Marc Levine, Director of Business Development, GMG Americas12.03.20

Today, printers are faced with more choices and more challenges than ever when it comes to printing.

Printers can use either conventional presses or digital printers, or both. They need to offer flexible production timelines and accommodate both large and short print runs. With the emergence of industry-standard practices and print quality programs, expectations for color matching and color quality have never been higher. Considering these business challenges, the need for reliable color management has never been more critical.

For digital print, color management and correct data preparation are especially important because spot colors cannot be produced with a single inks and must be transformed accurately into a combination of multiple inks that will produce the right color. While using a fixed ink set with additional colors to print "spots" is not a new concept, the related technologies have evolved over time. Today, improved press, ink, and plate technologies make print more predictable, offering a wider range of colors. In addition, software technology has made significant advances, making extended color printing a truly viable solution for producing accurate brand colors, using a fixed set of inks for both conventional and digital print.

Many digital print facilities find that their color management technology and workflow do not consistently deliver expected results, requiring a significant amount of trial and error to match spot colors. They find it difficult to estimate how production color will look and to communicate that effectively to their print buyers. Their goal is to realize their best color and present their customers with an accurate prediction (proof) that their customers can trust. With a competent color management process and proofing system, this is easy to do. Using the right technology enables printers to manage their clients’ expectations, avoiding confusion, and even streamlining the approval process by eliminating extra approval cycles.

There are two primary ingredients that can help printers deliver more color, with higher consistency, on time, for lower cost: centralized color management and multicolor workflow.

Ad hoc versus centralized color management

Today, almost every printing device—from a small desktop inkjet printer, to a proofer with a proofing RIP, to a digital production printer, to a conventional print workflow—comes with color management tools. While all of these systems "do the same thing," they typically do not "do it the same way." In addition, separate systems can and will use different settings and different color references, introducing color variation that printers cannot solve. From a technical perspective, this ad hoc approach appears reasonable on paper. However, printers often find themselves compromising on expectations because they simply can’t "get there."

Centralized color management is different. In a centralized system, all color transformations are performed using the same color technology, using the same references and the same tools. This provides three immediate benefits: more consistent results using common references and configurations, more predictable color across all print applications (including conventional and digital), and more accountability to color performance.

If a print facility has many production print machines, along with proofing RIPs (each having its own built-in color management technology), then the printer has a lot to juggle. There can be duplication of color libraries, profiles, and calibrations, as well as different versions of these items that secretly impose a color difference. Even the variety of different user experiences, with different color management tools, can impose differences on the final product. In short, without using a standardized and centralized approach, it’s more likely that things will go wrong and—more often that they do.

A centralized color management ensures that everybody is matching to the beat of the same drum. Every job is managed to the same target. Every color management conversation uses the same engine. Regardless of the printing technology used, calibration works the same way and does the same thing. By aligning all of these elements, centralized color management ensures visually consistent and color matched results to any output device.

What is multicolor print technology?

In packaging, spot colors are used to specify the design intent of important brand colors. In traditional conventional print, printers have used special inks with special formulas that are built to make the right color on the production substrate. However, because digital printing machines do not use special inks, brand colors must be printed using a combination of inks. So how do you achieve accurate brand colors using digital print where only a fixed color set is available? Multicolor print technology.

Multicolor print technology transforms spot colors into recipes that will produce an accurate color simulation using an extended set of inks (most commonly, CMYK + orange, green, and violet). By optimizing how colors are produced on each device, jobs can be moved between different presses—and even printing plants—while maintaining consistent, predictable color results. Consistent and predictable results translates to eliminating countless iterations between prepress and the pressroom, and communicating color to clients with greater accuracy and repeatability.

Multicolor printing has grown significantly in recent years for both in conventional and digital print. In conventional print processes such as flexo, gravure, and offset, it has enabled printers to gang work together, eliminating the cost of washups between jobs and streamlining the total print production process. For digital print, multicolor printing has helped printers achieve wider gamuts and higher speeds, enabling use of digital print in more applications.

Multicolor printing is not a "magic pill." Printers and print buyers should look at the specific application and color requirements. It may make sense to run a four-color job with just one extra spot instead of a seven-color process. In some cases, printing equipment may not have enough decks to run a standard multicolor process. Also note that the process of specifying spot colors works differently too, as the printer cannot use drawdowns to match color in advance of the print run.

A color solution for digital packaging printing

Without having dedicated tools and technologies, preparing digital files for an extended color gamut workflow can be complex and challenging. Print providers need a complete set of tools that seamlessly integrates with their existing workflows—including proofing, profiling, conversion and calibration tools – to make color separation simple and efficient.

A competent multicolor workflow gives packaging printers control over their extended gamut color separation and print process, using either digital or conventional print. With color in control, printers can simulate brands colors accurately. Printers can also choose how they proof, with the flexibility to move proofing away from the production floor, allowing more production scheduling flexibility and increasing production capacity.

Multicolor is not just for seven-color process printing. Using a multicolor workflow, printers can convert that extra spot color into a fifth process color, allowing printers to expand their printing gamut even with one or two additional special inks. Multicolor tools let printers and prepress operators customize the way they separate art and accurately transform the design intent for use with a custom print process.

A multicolor workflow enables printers to fully utilize their digital print gamut, reduce press make-ready time, improve speed, and reduce click costs. The combination of a multicolor workflow and centralized color management lets printers increase capacity without adding more machines, Artwork preparation becomes fast and reliable, with automated separation/conversion reducing time and effort.

Some challenges can use help

Time is money. For printers that have purchased new printing machines, they want to make sure that their new equipment is up and running as quickly as possible, but may not have the time to build up the color management settings around it. Other print businesses may wish to avoid purchasing new printing machines by increasing the performance and capacity of their existing machines. In either case, engaging with consultants can help printers make the right choices to produce their best color and meet their business objectives . A capable consultant can advise on industry practices and recommend the ideal configuration of a solution—such as choice of ink sets, characterization of the printing process, and other best practices.

With more presses running a variety of jobs requiring consistent color, centralized color management is essential. In addition, as changing inks on press becomes more and more unpopular—multicolor technology can provide a path to accurate and predictable color.

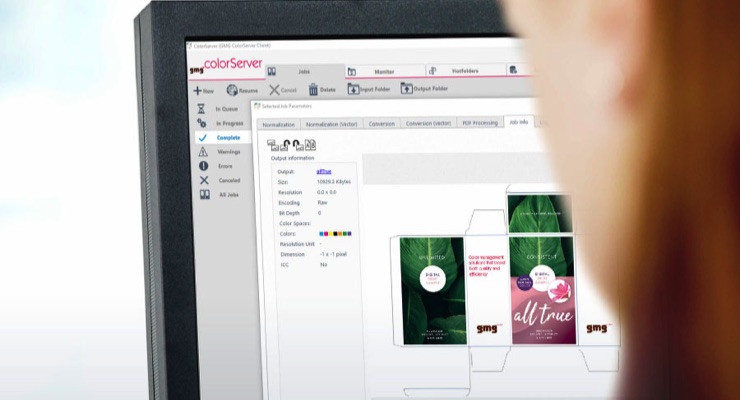

GMG Color is a manufacturer of high-performance color software for printers, brands and brand partners across the supply chain. GMG ColorServer bundles provide all the tools to centralize and automate multicolor separations. GMG ColorProof, DotProof, and FlexoProof continue to set the standard in proofing and prototyping color performance. Both ColorServer and ColorProof connect to GMG OpenColor, GMG’s next-generation color management technology using the power of spectral data to predict and transform color precisely.

Printers can use either conventional presses or digital printers, or both. They need to offer flexible production timelines and accommodate both large and short print runs. With the emergence of industry-standard practices and print quality programs, expectations for color matching and color quality have never been higher. Considering these business challenges, the need for reliable color management has never been more critical.

For digital print, color management and correct data preparation are especially important because spot colors cannot be produced with a single inks and must be transformed accurately into a combination of multiple inks that will produce the right color. While using a fixed ink set with additional colors to print "spots" is not a new concept, the related technologies have evolved over time. Today, improved press, ink, and plate technologies make print more predictable, offering a wider range of colors. In addition, software technology has made significant advances, making extended color printing a truly viable solution for producing accurate brand colors, using a fixed set of inks for both conventional and digital print.

Many digital print facilities find that their color management technology and workflow do not consistently deliver expected results, requiring a significant amount of trial and error to match spot colors. They find it difficult to estimate how production color will look and to communicate that effectively to their print buyers. Their goal is to realize their best color and present their customers with an accurate prediction (proof) that their customers can trust. With a competent color management process and proofing system, this is easy to do. Using the right technology enables printers to manage their clients’ expectations, avoiding confusion, and even streamlining the approval process by eliminating extra approval cycles.

There are two primary ingredients that can help printers deliver more color, with higher consistency, on time, for lower cost: centralized color management and multicolor workflow.

Ad hoc versus centralized color management

Today, almost every printing device—from a small desktop inkjet printer, to a proofer with a proofing RIP, to a digital production printer, to a conventional print workflow—comes with color management tools. While all of these systems "do the same thing," they typically do not "do it the same way." In addition, separate systems can and will use different settings and different color references, introducing color variation that printers cannot solve. From a technical perspective, this ad hoc approach appears reasonable on paper. However, printers often find themselves compromising on expectations because they simply can’t "get there."

Centralized color management is different. In a centralized system, all color transformations are performed using the same color technology, using the same references and the same tools. This provides three immediate benefits: more consistent results using common references and configurations, more predictable color across all print applications (including conventional and digital), and more accountability to color performance.

If a print facility has many production print machines, along with proofing RIPs (each having its own built-in color management technology), then the printer has a lot to juggle. There can be duplication of color libraries, profiles, and calibrations, as well as different versions of these items that secretly impose a color difference. Even the variety of different user experiences, with different color management tools, can impose differences on the final product. In short, without using a standardized and centralized approach, it’s more likely that things will go wrong and—more often that they do.

A centralized color management ensures that everybody is matching to the beat of the same drum. Every job is managed to the same target. Every color management conversation uses the same engine. Regardless of the printing technology used, calibration works the same way and does the same thing. By aligning all of these elements, centralized color management ensures visually consistent and color matched results to any output device.

What is multicolor print technology?

In packaging, spot colors are used to specify the design intent of important brand colors. In traditional conventional print, printers have used special inks with special formulas that are built to make the right color on the production substrate. However, because digital printing machines do not use special inks, brand colors must be printed using a combination of inks. So how do you achieve accurate brand colors using digital print where only a fixed color set is available? Multicolor print technology.

Multicolor print technology transforms spot colors into recipes that will produce an accurate color simulation using an extended set of inks (most commonly, CMYK + orange, green, and violet). By optimizing how colors are produced on each device, jobs can be moved between different presses—and even printing plants—while maintaining consistent, predictable color results. Consistent and predictable results translates to eliminating countless iterations between prepress and the pressroom, and communicating color to clients with greater accuracy and repeatability.

Multicolor printing has grown significantly in recent years for both in conventional and digital print. In conventional print processes such as flexo, gravure, and offset, it has enabled printers to gang work together, eliminating the cost of washups between jobs and streamlining the total print production process. For digital print, multicolor printing has helped printers achieve wider gamuts and higher speeds, enabling use of digital print in more applications.

Multicolor printing is not a "magic pill." Printers and print buyers should look at the specific application and color requirements. It may make sense to run a four-color job with just one extra spot instead of a seven-color process. In some cases, printing equipment may not have enough decks to run a standard multicolor process. Also note that the process of specifying spot colors works differently too, as the printer cannot use drawdowns to match color in advance of the print run.

A color solution for digital packaging printing

Without having dedicated tools and technologies, preparing digital files for an extended color gamut workflow can be complex and challenging. Print providers need a complete set of tools that seamlessly integrates with their existing workflows—including proofing, profiling, conversion and calibration tools – to make color separation simple and efficient.

A competent multicolor workflow gives packaging printers control over their extended gamut color separation and print process, using either digital or conventional print. With color in control, printers can simulate brands colors accurately. Printers can also choose how they proof, with the flexibility to move proofing away from the production floor, allowing more production scheduling flexibility and increasing production capacity.

Multicolor is not just for seven-color process printing. Using a multicolor workflow, printers can convert that extra spot color into a fifth process color, allowing printers to expand their printing gamut even with one or two additional special inks. Multicolor tools let printers and prepress operators customize the way they separate art and accurately transform the design intent for use with a custom print process.

A multicolor workflow enables printers to fully utilize their digital print gamut, reduce press make-ready time, improve speed, and reduce click costs. The combination of a multicolor workflow and centralized color management lets printers increase capacity without adding more machines, Artwork preparation becomes fast and reliable, with automated separation/conversion reducing time and effort.

Some challenges can use help

Time is money. For printers that have purchased new printing machines, they want to make sure that their new equipment is up and running as quickly as possible, but may not have the time to build up the color management settings around it. Other print businesses may wish to avoid purchasing new printing machines by increasing the performance and capacity of their existing machines. In either case, engaging with consultants can help printers make the right choices to produce their best color and meet their business objectives . A capable consultant can advise on industry practices and recommend the ideal configuration of a solution—such as choice of ink sets, characterization of the printing process, and other best practices.

With more presses running a variety of jobs requiring consistent color, centralized color management is essential. In addition, as changing inks on press becomes more and more unpopular—multicolor technology can provide a path to accurate and predictable color.

GMG Color is a manufacturer of high-performance color software for printers, brands and brand partners across the supply chain. GMG ColorServer bundles provide all the tools to centralize and automate multicolor separations. GMG ColorProof, DotProof, and FlexoProof continue to set the standard in proofing and prototyping color performance. Both ColorServer and ColorProof connect to GMG OpenColor, GMG’s next-generation color management technology using the power of spectral data to predict and transform color precisely.