07.17.19

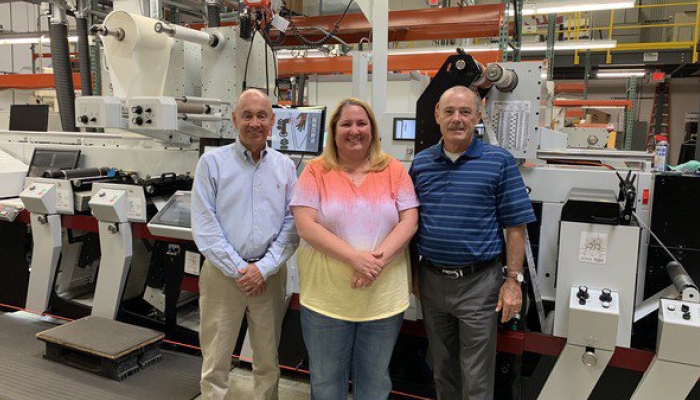

A North American label printer has realized success with a Mark Andy Digital Series HD. Cypress Multigraphics, located in Tinley Park, IL, USA, purchased the solution in the summer of 2018 and took delivery in late September, directly following Labelexpo Americas.

As an early adopter of the Digital Series HD production class inkjet press, Cypress Multigraphics had kept a keen eye on the industry and where technology was evolving before investing in its first non-acquired digital asset. Brad Weber, president/owner, Cypress Multigraphics, says, “We’ve been watching the digital market develop over the last 10 years and up until recently, we felt the process was treated like an afterthought. Like a copier tucked away in the back of the pressroom that required additional production steps. It went against the grain of everything we believed in from our flexo upbringing.”

What piqued the company's leadership team’s interest, however, was the new way of technology coming to market: hybrid. “Hybrid capability is what got our interest going in the Mark Andy Digital Series HD. And for a while, competitive digital press resolution, speed, and capability weren't there for the standards our customers required," says Tim Thomas, general manager, Cypress Multigraphics.

Cypress Multigraphics’ configuration consists of four flexo print stations: two before and two after the 7-color UV inkjet digital module. These features coupled with a rail system and QCDC-SR semi-rotary diecutting allow the company to marry printing, decorating and finishing at 240 fpm in a single pass. High opacity digital white, in excess of 85%, has also served as an acceptable alternative for customers that require screen printing.

On their decision to pursue a highly configurable press, Thomas, Cypress’ driving force behind evaluating True Hybrid technology, explains, “When you take things off-line, it’s another department to schedule and a large footprint in our operation.”

Methodically using its Digital Series HD acquisition to phase out 2-3 legacy flexo presses, the business also stands to attract additional work through the added capabilities and new markets. In addition to aggressively pursuing craft beer market share, the company has the technology to continue its dominant position as a provider of durables, nutraceutical, automotive and food market applications. Thomas makes it clear that expanding their book of business is a top priority, expressing, “There is a lot of new work to be won and we are always hungry.”

“Speaking candidly, digital scared our team to death at first. Making the switch was like going from water to UV-based inks in flexo. But it’s paid off quick and everyone is on the hybrid bandwagon and excited to have this new capability and learning experience,” shares Weber. He concludes “The way I see it, with the value Mark Andy hybrid brings to our operation, I don’t see us purchasing a conventional press again.”

As an early adopter of the Digital Series HD production class inkjet press, Cypress Multigraphics had kept a keen eye on the industry and where technology was evolving before investing in its first non-acquired digital asset. Brad Weber, president/owner, Cypress Multigraphics, says, “We’ve been watching the digital market develop over the last 10 years and up until recently, we felt the process was treated like an afterthought. Like a copier tucked away in the back of the pressroom that required additional production steps. It went against the grain of everything we believed in from our flexo upbringing.”

What piqued the company's leadership team’s interest, however, was the new way of technology coming to market: hybrid. “Hybrid capability is what got our interest going in the Mark Andy Digital Series HD. And for a while, competitive digital press resolution, speed, and capability weren't there for the standards our customers required," says Tim Thomas, general manager, Cypress Multigraphics.

Cypress Multigraphics’ configuration consists of four flexo print stations: two before and two after the 7-color UV inkjet digital module. These features coupled with a rail system and QCDC-SR semi-rotary diecutting allow the company to marry printing, decorating and finishing at 240 fpm in a single pass. High opacity digital white, in excess of 85%, has also served as an acceptable alternative for customers that require screen printing.

On their decision to pursue a highly configurable press, Thomas, Cypress’ driving force behind evaluating True Hybrid technology, explains, “When you take things off-line, it’s another department to schedule and a large footprint in our operation.”

Methodically using its Digital Series HD acquisition to phase out 2-3 legacy flexo presses, the business also stands to attract additional work through the added capabilities and new markets. In addition to aggressively pursuing craft beer market share, the company has the technology to continue its dominant position as a provider of durables, nutraceutical, automotive and food market applications. Thomas makes it clear that expanding their book of business is a top priority, expressing, “There is a lot of new work to be won and we are always hungry.”

“Speaking candidly, digital scared our team to death at first. Making the switch was like going from water to UV-based inks in flexo. But it’s paid off quick and everyone is on the hybrid bandwagon and excited to have this new capability and learning experience,” shares Weber. He concludes “The way I see it, with the value Mark Andy hybrid brings to our operation, I don’t see us purchasing a conventional press again.”