Ravenwood debuts two new linerless machines

09.18.23

The Nobac 1500 is a cost effective linerless label applicator aimed at replacing standard self-adhesive top and (or) base labelers.

Ravenwood has expanded its machinery portfolio and announced the unveiling of two new linerless machines at this year’s Labelexpo in Brussels. The two new innovations will feature alongside a Nobac 5000, Nobac Stacker and Com 500.

New Innovations: Nobac 1500 and Nobac 40 Vac

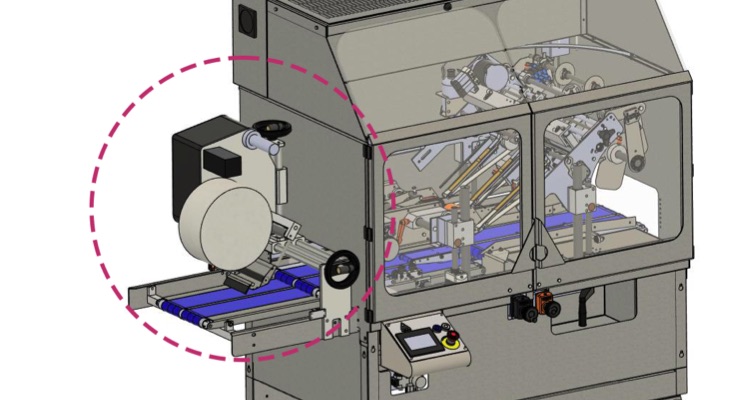

The Nobac 1500 is a cost effective linerless label applicator aimed at replacing standard self-adhesive top and (or) base labellers. The new machine applies labels across conventional MAP trays with no protrusion. Label weights range from 100 – 200gsm in both paper and plastic. There is also the option to link weigh price labellers with no need for compressed air. Choose as a standalone top labeller for integrating into existing conveyors or top and (or) base with an integral conveyor.

Prior to the release of the 1500, a full Nobac 5000 applicator would need to be purchased, capable of a diverse range of linerless label formats, to cover top and base label application. Subsequently, the tailored 1500 is a welcome addition to the 5000 family.

The Nobac 40 Vac is a small linerless promo labeller and is the first of its kind, marking the beginning of a new era in linerless promo flash labelling. The new labeller is extremely cost efficient and outperforms other self-adhesive labellers in its class, providing retailers and packers with a more sustainable labelling solution. The Nobac 40 Vac works alongside Ravenwood’s Nobac 5000 range. Expect line speeds to reach a maximum of 40 metres per minute. Various mountings are available on request including a conventional beak apply system.

Established Machinery: Nobac 5000, Stacker and Com 500 Coater

Since 2004, Ravenwood has steadily built up an impressive and diverse portfolio of Nobac 5000 applicators. Machine variants are designed for maximum flexibility and are dependent on product type and specification. These machines can sleeve fixed weight products as well as link to weigh-scales for variable weights.

The Stacker is a linerless label cutting and stacking machine that offers the perfect solution for hand applying low volume linerless labels. The machine cuts and stacks labels in a ‘post-it note’ style format – up to 100 labels per minute. Labels can be hand applied as and when required. The Stacker has been further developed since its launch in 2019 and now has the added benefit of coding - opt for thermal transfer or ink jet. For those with low label runs looking for a cost-effective, entry level, manual linerless labelling machine, the Stacker is the perfect option.

Ravenwood’s Com 500 Coater will also be ‘on demo’, on the life-sized video wall. It is the only coating system dedicated to running and delivering high quality Ravenwood linerless labels. Designed exclusively to the required specification for label application with Ravenwood’s Nobac 5000 machine range. The Coater produces linerless labels by adding glue and silicone lines to label reels. Labels are supplied in a range of weights and materials, including paper and polypropylene.

Environmentally Friendly Technologies

All Ravenwood machinery is built in the UK. This means that carbon emissions are kept to a minimum and is especially apparent where the Nobac 5000 linerless applicator is concerned. Over 90% of the machine’s weight is produced in the UK and all parts are machined on site at Ravenwood’s factory in Norwich or sourced within a 4-mile radius.

More and more brand owners are now switching to linerless. The main USP is that there is no release liner and subsequently, no waste. Unlike self-adhesive labels which feature backing paper, linerless avoids the need for liner disposal. Current methods include burying into landfill, costly recycling programmes and incineration. All come at a financial and environmental cost.

New Innovations: Nobac 1500 and Nobac 40 Vac

The Nobac 1500 is a cost effective linerless label applicator aimed at replacing standard self-adhesive top and (or) base labellers. The new machine applies labels across conventional MAP trays with no protrusion. Label weights range from 100 – 200gsm in both paper and plastic. There is also the option to link weigh price labellers with no need for compressed air. Choose as a standalone top labeller for integrating into existing conveyors or top and (or) base with an integral conveyor.

Prior to the release of the 1500, a full Nobac 5000 applicator would need to be purchased, capable of a diverse range of linerless label formats, to cover top and base label application. Subsequently, the tailored 1500 is a welcome addition to the 5000 family.

The Nobac 40 Vac is a small linerless promo labeller and is the first of its kind, marking the beginning of a new era in linerless promo flash labelling. The new labeller is extremely cost efficient and outperforms other self-adhesive labellers in its class, providing retailers and packers with a more sustainable labelling solution. The Nobac 40 Vac works alongside Ravenwood’s Nobac 5000 range. Expect line speeds to reach a maximum of 40 metres per minute. Various mountings are available on request including a conventional beak apply system.

Established Machinery: Nobac 5000, Stacker and Com 500 Coater

Since 2004, Ravenwood has steadily built up an impressive and diverse portfolio of Nobac 5000 applicators. Machine variants are designed for maximum flexibility and are dependent on product type and specification. These machines can sleeve fixed weight products as well as link to weigh-scales for variable weights.

The Stacker is a linerless label cutting and stacking machine that offers the perfect solution for hand applying low volume linerless labels. The machine cuts and stacks labels in a ‘post-it note’ style format – up to 100 labels per minute. Labels can be hand applied as and when required. The Stacker has been further developed since its launch in 2019 and now has the added benefit of coding - opt for thermal transfer or ink jet. For those with low label runs looking for a cost-effective, entry level, manual linerless labelling machine, the Stacker is the perfect option.

Ravenwood’s Com 500 Coater will also be ‘on demo’, on the life-sized video wall. It is the only coating system dedicated to running and delivering high quality Ravenwood linerless labels. Designed exclusively to the required specification for label application with Ravenwood’s Nobac 5000 machine range. The Coater produces linerless labels by adding glue and silicone lines to label reels. Labels are supplied in a range of weights and materials, including paper and polypropylene.

Environmentally Friendly Technologies

All Ravenwood machinery is built in the UK. This means that carbon emissions are kept to a minimum and is especially apparent where the Nobac 5000 linerless applicator is concerned. Over 90% of the machine’s weight is produced in the UK and all parts are machined on site at Ravenwood’s factory in Norwich or sourced within a 4-mile radius.

More and more brand owners are now switching to linerless. The main USP is that there is no release liner and subsequently, no waste. Unlike self-adhesive labels which feature backing paper, linerless avoids the need for liner disposal. Current methods include burying into landfill, costly recycling programmes and incineration. All come at a financial and environmental cost.