04.08.19

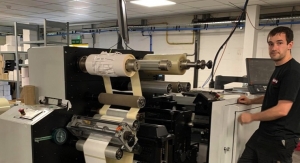

In an unusual application, Slovakia-based Radaflex has adapted a Mark Andy Performance Series P3 to print on aluminium foil at its facility in Tmava. The converter’s new P3 is an 8-color flexo press, with a 10-inch (250mm) web width, fitted with hardened idler rolls coated with Teflon.

The modern flexo press replaces a Mark Andy 2200 press providing the printer the ability to cut waste while increasing up time, with Performance Series presses providing 50% less waste than conventional inline presses. Configured with eight flexo print units, reverse side printing, cold foil capability and two die cutting stations, the P3 also has full UV curing. It is fast to make ready between jobs, which is a bonus considering the range of work and different substrates that Radaflex copes with daily.

According to Radaflex co-owner Daniel Lukac: “The new P3 fits well with our existing production capability which sees 50% of our work supplied on aluminium foil to the pharmaceutical industry and also as lids for plastic cans in the food sector, where 35-micron foil is the preferred material for yoghurt pots and the like, because it provides a safe barrier for the food.”

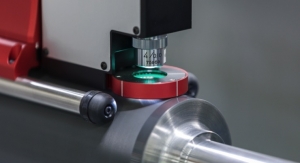

Unlike filmic material, foil is more stable during the print process. The mechanical drive of the P3, manual registration and control is well suited for Radaflex’s work. With years of experience in this field, Mr Lukac says his press operators have the necessary skills to man the mechanical press. The stroboscopic camera monitors the run's register. After printing, the company has specialized finishing and punching technology on hand.

Installation of the new P3 went smoothly under the supervision of Radim Krutis of Enginne, Mark Andy’s distributor for Slovakia. Limiting the early jobs to labels allowed the operators time to become acquainted with the new press. Operators found it faster and more productive than its legacy 2200 predecessor. Radaflex expects significantly less waste to be produced as well.

Once they felt confident, Radaflex introduced foil work, which forms a substantial part of the P3's workload. “The P3 handles [the work] with ease which shows how well designed and manufactured it is. It has fulfilled all our requirements for print quality and has saved us material and time since it came onstream,” Lukac concludes.

The modern flexo press replaces a Mark Andy 2200 press providing the printer the ability to cut waste while increasing up time, with Performance Series presses providing 50% less waste than conventional inline presses. Configured with eight flexo print units, reverse side printing, cold foil capability and two die cutting stations, the P3 also has full UV curing. It is fast to make ready between jobs, which is a bonus considering the range of work and different substrates that Radaflex copes with daily.

According to Radaflex co-owner Daniel Lukac: “The new P3 fits well with our existing production capability which sees 50% of our work supplied on aluminium foil to the pharmaceutical industry and also as lids for plastic cans in the food sector, where 35-micron foil is the preferred material for yoghurt pots and the like, because it provides a safe barrier for the food.”

Unlike filmic material, foil is more stable during the print process. The mechanical drive of the P3, manual registration and control is well suited for Radaflex’s work. With years of experience in this field, Mr Lukac says his press operators have the necessary skills to man the mechanical press. The stroboscopic camera monitors the run's register. After printing, the company has specialized finishing and punching technology on hand.

Installation of the new P3 went smoothly under the supervision of Radim Krutis of Enginne, Mark Andy’s distributor for Slovakia. Limiting the early jobs to labels allowed the operators time to become acquainted with the new press. Operators found it faster and more productive than its legacy 2200 predecessor. Radaflex expects significantly less waste to be produced as well.

Once they felt confident, Radaflex introduced foil work, which forms a substantial part of the P3's workload. “The P3 handles [the work] with ease which shows how well designed and manufactured it is. It has fulfilled all our requirements for print quality and has saved us material and time since it came onstream,” Lukac concludes.