GMG shows how color management is key to success

09.18.23

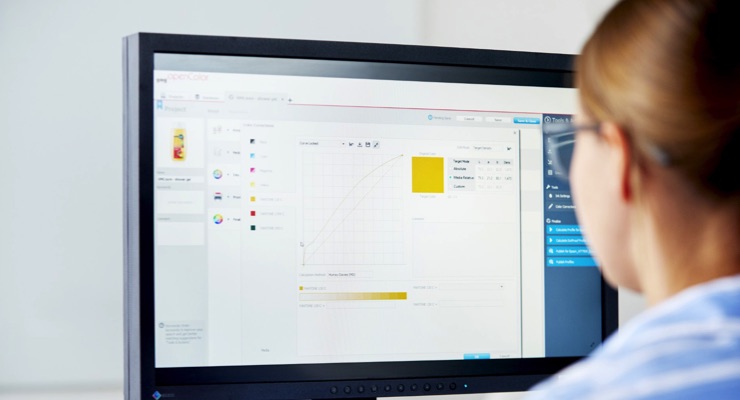

The company exhibited its comprehensive portfolio, which includes GMG ColorProof, GMG OpenColor, and GMG ColorServer.

Today’s label production presents numerous challenges all at once: managing digital and analog print processes, producing repeat orders of identical color quality, maintaining consistency across different locations, ensuring predictable results, and managing time and cost pressures.

At Labelexpo in Brussels, GMG showed how label printing companies can future-proof their business by implementing a powerful color management solution to address all the above-mentioned challenges.

Jens Blöck, product manager at GMG, firmly believes that there is still significant potential in the prepress phase. Substantial improvements are quick to achieve and come at comparatively low cost, he explains, noting, “Expectations have risen significantly, especially for label printing. Brand owners simply don’t accept inconsistencies when it comes to the reproduction of their brand colors. One of the typical challenges is the printing of brand spot colors on a digital press. GMG’s color management ensures that the outcome is always accurate, regardless of the printing conditions.”

GMG offers a portfolio including GMG ColorProof, GMG OpenColor, and GMG ColorServer. These solutions are widely regarded as de facto standards by many companies in the label and packaging industry.

Example GMG OpenColor: The latest update brought spectacular performance gains. With the new GMG Spectral MX Color Engine, for instance, the profile calculation is up to 15 times faster, the profile quality is improved, and the profile size is up to 90% smaller. The higher-resolution MXN profiles lead to better color matching between proof and print, hence optimize print approvals in the packaging supply chain. In an industry where speed, volume, and efficiency are paramount, the advantages are obvious.

Stefan Zrenner, head of sales and marketing at GMG, says, "GMG OpenColor users benefit from a central platform where all data and profiles for process characterization and spot colors are stored. As a result, the same reference data source can be used for both proofing and color conversions.”

At Labelexpo in Brussels, GMG showed how label printing companies can future-proof their business by implementing a powerful color management solution to address all the above-mentioned challenges.

Jens Blöck, product manager at GMG, firmly believes that there is still significant potential in the prepress phase. Substantial improvements are quick to achieve and come at comparatively low cost, he explains, noting, “Expectations have risen significantly, especially for label printing. Brand owners simply don’t accept inconsistencies when it comes to the reproduction of their brand colors. One of the typical challenges is the printing of brand spot colors on a digital press. GMG’s color management ensures that the outcome is always accurate, regardless of the printing conditions.”

GMG offers a portfolio including GMG ColorProof, GMG OpenColor, and GMG ColorServer. These solutions are widely regarded as de facto standards by many companies in the label and packaging industry.

Example GMG OpenColor: The latest update brought spectacular performance gains. With the new GMG Spectral MX Color Engine, for instance, the profile calculation is up to 15 times faster, the profile quality is improved, and the profile size is up to 90% smaller. The higher-resolution MXN profiles lead to better color matching between proof and print, hence optimize print approvals in the packaging supply chain. In an industry where speed, volume, and efficiency are paramount, the advantages are obvious.

Stefan Zrenner, head of sales and marketing at GMG, says, "GMG OpenColor users benefit from a central platform where all data and profiles for process characterization and spot colors are stored. As a result, the same reference data source can be used for both proofing and color conversions.”