Durst discusses enhanced quality with RSC platform

09.29.21

Durst’s 1200 x 1200 dpi inkjet quality can rival both flexo and toner while providing the advantages that inkjet production provides.

With surging interest in digital printing, Durst’s product experts are highlighting the company’s Tau RSC technology at Label Congress. The emphasis is speed and quality, courtesy of 1200 dpi printing.

Durst’s 1200 x 1200 dpi inkjet quality can rival both flexo and toner while providing the advantages that inkjet production provides. Along with delivering high quality, Durst has increased speeds, added additional width and inline finishing options, and lowered running costs to allow more work and longer runs to be converted to digital.

“Durst has led the inkjet market transition to true 1200 dpi quality,” states Steve Lynn, director of labels and packaging, Durst Image Technology US. “We can now print the most demanding labels at speeds and costs that allow for higher rates of conversion to digital production. We feel Durst is uniquely positioned with a portfolio of products that suit any size of converter, printing short/medium/long run lengths cost effectively and with inline finishing options if needed.”

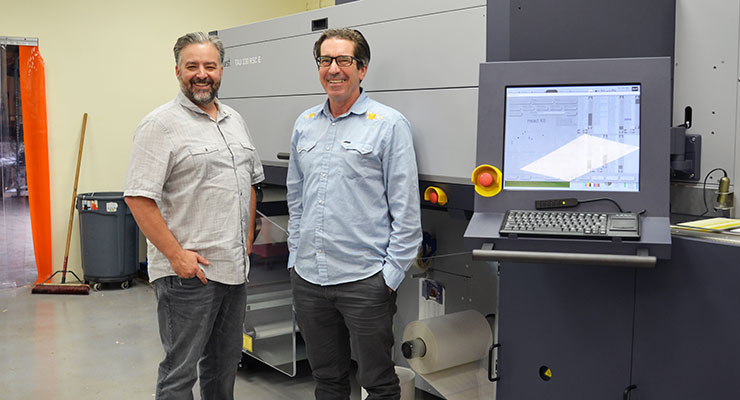

Durst has seen increased adoption of its technologies over the past year. Label Solutions chose the Durst RSC-E UV inkjet label press, which president Chris Merlick described as “a Ferrari in a sea of Chevrolets.” Meanwhile, Label Resources became the first company in Canada to install the Durst TAU RSCi with a hybrid platform.

“We have led the inkjet market conversion to true 1200 dpi quality over the last two years, added options for expanded widths, along with flexibility on configuration of inline finishing options,” comments Lynn. “We have the most comprehensive, highest quality and most efficient digital portfolio available today. In the future, we will continue to expand that portfolio and look at efficient ways to produce longer run lengths and provide more hardware and software solutions to make label converters more profitable.”

Label Congress provides a suitable platform for Durst to detail its latest innovations. According to Lynn, the team welcomes the opportunity to return to an in-person setting.

“We have been looking forward to meeting both existing and new customers in person,” he says. “While virtual meetings have been successful for us, we are excited to be able to network in person and discuss how Durst technology can help label converters be successful. Our Durst team has been resilient and adapted to many changes over the last 18 months, and the results have been exceptional. Durst continue as a technology leader in the digital label market, with a growing North American install base, utilizing all models from our 1200 dpi inkjet portfolio.”

Durst’s 1200 x 1200 dpi inkjet quality can rival both flexo and toner while providing the advantages that inkjet production provides. Along with delivering high quality, Durst has increased speeds, added additional width and inline finishing options, and lowered running costs to allow more work and longer runs to be converted to digital.

“Durst has led the inkjet market transition to true 1200 dpi quality,” states Steve Lynn, director of labels and packaging, Durst Image Technology US. “We can now print the most demanding labels at speeds and costs that allow for higher rates of conversion to digital production. We feel Durst is uniquely positioned with a portfolio of products that suit any size of converter, printing short/medium/long run lengths cost effectively and with inline finishing options if needed.”

Durst has seen increased adoption of its technologies over the past year. Label Solutions chose the Durst RSC-E UV inkjet label press, which president Chris Merlick described as “a Ferrari in a sea of Chevrolets.” Meanwhile, Label Resources became the first company in Canada to install the Durst TAU RSCi with a hybrid platform.

“We have led the inkjet market conversion to true 1200 dpi quality over the last two years, added options for expanded widths, along with flexibility on configuration of inline finishing options,” comments Lynn. “We have the most comprehensive, highest quality and most efficient digital portfolio available today. In the future, we will continue to expand that portfolio and look at efficient ways to produce longer run lengths and provide more hardware and software solutions to make label converters more profitable.”

Label Congress provides a suitable platform for Durst to detail its latest innovations. According to Lynn, the team welcomes the opportunity to return to an in-person setting.

“We have been looking forward to meeting both existing and new customers in person,” he says. “While virtual meetings have been successful for us, we are excited to be able to network in person and discuss how Durst technology can help label converters be successful. Our Durst team has been resilient and adapted to many changes over the last 18 months, and the results have been exceptional. Durst continue as a technology leader in the digital label market, with a growing North American install base, utilizing all models from our 1200 dpi inkjet portfolio.”