01.21.19

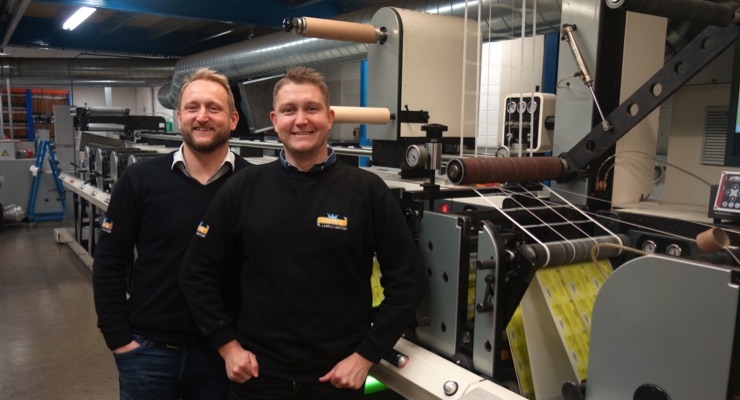

Established in 1987 by Paul Board, and now managed by his sons John and Chris, Crown Labels has established a reputation for high quality work from its base at Redditch, in the UK’s West Midlands. In 2018, its 20 employees will generate sales of labels and tags in excess of £3.6m on a range of modern narrow web flexo presses from Nilpeter, Mark Andy and ABG.

Supplying to a cross section of industry brings its own level of demand for consistent quality, and according to John Board, RotoMetrics’ tooling has been fundamental to the company’s success. “My Father and Neil Lilly began the working partnership many years ago and we have enjoyed nothing but the best service from Rotometrics ever since. They have helped and advised us at all stages of our growth, and are brilliant problem solvers on any tricky job,” he says.

Drawing praise for the manner in which RotoMetrics treats small and large customers alike, Board says that in todays’ competitive market there are always cheaper options, especially from Asia, but affirmed that: “You get what you pay for and in our line of business we need to get things right the first time, so the speed and quality of service is as important as the quality of product.”

In addition to the standard tooling on Crown’s presses, RotoMetrics has also supplied a Pin Eject die for a special mailing job. This die contains a special core material that allows hardened ejector pins to compress into the die upon contact with the anvil. This revolutionary technology has worked so well in the tag and label market it has opened doors to new applications that require small die cut shapes produced at high speed and in large volumes. This investment in technology to improve productivity typifies the Crown Labels policy of lean manufacturing and control of all processes in-house.

Fully accredited to BRC, ISO 9001 and 14001, the company is Citation Health & Safety approved and an ASDA approved supplier. “We pride ourselves on the quality of our products and service, which has made us financially secure and able to offer lead times as short as five days,” he concludes.

Supplying to a cross section of industry brings its own level of demand for consistent quality, and according to John Board, RotoMetrics’ tooling has been fundamental to the company’s success. “My Father and Neil Lilly began the working partnership many years ago and we have enjoyed nothing but the best service from Rotometrics ever since. They have helped and advised us at all stages of our growth, and are brilliant problem solvers on any tricky job,” he says.

Drawing praise for the manner in which RotoMetrics treats small and large customers alike, Board says that in todays’ competitive market there are always cheaper options, especially from Asia, but affirmed that: “You get what you pay for and in our line of business we need to get things right the first time, so the speed and quality of service is as important as the quality of product.”

In addition to the standard tooling on Crown’s presses, RotoMetrics has also supplied a Pin Eject die for a special mailing job. This die contains a special core material that allows hardened ejector pins to compress into the die upon contact with the anvil. This revolutionary technology has worked so well in the tag and label market it has opened doors to new applications that require small die cut shapes produced at high speed and in large volumes. This investment in technology to improve productivity typifies the Crown Labels policy of lean manufacturing and control of all processes in-house.

Fully accredited to BRC, ISO 9001 and 14001, the company is Citation Health & Safety approved and an ASDA approved supplier. “We pride ourselves on the quality of our products and service, which has made us financially secure and able to offer lead times as short as five days,” he concludes.