Esko urges Labelexpo visitors to 'Digitize, Automate, Connect'

09.16.22

The company is showing how its products deliver workflow improvements to boost both digital print productivity and operational efficiencies.

Esko is showcasing at Labelexpo how its latest products deliver workflow improvements to boost both digital print productivity and operational efficiencies.

During the show, Esko is demonstrating how its portfolio of hardware and software solutions enable businesses to better digitize, automate and connect to accelerate the go-to-market process of packaged goods.

“We know that label converters face tremendous pressure in today’s turbulent and volatile market, with an ever-growing need for accuracy, consistency and efficiency,” says Melissa Plemen, Sr. Director of Inside Sales and Marketing at Esko. “From our CDI Crystal XPS flexo platemaking solution through to our AVT print inspection technologies, visitors to booth #5203 can learn how Esko solutions empower label professionals to improve ways of working, eradicate waste and optimize operational processes.

“We will demonstrate how our software and hardware solutions combine to deliver the most effective, state-of-the-art workflow automation and quality inspection for label converters,” adds Plemen. “Thanks to cloud-based workflow automation, complete integration with MIS is possible throughout the entire prepress workflow. So now all processes are connected - from design, editing and color accuracy through to customer feedback and approvals with WebCenter.”

Esko is also featuring innovations in ArtPro+ including printing unit support and seamless repeat layout creation, as well as folding carton improvements and a new usage dashboard, and enhanced WebCenter usability features improving ease of use and maximizing productivity and efficiency.

“We’ll also demonstrate how the recently acquired Tilia Labs range of intelligent algorithms for sheet layout, estimation and planning have been integrated with Automation Engine and the Esko software platform,” she says. “As a wholly-owned subsidiary of Esko, Tilia Labs will have an adjacent booth where visitors can discover how they can benefit from driving greater sheet layout efficiency, especially for short run digital printing.”

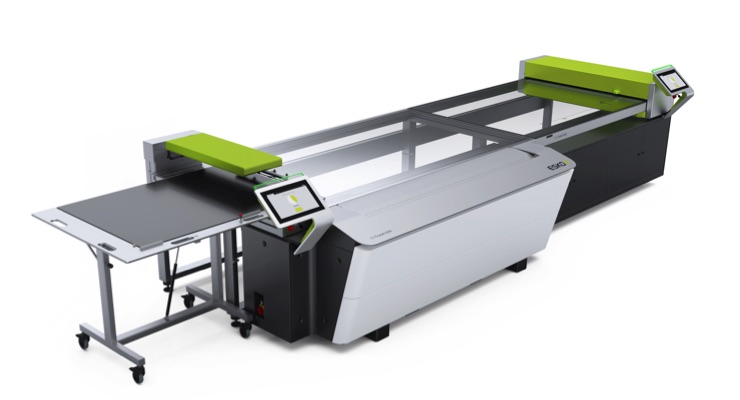

At the heart of the Esko booth, the CDI Crystal 4260 XPS, in combination with the new Flexo Engine module, is showing how digitization in flexo production also boosts efficiency while delivering the best quality plates. “The CDI Crystal XPS excels in efficiency, reducing manual steps by 50% and errors by 50% resulting in less plate waste, alongside reducing operator time by as much as 73%,” Plemen says. “Boosted by our Print Control Wizard software – which in the latest release now includes additional X-Rite color profiling, reducing the number of print trials for press fingerprinting – the system produces plates that deliver the optimum print results.

During the show, Esko is demonstrating how its portfolio of hardware and software solutions enable businesses to better digitize, automate and connect to accelerate the go-to-market process of packaged goods.

“We know that label converters face tremendous pressure in today’s turbulent and volatile market, with an ever-growing need for accuracy, consistency and efficiency,” says Melissa Plemen, Sr. Director of Inside Sales and Marketing at Esko. “From our CDI Crystal XPS flexo platemaking solution through to our AVT print inspection technologies, visitors to booth #5203 can learn how Esko solutions empower label professionals to improve ways of working, eradicate waste and optimize operational processes.

“We will demonstrate how our software and hardware solutions combine to deliver the most effective, state-of-the-art workflow automation and quality inspection for label converters,” adds Plemen. “Thanks to cloud-based workflow automation, complete integration with MIS is possible throughout the entire prepress workflow. So now all processes are connected - from design, editing and color accuracy through to customer feedback and approvals with WebCenter.”

Esko is also featuring innovations in ArtPro+ including printing unit support and seamless repeat layout creation, as well as folding carton improvements and a new usage dashboard, and enhanced WebCenter usability features improving ease of use and maximizing productivity and efficiency.

“We’ll also demonstrate how the recently acquired Tilia Labs range of intelligent algorithms for sheet layout, estimation and planning have been integrated with Automation Engine and the Esko software platform,” she says. “As a wholly-owned subsidiary of Esko, Tilia Labs will have an adjacent booth where visitors can discover how they can benefit from driving greater sheet layout efficiency, especially for short run digital printing.”

At the heart of the Esko booth, the CDI Crystal 4260 XPS, in combination with the new Flexo Engine module, is showing how digitization in flexo production also boosts efficiency while delivering the best quality plates. “The CDI Crystal XPS excels in efficiency, reducing manual steps by 50% and errors by 50% resulting in less plate waste, alongside reducing operator time by as much as 73%,” Plemen says. “Boosted by our Print Control Wizard software – which in the latest release now includes additional X-Rite color profiling, reducing the number of print trials for press fingerprinting – the system produces plates that deliver the optimum print results.