ETI Converting running live demos of Mini-Cohesio

09.26.17

The Mini-Cohesio can convert any type of paper, board or film into self-adhesive material or labels.

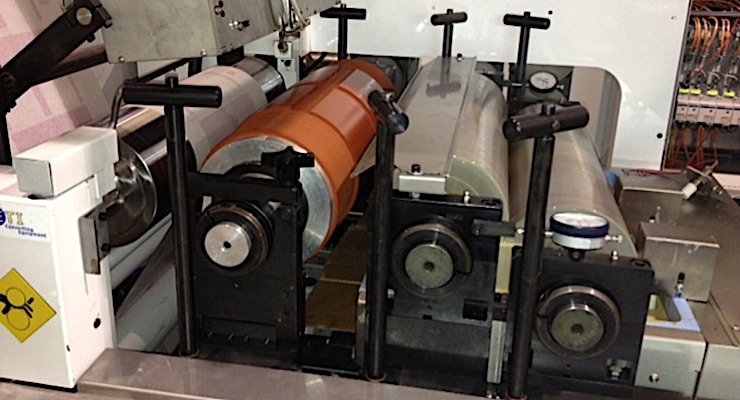

ETI Converting Equipment, a Canadian company specializing in multi-functional inline coating and printing equipment, is demonstrating its Mini-Cohesio machine at Labelexpo Europe.

Designed with features such as short length (7.3 m/24 ft), two unwind for facestock and liner, silicone applicator, adhesive coating station, register system to synchronize the lamination of two pre-printed webs, the Mini- Cohesio is available in 13" (330 mm). The Mini-Cohesio is also equipped with the high speed rotary diecutting unit, the Pellicut, allowing it to diecut on very thin liner polyester film (.72 mil) or SCK or glassine paper (20 lb). The machine can also produce linerless material.

The Mini-Cohesio can convert any type of paper, board or film into self-adhesive material or labels using different adhesive technologies: standard hot-melt, UV curable hot-melt acrylic and water-based emulsion adhesive. The machine can be offered with inline printing capabilities.

ETI is also presenting a pattern hot-melt coater. This unit allows variable repeat from 16" (406 mm) to 32" (812 mm) with automatic register and very accurate pre-register to minimize waste. This unit also allows full web coating at 150 m/m with accurate coat weight control as low as 5 gr/sqm. It provides label makers with new opportunities such as adhesive spots, coupons and special adhesive forms, including laser sheets.

Recently, ETI has developed a new coating head capable of applying as little as 12 grams (1⁄2 mil) of UV hot-melt adhesive, as well as regular hot-melt, on 20.5" (520 mm) width at 500 fpm (150m/m). This new coating head gives an excellent clear/clear label without any marks or stripes.

The demonstrations are being held daily, every hour.

Designed with features such as short length (7.3 m/24 ft), two unwind for facestock and liner, silicone applicator, adhesive coating station, register system to synchronize the lamination of two pre-printed webs, the Mini- Cohesio is available in 13" (330 mm). The Mini-Cohesio is also equipped with the high speed rotary diecutting unit, the Pellicut, allowing it to diecut on very thin liner polyester film (.72 mil) or SCK or glassine paper (20 lb). The machine can also produce linerless material.

The Mini-Cohesio can convert any type of paper, board or film into self-adhesive material or labels using different adhesive technologies: standard hot-melt, UV curable hot-melt acrylic and water-based emulsion adhesive. The machine can be offered with inline printing capabilities.

ETI is also presenting a pattern hot-melt coater. This unit allows variable repeat from 16" (406 mm) to 32" (812 mm) with automatic register and very accurate pre-register to minimize waste. This unit also allows full web coating at 150 m/m with accurate coat weight control as low as 5 gr/sqm. It provides label makers with new opportunities such as adhesive spots, coupons and special adhesive forms, including laser sheets.

Recently, ETI has developed a new coating head capable of applying as little as 12 grams (1⁄2 mil) of UV hot-melt adhesive, as well as regular hot-melt, on 20.5" (520 mm) width at 500 fpm (150m/m). This new coating head gives an excellent clear/clear label without any marks or stripes.

The demonstrations are being held daily, every hour.