07.11.17

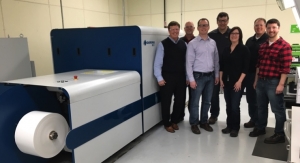

Outlook Group has announced the addition of new equipment to its Pre-Press and Flex departments to support enhanced graphics, improved quality and continued growth.

The Comexi SL2 solvent-free laminator, Outlook Group’s latest addition to the Flexible Packaging Department, offers safety, flexibility and efficiency. It is considered to be ‘one of the most successful models of the Comexi NEXUS brand since 2013’ and will be used at Outlook Group to produce laminated film structures for stand up pouches (SUPs), flow wrap and form-fill-seal packages in the Food & Beverage and Retail Goods market. Engineered for efficiency, the Comexi SL2 allows for quick, semi automatic job changes and is able to laminate at a maximum speed of 1,475 fpm between the widths of 18”-52”.

Joe Gerrits, Flex Department Manager at Outlook Group, states, “This machine is safer and takes up less floor space than the old one. On top of that, it is extremely efficient, allowing us to produce consistent and overall higher quality products in a shorter amount of time.”

Joel Schmidt, Outlook Group’s Director of Market Development, adds, “We are excited about the additional capability and capacity these investments provide for our flexible packaging customers. The Flexible Packaging Association (FPA) recently released a study showing 31% of brand owners intend to switch entirely or to a higher mix of flexible packaging to enhance operational efficiencies and increase sales, and we at Outlook Group look forward to helping our customers achieve those goals.”

Along with the equipment update to the Flexible Packaging Department, Outlook Group has also purchased and installed new equipment to its Pre-Press Department. These pieces of equipment include a ThermoFlex TFXX48-S Flexo plate imager, a Vianord EVO 3A Flexo plate all-in-one unit and an Epson P-9000 CE SureColor with an in-line X-Rite SpecctroProofer.

The ThermoFlex TFXX48-S is used by Outlook Group’s Pre-Press Department to produce plates for the Label and Flexible Packaging departments. This machine offers high resolution plates including 2400 dpi, 2540 dpi, 4000 dpi and 5080 dpi.

Outlook Group’s Pre-Press Manager Wyatt Benz says, “Our old machine only had one resolution setting and this one has four. This machine puts us in the HD market, which is something we were not able to do before.”

Benz also comments on the addition of the Vionard EVO 3A to the Pre-Press Department. “Since the EVO is an all-in-one washing, exposure and drying unit, it saves us a lot of floor space,” he said. “It has also proven to be very efficient, saving us on labor hours and using about half as much solvent than our old machine. This helps us achieve our sustainability goals by reducing our carbon footprint," he says.

Finally, the addition of the Epson P-9000 has allowed the Pre-Press Department to produce high quality proofs for every job. This machine uses the latest imaging technologies to ensure that each proof is clear and precise. It also has G-7 profiling capabilities, which helps to improve the spot color printing accuracy of orange, green and violet inks.

As Outlook Group celebrates its 40th anniversary this year, these strategic investments position the company for continued growth into the future.

The Comexi SL2 solvent-free laminator, Outlook Group’s latest addition to the Flexible Packaging Department, offers safety, flexibility and efficiency. It is considered to be ‘one of the most successful models of the Comexi NEXUS brand since 2013’ and will be used at Outlook Group to produce laminated film structures for stand up pouches (SUPs), flow wrap and form-fill-seal packages in the Food & Beverage and Retail Goods market. Engineered for efficiency, the Comexi SL2 allows for quick, semi automatic job changes and is able to laminate at a maximum speed of 1,475 fpm between the widths of 18”-52”.

Joe Gerrits, Flex Department Manager at Outlook Group, states, “This machine is safer and takes up less floor space than the old one. On top of that, it is extremely efficient, allowing us to produce consistent and overall higher quality products in a shorter amount of time.”

Joel Schmidt, Outlook Group’s Director of Market Development, adds, “We are excited about the additional capability and capacity these investments provide for our flexible packaging customers. The Flexible Packaging Association (FPA) recently released a study showing 31% of brand owners intend to switch entirely or to a higher mix of flexible packaging to enhance operational efficiencies and increase sales, and we at Outlook Group look forward to helping our customers achieve those goals.”

Along with the equipment update to the Flexible Packaging Department, Outlook Group has also purchased and installed new equipment to its Pre-Press Department. These pieces of equipment include a ThermoFlex TFXX48-S Flexo plate imager, a Vianord EVO 3A Flexo plate all-in-one unit and an Epson P-9000 CE SureColor with an in-line X-Rite SpecctroProofer.

The ThermoFlex TFXX48-S is used by Outlook Group’s Pre-Press Department to produce plates for the Label and Flexible Packaging departments. This machine offers high resolution plates including 2400 dpi, 2540 dpi, 4000 dpi and 5080 dpi.

Outlook Group’s Pre-Press Manager Wyatt Benz says, “Our old machine only had one resolution setting and this one has four. This machine puts us in the HD market, which is something we were not able to do before.”

Benz also comments on the addition of the Vionard EVO 3A to the Pre-Press Department. “Since the EVO is an all-in-one washing, exposure and drying unit, it saves us a lot of floor space,” he said. “It has also proven to be very efficient, saving us on labor hours and using about half as much solvent than our old machine. This helps us achieve our sustainability goals by reducing our carbon footprint," he says.

Finally, the addition of the Epson P-9000 has allowed the Pre-Press Department to produce high quality proofs for every job. This machine uses the latest imaging technologies to ensure that each proof is clear and precise. It also has G-7 profiling capabilities, which helps to improve the spot color printing accuracy of orange, green and violet inks.

As Outlook Group celebrates its 40th anniversary this year, these strategic investments position the company for continued growth into the future.