Greg Hrinya, Editor04.03.20

When printing labels, inspection might not be the process that jumps to the forefront of everyone’s mind – but the results can be monumental. A mistake on a label can run the gamut from insignificant to life altering. A mild smudge on a graphic might be unpleasant to the eye, but no harm will be done. A mistake that leads to an incorrect dose or direction on a pharmaceutical or food label, however, can be deadly.

The other pitfall can be lethal from a business perspective. Repeated labeling mistakes can lead a brand to seek a different converter. Frequent mistakes can also lead to poor efficiency, increased waste and slower turnaround times. Developing a quality assurance program, complete with a set of standards, can make all the difference in the bottom line.

“To deliver improved economics, converters need to reduce waste and optimize their label production processes, shifting from their overall practice of web viewing inspection toward 100% print inspection technologies,” states Yael Cooper, marketing manager at AVT. “At the same time, they need to implement quality standardization methods across jobs and applications in order to meet brand owners’ expectations for quality and repetitiveness across their SKU portfolio – a challenge that requires a more comprehensive approach to their quality assurance practices.”

Inspection equipment seeks to remedy all these hazards of the trade. Not all products are created equally, either. Some label converters might need a basic form of quality assurance, while others will require more advanced systems. Converters do need some form of quality assurance, though.

“The consequences of not having a robust, 100% inspection process can be severe,” explains Craig Du Mez, global branding, PR and communications manager at Baldwin Vision Systems. “Missing or broken text on a pharmaceutical label can be a matter of life and death. Inaccurate variable data on security print can result in massive costs and litigation. Even if you’re not printing in those high-accountability scenarios, everyone should consider the high cost of returns if you fail to ensure that no defects get into the hands of your customers.”

“I find it difficult to understand how some label printers don’t use inspection,” says Robert Buongiorno, president, BST North America. “In the pharmaceutical world it’s not even an option, since a missing dot can make the difference from a .10% solution to a 10% solution.”

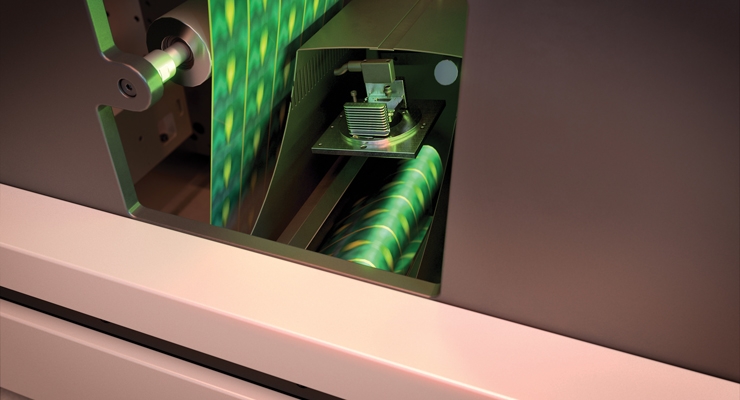

Inspection equipment can encompass several different technologies such as area cameras and line-scan cameras. An area camera would not be classified as true 100% inspection, as these cameras are positioned on a traverse, where they move and zoom to an identified location of the printed web. Meanwhile, line-scan cameras will identify even the smallest defects and notify the press or rewinder operator.

“With 100% inspection, the operator must identify a baseline printed repeat or image, which we call the ‘Golden Image,” notes Buongiorno. “Once this is established, every millimeter of the printed web is compared to the Golden Image, and when something is identified that was not on or part of the Golden Image, it will notify the operator of a defect.”

The latest inspection equipment must also take into account a wide range of technologies and guidelines. “Modern inspection solutions must be able to perform variable print inspections independent of material and format,” says Nico Hagemann, product manager, EyeC. “They must also be easy to integrate into existing workflows and be able to securely process production data from other information systems in use. These systems must be developed and produced in accordance to applicable guidelines and standards, such as ISO 9001, GMP, GAMP 5 and 21 CFR Part 11.”

When thinking about ROI, converters often focus on press speeds and changeovers times. While those are critical, they might forget about the benefits of inspection equipment.

“It doesn’t take much to realize that preventing errors with a strong, data-connected defect management workflow will deliver a very fast return on investment,” adds Du Mez. “Having systems in place to ensure process efficiency and deliver process data will help printers to make informed decisions quickly, and compare historical quality and efficiency information.”

Inspection evolution

Inspection equipment has evolved to meet greater demand and provide enhanced accuracy. According to AVT’s Cooper, the latest 100% automatic inspection systems provide greater resolution, speeds, breadth of features, and improved workflows and automation.

“In the past, there were many low-resolution cameras designed to detect obvious defects,” says Cooper. “Today, labels and the graphics included in them, such as text, barcodes and image details, are becoming smaller, and so is the size of the defect that requires detection. This has created a new standard in the marketplace, and resolution today can get to nearly 50 microns.”

Inspection equipment has also allotted for increased press speeds. Historically, there would be a trade-off between speed and resolution accuracy, but today’s vendors have significantly invested in R&D to ensure both are feasible.

“Our newest model, the fleyeVision 4k color system, shows a 50-80% higher level of performance, meaning maximum inspection speeds,” says Ralf Wirtz, sales manager at AB Graphic International. “This enhanced performance is driven by an OCR and barcode inspection rate four times faster than before, and is linked to hardware with higher performance and software optimization.”

BST North America’s Buongiorno adds that the greatest improvements have come in the form of the software. “The hardware around view camera systems hasn’t changed very much but the software driving it certainly has,” he says. “In 100% inspection, advances in computers, software and hardware have made 100% inspection very reliable for just about any application. Anyone who judges inspection systems with 10-year-old information is very ill-informed.”

Inspection equipment is becoming increasingly automated, especially in the complex market of pharmaceuticals. “In order to meet increased quality requirements and strict customer specifications, such as in the pharmaceutical sector, automated inspection processes are more and more implemented as a standard in production to increase the accuracy and traceability of quality controls,” says EyeC’s Hagemann. “Serialization has brought a lot of challenges, especially for pharmaceutical companies and their suppliers. Modern inspection systems must therefore be able to support pharmaceutical companies and their suppliers with managing the data along the entire supply chain.”

A deep dive

How, exactly, are mistakes spotted? While there are multiple ways to integrate inspection – inline or off-line – into a production environment to accommodate a host of different workflows, the process ultimately relies on vision technologies to compare print images on the web.

Following a print run, the press operator uses the inspection system to take a scan of the web, capturing a single repeat. When the inspection system is located on the rewinder, this can be done immediately upon roll upload. After reviewing the image and assuring it is defect-free, the operator defines the “Golden Image” that BST North America’s Buongiorno referred to earlier.

“Once the system begins inspection, it captures every single repeat on the web and compares it to the master image defined by the operator,” states AVT’s Cooper. “If both images are the same, it means that the printed web is in good quality. However, if the scanned images demonstrate misalignments when compared to the master image, the system will identify these misalignments as defects and will alert the operator on these defects.”

At AB Graphic, image processing is handled in the computer. Here, the labels are continuously recorded and are compared to the previously created master image.

“After starting the machine, the reference images are programmed and the printer tolerance is determined,” says ABG’s Wirtz. “Irrelevant print areas are removed from the inspection process. It is also possible to define special parameters for various sections. When the electronic controller starts, the product is subject to 100% inspection. If an error occurs, the machine stops and the error is brought to a pre-defined position.”

When an error is detected, the type and position of the error is indicated on the touchscreen monitor, allowing the operator to correct the error. Any stored errors are then processed in sequence.

Inspection equipment has been engineered to make the process as easy as possible for operators. “The clear presentation of deviations and key statistical information – such as the defect heatmap – help the operator to understand the location and origin of printing defects easily,” explains EyeC’s Hagemann. “A comprehensive inspection report is automatically produced at the end of each job, offering tracking, analysis and communication support for printers and converters.”

Baldwin’s Du Mez states the way in which converters perceive inspection has to shift, as well. “Advanced 100% inline inspection systems go beyond identifying defects by monitoring your processes to prevent defects from occurring in the first place. It is essential that printers think in terms of eliminating rather than simply finding or minimizing defects,” he says. “Must-have features that make this possible include advanced defect mapping, which allows you to track and manage defects throughout the entire process, make appropriate adjustments in real time, and record defect positions and images for multiple post-press processes.”

According to Baldwin, object-based inspection ensures tighter tolerances and fewer false defects. Operators can define areas of interest for enhanced or reduced levels of inspection. Other important features include automated job setup, dynamic learning, barcode decoding, barcode ANSI/ISO grading, PDF verification, and variable data verification. Connecting data to technologies for monitoring and reporting is also a must-have feature, adds Du Mez.

AB Graphic, which offers fleyeVision for 100% print inspection, sees the technology growing swiftly this year. “2020 will see increased demands on productivity, and also the continued increase in the quality of label printing,” states Wirtz. “We will see continued automation, with JDF and zero-point automatic setup, customization for variable data control, and integrated solutions, with the inspection system controlling complete processes and machines.”

What’s new?

Inspection equipment has been optimized to accommodate numerous trends in the label and packaging space. The equipment must handle growth markets like flexible packaging, e-commerce, variable data, and digital printing in general.

“Tracking and comparing many different production metrics, and sharing data not only between systems on an individual press – but also between multiple facilities – is where the industry is going,” notes Baldwin’s Du Mez. “The technology is already here and is increasingly required by print customers. Adoption of the technology needs to keep pace with rapidly-growing expectations from brand owners.”

“Sustainability regulations will drive new print applications, with thinner materials, boxless products, linerless labels and recyclable materials,” says AVT’s Cooper. “This will require AiS (automatic inspection system) technology to meet new challenges when dealing with new inspection complexities. Shorter runs and an increasing number of SKUs will require inspection technologies to enhance production efficiencies through automation in different production phases, and will drive new solutions in close-loop automation between AiS and the press.”

Suppliers are responding to these new trends with multiple product enhancements.

AB Graphic provides fleyeVision, a 100% print inspection system that has been designed to produce excellent results, prevent costly customer rejections and deliver an enhanced return on investment. The system checks text images for print errors and can recognize and classify all standard barcodes, check data in OCR characters and check braille for errors. Images are recorded by a digital line scan camera with between 1024 and 8196 pixels as a color or a gray-scale picture.

As a standalone system, fleyeVision can be integrated into any press, converting machine or control system – ready to use, customized and upgradeable. The fleyeVision system can also be incorporated with fleyeLink to optimize smart workflows. By using this approach, all defects can be recognized at an early stage during printing, allowing for immediate actions to avoid waste, over-production and reprints.

“fleyeVision operation is simple: all data is entered using symbols on the touchscreen monitor,” says ABG’s Wirtz. “fleyeVision software guides the operator through the necessary inputs, step-by-step. We are the only manufacturer to offer this one-stop technology – providing expert advice to ensure perfectly matched process parameters, customized solutions and all-around global support, installation, training and retrofits.”

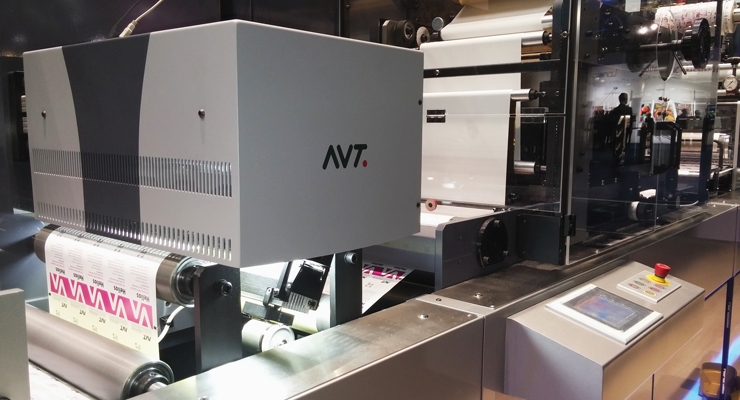

AVT offers the Helios AiS product family, which can accommodate all narrow web press and rewinders from 13" wide up to 27". With over 2,000 installations worldwide, the AVT Helios product line is a proven automatic 100% inspection product designed for labels and other narrow web printing applications.

Helios automatically inspects printed labels or packages for defects and imperfections, delivering excellent quality results while eliminating customer rejections. Meanwhile, SolidProof ensures that no critical errors have been overlooked in the print production process, automatically eliminating conversion errors and undetected defects during the prepress stage.

AVT’s inspection equipment offers more than just the detection of inconsistent text or graphics. “The AVT IDEal feature allows inline Delta E color measurements, monitoring any color shifts during the run,” explains Cooper. “When the AiS is placed on the press, the operator will be alerted on these shifts and will be able to apply corrections to the press. Another example is the AVT Barcode and Variable Data Verification, which enables inline decoding and grading of 100% of the barcodes and human readables throughout the run, plus detection of duplication or sequencing issues when dealing with variable data items.”

Baldwin has an extensive range of quality-assurance products to offer label converters. Guardian PQV 100% print inspection provides print quality verification throughout every step of the printing process, enabling operators to get an accurate, data-connected workflow. Guardian RTM Real-Time Monitoring uses a central server to monitor, collect, and display real-time inspection data on a simple, uncluttered dashboard. RTM can simultaneously collect data for multiple presses, jobs, and even across multiple plants. The combination of Guardian PQV and RTM ties together how printers manage their processes, print customers and even employees.

“Based on clear industry trends, Baldwin Vision Systems has focused our research and development efforts on more efficient, accurate, data-connected inspection workflows,” says Du Mez. “We’ve developed new technologies that enable press managers to monitor changes as they happen, and make highly-informed decisions about print quality, defect management and even operator-to-operator performance.”

Additionally, Guardian OLP off-line proofing and inspection verifies that the files used for production – or the beginning-of-run press samples – match the customer-approved master file 100%. By comparing any prepress file or scanned press sample to the customer-approved original in a matter of seconds, advanced software automatically locates and highlights even the smallest of differences in print quality.

BST North America boasts a wide range of products based on converter needs and applications. Focusing on the label and narrow web space, the company offers TubeScan, which has been designed to meet the needs of any label printer, whether they install it on a press or a rewinder.

For wider web, BST North America provides IPQ Check, which like TubeScan, can be customized to suit the needs of its customers. “Now that 100% defect detection is more established in the industry, the biggest trends we see are inspection and verification throughout the complete workflow, Delta E or spectral color inspection, and coating or cold seal inspection,” says BST North America’s Buongiorno. “BST has products and features that will accomplish this in our TubeScan and IPQ product lines.”

EyeC has engineered its inspection systems to help label printers and converters ensure the design, production and delivery of high quality, error-free labels. With the help of EyeC Proofiler Content, errors are detected early during the creation of the artwork file. At the prepress stage, the EyeC Proofiler Graphic and the EyeC Driver or EyeC Workflow Integration help printers to boost security and efficiency.

The integration of prepress inspections into existing workflows triggers inspection procedures automatically, retrieving job data, files and inspection parameters from the workflow system to correct defects before plate production.

“The EyeC Proofiler series offers fast and secure testing of samples in various formats,” says EyeC’s Hagemann. “These systems are used for continuous sample testing during the printing process or to secure outgoing quality controls of label printers. In comparison, the EyeC ProofRunner Web series inspects any type of narrow-to mid-web products, including transparent or metalized labels, flexible materials or films – and performs a 100% print inspection on a press or a rewinder. As a result, label printers and converters can be sure to deliver exactly what their customers expect and avoid customer reclamations or product recalls.”

The other pitfall can be lethal from a business perspective. Repeated labeling mistakes can lead a brand to seek a different converter. Frequent mistakes can also lead to poor efficiency, increased waste and slower turnaround times. Developing a quality assurance program, complete with a set of standards, can make all the difference in the bottom line.

“To deliver improved economics, converters need to reduce waste and optimize their label production processes, shifting from their overall practice of web viewing inspection toward 100% print inspection technologies,” states Yael Cooper, marketing manager at AVT. “At the same time, they need to implement quality standardization methods across jobs and applications in order to meet brand owners’ expectations for quality and repetitiveness across their SKU portfolio – a challenge that requires a more comprehensive approach to their quality assurance practices.”

Inspection equipment seeks to remedy all these hazards of the trade. Not all products are created equally, either. Some label converters might need a basic form of quality assurance, while others will require more advanced systems. Converters do need some form of quality assurance, though.

“The consequences of not having a robust, 100% inspection process can be severe,” explains Craig Du Mez, global branding, PR and communications manager at Baldwin Vision Systems. “Missing or broken text on a pharmaceutical label can be a matter of life and death. Inaccurate variable data on security print can result in massive costs and litigation. Even if you’re not printing in those high-accountability scenarios, everyone should consider the high cost of returns if you fail to ensure that no defects get into the hands of your customers.”

“I find it difficult to understand how some label printers don’t use inspection,” says Robert Buongiorno, president, BST North America. “In the pharmaceutical world it’s not even an option, since a missing dot can make the difference from a .10% solution to a 10% solution.”

Inspection equipment can encompass several different technologies such as area cameras and line-scan cameras. An area camera would not be classified as true 100% inspection, as these cameras are positioned on a traverse, where they move and zoom to an identified location of the printed web. Meanwhile, line-scan cameras will identify even the smallest defects and notify the press or rewinder operator.

“With 100% inspection, the operator must identify a baseline printed repeat or image, which we call the ‘Golden Image,” notes Buongiorno. “Once this is established, every millimeter of the printed web is compared to the Golden Image, and when something is identified that was not on or part of the Golden Image, it will notify the operator of a defect.”

The latest inspection equipment must also take into account a wide range of technologies and guidelines. “Modern inspection solutions must be able to perform variable print inspections independent of material and format,” says Nico Hagemann, product manager, EyeC. “They must also be easy to integrate into existing workflows and be able to securely process production data from other information systems in use. These systems must be developed and produced in accordance to applicable guidelines and standards, such as ISO 9001, GMP, GAMP 5 and 21 CFR Part 11.”

When thinking about ROI, converters often focus on press speeds and changeovers times. While those are critical, they might forget about the benefits of inspection equipment.

“It doesn’t take much to realize that preventing errors with a strong, data-connected defect management workflow will deliver a very fast return on investment,” adds Du Mez. “Having systems in place to ensure process efficiency and deliver process data will help printers to make informed decisions quickly, and compare historical quality and efficiency information.”

Inspection evolution

Inspection equipment has evolved to meet greater demand and provide enhanced accuracy. According to AVT’s Cooper, the latest 100% automatic inspection systems provide greater resolution, speeds, breadth of features, and improved workflows and automation.

“In the past, there were many low-resolution cameras designed to detect obvious defects,” says Cooper. “Today, labels and the graphics included in them, such as text, barcodes and image details, are becoming smaller, and so is the size of the defect that requires detection. This has created a new standard in the marketplace, and resolution today can get to nearly 50 microns.”

Inspection equipment has also allotted for increased press speeds. Historically, there would be a trade-off between speed and resolution accuracy, but today’s vendors have significantly invested in R&D to ensure both are feasible.

“Our newest model, the fleyeVision 4k color system, shows a 50-80% higher level of performance, meaning maximum inspection speeds,” says Ralf Wirtz, sales manager at AB Graphic International. “This enhanced performance is driven by an OCR and barcode inspection rate four times faster than before, and is linked to hardware with higher performance and software optimization.”

BST North America’s Buongiorno adds that the greatest improvements have come in the form of the software. “The hardware around view camera systems hasn’t changed very much but the software driving it certainly has,” he says. “In 100% inspection, advances in computers, software and hardware have made 100% inspection very reliable for just about any application. Anyone who judges inspection systems with 10-year-old information is very ill-informed.”

Inspection equipment is becoming increasingly automated, especially in the complex market of pharmaceuticals. “In order to meet increased quality requirements and strict customer specifications, such as in the pharmaceutical sector, automated inspection processes are more and more implemented as a standard in production to increase the accuracy and traceability of quality controls,” says EyeC’s Hagemann. “Serialization has brought a lot of challenges, especially for pharmaceutical companies and their suppliers. Modern inspection systems must therefore be able to support pharmaceutical companies and their suppliers with managing the data along the entire supply chain.”

A deep dive

How, exactly, are mistakes spotted? While there are multiple ways to integrate inspection – inline or off-line – into a production environment to accommodate a host of different workflows, the process ultimately relies on vision technologies to compare print images on the web.

Following a print run, the press operator uses the inspection system to take a scan of the web, capturing a single repeat. When the inspection system is located on the rewinder, this can be done immediately upon roll upload. After reviewing the image and assuring it is defect-free, the operator defines the “Golden Image” that BST North America’s Buongiorno referred to earlier.

“Once the system begins inspection, it captures every single repeat on the web and compares it to the master image defined by the operator,” states AVT’s Cooper. “If both images are the same, it means that the printed web is in good quality. However, if the scanned images demonstrate misalignments when compared to the master image, the system will identify these misalignments as defects and will alert the operator on these defects.”

At AB Graphic, image processing is handled in the computer. Here, the labels are continuously recorded and are compared to the previously created master image.

“After starting the machine, the reference images are programmed and the printer tolerance is determined,” says ABG’s Wirtz. “Irrelevant print areas are removed from the inspection process. It is also possible to define special parameters for various sections. When the electronic controller starts, the product is subject to 100% inspection. If an error occurs, the machine stops and the error is brought to a pre-defined position.”

When an error is detected, the type and position of the error is indicated on the touchscreen monitor, allowing the operator to correct the error. Any stored errors are then processed in sequence.

Inspection equipment has been engineered to make the process as easy as possible for operators. “The clear presentation of deviations and key statistical information – such as the defect heatmap – help the operator to understand the location and origin of printing defects easily,” explains EyeC’s Hagemann. “A comprehensive inspection report is automatically produced at the end of each job, offering tracking, analysis and communication support for printers and converters.”

Baldwin’s Du Mez states the way in which converters perceive inspection has to shift, as well. “Advanced 100% inline inspection systems go beyond identifying defects by monitoring your processes to prevent defects from occurring in the first place. It is essential that printers think in terms of eliminating rather than simply finding or minimizing defects,” he says. “Must-have features that make this possible include advanced defect mapping, which allows you to track and manage defects throughout the entire process, make appropriate adjustments in real time, and record defect positions and images for multiple post-press processes.”

According to Baldwin, object-based inspection ensures tighter tolerances and fewer false defects. Operators can define areas of interest for enhanced or reduced levels of inspection. Other important features include automated job setup, dynamic learning, barcode decoding, barcode ANSI/ISO grading, PDF verification, and variable data verification. Connecting data to technologies for monitoring and reporting is also a must-have feature, adds Du Mez.

AB Graphic, which offers fleyeVision for 100% print inspection, sees the technology growing swiftly this year. “2020 will see increased demands on productivity, and also the continued increase in the quality of label printing,” states Wirtz. “We will see continued automation, with JDF and zero-point automatic setup, customization for variable data control, and integrated solutions, with the inspection system controlling complete processes and machines.”

What’s new?

Inspection equipment has been optimized to accommodate numerous trends in the label and packaging space. The equipment must handle growth markets like flexible packaging, e-commerce, variable data, and digital printing in general.

“Tracking and comparing many different production metrics, and sharing data not only between systems on an individual press – but also between multiple facilities – is where the industry is going,” notes Baldwin’s Du Mez. “The technology is already here and is increasingly required by print customers. Adoption of the technology needs to keep pace with rapidly-growing expectations from brand owners.”

“Sustainability regulations will drive new print applications, with thinner materials, boxless products, linerless labels and recyclable materials,” says AVT’s Cooper. “This will require AiS (automatic inspection system) technology to meet new challenges when dealing with new inspection complexities. Shorter runs and an increasing number of SKUs will require inspection technologies to enhance production efficiencies through automation in different production phases, and will drive new solutions in close-loop automation between AiS and the press.”

Suppliers are responding to these new trends with multiple product enhancements.

AB Graphic provides fleyeVision, a 100% print inspection system that has been designed to produce excellent results, prevent costly customer rejections and deliver an enhanced return on investment. The system checks text images for print errors and can recognize and classify all standard barcodes, check data in OCR characters and check braille for errors. Images are recorded by a digital line scan camera with between 1024 and 8196 pixels as a color or a gray-scale picture.

As a standalone system, fleyeVision can be integrated into any press, converting machine or control system – ready to use, customized and upgradeable. The fleyeVision system can also be incorporated with fleyeLink to optimize smart workflows. By using this approach, all defects can be recognized at an early stage during printing, allowing for immediate actions to avoid waste, over-production and reprints.

“fleyeVision operation is simple: all data is entered using symbols on the touchscreen monitor,” says ABG’s Wirtz. “fleyeVision software guides the operator through the necessary inputs, step-by-step. We are the only manufacturer to offer this one-stop technology – providing expert advice to ensure perfectly matched process parameters, customized solutions and all-around global support, installation, training and retrofits.”

AVT offers the Helios AiS product family, which can accommodate all narrow web press and rewinders from 13" wide up to 27". With over 2,000 installations worldwide, the AVT Helios product line is a proven automatic 100% inspection product designed for labels and other narrow web printing applications.

Helios automatically inspects printed labels or packages for defects and imperfections, delivering excellent quality results while eliminating customer rejections. Meanwhile, SolidProof ensures that no critical errors have been overlooked in the print production process, automatically eliminating conversion errors and undetected defects during the prepress stage.

AVT’s inspection equipment offers more than just the detection of inconsistent text or graphics. “The AVT IDEal feature allows inline Delta E color measurements, monitoring any color shifts during the run,” explains Cooper. “When the AiS is placed on the press, the operator will be alerted on these shifts and will be able to apply corrections to the press. Another example is the AVT Barcode and Variable Data Verification, which enables inline decoding and grading of 100% of the barcodes and human readables throughout the run, plus detection of duplication or sequencing issues when dealing with variable data items.”

Baldwin has an extensive range of quality-assurance products to offer label converters. Guardian PQV 100% print inspection provides print quality verification throughout every step of the printing process, enabling operators to get an accurate, data-connected workflow. Guardian RTM Real-Time Monitoring uses a central server to monitor, collect, and display real-time inspection data on a simple, uncluttered dashboard. RTM can simultaneously collect data for multiple presses, jobs, and even across multiple plants. The combination of Guardian PQV and RTM ties together how printers manage their processes, print customers and even employees.

“Based on clear industry trends, Baldwin Vision Systems has focused our research and development efforts on more efficient, accurate, data-connected inspection workflows,” says Du Mez. “We’ve developed new technologies that enable press managers to monitor changes as they happen, and make highly-informed decisions about print quality, defect management and even operator-to-operator performance.”

Additionally, Guardian OLP off-line proofing and inspection verifies that the files used for production – or the beginning-of-run press samples – match the customer-approved master file 100%. By comparing any prepress file or scanned press sample to the customer-approved original in a matter of seconds, advanced software automatically locates and highlights even the smallest of differences in print quality.

BST North America boasts a wide range of products based on converter needs and applications. Focusing on the label and narrow web space, the company offers TubeScan, which has been designed to meet the needs of any label printer, whether they install it on a press or a rewinder.

For wider web, BST North America provides IPQ Check, which like TubeScan, can be customized to suit the needs of its customers. “Now that 100% defect detection is more established in the industry, the biggest trends we see are inspection and verification throughout the complete workflow, Delta E or spectral color inspection, and coating or cold seal inspection,” says BST North America’s Buongiorno. “BST has products and features that will accomplish this in our TubeScan and IPQ product lines.”

EyeC has engineered its inspection systems to help label printers and converters ensure the design, production and delivery of high quality, error-free labels. With the help of EyeC Proofiler Content, errors are detected early during the creation of the artwork file. At the prepress stage, the EyeC Proofiler Graphic and the EyeC Driver or EyeC Workflow Integration help printers to boost security and efficiency.

The integration of prepress inspections into existing workflows triggers inspection procedures automatically, retrieving job data, files and inspection parameters from the workflow system to correct defects before plate production.

“The EyeC Proofiler series offers fast and secure testing of samples in various formats,” says EyeC’s Hagemann. “These systems are used for continuous sample testing during the printing process or to secure outgoing quality controls of label printers. In comparison, the EyeC ProofRunner Web series inspects any type of narrow-to mid-web products, including transparent or metalized labels, flexible materials or films – and performs a 100% print inspection on a press or a rewinder. As a result, label printers and converters can be sure to deliver exactly what their customers expect and avoid customer reclamations or product recalls.”