Steve Katz, Contributing Editor01.28.21

When two or more surfaces are in close contact and then separated, the phenomenon known as static electricity occurs. In the label converting workflow, with rolls of stock becoming unwound and processed through a web, two surfaces are perpetually contacting and separating, thus, static is a constant issue for label manufacturers, and something that must be kept in check. If static is not addressed, the resulting contamination causes print defects, lost jobs, and an increase in labor and revenue.

What follows are descriptions of some of the label industry’s newest and most effective static control products, as well as leading supplier thoughts on overcoming static challenges within the current state of the label converting industry.

Simco-Ion

“Brands are increasingly reliant on labels and packaging to help them stand out in a crowded marketplace,” says Kevin Coldren, sales and business development manager for Simco-Ion. “And efficient processing of high-quality labels can be defeated by poor static management.”

According to Coldren, contamination has always been one of the greatest barriers to achieving high-quality labels for converters. He explains, “Dust and other organic material are present in the air and can be bound to the substrate by static charge. If this contamination remains on the material before converting, the material is compromised throughout the entire process. High output, active static bars continue to eliminate static in challenging, high-speed environments.”

Coldren points out that converters today understand the necessity for intelligent, reliable and effective static control to meet their evolving needs, while overcoming static charges that create process inefficiencies leading to downtime and waste. “Increasingly,” he says, “they would like their static control needs met without the use of compressed air. Thus, in designing our new IQ Easy Low Profile (LP) static bar, we understood that in 2021 the converting market requires a small (19mm tall), powerful (integrated 24-volt power supply can drive 215cm of ionizing pins) and intelligent static bar. For label converters, the power supply design is especially important. You need enough power to overcome environmental pin contamination and maintain high ion output – and the intelligence to react to changing circumstances and substrates.The Easy LP does it all.”

Simco-Ion’s customers have come to rely on today’s newest systems that monitor ionization, record data and signal potential problems. The future trend, Coldren says, will continue with more communication and data collection. “Systems of tomorrow may focus on predictive elements that enable possible problems to be addressed before it becomes an actual problem that impacts production. These types of intelligent products will communicate in real time, thus satisfying customer requirements for Industry 4.0 and demands of the future,” says Coldren, adding, “Active systems have seen significant advances in the last few years, and current generation active systems can adjust, display and record ionizer status, ionizer output and in-process static charge levels. Faced with the quality, safety and general production issues that static charges can create, active systems can provide the intelligence necessary to manage and record performance which in turn keeps production running as quickly and safely as possible.”

Simco-Ion recently developed its IQ Power System, which allows customers to maintain Industry 4.0 standards. The core of the IQ Power System is the Control Station, which includes a full color touchscreen designed with an intuitive interface and user-friendly features that help users monitor and control the system globally or by device.

“The Control Station provides information you can rely on, including system name, status, output and current. Also shown are upstream and sensor bar data for operator safety and verification,”

Coldren explains.

The Control Station also offers upstream and downstream charge readings when used in conjunction with the IQ Easy Sensor Bar. Using the Sensor Bar allows the output of the power supply to be adjusted dynamically, resulting in optimized static neutralization. An optional web speed encoder can provide automatic web speed readings, if desired. It uses several relay output choices to suit desired alarm methods for streamlined operation and maximum productivity. Global relays, as well as individual IQ Power BPS power supply relays, are accessible for both warning and fault user selectable alarm thresholds.

With the most recent launch of the IQ Easy LP Bar Static Neutralizing Bar, Simco-Ion has increased its product offering to the industry. Coldren concludes, “This revolutionary new bar is engineered to be the ‘one bar that does it all.’ This compact, low profile bar is not only balanced and optimized for neutralizing on moving webs at close distances, but it also has pulse mode functionality for non-web distance neutralization. It is the one bar that can neutralize in any application.”

Meech international

“There are several different static related issues found at label converters,” states Matt Fyffe, vice president and general manager at Meech International. “Traditionally, a majority of these problems deal with print quality. Static electricity attracts dust and debris to the web, which can result in poor quality and high reject rates.”

With an increasing number of label converters going digital and also printing on film and coated stocks, Fyffe is noticing much higher demand for static control products. He says, “Digital printheads are especially susceptible to static issues. A high static charge on the web can actually repel the ink droplets from the digital printer. The repelled ink droplets will then gum up the printhead and will require more frequent cleaning. In extreme cases, high charges can actually cause permanent damage to the printheads.”

According to Fyffe, label converters today must be more adaptable and quick to change in order to compete. “This means they need to be able to print and convert various substrates at a moment’s notice with quick changeover. Therefore, they need static control and web cleaning systems that can be used on multiple substrates without requiring time to reset the controls.”

The systems provided by Meech require very little, if any, service and input from the operators, Fyffe says, adding, “They adjust themselves to maintain optimum performance.”

Fyffe points out that tacky roller web cleaners are the most popular form of web cleaning systems in the label converter market as they are fairly inexpensive and easy to install. “However,” he says, “there is a consumable cost involved, and they require regular maintenance and constant operator supervision.”

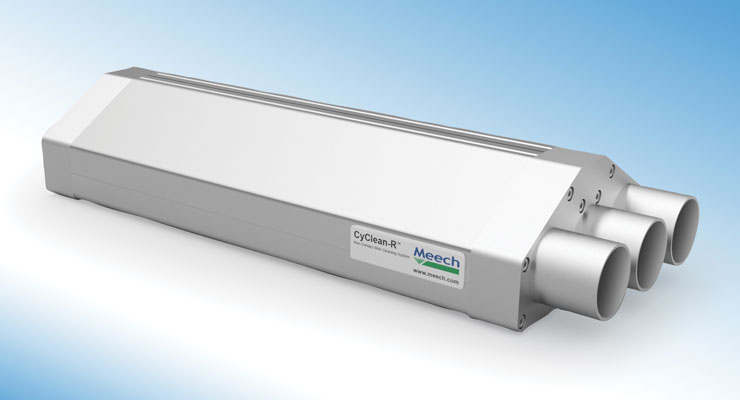

Meech has recently developed a fan driven non-contact web cleaning system for the narrow web industry as an upgrade to the tacky roller systems of old. The CyClean-R system from Meech boasts several advantages over tacky rollers, including no ongoing consumable costs; very little maintenance required; operation does not affect the web path; the ability to run at very low tensions; easy to install over an existing roller; flexibility to run on any substrate, including paper, film, or foil; and full press integration.

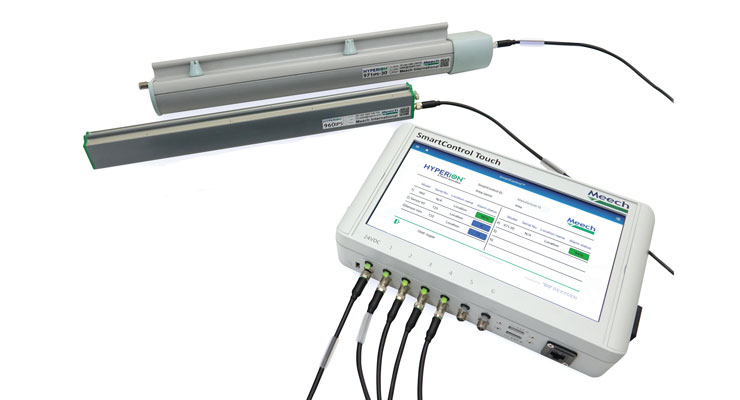

The SmartControl Touch is a recently launched static control product from Meech that Fyffe is very excited about. SmartControl Touch allows the user to monitor, control and adjust the performance of multiple connected comparable Hyperion ionizing bars and sensors via the integrated touchscreen or remotely via a mobile phone, tablet, or remote desktop.

“This means that at all times, the performance of the connected equipment may be monitored and optimized to achieve the best results, according to the application,” Fyffe says. “The ionizing equipment’s performance is easily tracked by the SmartControl Touch, which uses Meech’s Ion Current Monitoring Technology, allowing the user to monitor the ionizing performance. With the ability to connect six bars directly and an additional 24 bars using two expansion units (sold separately), SmartControl delivers exceptional central control.”

In light of the pandemic, Meech actually saw an uptick in business in 2020. Says Fyffe, “Surprisingly enough, the pandemic has had very little impact on our business. As the bulk of our products and services are used by essential businesses, we saw no drop in demand. If anything, we are further ahead compared to 2019. Our engineering group was able to devote uninterrupted time and energy into new product development, and we’ll be launching several new products and improvements in 2021.”

TAKK Industries

Terrance Clark, sales manager for TAKK Industries, notes there are several problems that static electricity can cause in label converting, chief among them are print quality related defects. He says, “Static electricity is prone to result in repulsion or attraction of ink to a substrate’s surface. In the case of repulsion of ink droplets or dots, a printer likely would see ink smears, fuzzy characters or print hickies that negatively impact production of high-quality printed labels.”

When it comes to the label industry’s major trend – digital printing – Clark points out, “Conversely, static electricity attraction effects in digital printing can cause ink to expand out in what should be white space of a label or cause drop out of incorrect colors during printing from the digital printhead. These static issues create unacceptable prints, causing wasted production time, ink and substrates, and considerable labor and re-work costs.”

Clark emphasizes that label converters continue to be laser focused on producing the best products with improved profit margins. “In pursuit of this goal, many savvy printers are looking for next generation static control technologies,” he says. “These automatically adjusting ionizers (static eliminators) have very high capabilities and versatility to match the unique, ever-evolving parameters that today’s leading label converters must have to deliver and meet their customers’ expectations.”

To meet these evolving converter needs, TAKK Industries brought to market its “Reactive Intelligence” static elimination technology in its NEOS series static eliminators.

“The NEOS, in addition to its exceptional static elimination capabilities, also continuously adjusts both its static elimination power and ion output to match the exact needs of the application,” Clark explains. “It can be installed at short or exceptionally long distances of up to 60 plus inches to accommodate changing diameter rolls or challenging space situations. The NEOS’s technology easily dovetails with today’s leading-edge PLC/HMI interfaces for instant status information about the unit’s operation in addition to local status indicators on the NEOS bar.”

According to Clark, TAKK’s NEOS Series Static Control Technology is fast becoming the comprehensive, fool-proof static control solution that meets the demands of label converters. “The NEOS Series is a new evolution in smart static controls, providing exceptional capabilities such as using ‘Reactive Intelligence’ that detects and delivers the exact amount of ionization required, thus maintaining consistent control of static.”

Models from the NEOS series eliminate static charges at distances up to 60" and speeds up to 4,500 fpm without air.

TAKK also offers a dynamic range of powerful 24 VDC static control technologies that cover virtually all processes of label printing and converting operations. Incorporating built-in power supplies powered by 24 VDC and LED indicators that continuously provide users with local or remote working status of the ionizer bar, these products ensure continuous positive control of static electricity.

TAKK recently introduced its 3024 Compact and 3024 Ultra DC Static Eliminators. These units are specially designed and suited for both OEM machinery and end users where there are tight constraints for mounting on digital or conventional label presses, tabletop winders, and related production machinery requiring high performance static elimination performance in a compact size. The 3024 has a built-in power supply and LED indicators that provide local and remote status for the ionizer bar. The 3024 Ultra and Compact are highly suited for narrow web labels, sleeves and tapes.

TAKK has been a supplier in the static control industry since 1943 with decades of accumulated expertise. Clark concludes, “This has made TAKK a natural choice for many companies that are producing products and materials for the COVID-19 pandemic, including personal protection equipment (PPE) or performing medical supply packaging and labeling. TAKK static control and static generation technologies have had definite, substantive benefit to helping companies in addressing the challenges and opportunities that the pandemic has created.”

Meech has formally unveiled its newest remote monitoring solution, SmartControl Touch. An advancement of Meech’s SmartControl device - the new unit allows users to monitor, control and adjust the performance of multiple connected Hyperion ionizing bars and sensors via an integrated touchscreen; or remotely via a mobile phone, tablet, or desktop.

“SmartControl Touch has been designed in line with the growth of Industry 4.0 technology, which is helping businesses maximise productivity and quality of output,” says Adam Battrick, sales director at Meech International. “It’s an advanced monitoring and controlling device that includes a 10" integrated touchscreen and data logging, as well as being compatible with Meech voltage and distance sensors – so monitoring the performance of our Hyperion static control bars is easier than ever before.”

SmartControl Touch has the capacity to connect up to six devices, with an additional 12 per expansion unit. In total, SmartControl Touch can monitor and control up to 30 devices. Battrick continues: “Our customers use a variety of our static control bars from our Hyperion range, so giving them maximum visibility and control of their performance via a single device allows for increased productivity and quality output on production lines.”

Fast and easy installation means SmartControl Touch can fit in seamlessly with operations. It is simple to use for operators, offering a user-friendly interface that requires minimal training. Changes can be made quickly and easily, and with voltage and distance sensor compatibility, SmartControl Touch offers more accurate neutralization of all charges on materials. Data logging also provides graphic representation of performance, which can be exported for additional analysis.

“Like all Meech products, SmartControl Touch has been designed in response to feedback from the industry,” concludes Battrick. “We work closely with our customers to understand their needs and how we can better help them to improve their quality control and productivity. Static charges have always been a threat to productivity for many manufacturing and converting sectors, and SmartControl Touch is yet another innovation from Meech designed to keep unwanted static under control and ensure smooth-running and safe production lines.”

What follows are descriptions of some of the label industry’s newest and most effective static control products, as well as leading supplier thoughts on overcoming static challenges within the current state of the label converting industry.

Simco-Ion

“Brands are increasingly reliant on labels and packaging to help them stand out in a crowded marketplace,” says Kevin Coldren, sales and business development manager for Simco-Ion. “And efficient processing of high-quality labels can be defeated by poor static management.”

According to Coldren, contamination has always been one of the greatest barriers to achieving high-quality labels for converters. He explains, “Dust and other organic material are present in the air and can be bound to the substrate by static charge. If this contamination remains on the material before converting, the material is compromised throughout the entire process. High output, active static bars continue to eliminate static in challenging, high-speed environments.”

Coldren points out that converters today understand the necessity for intelligent, reliable and effective static control to meet their evolving needs, while overcoming static charges that create process inefficiencies leading to downtime and waste. “Increasingly,” he says, “they would like their static control needs met without the use of compressed air. Thus, in designing our new IQ Easy Low Profile (LP) static bar, we understood that in 2021 the converting market requires a small (19mm tall), powerful (integrated 24-volt power supply can drive 215cm of ionizing pins) and intelligent static bar. For label converters, the power supply design is especially important. You need enough power to overcome environmental pin contamination and maintain high ion output – and the intelligence to react to changing circumstances and substrates.The Easy LP does it all.”

Simco-Ion’s customers have come to rely on today’s newest systems that monitor ionization, record data and signal potential problems. The future trend, Coldren says, will continue with more communication and data collection. “Systems of tomorrow may focus on predictive elements that enable possible problems to be addressed before it becomes an actual problem that impacts production. These types of intelligent products will communicate in real time, thus satisfying customer requirements for Industry 4.0 and demands of the future,” says Coldren, adding, “Active systems have seen significant advances in the last few years, and current generation active systems can adjust, display and record ionizer status, ionizer output and in-process static charge levels. Faced with the quality, safety and general production issues that static charges can create, active systems can provide the intelligence necessary to manage and record performance which in turn keeps production running as quickly and safely as possible.”

Simco-Ion recently developed its IQ Power System, which allows customers to maintain Industry 4.0 standards. The core of the IQ Power System is the Control Station, which includes a full color touchscreen designed with an intuitive interface and user-friendly features that help users monitor and control the system globally or by device.

“The Control Station provides information you can rely on, including system name, status, output and current. Also shown are upstream and sensor bar data for operator safety and verification,”

Coldren explains.

The Control Station also offers upstream and downstream charge readings when used in conjunction with the IQ Easy Sensor Bar. Using the Sensor Bar allows the output of the power supply to be adjusted dynamically, resulting in optimized static neutralization. An optional web speed encoder can provide automatic web speed readings, if desired. It uses several relay output choices to suit desired alarm methods for streamlined operation and maximum productivity. Global relays, as well as individual IQ Power BPS power supply relays, are accessible for both warning and fault user selectable alarm thresholds.

With the most recent launch of the IQ Easy LP Bar Static Neutralizing Bar, Simco-Ion has increased its product offering to the industry. Coldren concludes, “This revolutionary new bar is engineered to be the ‘one bar that does it all.’ This compact, low profile bar is not only balanced and optimized for neutralizing on moving webs at close distances, but it also has pulse mode functionality for non-web distance neutralization. It is the one bar that can neutralize in any application.”

Meech international

“There are several different static related issues found at label converters,” states Matt Fyffe, vice president and general manager at Meech International. “Traditionally, a majority of these problems deal with print quality. Static electricity attracts dust and debris to the web, which can result in poor quality and high reject rates.”

With an increasing number of label converters going digital and also printing on film and coated stocks, Fyffe is noticing much higher demand for static control products. He says, “Digital printheads are especially susceptible to static issues. A high static charge on the web can actually repel the ink droplets from the digital printer. The repelled ink droplets will then gum up the printhead and will require more frequent cleaning. In extreme cases, high charges can actually cause permanent damage to the printheads.”

According to Fyffe, label converters today must be more adaptable and quick to change in order to compete. “This means they need to be able to print and convert various substrates at a moment’s notice with quick changeover. Therefore, they need static control and web cleaning systems that can be used on multiple substrates without requiring time to reset the controls.”

The systems provided by Meech require very little, if any, service and input from the operators, Fyffe says, adding, “They adjust themselves to maintain optimum performance.”

Fyffe points out that tacky roller web cleaners are the most popular form of web cleaning systems in the label converter market as they are fairly inexpensive and easy to install. “However,” he says, “there is a consumable cost involved, and they require regular maintenance and constant operator supervision.”

Meech has recently developed a fan driven non-contact web cleaning system for the narrow web industry as an upgrade to the tacky roller systems of old. The CyClean-R system from Meech boasts several advantages over tacky rollers, including no ongoing consumable costs; very little maintenance required; operation does not affect the web path; the ability to run at very low tensions; easy to install over an existing roller; flexibility to run on any substrate, including paper, film, or foil; and full press integration.

The SmartControl Touch is a recently launched static control product from Meech that Fyffe is very excited about. SmartControl Touch allows the user to monitor, control and adjust the performance of multiple connected comparable Hyperion ionizing bars and sensors via the integrated touchscreen or remotely via a mobile phone, tablet, or remote desktop.

“This means that at all times, the performance of the connected equipment may be monitored and optimized to achieve the best results, according to the application,” Fyffe says. “The ionizing equipment’s performance is easily tracked by the SmartControl Touch, which uses Meech’s Ion Current Monitoring Technology, allowing the user to monitor the ionizing performance. With the ability to connect six bars directly and an additional 24 bars using two expansion units (sold separately), SmartControl delivers exceptional central control.”

In light of the pandemic, Meech actually saw an uptick in business in 2020. Says Fyffe, “Surprisingly enough, the pandemic has had very little impact on our business. As the bulk of our products and services are used by essential businesses, we saw no drop in demand. If anything, we are further ahead compared to 2019. Our engineering group was able to devote uninterrupted time and energy into new product development, and we’ll be launching several new products and improvements in 2021.”

TAKK Industries

Terrance Clark, sales manager for TAKK Industries, notes there are several problems that static electricity can cause in label converting, chief among them are print quality related defects. He says, “Static electricity is prone to result in repulsion or attraction of ink to a substrate’s surface. In the case of repulsion of ink droplets or dots, a printer likely would see ink smears, fuzzy characters or print hickies that negatively impact production of high-quality printed labels.”

When it comes to the label industry’s major trend – digital printing – Clark points out, “Conversely, static electricity attraction effects in digital printing can cause ink to expand out in what should be white space of a label or cause drop out of incorrect colors during printing from the digital printhead. These static issues create unacceptable prints, causing wasted production time, ink and substrates, and considerable labor and re-work costs.”

Clark emphasizes that label converters continue to be laser focused on producing the best products with improved profit margins. “In pursuit of this goal, many savvy printers are looking for next generation static control technologies,” he says. “These automatically adjusting ionizers (static eliminators) have very high capabilities and versatility to match the unique, ever-evolving parameters that today’s leading label converters must have to deliver and meet their customers’ expectations.”

To meet these evolving converter needs, TAKK Industries brought to market its “Reactive Intelligence” static elimination technology in its NEOS series static eliminators.

“The NEOS, in addition to its exceptional static elimination capabilities, also continuously adjusts both its static elimination power and ion output to match the exact needs of the application,” Clark explains. “It can be installed at short or exceptionally long distances of up to 60 plus inches to accommodate changing diameter rolls or challenging space situations. The NEOS’s technology easily dovetails with today’s leading-edge PLC/HMI interfaces for instant status information about the unit’s operation in addition to local status indicators on the NEOS bar.”

According to Clark, TAKK’s NEOS Series Static Control Technology is fast becoming the comprehensive, fool-proof static control solution that meets the demands of label converters. “The NEOS Series is a new evolution in smart static controls, providing exceptional capabilities such as using ‘Reactive Intelligence’ that detects and delivers the exact amount of ionization required, thus maintaining consistent control of static.”

Models from the NEOS series eliminate static charges at distances up to 60" and speeds up to 4,500 fpm without air.

TAKK also offers a dynamic range of powerful 24 VDC static control technologies that cover virtually all processes of label printing and converting operations. Incorporating built-in power supplies powered by 24 VDC and LED indicators that continuously provide users with local or remote working status of the ionizer bar, these products ensure continuous positive control of static electricity.

TAKK recently introduced its 3024 Compact and 3024 Ultra DC Static Eliminators. These units are specially designed and suited for both OEM machinery and end users where there are tight constraints for mounting on digital or conventional label presses, tabletop winders, and related production machinery requiring high performance static elimination performance in a compact size. The 3024 has a built-in power supply and LED indicators that provide local and remote status for the ionizer bar. The 3024 Ultra and Compact are highly suited for narrow web labels, sleeves and tapes.

TAKK has been a supplier in the static control industry since 1943 with decades of accumulated expertise. Clark concludes, “This has made TAKK a natural choice for many companies that are producing products and materials for the COVID-19 pandemic, including personal protection equipment (PPE) or performing medical supply packaging and labeling. TAKK static control and static generation technologies have had definite, substantive benefit to helping companies in addressing the challenges and opportunities that the pandemic has created.”

Meech has formally unveiled its newest remote monitoring solution, SmartControl Touch. An advancement of Meech’s SmartControl device - the new unit allows users to monitor, control and adjust the performance of multiple connected Hyperion ionizing bars and sensors via an integrated touchscreen; or remotely via a mobile phone, tablet, or desktop.

“SmartControl Touch has been designed in line with the growth of Industry 4.0 technology, which is helping businesses maximise productivity and quality of output,” says Adam Battrick, sales director at Meech International. “It’s an advanced monitoring and controlling device that includes a 10" integrated touchscreen and data logging, as well as being compatible with Meech voltage and distance sensors – so monitoring the performance of our Hyperion static control bars is easier than ever before.”

SmartControl Touch has the capacity to connect up to six devices, with an additional 12 per expansion unit. In total, SmartControl Touch can monitor and control up to 30 devices. Battrick continues: “Our customers use a variety of our static control bars from our Hyperion range, so giving them maximum visibility and control of their performance via a single device allows for increased productivity and quality output on production lines.”

Fast and easy installation means SmartControl Touch can fit in seamlessly with operations. It is simple to use for operators, offering a user-friendly interface that requires minimal training. Changes can be made quickly and easily, and with voltage and distance sensor compatibility, SmartControl Touch offers more accurate neutralization of all charges on materials. Data logging also provides graphic representation of performance, which can be exported for additional analysis.

“Like all Meech products, SmartControl Touch has been designed in response to feedback from the industry,” concludes Battrick. “We work closely with our customers to understand their needs and how we can better help them to improve their quality control and productivity. Static charges have always been a threat to productivity for many manufacturing and converting sectors, and SmartControl Touch is yet another innovation from Meech designed to keep unwanted static under control and ensure smooth-running and safe production lines.”