L&NW Staff10.27.20

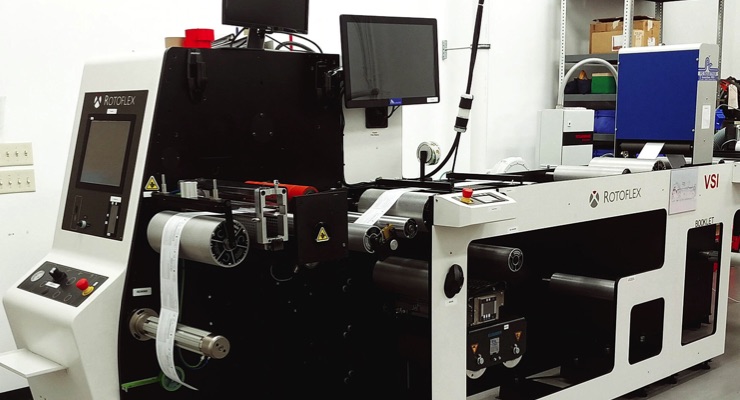

Rotoflex has successfully developed and installed a highly customized booklet label machine for printer JH Bertrand Inc.

Since 1981, JH Bertrand Inc. has focused production on booklet labels that expand copy space on CPG. Pharma, chemical, and consumer-industrial companies commonly use extended-content labels to comply with government regulations, translate information, detail product use directions, include promotional coupons and rebates, and to protect themselves from litigation.

Dedicated to handling a full range of booklet label sizes, the Rotoflex machine can process booklet labels with as many as 96 pages of text and graphics, a breakthrough solution in the multi-layer label market.

“JH Bertrand is a very innovative company. Our focus is booklet labels, so we are always trying to figure out new ways to make them. Many of our constructions need a gentle web path due to thickness and other factors. Recently, we had an idea for a straighter web path, so we presented it to the great people of Rotoflex. They took our ideas and turned it into a one-of-a-kind machine that we absolutely love,” says Jeff Bertrand, CEO of JH Bertrand Inc.

The machine is based on Rotoflex VSI platform and features a short and simple web path using large idlers to handle challenging booklet applications. A custom design for the inspection system area keeps the booklet labels intact when running underneath the camera. Additional unique aspects include a laterally moving guided unwind, straight-through special draw station with larger diameter roll, and a soft rubber nip roll with adjustable nipping distance and pressure -with a provided segmented nip roll if running more than several rows across the web.

“This customized solution we designed for JH Bertrand, a long-standing Rotoflex customer, is an example of our advanced technology developments and expertise in booklet material,” comments Manohar Dhugga, Rotoflex VP of Operations. “We are open to working with label printers and converters in designing bespoke label finishing machines to accommodate unique production needs, and we have a team of engineers on-site with years of design and finishing technology expertise,” adds Dhugga.

JH Bertrand Inc. is not only satisfied with the product itself, but also with the relationship established with Rotoflex over the years. “Since the very beginning, Rotoflex has been a truly wonderful partner. We get a lot of value from the relationship and enjoy doing business with the company very much,” concludes Bertrand.

Since 1981, JH Bertrand Inc. has focused production on booklet labels that expand copy space on CPG. Pharma, chemical, and consumer-industrial companies commonly use extended-content labels to comply with government regulations, translate information, detail product use directions, include promotional coupons and rebates, and to protect themselves from litigation.

Dedicated to handling a full range of booklet label sizes, the Rotoflex machine can process booklet labels with as many as 96 pages of text and graphics, a breakthrough solution in the multi-layer label market.

“JH Bertrand is a very innovative company. Our focus is booklet labels, so we are always trying to figure out new ways to make them. Many of our constructions need a gentle web path due to thickness and other factors. Recently, we had an idea for a straighter web path, so we presented it to the great people of Rotoflex. They took our ideas and turned it into a one-of-a-kind machine that we absolutely love,” says Jeff Bertrand, CEO of JH Bertrand Inc.

The machine is based on Rotoflex VSI platform and features a short and simple web path using large idlers to handle challenging booklet applications. A custom design for the inspection system area keeps the booklet labels intact when running underneath the camera. Additional unique aspects include a laterally moving guided unwind, straight-through special draw station with larger diameter roll, and a soft rubber nip roll with adjustable nipping distance and pressure -with a provided segmented nip roll if running more than several rows across the web.

“This customized solution we designed for JH Bertrand, a long-standing Rotoflex customer, is an example of our advanced technology developments and expertise in booklet material,” comments Manohar Dhugga, Rotoflex VP of Operations. “We are open to working with label printers and converters in designing bespoke label finishing machines to accommodate unique production needs, and we have a team of engineers on-site with years of design and finishing technology expertise,” adds Dhugga.

JH Bertrand Inc. is not only satisfied with the product itself, but also with the relationship established with Rotoflex over the years. “Since the very beginning, Rotoflex has been a truly wonderful partner. We get a lot of value from the relationship and enjoy doing business with the company very much,” concludes Bertrand.