Patrick Hogan11.16.18

Winston Churchill once said, “Those that fail to learn from history are doomed to repeat it.” Fortunately for us in flexography, the industry has learned from mistakes, applied those hard-earned lessons and continued the dynamic changes that keep our printing technology relevant and vibrant today.

While the flexographic printing industry traces its roots back to the 1800s, it has been the constant improvements in technology that have made flexography the vigorous industry it has become over the last 30 years. Developments in press manufacturing, inks, plates, tapes, mounting, graphics and aniloxes all paved the way for the industry we know today. Of course, the heart of the process has been the anilox. The story of the anilox is an amazing testament to both ingenuity and application.

How did anilox rolls come to be? Originally, inks used in the flexographic industry were made from aniline or coal tar derivatives. Early ink delivery systems for flexo were a combination of rubber transfer rolls that had varying amounts of pressure applied to meter the amount of ink transferred to the printing plate. The system was not very precise and didn’t lend itself to repeatability from job to job. As a result, print quality was unpredictable. It was through these struggles the idea for improvement in ink delivery was born.

One of the early flexo pioneers, Doug Tuttle, saw how gravure rolls were being used to deliver a precise amount of ink and looked for a way to integrate that process into flexography. In 1939, he applied for a US patent on an engraved roll used to transfer ink, but because he was interested in improving the flexo process he never pursued the patent so the industry wouldn’t have a single supplier for the roll. The “anilox roll” name came about because one of the early aniline ink manufacturers was Interchemical Corporation, and the suffix used in naming their inks often had an “ox” on it. Thus, aniline inks + “ox” = “anilox roll.”

Initially, cylinders were composed of chemically etched copper. These cylinders were processed similar to gravure cylinders but they had a poor lifespan due to the softness of the metal. Eventually a mechanically engraved, steel roll was developed as an alternative that could deliver a precise amount of ink. Thus, the anilox roll was substituted in for a rubber roll in the ink train. Using variable pressure between the rolls, varying ink viscosities and adjusting press speeds revealed the new limits of the early flexographic ink metering method. Early mechanically engraved rolls used inverted pyramid or quadrangular cell shapes. Usually linescreens of 360 cells per inch were not exceeded due to tooling and graphics limitations. In the 1970s, Harper Corporation of America developed the 60-degree hexagonal cell.

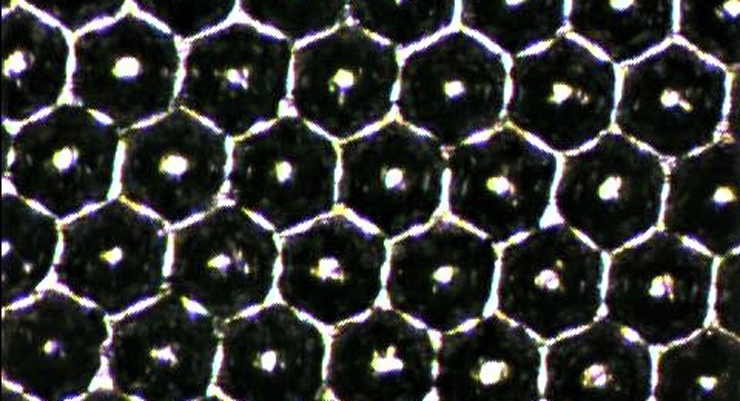

The hex has the same pattern as a honeycomb, and as we have learned from nature, it is a very efficient configuration. This cell configuration maximizes the space available to fit in a higher number of cells per inch. The combination of both greater cells per inch and reduced volumes allowed for less ink film thickness; leading to the possibility of advancements in process printing.

The introduction of the doctor blade to meter ink on the anilox roll allowed for even more precision in the transfer of ink to the printing plate. Unfortunately, it also led to increased anilox wear. The early steel covered rolls didn’t hold up to the friction, and moving to chrome coated rolls helped increase roll life. Chemically-etched copper rolls provided opportunities for linescreen and volume combinations that mechanically-etched rolls could not. A durable coating was needed to protect the copper and it was found that a thin layer of chrome over the copper provided extended resistance to blade wear and improved roll life. To get the chrome to adhere to the copper, the roll was immersed in an electrolyte bath comprising chromic acid, and an electric current was applied to the copper causing the chrome to bond to the copper. Typically, the chrome layer was about .008" thick. Chrome coated anilox rolls continued to be the industry standard for many years until the ceramic coated anilox was introduced in the 1970s.

While chrome plating was an improvement, even greater resistance to wear was needed. The development of advanced thermal spraying technologies, as well as fine powders, led to the innovation of the ceramic anilox roll. The plasma coating applied to early ceramic rolls was usually an aluminum dioxide – titanium dioxide material. Early ceramic coated rolls had no cell patterns and were just an “as sprayed” coating that didn’t have any geometric pattern engraved. These rolls relied on the porosity of the surface to accept and transfer ink.

In the early 1980s, Harper Corporation of America pioneered the world’s first mechanically-engraved ceramic coated anilox roll to go beyond 200 cells per inch. Converters saw the merits of ceramic coated roll technology with an increase in service life versus chrome coated rolls.

The use of sprayed coatings led the industry to a new terminology – porosity. Porosity, or “void fraction,” refers to the empty spaces in a material. The ability to spray on a coating with low porosity became a critical step toward maintaining consistency while engraving and keeping a uniform volume across the roll face. Today, the top quality anilox suppliers can achieve porosity averages of 1% or less.

In addition, ceramic covered rolls have a much higher “hardness” than chrome covered rolls. This increased hardness makes the ceramic coated roll much more durable and resistant to wear than the chrome covered anilox roll. Typical hardness of a ceramic coated roll averages 1200 Vickers, and is operated in a range between 1,100 to 1,300. Ceramic above 1,300 Vickers hardness will realize changes in mechanical properties and it becomes too brittle. Excessive hardness of the ceramic can cause rolls to crack and fail under pressures associated with regular press operating conditions. New, advanced plasma ceramic coatings made from Chromium Oxide provide a very hard surface within those Vickers specifications while improving corrosion protection. Chromium Oxide polishes well and provides superior resistance to doctor blade wear.

As with any new technology, there is a learning curve. Early ceramic covered rolls had much higher dyne levels than chrome covered rolls and their ink release characteristics were quite different. This would often lead to ink formulation issues when moving jobs from a press using chrome covered rolls to a press using ceramic rolls. Typical chrome covered rolls release ink with a higher effieciency than ceramic covered rolls. A good rule of thumb is to add a minimum 10% to the volume of an engraving when transitioning from chrome to ceramic.

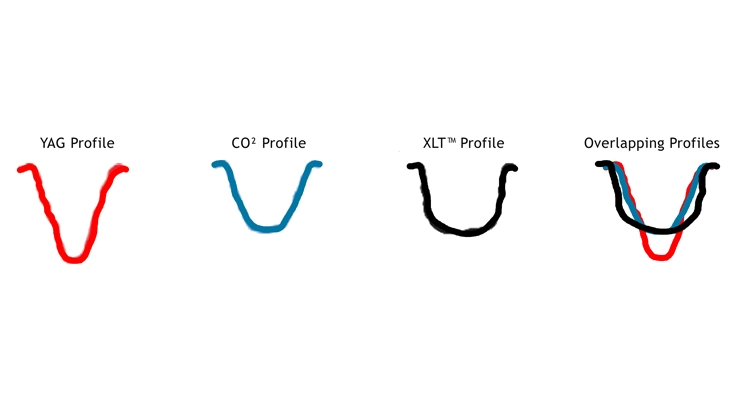

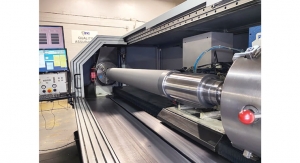

In the late 1970s, advancements in laser engraving technology, along with roll grinding and polishing techniques, saw the advent of the laser engraved ceramic coated anilox. The ability to laser engrave aniloxes opened up new frontiers in flexography, with new combinations of geometries and line screens available. Early laser technology used CO2 lasers to engrave the ceramic. Beam width limitation for CO2 restricted the ability to make rolls not exceeding 1,200 cells per inch. Subsequently, YAG (yttrium aluminum garnet) laser technology was developed. Both of these technologies worked well but because of the cell shape configuration, the depth to opening ratio of cells created by these lasers had limitations with ink release. YAG lasers could make higher line counts, but the cells were even deeper and more cone-shaped than CO2 engraved cells. The industry demanded an improvement in cell count and volume to compete with rival technologies like offset and gravure. Combination printing also created a gap between achievable color and print quality, a gap filled by extended volume aniloxes at high cell counts. Development of advanced digital fiber optic lasers resulted in innovative cell profiles compared to YAG and CO2 technology. Cells less conical in shape and more rounded at the bottom allowed for superior ink release characteristics. These improved cell profiles enabled the digital engraving of aniloxes at even more cells per inch with better control over volume. Line screens of over 2,000 cells per inch are possible. Advanced engravings with elongated cells, channels, and open cells have become available. The improvements in cell quality have kept pace with increasing difficulties in care for and cleaning of aniloxes, and has greatly reduced cell plugging on the press during long runs.

The evolution of press manufacturing technology – improvements in dryers, developments of servo drives, sleeve technology, higher press speeds and quick changeovers have triggered changes in anilox manufacturing methods as well. Quicker changeover on presses necessitated the development of anilox sleeves. Wider presses and higher speeds led to the development of carbon fiber sleeves to save weight and provide the stiffness needed to avoid deflection and maintain the total indicated runout needs of modern presses. Typically, anilox manufacturing produces rolls with a total indicated runout of +/- of .001". The higher press speeds also made it necessary to increase the circumference of anilox rolls to improve ink release characteristics. It boils down to basic physics – larger diameter aniloxes need less force to get the ink out of a cell (force = mass x velocity²/radius). “Smart” aniloxes with microchips helping to identify in real time what is in the press have been introduced. It is fair to say that all the components of flexography have grown together, continue to support each new advance and make flexography more efficient at higher speeds to keep it competitive with other print technologies.

What other developments are on the horizon for aniloxes? New solid-state lasers capable of innovative cell profiles and geometries offering higher volumes of ink delivery. Advanced, more durable roll coatings that have much higher wear resistance and ink release properties. These new coatings will open new markets for suppliers because of their enhanced capabilities. Along with energy curable inks will come higher cell counts and volumes, pushing flexography to potentially rival the printing capabilities of gravure. Imagine an anilox with the ink release properties of chrome and wear resistance that exceeded ceramic. From the early “rubber stamp” printing days to the modern laser engraving and use of digital workflows, the future of aniloxes and flexography continues to look very bright!

Patrick Hogan is Technical Service Representative Midwest for Harper Corporation of America. Prior to joining Harper, he was Print Services Manager for Bemis, a leader in flexible packaging. He is a Six Sigma Green Belt with extensive knowledge of flexographic and rotogravure print processes and an expert in graphic arts. Recognized as a strategic thinker, relationship builder, effective mentor, and team member with proven success identifying and implementing process improvements and ensuring customer satisfaction, Patrick is known for delivering successful outcomes via robust troubleshooting and technical abilities.

While the flexographic printing industry traces its roots back to the 1800s, it has been the constant improvements in technology that have made flexography the vigorous industry it has become over the last 30 years. Developments in press manufacturing, inks, plates, tapes, mounting, graphics and aniloxes all paved the way for the industry we know today. Of course, the heart of the process has been the anilox. The story of the anilox is an amazing testament to both ingenuity and application.

How did anilox rolls come to be? Originally, inks used in the flexographic industry were made from aniline or coal tar derivatives. Early ink delivery systems for flexo were a combination of rubber transfer rolls that had varying amounts of pressure applied to meter the amount of ink transferred to the printing plate. The system was not very precise and didn’t lend itself to repeatability from job to job. As a result, print quality was unpredictable. It was through these struggles the idea for improvement in ink delivery was born.

One of the early flexo pioneers, Doug Tuttle, saw how gravure rolls were being used to deliver a precise amount of ink and looked for a way to integrate that process into flexography. In 1939, he applied for a US patent on an engraved roll used to transfer ink, but because he was interested in improving the flexo process he never pursued the patent so the industry wouldn’t have a single supplier for the roll. The “anilox roll” name came about because one of the early aniline ink manufacturers was Interchemical Corporation, and the suffix used in naming their inks often had an “ox” on it. Thus, aniline inks + “ox” = “anilox roll.”

Initially, cylinders were composed of chemically etched copper. These cylinders were processed similar to gravure cylinders but they had a poor lifespan due to the softness of the metal. Eventually a mechanically engraved, steel roll was developed as an alternative that could deliver a precise amount of ink. Thus, the anilox roll was substituted in for a rubber roll in the ink train. Using variable pressure between the rolls, varying ink viscosities and adjusting press speeds revealed the new limits of the early flexographic ink metering method. Early mechanically engraved rolls used inverted pyramid or quadrangular cell shapes. Usually linescreens of 360 cells per inch were not exceeded due to tooling and graphics limitations. In the 1970s, Harper Corporation of America developed the 60-degree hexagonal cell.

The hex has the same pattern as a honeycomb, and as we have learned from nature, it is a very efficient configuration. This cell configuration maximizes the space available to fit in a higher number of cells per inch. The combination of both greater cells per inch and reduced volumes allowed for less ink film thickness; leading to the possibility of advancements in process printing.

The introduction of the doctor blade to meter ink on the anilox roll allowed for even more precision in the transfer of ink to the printing plate. Unfortunately, it also led to increased anilox wear. The early steel covered rolls didn’t hold up to the friction, and moving to chrome coated rolls helped increase roll life. Chemically-etched copper rolls provided opportunities for linescreen and volume combinations that mechanically-etched rolls could not. A durable coating was needed to protect the copper and it was found that a thin layer of chrome over the copper provided extended resistance to blade wear and improved roll life. To get the chrome to adhere to the copper, the roll was immersed in an electrolyte bath comprising chromic acid, and an electric current was applied to the copper causing the chrome to bond to the copper. Typically, the chrome layer was about .008" thick. Chrome coated anilox rolls continued to be the industry standard for many years until the ceramic coated anilox was introduced in the 1970s.

While chrome plating was an improvement, even greater resistance to wear was needed. The development of advanced thermal spraying technologies, as well as fine powders, led to the innovation of the ceramic anilox roll. The plasma coating applied to early ceramic rolls was usually an aluminum dioxide – titanium dioxide material. Early ceramic coated rolls had no cell patterns and were just an “as sprayed” coating that didn’t have any geometric pattern engraved. These rolls relied on the porosity of the surface to accept and transfer ink.

In the early 1980s, Harper Corporation of America pioneered the world’s first mechanically-engraved ceramic coated anilox roll to go beyond 200 cells per inch. Converters saw the merits of ceramic coated roll technology with an increase in service life versus chrome coated rolls.

The use of sprayed coatings led the industry to a new terminology – porosity. Porosity, or “void fraction,” refers to the empty spaces in a material. The ability to spray on a coating with low porosity became a critical step toward maintaining consistency while engraving and keeping a uniform volume across the roll face. Today, the top quality anilox suppliers can achieve porosity averages of 1% or less.

In addition, ceramic covered rolls have a much higher “hardness” than chrome covered rolls. This increased hardness makes the ceramic coated roll much more durable and resistant to wear than the chrome covered anilox roll. Typical hardness of a ceramic coated roll averages 1200 Vickers, and is operated in a range between 1,100 to 1,300. Ceramic above 1,300 Vickers hardness will realize changes in mechanical properties and it becomes too brittle. Excessive hardness of the ceramic can cause rolls to crack and fail under pressures associated with regular press operating conditions. New, advanced plasma ceramic coatings made from Chromium Oxide provide a very hard surface within those Vickers specifications while improving corrosion protection. Chromium Oxide polishes well and provides superior resistance to doctor blade wear.

As with any new technology, there is a learning curve. Early ceramic covered rolls had much higher dyne levels than chrome covered rolls and their ink release characteristics were quite different. This would often lead to ink formulation issues when moving jobs from a press using chrome covered rolls to a press using ceramic rolls. Typical chrome covered rolls release ink with a higher effieciency than ceramic covered rolls. A good rule of thumb is to add a minimum 10% to the volume of an engraving when transitioning from chrome to ceramic.

In the late 1970s, advancements in laser engraving technology, along with roll grinding and polishing techniques, saw the advent of the laser engraved ceramic coated anilox. The ability to laser engrave aniloxes opened up new frontiers in flexography, with new combinations of geometries and line screens available. Early laser technology used CO2 lasers to engrave the ceramic. Beam width limitation for CO2 restricted the ability to make rolls not exceeding 1,200 cells per inch. Subsequently, YAG (yttrium aluminum garnet) laser technology was developed. Both of these technologies worked well but because of the cell shape configuration, the depth to opening ratio of cells created by these lasers had limitations with ink release. YAG lasers could make higher line counts, but the cells were even deeper and more cone-shaped than CO2 engraved cells. The industry demanded an improvement in cell count and volume to compete with rival technologies like offset and gravure. Combination printing also created a gap between achievable color and print quality, a gap filled by extended volume aniloxes at high cell counts. Development of advanced digital fiber optic lasers resulted in innovative cell profiles compared to YAG and CO2 technology. Cells less conical in shape and more rounded at the bottom allowed for superior ink release characteristics. These improved cell profiles enabled the digital engraving of aniloxes at even more cells per inch with better control over volume. Line screens of over 2,000 cells per inch are possible. Advanced engravings with elongated cells, channels, and open cells have become available. The improvements in cell quality have kept pace with increasing difficulties in care for and cleaning of aniloxes, and has greatly reduced cell plugging on the press during long runs.

The evolution of press manufacturing technology – improvements in dryers, developments of servo drives, sleeve technology, higher press speeds and quick changeovers have triggered changes in anilox manufacturing methods as well. Quicker changeover on presses necessitated the development of anilox sleeves. Wider presses and higher speeds led to the development of carbon fiber sleeves to save weight and provide the stiffness needed to avoid deflection and maintain the total indicated runout needs of modern presses. Typically, anilox manufacturing produces rolls with a total indicated runout of +/- of .001". The higher press speeds also made it necessary to increase the circumference of anilox rolls to improve ink release characteristics. It boils down to basic physics – larger diameter aniloxes need less force to get the ink out of a cell (force = mass x velocity²/radius). “Smart” aniloxes with microchips helping to identify in real time what is in the press have been introduced. It is fair to say that all the components of flexography have grown together, continue to support each new advance and make flexography more efficient at higher speeds to keep it competitive with other print technologies.

What other developments are on the horizon for aniloxes? New solid-state lasers capable of innovative cell profiles and geometries offering higher volumes of ink delivery. Advanced, more durable roll coatings that have much higher wear resistance and ink release properties. These new coatings will open new markets for suppliers because of their enhanced capabilities. Along with energy curable inks will come higher cell counts and volumes, pushing flexography to potentially rival the printing capabilities of gravure. Imagine an anilox with the ink release properties of chrome and wear resistance that exceeded ceramic. From the early “rubber stamp” printing days to the modern laser engraving and use of digital workflows, the future of aniloxes and flexography continues to look very bright!

Patrick Hogan is Technical Service Representative Midwest for Harper Corporation of America. Prior to joining Harper, he was Print Services Manager for Bemis, a leader in flexible packaging. He is a Six Sigma Green Belt with extensive knowledge of flexographic and rotogravure print processes and an expert in graphic arts. Recognized as a strategic thinker, relationship builder, effective mentor, and team member with proven success identifying and implementing process improvements and ensuring customer satisfaction, Patrick is known for delivering successful outcomes via robust troubleshooting and technical abilities.