookfield, WI, is a manufacturer of digital inkjet label presses and works with LasX to implement a laser cutting system into its printing and converting equipment. Marketing manager Katelyn Bohr says that two of the company’s digital presses include laser cutters. “The 2800 series Mini Laser Pro is a good system for people who are looking to start in digital printing, who might be new to digital or who want a standalone system,” she says. The 3600 series is a complete finishing system that incorporates a laser cutting unit. With a bit of training it’s easy to operate,” she adds. “The 2800 Mini Laser Pro is designed for anyone to use.”

The majority of converters using Colordyne systems are focusing on short runs, Bohr says. “They are doing customization, seasonal products, test markets, changing SKUs. With private branding, there might not be a lot of changes to the artwork, but altering the product information can be costly when using solid dies and waiting for the tooling to be made.”

Spartanics’ laser systems are made to work inline, near line, or off-line. “Of those three, the majority of converters are still doing it off-line,” says O’Hara. “But that might be changing: I think inline is becoming the direction. Both the printing and the finishing from the software perspective is getting better at managing uptime.”

The basic Spartanics’ design is modular, with a single or dual laser head. “Then there are other options that might be needed: spot or flood varnish, laminating, a manual or auto back score unit, slitting, rewinding. What works best in that space is modular, so the converter can basically get the functionality they need and in the order in which they want it to be.” Prices for the modular units start around $250,000, though customized machines featuring many different finishing treatments have reached $750,000.

At Labelexpo Americas this year, Spartanics is introducing its Laser Lite, a lower cost machine. O’Hara says it’s for those who are producing labels satisfactorily at 9 or 18 m/m. The Laser Lite comes with fewer options and will be positioned under $100,000. “But still with all the software functionality,” he adds.

Delta ModTech offers roll-to-roll Edge laser systems, using CO2, IR or UV beam delivery to provide various powers and wavelengths, according to Grenwis. “Lasers can provide a variety of cuts: ablation, kiss cutting, drilling, slitting, perforation, through cuts and slug removal, scoring, reject marking, scribing and sequential numbering,” he says. “The Edge CO2 is the most common with converters due to its flexibility in both product web paths and cutting of various materials. It can be moved to five different positions on the machine, offering countless web path options. It also can be moved up and out of the way, allowing the use of all seven stations on the machine for a conventional diecutting process.”

Delta also has a portable Flex Edge system that can be used inline or off-line with various configurations in both roll-to-roll and sheetfed. It can be bolted inline to an existing Delta machine or run as a standalone unit.

Custom Delta systems can use various beam delivery types and multiple laser heads. “We’ve built machines with up to 18 lasers for a single process,” Grenwis says.

Laser units from Cartes come in standard or customized form. The company produces finishing equipment ranging from simple to complex. “We can configure our systems with or without laser units, and we also produce standalone laser machines,” says Virgilio Micale. Cartes, which has worked for 20 years with an Italian laser manufacturer, markets its Semi-Sealed 350-watt laser that works with fresh gas inside its laser component. The company says that this provides two advantages: “The power of the laser is always constant and at the top of its performance, and the quality of the cut is always the most precise you can get.”

Substrates

Manufacturers and converters agree that most label substrates can safely and functionally be subjected to laser cutting. Here’s a list supplied by Delta ModTech: PSA, polyester, paper, abrasives, cork, foam, rubber, neoprene, silicone, PU, PE, PET, polycarbonate, polyethylene, polypropylene, thin foil, and metal.

The above list includes ablated metals bonded to polyester or similar substrates; and abrasives, adhesives, fabric, paper, plastic, rubber, and textiles.

The main exception is PVC or any other material that contains chlorine. Micale explains, “Polyvinyl chloride is not recommended, since burning this plastic can release chlorine dioxins, which are the most potent synthetic carcinogen ever tested in a laboratory and very dangerous for humans.”

Tiburzi from Arrow points out that certain plastics could be challenging. He says, “Due to the heat of the laser, non-PET film liners (PP and BOPP) have a tendency to react with the laser heat and substrate above. Because the heat tolerances of PP and BOPP are not very high, they are susceptible to distortions or melting from the heat, which may affect the final product.”

Benefits, Challenges

The obvious benefit to laser diecutting is that it eliminates the need for solid or flexible dies, which includes the ordering, the manufacturing and shipping time, the storage, the wear and the sharpening. Make-ready time is minimal.

Low waste is another advantage, thanks to the software that powers the system. Constant improvements are being made to the operating software, which now can incorporate job data of all kinds and, for the past couple of years, enable on-the-fly job changes: Switching from one diecutting pattern to another without hesitation. “There’s no need to stop the machine to change dies between jobs,” says Montella of AB Graphic.

Spartanics’ O’Hara cites ease of operation as a great satisfaction among users. “I cannot think of a customer who doesn’t tell me it’s the most used machine on their floor. Even if they have a die, they’d rather run it on the laser.”

A laser can cut highly intricate shapes, sharp corners, fine contours with pinpoint accuracy and minimal waste, adds Montella. “There are no limits when it comes to creativity, with kiss cutting, engraving, through cutting and bit removal.”

Challenges are common with every process, of course. Some materials are difficult to cut, and lasers might struggle with them. A rotary die usually cuts through any substrate at approximately the same speed; the laser speed will be dependent on the cut pattern. Then there’s the run length: A rotary die can handle a long run because it cuts at a faster rate, and therefore a lower cost.

“Speed is always going to be an issue,” says O’Hara. “Everybody wants to go faster. In the digital world you should be thinking of number of jobs a day, or total turnaround to run a job. If you’re thinking in terms of speed components, you’ll always be disappointed if you compare against conventional diecutting.

“It’s no longer a question of whether laser can do the job,” he adds. “The question is: Is laser too slow? In a large run it is. But with small and medium runs, that’s not true – you will be much faster with digital finishing than with traditional equipment. That’s an education process with customers. They do get it when you run the numbers and demonstrate.”

“As in the adoption of digital printing, the greatest challenge for laser finishing is the fear of the unknown and understanding the business case for a new technology,” says Steve Leibin of Matik.

Leibin continues, “Laser speeds, of course, are related to square inches of cutting required, the intricacy of the cut and the substrate involved, which can also be a limitation in many conventional diecutting applications.”

The concept behind the development of the laser was proposed by Albert Einstein in his 1917 paper Zur Quantentheorie der Strahlung (On the Quantum Theory of Radiation). Over the next four decades, teams of scientists in Europe and North America pursued the concept, producing remarkable developments. In 1958, Bell Labs researchers Charles Townes and Arthur Schawlow filed a patent application for the laser.

The first practical laser was produced two years later. The thing was, nobody knew what to do with it. It was referred to as “a solution looking for a problem.” One early attempt at finding a use for the concentrated light beam showed up in Goldfinger, an early 007 motion picture. Secret agent James Bond (played by the inimitable Sean Connery) was nearly sliced in half – a truly cringeworthy scene – by a crude laser. Nice try, but not much of a market there.

Laser stands for “light amplification by stimulated emission of radiation.” The light is described as coherent and differs from ordinary light by the behavior of its light waves. Compare: A flashlight beam is like a crowd of commuters jostling their way helter-skelter onto a train; a laser beam is like a legion of soldiers marching in lock step. Unless you have a strong scientific bent, that’s all you have to know.

Lasers are everywhere today. They proliferate in science, the military, medicine and just about every industry. They are used for cutting, welding, drilling, marking, surveying, guiding, and shooting the moon. Your eye doctor and dentist use them on you. They live in our home entertainment components, printers and computer mice. We play tag with them. Your cat finds them irresistible.