Greg Hrinya, Associate Editor10.12.18

For converters looking to expand their business, shrink sleeves provide a viable alternative to capitalize on existing equipment. The global shrink sleeve market is growing, providing brands the opportunity to utilize the entire canvas of a product.

Shrink sleeves are most popular in beverage applications, but they are commonly seen with any end use that requires a label to fit a contoured shape.

“Shrink sleeves are one of the fastest growing markets for our industry,” says Paul Teachout, vice president of sales and marketing at Nilpeter USA. “Just passing through a grocery store will show how many brand owners have moved from prime labels to a full 360 degree view of graphics and information to appeal to the modern consumer.”

Accraply finds shrink sleeves being utilized for many types of products, ranging from the dairy aisle of supermarkets all the way to motor oil. “Beverage and household cleaning products that were traditionally labeled with roll-fed and self-adhesive labels are now utilizing the shelf impact of shrink sleeves,” says Ben Ritter, regional sales executive at Accraply. “The requirement for cost effective tamper evidence solutions has also contributed to the volumes of shrink sleeves being called for in the market.”

“I think it’s really important to note that shrink sleeves, in terms of usage, are 50/50 with prime labels,” explains Ben Cunningham, director of global sales, Shrink Sleeve Converting, at Karlville. “If you factor in the enormous growth that self-adhesive labels have had for shipping, then self-adhesive looks a lot more dominant. The information can get skewed. For people who are not in shrink sleeves yet, that’s a wakeup call.”

Many companies are nearly equipped to produce shrink sleeves right now, even if they don’t realize that fact. “If you’re doing prime labels today, then you probably have customers that are using shrink sleeves,” adds Cunningham. “With new presses and new equipment out on the market, you’ve probably made 80% of the investment already, so what’s holding you back? I look at companies, some of the prime label printers, and think some of them are missing out on these opportunities.”

LabelValue.com, a converter based in Tampa, FL, USA, prints shrink sleeves with an HP Indigo WS6800 series digital press. AB Graphic Digicon finishing machinery is then used to slit and varnish the sleeves. Finally, the sleeves need to be seamed and either finished on rolls or individually cut for hand application. LabelValue utilizes Karlville seaming and finishing machinery for this process.

According to Corey Reardon, president and CEO at market research firm AWA Alexander Watson Associates, of the 62 billion square meters of label materials produced on a global scale, pressure sensitive labeling accounts for 40% of the global market, with sleeving representing 18%. The Asia Pacific region is a driving force in this labeling application, but it is seeing continued growth everywhere.

“Sleeve labeling is growing faster than the average label market growth at 5.5%,” Reardon recently stated at the AWA International Sleeve Label Conference & Exhibition.

Josh Dickson, marketing manager at LabelValue, sees no slowdown, either. “I see shrink sleeves continuing to grow at higher rates than other labeling formats,” he says. “The benefits that shrink sleeves provide in hyper-competitive markets cannot be overlooked. Additionally, as the barriers to produce shrink sleeves for small-to-medium sized companies continue to be dropped, more brand owners will opt for the enhanced market and shelf presence that shrink sleeves provide.”

Inland, a label manufacturer based in La Crosse, WI, offers both standard shrink sleeves and roll-fed shrink sleeves. The standard (TDO) shrink sleeve involves five steps: printing, slitting, seaming, inspection and application. Meanwhile, roll-fed (MDO) shrink labels involve three steps: printing, slitting and application.

“The major difference between the two is that standard (TDO) shrink sleeves are seamed at the printer/converter, whereas roll-fed (MDO) shrink sleeves get seamed at the time of application to the container,” explains Kim Young, marketing communications specialist at Inland.

Heat shrink sleeves are the fastest grower in sleeving, and they also make up 88% of the sleeve market. Stretch sleeves account for 8% and RFS/ROSO MD sleeves make up 4%. AWA has published a detailed report, the AWA Global Sleeve Label Market Study 2018, that takes a deep dive into this labeling segment. Converters have several options when it comes to film-based substrates for sleeves. PVC has long been the leader in this market, the report says, but PETG is seeing increased usage. PETG use is rising significantly in the Americas and Europe. OPS is an alternative, as well.

“The co-polyester films, like PET and PETG, are very popular because of their high shrink capability, clarity and printability,” explains George Pinter, partner at Klear Plastic Ventures (KPV). “Surprisingly, there is still a large use of PVC films, despite the negative environmental perception. Klear Plastic Ventures and others have developed co-polyester films with shrink characteristics that mimic cast PVC film. This may help fuel further conversion to co-polyester film.”

Beverage Boom

From beer labels to transparent films, there are a wealth of opportunities to produce eye-popping and revenue-generating designs.

“The ability for full body coverage on just about any shape offers brand owners and package designers an incredible level of design-freedom,” says Accraply’s Ritter. “The ability to market on the entire surface of the container, combined with the element of shape, makes the shrink sleeve label format truly unique. The addition of tactile coatings adding a ‘feel’ element only pushes it over the top.”

“The shrink sleeve label is ubiquitous,” adds KPV’s Pinter. “It is a part of our everyday life. The 360-degree appeal of the graphics is so compelling it connects with both brand owners and consumers alike.”

The shrink sleeve market provides the flexibility and convenience that consumers require, which has helped to drive growth. “A perfect example of where we are seeing a significant spike in adoption is in the wine market, where run sizes are smaller and shrink sleeves eliminate the need to buy large volumes of preprinted cans,” says Inland’s Young, who adds that in 2016 alone, sales of wine in cans grew by 125%. Cans provide an overall appeal to consumers because of their convenience in taking beverages on-the-go.

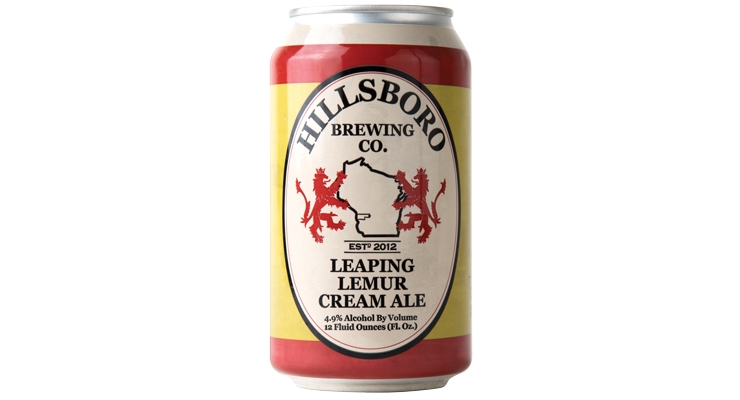

For Karlville, beer labels – specifically in the craft beer segment – are a burgeoning market for shrink sleeves. “When I take a new customer call, one out of two is a customer that’s printing digital and wants to get into craft beers, and that’s 50% of the new business we’re seeing today,” says Cunningham. “Craft breweries don’t regularly make a quarter million of the same flavor. That’s where shrink sleeves come in and there’s a lot of different ways to answer that demand on the market.”

Inland has also seen the benefit of shrink sleeves in the beer segment. The company works with over 150 craft beer customers and has had many projects involving shrink sleeves on beer cans. Preprinted cans require a major investment, and longer runs are cost-prohibitive for smaller breweries. “A truckload of preprinted cans may work for a flagship brewer but works against a brewery looking to have multiple brews throughout the year,” says Young. “Breweries can end up being stuck with cans that aren’t useable due to the artwork becoming obsolete or a brew not being as successful as anticipated.”

KPV’s Pinter notes an increasing number of sleeve label producers are also vertically integrating upstream to supply the already sleeved can to their craft beer customers. “This is making it even easier and more economical to use sleeve labels,” he says. “Combine this with the flexibility of digital printing and you can see why the sleeved can is becoming the package of choice for many craft beer companies.”

Nilpeter’s Teachout sees shrink sleeves competing with PSA labels and flexible packaging. The ability to use the full landscape of a product is a major selling point, and brands are taking notice. “More and more brand owners are changing the way they present their products to take advantage of more real estate on the container to decorate, inform and appeal to the consumer,” says Teachout. “We are now seeing everything from wine and spirits to pet food and anything in between.”

In addition, shrink sleeves are a more reliable choice than pressure sensitive when it comes to beer cans. “Oftentimes, labeling the cans with pressure sensitive labels really detracts from the consistency of the brand, especially when the brand also uses printed cans for their flagship offerings,” says LabelValue’s Dickson. “Shrink sleeves provide the perfect opportunity for brands to maintain brand consistency while still allowing for experimentation with different varieties, packaging and messaging.”

Ritter adds that shrink sleeves should remain a viable growth option. He says, “The volume of shrink sleeves in the market will increase, and growth will be healthy for the foreseeable future.”

On the shelf, Dickson says there are clear benefits to using shrink sleeves. “Consumers have been shown to be more drawn to shrink sleeves than pressure sensitive labels,” he notes. “More than that though, consumers have been shown to have greater engagement with shrink sleeve packaging. This means that the brand that is using shrink sleeves can captivate their audience in new ways, using things like personalization to take their product packaging to a whole new level.”

A Learning Curve

As is evident with the name, shrink sleeve materials physically shrink during the application process. The prepress process is important, as it requires printers to calculate the sleeve’s dimensions and how the material will react to the container. Since shrink sleeves shrink with heat, printers need a press that can eliminate heat, with a chill drum at the drying stations, or not generate it at all with LED curing, notes Karlville’s Cunningham. It’s also important to invest in a reliable seamer that can maintain perfect tension.

As Accraply’s Ritter notes, artwork must be printed in a distorted fashion to account for shrink, which makes prepress vital. Printing of the label can be done with any number of methods, including flexo, gravure, digital or offset. The label then goes through slitting or trimming, which can be accomplished inline or off-line.

The seaming process involves solvent application to one edge, and then a sleeve or tube is created from the flat. “These seamed rolls are typically inspected for seam quality and lay-flat (width) tolerance,” says Ritter. “The converter’s process typically ends at this point, unless the sleeves will be hand-applied, in which case they will need to be sheeted or cut into individual sleeves, with or without perforation. Whether hand-applied or automatically applied, the sleeves are ultimately shrunk around the container using steam, radiant or hot air tunnels.”

“There is a learning curve because one of the main differences with shrink sleeves, compared to self-adhesive, is that the material really impacts your job. You’ve got to be careful to pick the right material for the right kind of bottle and the right kind of shrink,” says Cunningham. “The material also has a machine direction shrink.”

According to Cunningham, this requires proper measurement. If a converter is seeking 100mm in height for the completed label, he or she must take into account that the material shrinks up and down. If the label has a 5% shrink rate, you need to add 5% to that 100mm and print 105mm. As printers gain experience, they can experiment with a wider range of substrates, as well.

“It is a detail-oriented process,” says Cunningham. “But it’s not rocket science. It’s developing maybe five or six different formulas, going through the motions, going through a couple test runs and making sure you’re comfortable.”

In order to facilitate shrink sleeve knowledge, Karlville has also developed a detailed manual for printers and converters. Karlville’s Get Started Guide explains market shares, the manufacturing process, popular materials, and methods for printing, sizing, warehousing and quality control. The application process is also covered in the guide.

Even with all the information available today, Cunningham adds that companies will need to go through a few test runs of trial and error to find what method works best and what is most cost-effective.

Shrink sleeves are most popular in beverage applications, but they are commonly seen with any end use that requires a label to fit a contoured shape.

“Shrink sleeves are one of the fastest growing markets for our industry,” says Paul Teachout, vice president of sales and marketing at Nilpeter USA. “Just passing through a grocery store will show how many brand owners have moved from prime labels to a full 360 degree view of graphics and information to appeal to the modern consumer.”

Accraply finds shrink sleeves being utilized for many types of products, ranging from the dairy aisle of supermarkets all the way to motor oil. “Beverage and household cleaning products that were traditionally labeled with roll-fed and self-adhesive labels are now utilizing the shelf impact of shrink sleeves,” says Ben Ritter, regional sales executive at Accraply. “The requirement for cost effective tamper evidence solutions has also contributed to the volumes of shrink sleeves being called for in the market.”

“I think it’s really important to note that shrink sleeves, in terms of usage, are 50/50 with prime labels,” explains Ben Cunningham, director of global sales, Shrink Sleeve Converting, at Karlville. “If you factor in the enormous growth that self-adhesive labels have had for shipping, then self-adhesive looks a lot more dominant. The information can get skewed. For people who are not in shrink sleeves yet, that’s a wakeup call.”

Many companies are nearly equipped to produce shrink sleeves right now, even if they don’t realize that fact. “If you’re doing prime labels today, then you probably have customers that are using shrink sleeves,” adds Cunningham. “With new presses and new equipment out on the market, you’ve probably made 80% of the investment already, so what’s holding you back? I look at companies, some of the prime label printers, and think some of them are missing out on these opportunities.”

LabelValue.com, a converter based in Tampa, FL, USA, prints shrink sleeves with an HP Indigo WS6800 series digital press. AB Graphic Digicon finishing machinery is then used to slit and varnish the sleeves. Finally, the sleeves need to be seamed and either finished on rolls or individually cut for hand application. LabelValue utilizes Karlville seaming and finishing machinery for this process.

According to Corey Reardon, president and CEO at market research firm AWA Alexander Watson Associates, of the 62 billion square meters of label materials produced on a global scale, pressure sensitive labeling accounts for 40% of the global market, with sleeving representing 18%. The Asia Pacific region is a driving force in this labeling application, but it is seeing continued growth everywhere.

“Sleeve labeling is growing faster than the average label market growth at 5.5%,” Reardon recently stated at the AWA International Sleeve Label Conference & Exhibition.

Josh Dickson, marketing manager at LabelValue, sees no slowdown, either. “I see shrink sleeves continuing to grow at higher rates than other labeling formats,” he says. “The benefits that shrink sleeves provide in hyper-competitive markets cannot be overlooked. Additionally, as the barriers to produce shrink sleeves for small-to-medium sized companies continue to be dropped, more brand owners will opt for the enhanced market and shelf presence that shrink sleeves provide.”

Inland, a label manufacturer based in La Crosse, WI, offers both standard shrink sleeves and roll-fed shrink sleeves. The standard (TDO) shrink sleeve involves five steps: printing, slitting, seaming, inspection and application. Meanwhile, roll-fed (MDO) shrink labels involve three steps: printing, slitting and application.

“The major difference between the two is that standard (TDO) shrink sleeves are seamed at the printer/converter, whereas roll-fed (MDO) shrink sleeves get seamed at the time of application to the container,” explains Kim Young, marketing communications specialist at Inland.

Heat shrink sleeves are the fastest grower in sleeving, and they also make up 88% of the sleeve market. Stretch sleeves account for 8% and RFS/ROSO MD sleeves make up 4%. AWA has published a detailed report, the AWA Global Sleeve Label Market Study 2018, that takes a deep dive into this labeling segment. Converters have several options when it comes to film-based substrates for sleeves. PVC has long been the leader in this market, the report says, but PETG is seeing increased usage. PETG use is rising significantly in the Americas and Europe. OPS is an alternative, as well.

“The co-polyester films, like PET and PETG, are very popular because of their high shrink capability, clarity and printability,” explains George Pinter, partner at Klear Plastic Ventures (KPV). “Surprisingly, there is still a large use of PVC films, despite the negative environmental perception. Klear Plastic Ventures and others have developed co-polyester films with shrink characteristics that mimic cast PVC film. This may help fuel further conversion to co-polyester film.”

Beverage Boom

From beer labels to transparent films, there are a wealth of opportunities to produce eye-popping and revenue-generating designs.

“The ability for full body coverage on just about any shape offers brand owners and package designers an incredible level of design-freedom,” says Accraply’s Ritter. “The ability to market on the entire surface of the container, combined with the element of shape, makes the shrink sleeve label format truly unique. The addition of tactile coatings adding a ‘feel’ element only pushes it over the top.”

“The shrink sleeve label is ubiquitous,” adds KPV’s Pinter. “It is a part of our everyday life. The 360-degree appeal of the graphics is so compelling it connects with both brand owners and consumers alike.”

The shrink sleeve market provides the flexibility and convenience that consumers require, which has helped to drive growth. “A perfect example of where we are seeing a significant spike in adoption is in the wine market, where run sizes are smaller and shrink sleeves eliminate the need to buy large volumes of preprinted cans,” says Inland’s Young, who adds that in 2016 alone, sales of wine in cans grew by 125%. Cans provide an overall appeal to consumers because of their convenience in taking beverages on-the-go.

For Karlville, beer labels – specifically in the craft beer segment – are a burgeoning market for shrink sleeves. “When I take a new customer call, one out of two is a customer that’s printing digital and wants to get into craft beers, and that’s 50% of the new business we’re seeing today,” says Cunningham. “Craft breweries don’t regularly make a quarter million of the same flavor. That’s where shrink sleeves come in and there’s a lot of different ways to answer that demand on the market.”

Inland has also seen the benefit of shrink sleeves in the beer segment. The company works with over 150 craft beer customers and has had many projects involving shrink sleeves on beer cans. Preprinted cans require a major investment, and longer runs are cost-prohibitive for smaller breweries. “A truckload of preprinted cans may work for a flagship brewer but works against a brewery looking to have multiple brews throughout the year,” says Young. “Breweries can end up being stuck with cans that aren’t useable due to the artwork becoming obsolete or a brew not being as successful as anticipated.”

KPV’s Pinter notes an increasing number of sleeve label producers are also vertically integrating upstream to supply the already sleeved can to their craft beer customers. “This is making it even easier and more economical to use sleeve labels,” he says. “Combine this with the flexibility of digital printing and you can see why the sleeved can is becoming the package of choice for many craft beer companies.”

Nilpeter’s Teachout sees shrink sleeves competing with PSA labels and flexible packaging. The ability to use the full landscape of a product is a major selling point, and brands are taking notice. “More and more brand owners are changing the way they present their products to take advantage of more real estate on the container to decorate, inform and appeal to the consumer,” says Teachout. “We are now seeing everything from wine and spirits to pet food and anything in between.”

In addition, shrink sleeves are a more reliable choice than pressure sensitive when it comes to beer cans. “Oftentimes, labeling the cans with pressure sensitive labels really detracts from the consistency of the brand, especially when the brand also uses printed cans for their flagship offerings,” says LabelValue’s Dickson. “Shrink sleeves provide the perfect opportunity for brands to maintain brand consistency while still allowing for experimentation with different varieties, packaging and messaging.”

Ritter adds that shrink sleeves should remain a viable growth option. He says, “The volume of shrink sleeves in the market will increase, and growth will be healthy for the foreseeable future.”

On the shelf, Dickson says there are clear benefits to using shrink sleeves. “Consumers have been shown to be more drawn to shrink sleeves than pressure sensitive labels,” he notes. “More than that though, consumers have been shown to have greater engagement with shrink sleeve packaging. This means that the brand that is using shrink sleeves can captivate their audience in new ways, using things like personalization to take their product packaging to a whole new level.”

A Learning Curve

As is evident with the name, shrink sleeve materials physically shrink during the application process. The prepress process is important, as it requires printers to calculate the sleeve’s dimensions and how the material will react to the container. Since shrink sleeves shrink with heat, printers need a press that can eliminate heat, with a chill drum at the drying stations, or not generate it at all with LED curing, notes Karlville’s Cunningham. It’s also important to invest in a reliable seamer that can maintain perfect tension.

As Accraply’s Ritter notes, artwork must be printed in a distorted fashion to account for shrink, which makes prepress vital. Printing of the label can be done with any number of methods, including flexo, gravure, digital or offset. The label then goes through slitting or trimming, which can be accomplished inline or off-line.

The seaming process involves solvent application to one edge, and then a sleeve or tube is created from the flat. “These seamed rolls are typically inspected for seam quality and lay-flat (width) tolerance,” says Ritter. “The converter’s process typically ends at this point, unless the sleeves will be hand-applied, in which case they will need to be sheeted or cut into individual sleeves, with or without perforation. Whether hand-applied or automatically applied, the sleeves are ultimately shrunk around the container using steam, radiant or hot air tunnels.”

“There is a learning curve because one of the main differences with shrink sleeves, compared to self-adhesive, is that the material really impacts your job. You’ve got to be careful to pick the right material for the right kind of bottle and the right kind of shrink,” says Cunningham. “The material also has a machine direction shrink.”

According to Cunningham, this requires proper measurement. If a converter is seeking 100mm in height for the completed label, he or she must take into account that the material shrinks up and down. If the label has a 5% shrink rate, you need to add 5% to that 100mm and print 105mm. As printers gain experience, they can experiment with a wider range of substrates, as well.

“It is a detail-oriented process,” says Cunningham. “But it’s not rocket science. It’s developing maybe five or six different formulas, going through the motions, going through a couple test runs and making sure you’re comfortable.”

In order to facilitate shrink sleeve knowledge, Karlville has also developed a detailed manual for printers and converters. Karlville’s Get Started Guide explains market shares, the manufacturing process, popular materials, and methods for printing, sizing, warehousing and quality control. The application process is also covered in the guide.

Even with all the information available today, Cunningham adds that companies will need to go through a few test runs of trial and error to find what method works best and what is most cost-effective.