Live From Shows

-

Labelexpo Americas

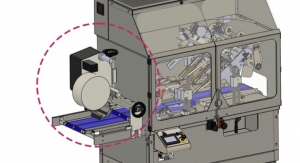

Martin Automatic touting automation at Labelexpo Americas

Martin Automatic touting automation at Labelexpo Americas

Along with LemuGroup and ETI Converting, the three companies will manufacture a label production job in real-time, utilizing an 800 fpm MBS butt splicer.

-

Labelexpo Europe

UPM Raflatac wins Sustainability Award for Ocean Action label

UPM Raflatac wins Sustainability Award for Ocean Action label

It is the world’s first certified label material to fight ocean bound plastic pollution.

-

Labelexpo Europe

Durst Tau RSCi’s 1200 dpi capability has Reel Appeal at Labelexpo

Durst Tau RSCi’s 1200 dpi capability has Reel Appeal at Labelexpo

Announced at the show, the sale of the Durst Tau RSCi press marks the first installation of its kind in the UK and Ireland.

-

Labelexpo Europe

Dantex unveils technology advancements to Pico range

Dantex unveils technology advancements to Pico range

In addition to the new look PicoJet 1200, the company showcased upgrades to its interface, print quality and finishing capabilities.

-

Labelexpo Europe

Label Industry Global Awards 2023 winners revealed

Label Industry Global Awards 2023 winners revealed

The awards recognize organizations and individuals that have excelled in the label and package printing sector through innovation and personal example.

-

Labelexpo Europe

Fiery and Esko unveil new workflow integration

Fiery and Esko unveil new workflow integration

The integration allows customers to easily migrate their existing workflows for digital print technologies.

-

Labelexpo Europe

Fujijifilm presents Jet Press FP790 digital flexible packaging press

Fujijifilm presents Jet Press FP790 digital flexible packaging press

The company also featured Flenex FW plates, LED and low migration inks, the 42K Imprinting Bar System, and Revoria PC1120 toner press.

-

Labelexpo Europe

Lintec launches material that improves recyclability of PET bottle

Lintec launches material that improves recyclability of PET bottle

MMP Mono Material Polyester (PET) is designed for application to polyester packaging such as single use water bottles.

-

Labelexpo Europe

Arrow Systems and Katun expand European partnership

Arrow Systems and Katun expand European partnership

As part of the collaboration, Katun will open an Experience Center in Tiel, the Netherlands featuring a range of Arrow Systems equipment.

-

Labelexpo Europe

Femalabel invests in Grafotronic technology

Femalabel invests in Grafotronic technology

Owner of Femalabel, Wim Feys, signed the purchase order during the show, where he was impressed by the performance of Grafotronic’s multilayer label technology.

-

Labelexpo Europe

GIS exhibits latest image print quality products

GIS exhibits latest image print quality products

The GIS Atlas software suite of products offers the label and packaging sector the optimal digital image print technology for rapid product development.

-

Labelexpo Europe

Lake Image Systems unveils advanced print inspection systems

Lake Image Systems unveils advanced print inspection systems

"Robust print inspection processes have become indispensable for label and packaging production workflows," says Martin Keats, managing director.

-

Labelexpo Europe

HP Indigo launches next-generation flexible packaging press

HP Indigo launches next-generation flexible packaging press

HP Indigo reports a 30% improvement in speed and up to 45% increase in productivity over the HP Indigo 25K digital press.

-

Labelexpo Europe

Lecta details commitment to circular economy

Lecta details commitment to circular economy

Featured products included one-side coated Creaset, high-gloss Eurokote, metalized Metalvac, and thermal Termax, its new "Recy" papers.

-

Labelexpo Europe

Ravenwood debuts two new linerless machines

Ravenwood debuts two new linerless machines

The Nobac 1500 is a cost effective linerless label applicator aimed at replacing standard self-adhesive top and (or) base labelers.

-

Labelexpo Europe

Hamillroad announces partnership with Asahi Photoproducts

Hamillroad announces partnership with Asahi Photoproducts

The move provides a more environmentally friendly water-wash platemaking process that delivers best-in-class image reproduction.

-

Labelexpo Europe

GMG shows how color management is key to success

GMG shows how color management is key to success

The company exhibited its comprehensive portfolio, which includes GMG ColorProof, GMG OpenColor, and GMG ColorServer.

-

Labelexpo Europe

PrintCity Alliance demos one-stop-shop for label innovation

PrintCity Alliance demos one-stop-shop for label innovation

The network of suppliers includes DG press, GMG, IST Metz, Kocher+Beck, KURZ, Weilburger, Westland and Zeller+Gmelin.

-

Labelexpo Europe

Maxcess brings wide range of products to Labelexpo Europe

Maxcess brings wide range of products to Labelexpo Europe

A new Flexible Die portfolio and the RotoScan Intelligent Die Station from RotoMetrics are two of the booth highlights.

-

Labelexpo Europe

Fedrigoni Self-Adhesives focuses on future of labeling

Fedrigoni Self-Adhesives focuses on future of labeling

Featured products include the new Manter neck labels range, a line of premium self-adhesive materials combining collars and labels for luxury products.