07.29.19

The Watershed Group, a privately-owned international labeling and packaging company based in Ireland, has just completed a €3m investment that includes a move to new headquarters in Dublin, and the addition of another Mark Andy P5E Performance Series flexo press.

The factory move, which was carefully planned and handled by a team of technicians from Mark Andy UK to ensure no loss of production, offers Watershed twice as much space as before, and is seen as key part of the Group’s €30m revenue target over the next two years. Staff numbers have continued to grow in an operation that is renowned for its high efficiency.

With 11 Mark Andy presses distributed across the Group’s production sites in Ireland, Germany and Poland, the commitment to the American company’s technology has been fundamental to Watershed’s continuing double-digit growth. “We decided that building close strategic partnerships is a key element of our growth strategy and aligning our business with Mark Andy continues to be the right decision. As with all partnerships, it’s not been without issue, but both sides have benefited from their commitment to work at a problem and develop the solution,” explains Watershed CEO Liz Waters. “We were the first label company to operate Mark Andy presses in Poland, Germany and Ireland, and we envisage that the relationship will continue to grow."

The decision in 2018 to install the first digital hybrid press in the UK and Ireland was part of the Group’s strategy to compete in the market for premium drinks labels. This also involved the acquisition of an existing speciality drinks business, the multiple award-winning company, "The Label Factory," which provided an instant entry into that sector.

Looking to bring its brand of innovation to this market, Watershed knew that specialist technology in the shape of future-proof, inkjet technology was required to differentiate themselves from other label converters and offer a wider range of new and exciting print options to their customer base.

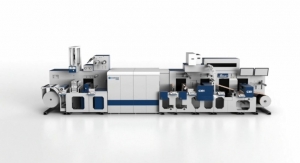

The Mark Andy Digital Series offers Watershed speed and flexibility to cater top-quality short to medium run labels across a range of substrates with inline finishing. According to Watershed director Patrick Murphy, “We know how good Mark Andy flexo quality is, so the commercial possibilities and cost saving benefits of combining flexo with the flexibility of digital inkjet in one press was too tempting to resist. The digital quality matches the flexo, and if need be, we can bypass the digital engine and run the press all flexo.”

The latest machinery package includes another Mark Andy Performance Series P5E flexo press (Watershed’s seventh), the Digital Series inkjet hybrid press based on the modular P7E platform and two Rotoflex HSI, pharmaceutical standard inspection rewinders, fitted with EyeC technology for 100% accuracy. The P5E is an 8-colour, 17” (430mm) model fitted with full UV, turnbars, delam/relam, chilled impression rolls and the QCDC die station. The Digital Series has a 13” web width and is fitted with four flexo units, one with reverse print option, along with the CMYK plus white inkjet engine, laminating and QCDC-SR die station.

According to Liz Waters, the international label business is becoming even more consolidated and it’s here that she sees the advantage of production capabilities in different locations. “The recent installation of Label Traxx MIS has provided us with so much quality information that we can evaluate the productivity and potential of each press in each plant to give us and our brand owners complete supply chain flexibility," she says. "The analytics which we get from LabelTraxx are essential to running any multi-press operation to its maximum efficiency. For an operation like ours, which is margin driven, live accurate data is vital."

The factory move, which was carefully planned and handled by a team of technicians from Mark Andy UK to ensure no loss of production, offers Watershed twice as much space as before, and is seen as key part of the Group’s €30m revenue target over the next two years. Staff numbers have continued to grow in an operation that is renowned for its high efficiency.

With 11 Mark Andy presses distributed across the Group’s production sites in Ireland, Germany and Poland, the commitment to the American company’s technology has been fundamental to Watershed’s continuing double-digit growth. “We decided that building close strategic partnerships is a key element of our growth strategy and aligning our business with Mark Andy continues to be the right decision. As with all partnerships, it’s not been without issue, but both sides have benefited from their commitment to work at a problem and develop the solution,” explains Watershed CEO Liz Waters. “We were the first label company to operate Mark Andy presses in Poland, Germany and Ireland, and we envisage that the relationship will continue to grow."

The decision in 2018 to install the first digital hybrid press in the UK and Ireland was part of the Group’s strategy to compete in the market for premium drinks labels. This also involved the acquisition of an existing speciality drinks business, the multiple award-winning company, "The Label Factory," which provided an instant entry into that sector.

Looking to bring its brand of innovation to this market, Watershed knew that specialist technology in the shape of future-proof, inkjet technology was required to differentiate themselves from other label converters and offer a wider range of new and exciting print options to their customer base.

The Mark Andy Digital Series offers Watershed speed and flexibility to cater top-quality short to medium run labels across a range of substrates with inline finishing. According to Watershed director Patrick Murphy, “We know how good Mark Andy flexo quality is, so the commercial possibilities and cost saving benefits of combining flexo with the flexibility of digital inkjet in one press was too tempting to resist. The digital quality matches the flexo, and if need be, we can bypass the digital engine and run the press all flexo.”

The latest machinery package includes another Mark Andy Performance Series P5E flexo press (Watershed’s seventh), the Digital Series inkjet hybrid press based on the modular P7E platform and two Rotoflex HSI, pharmaceutical standard inspection rewinders, fitted with EyeC technology for 100% accuracy. The P5E is an 8-colour, 17” (430mm) model fitted with full UV, turnbars, delam/relam, chilled impression rolls and the QCDC die station. The Digital Series has a 13” web width and is fitted with four flexo units, one with reverse print option, along with the CMYK plus white inkjet engine, laminating and QCDC-SR die station.

According to Liz Waters, the international label business is becoming even more consolidated and it’s here that she sees the advantage of production capabilities in different locations. “The recent installation of Label Traxx MIS has provided us with so much quality information that we can evaluate the productivity and potential of each press in each plant to give us and our brand owners complete supply chain flexibility," she says. "The analytics which we get from LabelTraxx are essential to running any multi-press operation to its maximum efficiency. For an operation like ours, which is margin driven, live accurate data is vital."