Jim Edmondson10.12.18

The origins of the Cast and Cure process are unclear, but we can track its use in Asia back as early as the 1980s. Its purpose then was to create a high gloss finish on a printed substrate. The process employed a plastic film laid onto a printed web with a curable coating. When the coating was cured and the film removed, the printed substrate remained with a unique and durable gloss finish.

Since then, the industry’s interest in achieving special finishes has clearly accelerated. For the most part, the applications and advancements have been driven by brand owners seeking to attract consumer attention, create brand differentiation, protect their brands from a growing world of counterfeiters, or all of the above. As global markets expand, and with it the number of brands in any one category, packaging designs and finishes continue to evolve in the fight for consumer dollars.

A few of the most common solutions to creating unique product appearances have been package shape, coatings and foil applications. The first patent for hot stamping was recorded in Germany by Ernst Oeser in 1892. Reflective foils are popular for spot applications, and with many color choices, it can be a designer’s dream. Water-based and UV (Ultra Violet) coatings have evolved to create a variety of finishes that protect, reflect or flatten the look of printed items. The enhancements made to UV coatings have increased production speeds and reduced the emission of VOC’s (Volatile Organic Compounds).

The Cast and Cure process has also evolved with these advances in coating technology. Today, there are a wide variety of casting film choices available to create holographic, lens, matte and iridescent effects.

The Cast and Cure Process

As in its earliest applications, the Cast and Cure process was one of embossing an image or shape into a coating or varnish. Today, however, the casting effect is incredibly enhanced with the use of new films along with the related enhancements in coating technology.

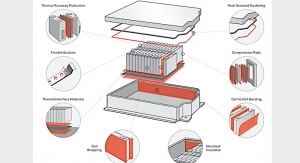

The Cast and Cure process starts with a UV-curable coating applied directly to a printed web. A web of Cast and Cure film is then laminated to the wet surface via a nip station. The film’s unique micro-embossed surface will now impart (cast) its pattern onto the coated surface.

UV stations are commonly used immediately inline to dry (cure) the coating and give permanency to the new surface pattern. Immediately following curing, the Cast and Cure film is delaminated from the printed web and rewound, whereupon the film can be reused again and again.

Today, there are many coatings that perform exceptionally well with the film casting process while also possessing excellent UV curing properties. While the Cast and Cure process works with virtually any UV coating, many companies manufacture products specifically for the Cast and Cure process. ALTANA/Actega, Flint Group, Sakata/INX International, Siegwerk Group, Nazdar and Sun Chemical all manufacture specific coating products for Cast and Cure.

The use of EB (electron beam) energy for curing is also taking hold, according to Tim Cain, president of Breit Technologies, a provider of Cast and Cure films, as well as related equipment. He says, “With the expansion of the Cast and Cure process using EB varnishes, the process has expanded into many applications that traditionally shied away from UV, including salty snacks, confection, cereal and kids’ snack foods.”

The Evolution of Cast and Cure Films

At the helm of this evolution is Breit Technologies, based in Overland Park, KS. In 2005, the company started selling special films and equipment for Cast and Cure processes in the North American market. It also began the arduous task of educating printers and brand owners about the process.

“The early days of selling the Cast and Cure process were challenging. We had a cost-effective, environmentally-conscious and design-friendly process that no one knew about. The printers loved it, but no one was asking for it. We knew that to drive the process forward, the brand owners and design firms must be educated as to the benefits and capabilities of Cast and Cure,” Cain says.

Breit Technologies now claims to have the largest inventory in the world of Cast and Cure films to serve its global customer base. Most of their 20-plus stock films are for producing holographic finishes – a dazzling array of colorful lines, dots and patterns that change color or shift when viewed at different angles. Other films are available to produce a deep matte finish, super-high gloss, brushed metallic, and linen textures. In addition, custom patterns can be created to offer enhanced looks or to enhance brand protection strategies.

Advantages

Part of the allure of the Cast and Cure process is its flexibility. The effect is applied only where the UV coating is printed, allowing for a wide range of design options from spot to flood coverage. When using Cast and Cure compared to laminated holographic films and papers, where the effect is overall, the Cast and Cure treatment is placed strategically to enhance the design features. In addition, there is no need to print opaque whites to knock out the holographic areas throughout the package.

Additionally, the process can be applied to almost any substrate that can be UV coated. Examples of Cast and Cure’s substrate capabilities include usage on toothpaste tubes and cartons, DVD “O” covers and slip sheets, outer cartons, as well as container labels. With the growth of pouch packaging, such visual effects are even more important as these products don’t sit on retail shelves with the same flat surfaces and rigid posture of boxed products.

Unlike foils that are consumed with each application, there is no material transferred to the printed web when using Cast and Cure. The film is not consumed with a single application but can be reused 10-20 times depending upon the application and equipment.

Environmental advantages are also noteworthy. The ability to recycle Cast and Cure finished packaging is not restricted as with foiled packages. Additionally, the casting film is easily recycled through traditional methods. Since the process uses UV and EB varnishes, no VOCs are released with its application.

While special equipment exists to ensure proper and consistent results while maximizing Cast and Cure film reuse, a standard cold foil setup is often a good starting point for testing and sample runs.

Cold foil operators are cautioned, however, that their rewind systems – generally designed for waste product collection – may need to be upgraded to achieve the optimal tension. Also, the wet lamination often travels too far before being cured. The distance from lamination to UV cure can create inconsistencies in the effect and the issue with the rewind can limit film reuse.

Brand Security Applications

Brand security relies greatly upon design features that are difficult-to-impossible to recreate. Cast and Cure can readily serve as a security feature as a covert addition to packaging design or as part of an overall brand protection strategy. At the same time, Cast and Cure can be incorporated to enhance package design as a unique look that consumers can see and sometimes feel.

Decorative Packaging Applications

101-year old Ross Print Innovations of Spokane, WA, has become a fast fan of Cast and Cure over the last year while making big inroads into the state’s expanding cannabis market. According to Ross’ general manager Eric Smith, “The more exotic and expensive retail operations present product in either poly bags or glass jars inside well-lit glass counters. Customers often have to make their selections based on product name and packaging appeal.”

“The brand owners love the Cast and Cure holographic finishes on our labels,” says Smith. “The holographic packaging attracts buyer attention and helps create a unique brand perception. For us, Cast and Cure is a win-win. We can run it on virtually any substrate, including stand-up pouches. We run it easily on our cold foil equipment – and it’s easier to run than cold foil.”

In launching its new ProGlide razor several years ago, Gillette sought a package design that delivered sales results while also being environmentally friendly and reducing material use and costs. Gillette scored on all three counts with the help of Cast and Cure decorative finishing.

From a marketing perspective, the foremost objective was achieving a metalized holographic effect so shoppers could easily distinguish Fusion ProGlide from competitors on shelf. Fusion ProGlide was to be Gillette’s most technologically advanced razor, and the carton graphics’ hologram-like appearance enhanced perceptions of shaving comfort and performance.

Gillette achieved the eye-catching design in part with a UV metallic coating that provides the decorative effect of hot-foil stamping. During printing, the metallic coating was combined with Cast-and-Cure holographics. “The package has a definite ‘wow’ factor,” says Michael Marcinkowski, senior engineer of R&D, in Gillette’s Global Package Development area. Material lead-time for the ProGlide razor packages were reduced by six to 12 weeks. “It was a win/win/win,” Marcinkowski concludes. “The package is sustainable, the costs are lower, and there are marketing benefits. And all of this was done at no loss to the consumer.”

Early in 2018, General Mills unveiled the first new Lucky Charms marshmallow shape in 10 years while using Cast and Cure to add visual hype to the new cereal boxes. A magical unicorn has become a permanent member in the Lucky Charms marshmallow lineup – and now appears illustrated on the cereal box cover.

This was a big deal in the CPG industry – and for the Lucky Charms brand. The new cereal boxes had all new graphics, and one more bit of magical intrigue. Twinkling holographic marshmallows appeared all over the box cover. The cast and cure application was also somewhat unique. While most print treatments use UV as the curing source, this application used EB (Electron Beam), which met the FDA criteria for possible food contact.

The Future

The future of Cast and Cure remains bright for Breit Technologies. With the continued enhancements to the company’s line of Cast and Cure web and sheetfed presses, and through strategic alliances with other equipment manufacturers, the breadth of applications into areas such as digital, bag and pouch and specialty products continues to expand.

Breit also continues to expand the capabilities of the process overall through new film designs. Currently, there are films in development that will offer enhance graphical features, as well as functionality. The functionality benefits include grip, texture, and visual depth enhancements.

Breit has recently expanded its distribution to include over 55 countries around the world and finds itself on many billion-dollar product lines in several market segments. The growth of the technology has transformed it from a novel decorating approach, to its own self-sustaining decorative platform.

About the author: Jim Edmondson has specialized in B2B marketing for the last 35 years and has a history of writing about technical processes and applications. He owns Pyramid Creative Group, a Wisconsin-based marketing firm, and provides consulting services to OEMs in the converting and packaging industries throughout North America. He can be reached at jedmondson@pyramid-creative.com.

UV coating is applied directly to the printed web – Cast and Cure film is then laminated to the wet surface – next, the lamination enters a UV lamp – the UV light cures the coating that is sandwiched between the Cast and Cure film and the printed web – next, the Cast and Cure film is delaminated from the printed web and carefully re-wound for multiple reuses. Cast and Cure should be considered “last down” in the printing sequence.

Equipment has been designed to ensure proper and consistent results while maximizing the reuse of the film. However, in many cases a standard Cold Foil setup is a good starting point for testing and sample runs. Two areas of concern with most cold foil setups: First, the rewind is generally designed as a waste product rewind, and second, the wet lamination generally travels too far before being cured. The distance from lamination to UV cure can create inconsistencies in the effect and the issue with the rewind can prevent you from achieving 10 to 12 reuses of the Cast and Cure film. However, very good visual results can be achieved with cold foil setups, generally only falling short in the consistency and ability to reuse the Cast and Cure film. It should be kept in mind that the true cost to produce holographic effects can be as low as 3-cents per MSI if you achieve 12 reuses of the Cast and Cure film. Therefore, attention to this goal should be a priority.

Suggested preparation

Cast and Cure film: Select a holographic or special effect pattern from Breit Technologies film sample book or from the online web page

www.breit-tech.com.

There are two options for ordering material:

1. A predetermined sample roll of approximately 2000’ by 6” to 13” wide is available for purchase through the off-cut sample roll program.

2. Select a specific pattern and specific web width. Rolls are 8,200’ in length and can be slit at a minimum 6” wide to a max 40” wide. This option has a cost per MSI.

UV Coating:

Select a Cast and Cure UV coating from the recommended supplier list.

Anilox selection

Anilox rolls in the range of 200/6bcm to 7bcm will provide the best results for spot applications. When running a full flood coat of Cast and Cure, a heavier deposit (8 to 10bcm) of coating is recommended to achieve the best effects. In general, an anilox in the 6 to 7bcm range applies the most coating while maintaining proper edge definition for spot applications.

Cast and Cure web tension: The general rule regarding the Cast and Cure application is to minimize web tension at the unwind and rewind. Start with the lowest setting that allows the rewind to keep pace with the press. If the web wrinkles on the rewind core, it’s recommended to start over with a softer tension. Once the rewind has about 50 to 100’ on the core you might need to increase the tension to ensure the roll does not scope later.

Since then, the industry’s interest in achieving special finishes has clearly accelerated. For the most part, the applications and advancements have been driven by brand owners seeking to attract consumer attention, create brand differentiation, protect their brands from a growing world of counterfeiters, or all of the above. As global markets expand, and with it the number of brands in any one category, packaging designs and finishes continue to evolve in the fight for consumer dollars.

A few of the most common solutions to creating unique product appearances have been package shape, coatings and foil applications. The first patent for hot stamping was recorded in Germany by Ernst Oeser in 1892. Reflective foils are popular for spot applications, and with many color choices, it can be a designer’s dream. Water-based and UV (Ultra Violet) coatings have evolved to create a variety of finishes that protect, reflect or flatten the look of printed items. The enhancements made to UV coatings have increased production speeds and reduced the emission of VOC’s (Volatile Organic Compounds).

The Cast and Cure process has also evolved with these advances in coating technology. Today, there are a wide variety of casting film choices available to create holographic, lens, matte and iridescent effects.

The Cast and Cure Process

As in its earliest applications, the Cast and Cure process was one of embossing an image or shape into a coating or varnish. Today, however, the casting effect is incredibly enhanced with the use of new films along with the related enhancements in coating technology.

The Cast and Cure process starts with a UV-curable coating applied directly to a printed web. A web of Cast and Cure film is then laminated to the wet surface via a nip station. The film’s unique micro-embossed surface will now impart (cast) its pattern onto the coated surface.

UV stations are commonly used immediately inline to dry (cure) the coating and give permanency to the new surface pattern. Immediately following curing, the Cast and Cure film is delaminated from the printed web and rewound, whereupon the film can be reused again and again.

Today, there are many coatings that perform exceptionally well with the film casting process while also possessing excellent UV curing properties. While the Cast and Cure process works with virtually any UV coating, many companies manufacture products specifically for the Cast and Cure process. ALTANA/Actega, Flint Group, Sakata/INX International, Siegwerk Group, Nazdar and Sun Chemical all manufacture specific coating products for Cast and Cure.

The use of EB (electron beam) energy for curing is also taking hold, according to Tim Cain, president of Breit Technologies, a provider of Cast and Cure films, as well as related equipment. He says, “With the expansion of the Cast and Cure process using EB varnishes, the process has expanded into many applications that traditionally shied away from UV, including salty snacks, confection, cereal and kids’ snack foods.”

The Evolution of Cast and Cure Films

At the helm of this evolution is Breit Technologies, based in Overland Park, KS. In 2005, the company started selling special films and equipment for Cast and Cure processes in the North American market. It also began the arduous task of educating printers and brand owners about the process.

“The early days of selling the Cast and Cure process were challenging. We had a cost-effective, environmentally-conscious and design-friendly process that no one knew about. The printers loved it, but no one was asking for it. We knew that to drive the process forward, the brand owners and design firms must be educated as to the benefits and capabilities of Cast and Cure,” Cain says.

Breit Technologies now claims to have the largest inventory in the world of Cast and Cure films to serve its global customer base. Most of their 20-plus stock films are for producing holographic finishes – a dazzling array of colorful lines, dots and patterns that change color or shift when viewed at different angles. Other films are available to produce a deep matte finish, super-high gloss, brushed metallic, and linen textures. In addition, custom patterns can be created to offer enhanced looks or to enhance brand protection strategies.

Advantages

Part of the allure of the Cast and Cure process is its flexibility. The effect is applied only where the UV coating is printed, allowing for a wide range of design options from spot to flood coverage. When using Cast and Cure compared to laminated holographic films and papers, where the effect is overall, the Cast and Cure treatment is placed strategically to enhance the design features. In addition, there is no need to print opaque whites to knock out the holographic areas throughout the package.

Additionally, the process can be applied to almost any substrate that can be UV coated. Examples of Cast and Cure’s substrate capabilities include usage on toothpaste tubes and cartons, DVD “O” covers and slip sheets, outer cartons, as well as container labels. With the growth of pouch packaging, such visual effects are even more important as these products don’t sit on retail shelves with the same flat surfaces and rigid posture of boxed products.

Unlike foils that are consumed with each application, there is no material transferred to the printed web when using Cast and Cure. The film is not consumed with a single application but can be reused 10-20 times depending upon the application and equipment.

Environmental advantages are also noteworthy. The ability to recycle Cast and Cure finished packaging is not restricted as with foiled packages. Additionally, the casting film is easily recycled through traditional methods. Since the process uses UV and EB varnishes, no VOCs are released with its application.

While special equipment exists to ensure proper and consistent results while maximizing Cast and Cure film reuse, a standard cold foil setup is often a good starting point for testing and sample runs.

Cold foil operators are cautioned, however, that their rewind systems – generally designed for waste product collection – may need to be upgraded to achieve the optimal tension. Also, the wet lamination often travels too far before being cured. The distance from lamination to UV cure can create inconsistencies in the effect and the issue with the rewind can limit film reuse.

Brand Security Applications

Brand security relies greatly upon design features that are difficult-to-impossible to recreate. Cast and Cure can readily serve as a security feature as a covert addition to packaging design or as part of an overall brand protection strategy. At the same time, Cast and Cure can be incorporated to enhance package design as a unique look that consumers can see and sometimes feel.

Decorative Packaging Applications

101-year old Ross Print Innovations of Spokane, WA, has become a fast fan of Cast and Cure over the last year while making big inroads into the state’s expanding cannabis market. According to Ross’ general manager Eric Smith, “The more exotic and expensive retail operations present product in either poly bags or glass jars inside well-lit glass counters. Customers often have to make their selections based on product name and packaging appeal.”

“The brand owners love the Cast and Cure holographic finishes on our labels,” says Smith. “The holographic packaging attracts buyer attention and helps create a unique brand perception. For us, Cast and Cure is a win-win. We can run it on virtually any substrate, including stand-up pouches. We run it easily on our cold foil equipment – and it’s easier to run than cold foil.”

In launching its new ProGlide razor several years ago, Gillette sought a package design that delivered sales results while also being environmentally friendly and reducing material use and costs. Gillette scored on all three counts with the help of Cast and Cure decorative finishing.

From a marketing perspective, the foremost objective was achieving a metalized holographic effect so shoppers could easily distinguish Fusion ProGlide from competitors on shelf. Fusion ProGlide was to be Gillette’s most technologically advanced razor, and the carton graphics’ hologram-like appearance enhanced perceptions of shaving comfort and performance.

Gillette achieved the eye-catching design in part with a UV metallic coating that provides the decorative effect of hot-foil stamping. During printing, the metallic coating was combined with Cast-and-Cure holographics. “The package has a definite ‘wow’ factor,” says Michael Marcinkowski, senior engineer of R&D, in Gillette’s Global Package Development area. Material lead-time for the ProGlide razor packages were reduced by six to 12 weeks. “It was a win/win/win,” Marcinkowski concludes. “The package is sustainable, the costs are lower, and there are marketing benefits. And all of this was done at no loss to the consumer.”

Early in 2018, General Mills unveiled the first new Lucky Charms marshmallow shape in 10 years while using Cast and Cure to add visual hype to the new cereal boxes. A magical unicorn has become a permanent member in the Lucky Charms marshmallow lineup – and now appears illustrated on the cereal box cover.

This was a big deal in the CPG industry – and for the Lucky Charms brand. The new cereal boxes had all new graphics, and one more bit of magical intrigue. Twinkling holographic marshmallows appeared all over the box cover. The cast and cure application was also somewhat unique. While most print treatments use UV as the curing source, this application used EB (Electron Beam), which met the FDA criteria for possible food contact.

The Future

The future of Cast and Cure remains bright for Breit Technologies. With the continued enhancements to the company’s line of Cast and Cure web and sheetfed presses, and through strategic alliances with other equipment manufacturers, the breadth of applications into areas such as digital, bag and pouch and specialty products continues to expand.

Breit also continues to expand the capabilities of the process overall through new film designs. Currently, there are films in development that will offer enhance graphical features, as well as functionality. The functionality benefits include grip, texture, and visual depth enhancements.

Breit has recently expanded its distribution to include over 55 countries around the world and finds itself on many billion-dollar product lines in several market segments. The growth of the technology has transformed it from a novel decorating approach, to its own self-sustaining decorative platform.

About the author: Jim Edmondson has specialized in B2B marketing for the last 35 years and has a history of writing about technical processes and applications. He owns Pyramid Creative Group, a Wisconsin-based marketing firm, and provides consulting services to OEMs in the converting and packaging industries throughout North America. He can be reached at jedmondson@pyramid-creative.com.

UV coating is applied directly to the printed web – Cast and Cure film is then laminated to the wet surface – next, the lamination enters a UV lamp – the UV light cures the coating that is sandwiched between the Cast and Cure film and the printed web – next, the Cast and Cure film is delaminated from the printed web and carefully re-wound for multiple reuses. Cast and Cure should be considered “last down” in the printing sequence.

Equipment has been designed to ensure proper and consistent results while maximizing the reuse of the film. However, in many cases a standard Cold Foil setup is a good starting point for testing and sample runs. Two areas of concern with most cold foil setups: First, the rewind is generally designed as a waste product rewind, and second, the wet lamination generally travels too far before being cured. The distance from lamination to UV cure can create inconsistencies in the effect and the issue with the rewind can prevent you from achieving 10 to 12 reuses of the Cast and Cure film. However, very good visual results can be achieved with cold foil setups, generally only falling short in the consistency and ability to reuse the Cast and Cure film. It should be kept in mind that the true cost to produce holographic effects can be as low as 3-cents per MSI if you achieve 12 reuses of the Cast and Cure film. Therefore, attention to this goal should be a priority.

Suggested preparation

Cast and Cure film: Select a holographic or special effect pattern from Breit Technologies film sample book or from the online web page

www.breit-tech.com.

There are two options for ordering material:

1. A predetermined sample roll of approximately 2000’ by 6” to 13” wide is available for purchase through the off-cut sample roll program.

2. Select a specific pattern and specific web width. Rolls are 8,200’ in length and can be slit at a minimum 6” wide to a max 40” wide. This option has a cost per MSI.

UV Coating:

Select a Cast and Cure UV coating from the recommended supplier list.

Anilox selection

Anilox rolls in the range of 200/6bcm to 7bcm will provide the best results for spot applications. When running a full flood coat of Cast and Cure, a heavier deposit (8 to 10bcm) of coating is recommended to achieve the best effects. In general, an anilox in the 6 to 7bcm range applies the most coating while maintaining proper edge definition for spot applications.

Cast and Cure web tension: The general rule regarding the Cast and Cure application is to minimize web tension at the unwind and rewind. Start with the lowest setting that allows the rewind to keep pace with the press. If the web wrinkles on the rewind core, it’s recommended to start over with a softer tension. Once the rewind has about 50 to 100’ on the core you might need to increase the tension to ensure the roll does not scope later.