Steve Katz, Associate Editor07.13.20

The rotary die segment of the label converting industry is influenced by the trends making headlines and affecting the industry as a whole. In particular, the proliferation of digital printing, automation, and the demand for fast turnaround time from converters’ are all playing significant roles in the development of rotary dies and tooling.

Die and tooling manufacturers in the label industry have also had to contend with new requirements and regulations put in place in light of the coronavirus pandemic. Front and center amid this “new normal” are the service and support departments of leading die makers. Label converters rely on these companies as much as any other supplier in order to complete jobs on schedule while maintaining standards for high quality.

L&NW caught up with the label industry’s top rotary die and tooling suppliers to learn about not only what’s new, but also how these “essential” manufacturers are adjusting to evolving label converter needs.

Kocker + Beck

At Kocher + Beck, the continued move towards digital and hybrid printing platforms are playing a key role in the industry’s move as a whole to flexible dies and magnetic cylinders.

“Both digital and hybrid printing require short delivery times, but the same can now be said for other parts of the industry, and so a large area of our focus, development and investment continues to be on offering a high-quality product and service with the delivery times needed within the industry,” says Sarah Napolitano, marketing administrator at Kocher + Beck. “In addition, we’re also seeing a continued movement by converters to thin PET liners, which puts more emphasis on the ability to produce highly accurate tooling, as well as the ability to supply precision adjustable anvil systems, such as the original Kocher + Beck GapMaster.”

The Kocher + Beck family of dies include Universal, 3L, Chrome and GlueX. “All of these dies are manufactured to the tightest industry tolerances out of our Lenexa, KS, USA, facility. Each product is manufactured for specific substrates or applications based on individual converter needs,” Napolitano says.

The Universal is designed for basic converting and low to mid-sized runs. The 3L dies – L stands for laser, as in laser-hardened – feature a long life and will provide up to 50% more cutting life than a Universal die. The Chrome die is suited for the more difficult cuts such as thermal transfer and opaque white ink. And the GlueX is designed with release characteristics to prevent adhesive buildup. “In addition, our GapMaster adjustable anvil is world renowned with over 2,000 installs. Also, our TecScreen (Rotary Screen) product line has become very popular, as has our Rotary Hot Stamp tooling,” Napolitano says.

Most recently, Kocher + Beck introduced its new and improved GlueX anti-adhesive coating for flexible dies, and the company is anticipating several new product developments to be released later in the year.

With regard to the coronavirus pandemic, Napolitano emphasizes that Kocher + Beck’s primary response was and continues to be the health and safety of its employees. In light of this, the company has introduced new policies and procedures that enable all employees to work in a safe environment. “We then turned our attention on making sure we continued to be able to fully support converters by being able to offer the same high level of service and quality of product, so they themselves could focus on supporting the essential supply chain,” she says, adding that throughout the pandemic Kocher + Beck has worked with several converters to help then transition to producing PPE equipment.

“We have had no reduction in staff and are considered a ‘critical business,’ which has resulted in our customers receiving the same product lead time, allowing for proactive scheduling and production on their end,” Napolitano says. “The coronavirus pandemic, for the interim, has changed our manufacturing spacing methods, entry and exits, receiving supplies and servicing our own customers.

“We first implemented social distancing and procedures for our manufacturing team, as well as providing a company statement and guideline for our employees per the state of Kansas and the Federal Government directives,” she adds. “We have been involved with more Zoom and team meetings than in the past with our customers, but have also provided limited availability for on-site service and support to customers on a needs basis for technical support.”

Wilson Manufacturing

For the experts at Wilson Manufacturing, the die and tooling supplier headquartered in St. Louis, MO, flexible dies continue to increase in popularity as technology improvements allow them to handle more difficult-to-cut substrates.

According to Keith Chrisco, VP of sales at Wilson, not only can flexible dies cut more materials than ever before, but some of their “die lives” rival those of traditional solid, engraved dies. “And being that they are approximately 20% of the cost of a solid die, it makes them instantly popular,” he says.

With most traditional label jobs switching to flexible dies, Chrisco points out that a high percentage of Wilson’s solid tools are now deep-engraved, fully hardened tool steel dies. “Manifold style air-eject and vacuum dies are increasing in popularity as converters look for new ways to remove the scrap from their parts,” he explains. “These types of tools are commonly used in the automotive and medical industries. Because of the thick, complex materials that they cut, they require special blade angles and a machine-finished die.”

Chrisco notes that liners commonly used in high-speed automatic applications continue to get thinner and thinner. He says, “Once rare, now .00092” thick polyester liners are very common with both film and paper substrates. These thin liners make the sharpening tolerances of the dies even more critical than in the past. Plus, glassine paper liners are becoming more popular. Being thinner than the traditional 40 lb SCK liners, they also present a challenge for die manufacturers.”

Wilson Manufacturing continues to invest in engraving and sharpening technology to keep up with the short lead times that the label industry now demands. “We will continue to turn around flexible dies within 24 hours and solid dies within 1-3 days,” Chrisco says, adding that Wilson plans to introduce soon an “adjustable anvil” to its product line. “This tool will pay for itself in a short period of time by allowing customers to better utilize their current inventory of dies while also allowing them to keep up with the quick service demands of their customers,” he adds.

Wilson has been very busy the last few months, helping converters not only keep up with their customers’ quick-turn label demands but also in entering new markets. “When the pandemic hit back in March, everyone was scrambling to become ‘essential,’ Chrisco says. “Some of our customers were switching over to hand sanitizer labels and face shields in order to remain essential and to replace some of their business that had dropped off with the stay at home orders. We’ve probably made more face shield rotary dies in the past three months than we have in the past 10 years. Flexo converters were the perfect fit for the immediate high demand of face shields coming from the medical industry. That demand is still as strong today as it was back in April.”

RotoMetrics

Right before the coronavirus pandemic dominated the headlines, one of the biggest narrow web label industry stories of 2020 was the announcement of the merger between RotoMetrics and Maxcess.

Butch Schomber, global innovation manager at Maxcess, comments, “Press speeds are increasing, and synthetic labelstocks and carrier liners are becoming more difficult to print, control and cut. The support market to the converting industry must now also adapt to become more involved in the process. To this end, the joining of Maxcess and RotoMetrics is both logical and timely, as converters today are much different than a decade ago – simple labels with simple copy are no longer the norm. Never before seen converting speeds of 400 fpm and up to 1,000 fpm, print quality demands, as well as registration of print-to-die and between die stations, have now become everyday challenges.”

Because of this new normal in converting, Schomber explains, operators are driven to better control web path and web tensions. “Tolerance control and registration demands are tighter than ever before. As it gets harder to find, hire, and train today’s press operators, the demand for automated quality control systems continues to increase. This is the driving force for combining the market strength of the Maxcess brand of web-handling products and the world’s leading rotary die manufacturer, RotoMetrics.”

Schomber says the focus of the Maxcess/RotoMetrics alliance is to offer unsurpassed assistance in streamlining production methods, reducing downtime and increasing production output. “By becoming an integral partner with the converter/operator to assist in the learning of the best practices of press maintenance, and the understanding of today’s technologies in cutting dies, we continue to lead the industry in innovation and value,” Schomber says. “Our direction is evolving from being a single product supplier to integrating and complementing the overall web handling process. From infeed web control to finished product, Maxcess helps increase throughput by keeping your machine up, running and profitable.”

RotoMetrics recently introduced new products. The RotoMetrics Pin Eject Tool and available PS Switch Pin option offer a new concept in ejection and product placement with a fully mechanical, tight-tolerance solution. The operator can successfully remove slugs without the added noise and cost of air and vacuum. Schomber says, “By reducing waste collection challenges while increasing production speeds, the Pin Eject tools yield an extremely quick ROI. When used to hold or position parts onto the web during stripping, the operator reduces missing sellable product and the addition of secondary operations in label replacement and rewind costs.

RotoMetrics offers the RotoRepel Adhesive Control treatment for the reduction in adhesive buildup. Not only does it allow for presses to run faster, but it reduces shutdowns and the resulting lost production time due to press stoppages required to clean tools. “A converter can quickly justify the value of the investment in RotoRepel. By reducing or eliminating shutdowns, production output is increased and label replacement time due to label lift is considerably reduced,” Schomber explains.

WINK

Among the factors influencing rotary die R&D, Germany-based die manufacturer Wink points to digital printing, automation and digitization, and the increasing use of filmic instead of paper-based facestock and liners.

“In particular, ultra-thin (downgauged) liners are very demanding in terms of diecutting, because they are not compressible like glassine liners, and thus much more sensitive for die strikes,” explains Andre Gysbers, Wink’s marketing director. “To achieve perfect diecutting results, all components need to be in a perfect and absolutely clean condition: the diecutting unit and its cylinders, and of course the cutting tool, as well. We use special engraving and hardening techniques for our SuperCut dies to guarantee minimum tolerances, and we recommend using our SmartGap adjustable anvil roller to gain full control of the cutting depth.”

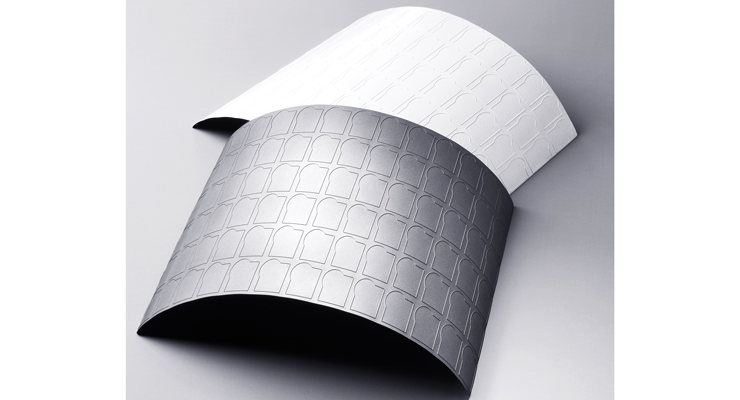

Wink’s SuperCut magnetic flexible dies guarantee minimum tolerances, maximum durability and therefore optimum cost-effectiveness. Gysbers says, “Our SuperCut dies cover all kinds of label and narrow web applications. Each tool is adapted to the customer’s requirements using the latest CNC technology. Special surface treatments significantly increase the service life of the tools. These finishes include laser hardening (especially for cutting-through applications and filmic materials); and our MCR MicroChrome coating for extreme long runs and abrasive materials, as well as various non-stick coatings that keep tools clean from adhesives and ink.”

Different cutting heights, as well as creasing and embossing, can be combined on one die. In addition, Wink offers a wide range of die variants for sheet-fed printing presses (commercial, packaging, IML) and envelope production. All Wink SuperCut dies are cut with laser technology, which not only guarantees perfectly parallel edges but also minimizes the risk of injury.

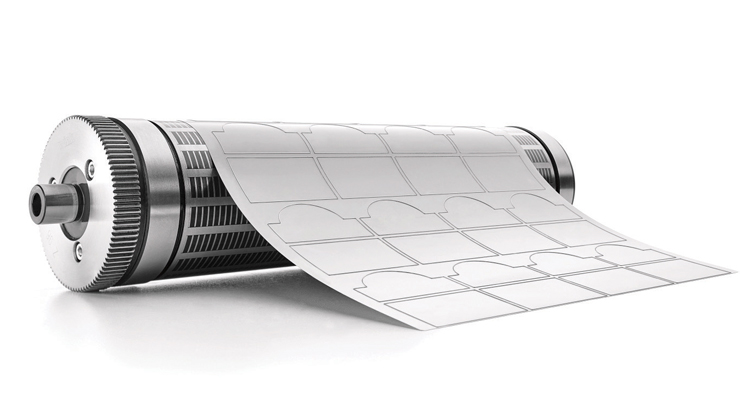

According to Gysbers, next to the basic tooling, adjustable anvils are crucial to optimize diecutting efficiency. He says, “The small gap between the magnetic and anvil cylinder, also known as ‘clearance’ or ‘undercut,’ plays a crucial role in label converting. In combination with the thickness and composition of the liner material, the gap dimension determines the optimum height of the flexible die. The smallest deviations decide on success and failure in diecutting, as changes in the gap size have a negative impact on the diecut quality.”

Wink’s SmartGap adjustable anvil system features a precise dual-side gap adjustment and a stable construction, which ensures running smoothness even at the highest speeds. “Cutting-through (metal-to-metal) and backside cuttings are likewise possible without difficulty,” Gysbers explains. “The cylinder gap – and thus the cutting depth – can be adapted very precisely to different facestocks and liner thicknesses, so that even with demanding applications and ultra-thin liners optimum

diecutting results are achieved.”

Wink offers multiple SmartGap options, with Advance, Touch and the new AutoControl version, which is equipped with a sensor bar and is designed specifically for Industry 4.0.

Kala, a Utah-based labels and packaging manufacturer, has announced that Wink has received Kala’s “Outstanding Vendor Award.” The award recognizes Wink for its performance as a tooling supplier and partner that provides excellent service, premium quality products, fast delivery and a very attractive price-performance ratio.

“The award also proves that Wink US has established itself in the North American market and has grown at an above-average rate, particularly in the past year,” says Sabine Pund, Wink sales director for the Americas. “With our performance and service package, we are helping to ensure that our customers also grow with us. This is a fantastic feeling.”

Ann-Kathrin Schippers, Wink senior customer relations manager and Wink’s sales representative for Kala, says, “Working with Kala and the Kala people is really great and fun. Especially because Kala is a trendsetting, dynamic company and shares our core philosophy – the whole Wink team is very proud to call Kala our customer and partner.”

Nikki Johnson, Kala’s EVP, revenue, comments, “Congratulations to Wink US, the recipient of the Kala Outstanding Vendor Award 2019. Wink has helped Kala save money and meet customer demands by giving extremely fast turnarounds for tooling, married with consistent quality and a collaborative spirit as we work to solve problems together. We truly appreciate the partnership.”

Die and tooling manufacturers in the label industry have also had to contend with new requirements and regulations put in place in light of the coronavirus pandemic. Front and center amid this “new normal” are the service and support departments of leading die makers. Label converters rely on these companies as much as any other supplier in order to complete jobs on schedule while maintaining standards for high quality.

L&NW caught up with the label industry’s top rotary die and tooling suppliers to learn about not only what’s new, but also how these “essential” manufacturers are adjusting to evolving label converter needs.

Kocker + Beck

At Kocher + Beck, the continued move towards digital and hybrid printing platforms are playing a key role in the industry’s move as a whole to flexible dies and magnetic cylinders.

“Both digital and hybrid printing require short delivery times, but the same can now be said for other parts of the industry, and so a large area of our focus, development and investment continues to be on offering a high-quality product and service with the delivery times needed within the industry,” says Sarah Napolitano, marketing administrator at Kocher + Beck. “In addition, we’re also seeing a continued movement by converters to thin PET liners, which puts more emphasis on the ability to produce highly accurate tooling, as well as the ability to supply precision adjustable anvil systems, such as the original Kocher + Beck GapMaster.”

The Kocher + Beck family of dies include Universal, 3L, Chrome and GlueX. “All of these dies are manufactured to the tightest industry tolerances out of our Lenexa, KS, USA, facility. Each product is manufactured for specific substrates or applications based on individual converter needs,” Napolitano says.

The Universal is designed for basic converting and low to mid-sized runs. The 3L dies – L stands for laser, as in laser-hardened – feature a long life and will provide up to 50% more cutting life than a Universal die. The Chrome die is suited for the more difficult cuts such as thermal transfer and opaque white ink. And the GlueX is designed with release characteristics to prevent adhesive buildup. “In addition, our GapMaster adjustable anvil is world renowned with over 2,000 installs. Also, our TecScreen (Rotary Screen) product line has become very popular, as has our Rotary Hot Stamp tooling,” Napolitano says.

Most recently, Kocher + Beck introduced its new and improved GlueX anti-adhesive coating for flexible dies, and the company is anticipating several new product developments to be released later in the year.

With regard to the coronavirus pandemic, Napolitano emphasizes that Kocher + Beck’s primary response was and continues to be the health and safety of its employees. In light of this, the company has introduced new policies and procedures that enable all employees to work in a safe environment. “We then turned our attention on making sure we continued to be able to fully support converters by being able to offer the same high level of service and quality of product, so they themselves could focus on supporting the essential supply chain,” she says, adding that throughout the pandemic Kocher + Beck has worked with several converters to help then transition to producing PPE equipment.

“We have had no reduction in staff and are considered a ‘critical business,’ which has resulted in our customers receiving the same product lead time, allowing for proactive scheduling and production on their end,” Napolitano says. “The coronavirus pandemic, for the interim, has changed our manufacturing spacing methods, entry and exits, receiving supplies and servicing our own customers.

“We first implemented social distancing and procedures for our manufacturing team, as well as providing a company statement and guideline for our employees per the state of Kansas and the Federal Government directives,” she adds. “We have been involved with more Zoom and team meetings than in the past with our customers, but have also provided limited availability for on-site service and support to customers on a needs basis for technical support.”

Wilson Manufacturing

For the experts at Wilson Manufacturing, the die and tooling supplier headquartered in St. Louis, MO, flexible dies continue to increase in popularity as technology improvements allow them to handle more difficult-to-cut substrates.

According to Keith Chrisco, VP of sales at Wilson, not only can flexible dies cut more materials than ever before, but some of their “die lives” rival those of traditional solid, engraved dies. “And being that they are approximately 20% of the cost of a solid die, it makes them instantly popular,” he says.

With most traditional label jobs switching to flexible dies, Chrisco points out that a high percentage of Wilson’s solid tools are now deep-engraved, fully hardened tool steel dies. “Manifold style air-eject and vacuum dies are increasing in popularity as converters look for new ways to remove the scrap from their parts,” he explains. “These types of tools are commonly used in the automotive and medical industries. Because of the thick, complex materials that they cut, they require special blade angles and a machine-finished die.”

Chrisco notes that liners commonly used in high-speed automatic applications continue to get thinner and thinner. He says, “Once rare, now .00092” thick polyester liners are very common with both film and paper substrates. These thin liners make the sharpening tolerances of the dies even more critical than in the past. Plus, glassine paper liners are becoming more popular. Being thinner than the traditional 40 lb SCK liners, they also present a challenge for die manufacturers.”

Wilson Manufacturing continues to invest in engraving and sharpening technology to keep up with the short lead times that the label industry now demands. “We will continue to turn around flexible dies within 24 hours and solid dies within 1-3 days,” Chrisco says, adding that Wilson plans to introduce soon an “adjustable anvil” to its product line. “This tool will pay for itself in a short period of time by allowing customers to better utilize their current inventory of dies while also allowing them to keep up with the quick service demands of their customers,” he adds.

Wilson has been very busy the last few months, helping converters not only keep up with their customers’ quick-turn label demands but also in entering new markets. “When the pandemic hit back in March, everyone was scrambling to become ‘essential,’ Chrisco says. “Some of our customers were switching over to hand sanitizer labels and face shields in order to remain essential and to replace some of their business that had dropped off with the stay at home orders. We’ve probably made more face shield rotary dies in the past three months than we have in the past 10 years. Flexo converters were the perfect fit for the immediate high demand of face shields coming from the medical industry. That demand is still as strong today as it was back in April.”

RotoMetrics

Right before the coronavirus pandemic dominated the headlines, one of the biggest narrow web label industry stories of 2020 was the announcement of the merger between RotoMetrics and Maxcess.

Butch Schomber, global innovation manager at Maxcess, comments, “Press speeds are increasing, and synthetic labelstocks and carrier liners are becoming more difficult to print, control and cut. The support market to the converting industry must now also adapt to become more involved in the process. To this end, the joining of Maxcess and RotoMetrics is both logical and timely, as converters today are much different than a decade ago – simple labels with simple copy are no longer the norm. Never before seen converting speeds of 400 fpm and up to 1,000 fpm, print quality demands, as well as registration of print-to-die and between die stations, have now become everyday challenges.”

Because of this new normal in converting, Schomber explains, operators are driven to better control web path and web tensions. “Tolerance control and registration demands are tighter than ever before. As it gets harder to find, hire, and train today’s press operators, the demand for automated quality control systems continues to increase. This is the driving force for combining the market strength of the Maxcess brand of web-handling products and the world’s leading rotary die manufacturer, RotoMetrics.”

Schomber says the focus of the Maxcess/RotoMetrics alliance is to offer unsurpassed assistance in streamlining production methods, reducing downtime and increasing production output. “By becoming an integral partner with the converter/operator to assist in the learning of the best practices of press maintenance, and the understanding of today’s technologies in cutting dies, we continue to lead the industry in innovation and value,” Schomber says. “Our direction is evolving from being a single product supplier to integrating and complementing the overall web handling process. From infeed web control to finished product, Maxcess helps increase throughput by keeping your machine up, running and profitable.”

RotoMetrics recently introduced new products. The RotoMetrics Pin Eject Tool and available PS Switch Pin option offer a new concept in ejection and product placement with a fully mechanical, tight-tolerance solution. The operator can successfully remove slugs without the added noise and cost of air and vacuum. Schomber says, “By reducing waste collection challenges while increasing production speeds, the Pin Eject tools yield an extremely quick ROI. When used to hold or position parts onto the web during stripping, the operator reduces missing sellable product and the addition of secondary operations in label replacement and rewind costs.

RotoMetrics offers the RotoRepel Adhesive Control treatment for the reduction in adhesive buildup. Not only does it allow for presses to run faster, but it reduces shutdowns and the resulting lost production time due to press stoppages required to clean tools. “A converter can quickly justify the value of the investment in RotoRepel. By reducing or eliminating shutdowns, production output is increased and label replacement time due to label lift is considerably reduced,” Schomber explains.

WINK

Among the factors influencing rotary die R&D, Germany-based die manufacturer Wink points to digital printing, automation and digitization, and the increasing use of filmic instead of paper-based facestock and liners.

“In particular, ultra-thin (downgauged) liners are very demanding in terms of diecutting, because they are not compressible like glassine liners, and thus much more sensitive for die strikes,” explains Andre Gysbers, Wink’s marketing director. “To achieve perfect diecutting results, all components need to be in a perfect and absolutely clean condition: the diecutting unit and its cylinders, and of course the cutting tool, as well. We use special engraving and hardening techniques for our SuperCut dies to guarantee minimum tolerances, and we recommend using our SmartGap adjustable anvil roller to gain full control of the cutting depth.”

Wink’s SuperCut magnetic flexible dies guarantee minimum tolerances, maximum durability and therefore optimum cost-effectiveness. Gysbers says, “Our SuperCut dies cover all kinds of label and narrow web applications. Each tool is adapted to the customer’s requirements using the latest CNC technology. Special surface treatments significantly increase the service life of the tools. These finishes include laser hardening (especially for cutting-through applications and filmic materials); and our MCR MicroChrome coating for extreme long runs and abrasive materials, as well as various non-stick coatings that keep tools clean from adhesives and ink.”

Different cutting heights, as well as creasing and embossing, can be combined on one die. In addition, Wink offers a wide range of die variants for sheet-fed printing presses (commercial, packaging, IML) and envelope production. All Wink SuperCut dies are cut with laser technology, which not only guarantees perfectly parallel edges but also minimizes the risk of injury.

According to Gysbers, next to the basic tooling, adjustable anvils are crucial to optimize diecutting efficiency. He says, “The small gap between the magnetic and anvil cylinder, also known as ‘clearance’ or ‘undercut,’ plays a crucial role in label converting. In combination with the thickness and composition of the liner material, the gap dimension determines the optimum height of the flexible die. The smallest deviations decide on success and failure in diecutting, as changes in the gap size have a negative impact on the diecut quality.”

Wink’s SmartGap adjustable anvil system features a precise dual-side gap adjustment and a stable construction, which ensures running smoothness even at the highest speeds. “Cutting-through (metal-to-metal) and backside cuttings are likewise possible without difficulty,” Gysbers explains. “The cylinder gap – and thus the cutting depth – can be adapted very precisely to different facestocks and liner thicknesses, so that even with demanding applications and ultra-thin liners optimum

diecutting results are achieved.”

Wink offers multiple SmartGap options, with Advance, Touch and the new AutoControl version, which is equipped with a sensor bar and is designed specifically for Industry 4.0.

Kala, a Utah-based labels and packaging manufacturer, has announced that Wink has received Kala’s “Outstanding Vendor Award.” The award recognizes Wink for its performance as a tooling supplier and partner that provides excellent service, premium quality products, fast delivery and a very attractive price-performance ratio.

“The award also proves that Wink US has established itself in the North American market and has grown at an above-average rate, particularly in the past year,” says Sabine Pund, Wink sales director for the Americas. “With our performance and service package, we are helping to ensure that our customers also grow with us. This is a fantastic feeling.”

Ann-Kathrin Schippers, Wink senior customer relations manager and Wink’s sales representative for Kala, says, “Working with Kala and the Kala people is really great and fun. Especially because Kala is a trendsetting, dynamic company and shares our core philosophy – the whole Wink team is very proud to call Kala our customer and partner.”

Nikki Johnson, Kala’s EVP, revenue, comments, “Congratulations to Wink US, the recipient of the Kala Outstanding Vendor Award 2019. Wink has helped Kala save money and meet customer demands by giving extremely fast turnarounds for tooling, married with consistent quality and a collaborative spirit as we work to solve problems together. We truly appreciate the partnership.”