Steve Katz, Editor03.13.17

In North America, the food and beverage sectors together make up a whopping 56% of the end use sector of the label market, according to 2015 data collected and reported by LPC Inc., a market research firm specializing in the label and flexible packaging industries. And the next two highest segments, according to the firm, are health & beauty/personal care and pharmaceuticals. There are common links between these end-use segments – they are all complex and regulated, and these regulations involve the materials used to construct the packaging, such as ink.

The label is often just one element of a package that gets scrutinized by end users and regulatory agencies; and the scrutiny involves product safety. Typically, though in not every instance, the label is applied to a container of some sort – whether it be a plastic or glass drinking bottle, or a folding carton for food. In some areas – such as produce – labels are applied directly onto the fruits and vegetables themselves.

The food & beverage and beauty & personal care markets are lucrative and competitive, and in order to gain entry and stay ahead within these spaces, label converters must be knowledgeable about the materials they use, and whether or not they can potentially damage a product or put a consumer in harms way via contamination. This is why, when it comes to labels and flexible packaging, the study and understanding of low migration inks has never been more important.

“Market awareness on issues surrounding the migration of compounds on food packaging has continued to cause increased concern in the global marketplace,” says Jim Bishop, field product manager, UV, EB & Conventional Packaging Inks, Sun Chemical. “This has naturally increased the demand for low migration inks and coatings in the label industry. It is important for both package printers and brand owners to understand the issues surrounding migration in food packaging, especially in three important aspects: knowing what low-migration ink and coating products are available, understanding proper process implementation and control, and the testing required.”

Dean Radford, vice president of technology, Narrow Web, Siegwerk, points out that the use of low migration UV/LED systems has experienced strong growth in the narrow web space, especially in UV flexo printing of self-adhesive labels, wraparound labels, IML labels and shrink sleeves. He says, “This trend is a result of more stringent regulations and it also reflects the growing awareness of issues related to food packaging by printers and processors. Inks that are not properly formulated for food packaging can result in product failures due to migration of unwanted materials into the packaged product. Siegwerk works closely with our customers when they are moving toward low migration UV systems. Working in partnership helps reduce risk and gets our customers on board with fewer risks.”

Understanding Migration

First, a definition. According to Rick Clendenning, president and CEO of INX International Ink Co., “Migration is the transfer of various components from the finished packaging to the product itself, such as a food item. These components can originate from inks, adhesives, varnishes, coatings, substrates or the environment. Often, migration cannot be detected by odor or taste, but instead must rely upon chemical analysis to identify if any migration has occurred.”

Niklas Olsson, global brand manager, Packaging and Narrow Web for Flint Group, states, “We believe that low migration UV inks – or as we define it – “food packaging compliant inks,” are going to become an industry norm and the “standard” ink to use very soon.”

Due to regulations that began in central Europe, the market demand for food packaging complaint inks kicked off in mid 2000, Olsson says, and has been growing steadily ever since. “Today, low migration UV curable inks are used widely across central Europe, and we feel the pull for the products expanding into Western Europe, the US, Latin America and Asia,” says Olsson, “This technology has grown exponentially and growth will continue – for sure. The demand comes from global brand owners as they extend their requirements in other regions, but is also being gradually supported by local regulations. Additionally, demand for these inks is coming from cosmetic and pharmaceutical applications.

A Growing, Complicated Market

While ink migration may be a slow process, the same cannot be said for the state of the low migration ink market itself.

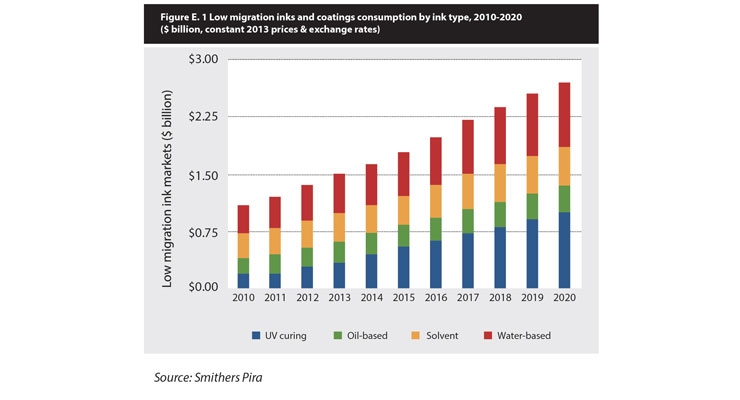

According to market research firm Smithers Pira, low migration inks and coatings are being increasingly adopted in packaging and label print applications with a total of 209,000 tons consumed globally in 2014, valued at $1.6 billion. The market will grow as the topic becomes more high profile, the firm reports, with volume up by an average CAGR of 7.7% between 2015 and 2020, while value will rise by an average of 8.7% as radiation curing grades increase their share.

Smithers Pira notes that much of the attention in low migration inks and coatings is focused on radiation curing formulations. This comes following the contamination, in 2005, of Nestle baby milk by ITX (isopropyl thioxanthone), a photoinitiator used in UV curing inks on the outside of the Tetra Pak cartons. “This incident set alarm bells ringing for regulatory authorities keen to ensure public safety. The principal that any packaging should not adversely affect the contents is followed everywhere, with varying degrees of testing in place. Potential corrective and legal actions also differ regionally. This means there is no globally accepted definition of what comprises a low migration formula,” says Jake Mercer, marketing specialist, marketing reports, at Smithers Pira.

In a new Smithers Pira report, the firm defines a low migration ink or coating as one considered to be a material used in the production of food packaging that conforms to the local regulations in force at the location of the converter, when used according to the manufacturers’ guidelines and following good manufacturing processes. Mercer says, “Brands, converters and ink/coating manufacturers are working to prevent a recurrence of such events, demonstrating their commitment to protect end users.”

Low migration inks make up a small proportion of the total graphics and packaging ink market. According to Smithers Pira, in 2010 it comprised 4.6% of the total tonnage, which is 4.5% of the market’s total value. The share has grown, in 2015 making up 5.5% of the value and 6.9% of the volume – over a quarter of all packaging inks and coatings – with 9.2% by weight in 2020. The 6.6% of the overall market value in 2020 reflects the growing proportion of high value digital grades in the overall sector. The higher value of the low migration inks and coatings in packaging reflects the predominantly analog types of products, with a significant price premium charged by suppliers over non-low migration grades, Smithers Pira reports.

The proportion of low migration inks is growing in packaging inks, from 19.5% of volume in 2010 to over 30% in 2020 by volume and 23.8% to 33.9% in value terms, the firm notes. Food (and beverage) packaging is the largest sector of the packaging market, accounting for well over half the market in 2014. This means that a significant amount of food packaging does not use low migration inks and coatings. Hence, opportunity abounds.

Minimizing Risk

When inks and coatings are separated from the packaged food by one or more layers of material, the suitability of those inks and coatings is determined by the barrier properties and the extraction properties of the packaged food.

“Possible sources of migration can come from paper, pressroom hygiene, fountain solution, press wash, type of inks and coatings, press operation procedures, and the environment around the printing, carton storage and transportation process, says Sun chemical’s Bishop. “The best way to ensure the lowest level of post-odor, off-flavor and residual extractables is to control each facet of the supply chain and printing process. It is important for brand owners to be aware of regulations around migration and to follow those rules. A careful choice of the right substrate and chemicals, combined with best-use application and handling practices helps to minimize chemical migration risk on food and beverage packaging,” says Bishop.

“However,” notes INX’s Rick Clendenning, “because there is a wide array of combinations of food types, packaging materials, and inks and coatings; there is a lack of clarity on the permeability of various combinations of plastic containers and film substrates. So, to be sure a packaging material acts as a functional barrier, migration tests with the final packaging construction are recommended.”

Containers such as pre-formed metal cans and glass bottles are considered low to no risk for migration. Clendenning says, “Low migration inks are recommended when it comes to UV/EB and conventional sheetfed printing – especially if thin film substrates or paper material with weak barrier properties are used as the primary packaging material.

“Low migration inks should be tested under standardized conditions to prove that they do not migrate above defined acceptable limits,” Clendenning continues. “Because these tests cannot simulate all possible food/substrate combinations, there cannot be 100% safety assurance without a suitable risk assessment. For every specific packaging and label application, it’s advisable to assess the risk of migration – this is especially recommended for packaging where no absolute barrier exists.”

For food packaging press runs, Clendenning suggests converters install extra controls to maintain the lowest possible levels of residual solvents and other volatile substances. “Such controls should also be employed to ensure sufficient dying occurs to meet requirements. Low odor and the elimination of any taint potential are important. Technical instructions from your consumable and equipment suppliers should be followed in full. If slow or low evaporating solvents are used for improved printability of solvent-based and water-based inks, care must be taken with these choices as slow solvents have a high potential to be retained in the printed product and could subsequently migrate to the packaged food,” he says.

To prevent accidents, it is suggested that no other general ink additives should be anywhere near the press. “To ensure that migration from inks or coatings in the finished package remains within legislative limits, additional graphic features that might be printed on top of the low migration ink design must also consist of materials that have proven low migration tendencies. And when converting a press from conventional printing ink to a low migration ink, the press must be thoroughly cleaned to avoid any contamination from those previously used high migration materials,” Clendenning says.

Niklas Olsson of Flint Group notes that it has become a common definition that “packaging” is what is sold over the counter – so this places any type of product decoration into scope – from PS labels on an outer pack of cheese, via shrink sleeves on PE bottles over to flexible packaging such as wrappers, bags, pouches and sachets. “There may be different end user demand depending on the application, and it should be pointed out that one always needs to consider the total packaging construction – as some of these constructions may possess full barrier properties,” Olsson explains, “such as glass, metal, and in some cases PET bottles. In these instances – where a true barrier is in use – low migration products are not necessary to use. Then again, the ultimate responsibility is with the ‘person placing the pack on the market.’ However, collaboration among all value chain partners is essential as responsibility for the compliance does not rest with just one individual member of the supply chain,” Olsson says.

Speaking of the supply chain, the label industry’s leading ink suppliers work in tandem with their respective raw material suppliers. “Siegwerk upholds a rigorous process of approving raw materials,” states Dean Radford. “We have an in-house team of experts who are responsible for the choice of suitable raw materials for our printing inks. Every new source material is checked using extensive and closely knit processes. Our raw material suppliers are required to answer comprehensive and highly detailed questions. In addition, they must provide evidence that the raw materials are neither toxic, mutagenic nor carcinogenic,” he says.

At Siegwerk, Radford stresses that strict purity criteria must also be fulfilled with regard to heavy metals and trace contamination with dioxins or primary aromatic amines – to cite just two examples. “This process ensures adherence to the strict requirements of the relevant chemical legislation of the various countries in which Siegwerk is active,” Radford says.

Concludes Sun Chemical’s Bishop, “Migration requirements for safe packaging are set by global government agencies, and depend on the end-use of the package. Secondary versus primary packaging and the type of food or drug that is placed in that container help delegate the type of chemicals that can be used, along with the type of testing that needs to be implemented to ensure that the package is consumer safe. Protocols usually call for extended temperature testing using food simulant chemicals over specific time frames to mimic a product sitting on a shelf for 6-9 months,” he says.

UV Curing and Low Migration

UV curing is a process where free radicals become excited under UV lamps and then initiate the cure process. According to Flint Group’s Olsson, traditionally low molecular weight photoinitiators are extremely efficient, and thus the first generation of low migration UV inks typically had much slower cure response, when compared to traditional products. “However,” Olsson says, “The traditional photoinitiators can also generate by-products which have an undesirable impact on taint and/or odor properties of the packaged product, so ink and coatings formulators are forced to combine these larger molecules in a way so that cure response is not impacted.”

Photoinitiators are not the only source of migrants when it comes to UV printing ink or coating. “The monomers,” Olsson explains, “which are the ‘solvents’ of these systems, differ from normal solvents as they are reactive and combine with the oligomers to form a film on curing. Many of the monomers which are effective in reducing the viscosity and controlling the rheological properties of a printing ink also have a low molecular weight themselves, or contain portions of low molecular weight materials, and can also contain other additives and stabilizers, which can potentially migrate.”

Another migration concern, although not restricted to UV inks alone, is the use of unsuitable pigments. A good example, Olsson points out, is so-called “fanal” pigments, which are often preferred by end users for their clarity, depth and cleanliness of color. “These can easily set-off on the backside of a print, or can bleed into foodstuffs and therefore also pose a potential risk,” he says.

Today’s low migration UV inks and varnishes are developed so that when correctly applied and cured, onto the correct choice of substrate, the legal migration limits are met. “Nevertheless, no ink or varnish supplier can guarantee that the formulated migration levels will always be achieved in practice, as so many practical factors have an impact,” Olsson says, “The printing ink or varnish manufacturer actually has only an obligation to formulate an ink, which when applied and cured under the correct conditions, should enable the end user to be in compliance with the framework regulation.”

Siegwerk’s Dean Radford emphasizes that low migration UV/LED systems consist of low odor, high purity raw materials that typically have high reactivity. Radford does a stellar job of putting an explanation of the process in layman’s terms, describing the relationship between the increased molecular weight of low migration monomers, and photoinitiators maximizing the degree of conversion of the inks while also reducing the potential for migration. “In other words,” Radford states, “the rather large size of the molecules cause them to become trapped in the tightly reacted network of the ink matrix. This concept can be compared to the net of a fisherman: Using a non-low migration UV system is like using a large mesh net that allows the smaller fish to swim through. Using a low migration UV system is equivalent to using a very tight mesh net and replacing all of the small fish with larger ones. Consequently, the bigger fish are trapped and unable to pass through the net.”

Migration Types and Testing

According to Flint Group’s Olsson, the sources of migration fit into four categories: inks/coatings, environment, substrate/barrier material, and the print/converting process. Migration occurs in four ways:

digital inkjet ink migration

With digital printing playing an increasingly more prominent role in the label industry, we’d be remiss not to mention the relationship between digital technology and low migration inks. Because this is an ink article, we’ll limit our area of focus to inkjet inks, while acknowledging that certain toner-based technologies such as Xeikon’s dry toners are very much safe and suitable for food packaging.

Mike Pruitt, SurePress product manager, Epson America, says Epson has UV and water-based ink options, which are both are low migration inks, yet the water-based ink has lower toxicity than the UV ink.

“In the digital inkjet space, low migration ink is different from other types of ink simply because the molecule in it is larger and has a much difficult time passing through the matrix of the media it is printed on,” Pruitt says, adding, “to get the ink to flow and dry both accurately and quickly, it’s easiest to use solvents in inks. Like flexo, inkjet has to use advanced chemistry to eliminate solvents of other toxic fluid modifiers.”

All Epson inks are low migration, which are offered for both the SurePress digital label press and the ColorWorks desktop label printers.Epson’s first single-pass industrial press, the SurePress L-6034VW, offers the technology with inline digital varnishing and high-opacity white using its own LED-UV inks. Epson publishes an extensive toxicity statement on both its water-based and UV ink sets.

Emily Kroll, business director, Labels & Packaging, Durst, is noticing more and more applications requiring inks with no or limited migration. “From our perspective, we see continued interest when it comes to inkjet low migration inks. Durst is installing year after year more and more Tau presses with low migration ink for specialized food, pharmaceutical and cosmetic applications,” Kroll says. For Durst press users, there are different ink requirements for different customers and applications, therefore the ink is part of the specification, qualification and decision process. “At present the low migration share is approximately 15% of all installs of Durst Tau 330 presses,”Kroll says.

In close partnership with Durst, Sunjet, a product group from Sun Chemical, developed high-pigmented UV inks which comply with the various different migration rules of regulatory agencies throughout the world including the EU, Swiss Ordinance, US FDA and NAPIM.

Adds Kroll, “The complexity of low-migration inks also takes into account the various different forms of migration, such as penetration, contact, evaporation and condensation, as well as the different packaging materials used. The Tau 330 was the first UV inkjet printing system for which low-migration inks were approved. Certification was carried out officially according to ISO 17025 by Sunjet and also by an independent lab. For printing primary packaging, the Tau 330 features an integrated chill roller for the processing of thin, heat-sensitive materials. In addition, the integrated inert gas system reduces the odors of UV inkjet printing so that the requirements of the food and pharma industries regarding low-odor printing processes are fulfilled. Currently, Durst and Sunjet’s focus is to educate the market on what low migration actually means and where the responsibility lies.”

The label is often just one element of a package that gets scrutinized by end users and regulatory agencies; and the scrutiny involves product safety. Typically, though in not every instance, the label is applied to a container of some sort – whether it be a plastic or glass drinking bottle, or a folding carton for food. In some areas – such as produce – labels are applied directly onto the fruits and vegetables themselves.

The food & beverage and beauty & personal care markets are lucrative and competitive, and in order to gain entry and stay ahead within these spaces, label converters must be knowledgeable about the materials they use, and whether or not they can potentially damage a product or put a consumer in harms way via contamination. This is why, when it comes to labels and flexible packaging, the study and understanding of low migration inks has never been more important.

“Market awareness on issues surrounding the migration of compounds on food packaging has continued to cause increased concern in the global marketplace,” says Jim Bishop, field product manager, UV, EB & Conventional Packaging Inks, Sun Chemical. “This has naturally increased the demand for low migration inks and coatings in the label industry. It is important for both package printers and brand owners to understand the issues surrounding migration in food packaging, especially in three important aspects: knowing what low-migration ink and coating products are available, understanding proper process implementation and control, and the testing required.”

Dean Radford, vice president of technology, Narrow Web, Siegwerk, points out that the use of low migration UV/LED systems has experienced strong growth in the narrow web space, especially in UV flexo printing of self-adhesive labels, wraparound labels, IML labels and shrink sleeves. He says, “This trend is a result of more stringent regulations and it also reflects the growing awareness of issues related to food packaging by printers and processors. Inks that are not properly formulated for food packaging can result in product failures due to migration of unwanted materials into the packaged product. Siegwerk works closely with our customers when they are moving toward low migration UV systems. Working in partnership helps reduce risk and gets our customers on board with fewer risks.”

Understanding Migration

First, a definition. According to Rick Clendenning, president and CEO of INX International Ink Co., “Migration is the transfer of various components from the finished packaging to the product itself, such as a food item. These components can originate from inks, adhesives, varnishes, coatings, substrates or the environment. Often, migration cannot be detected by odor or taste, but instead must rely upon chemical analysis to identify if any migration has occurred.”

Niklas Olsson, global brand manager, Packaging and Narrow Web for Flint Group, states, “We believe that low migration UV inks – or as we define it – “food packaging compliant inks,” are going to become an industry norm and the “standard” ink to use very soon.”

Due to regulations that began in central Europe, the market demand for food packaging complaint inks kicked off in mid 2000, Olsson says, and has been growing steadily ever since. “Today, low migration UV curable inks are used widely across central Europe, and we feel the pull for the products expanding into Western Europe, the US, Latin America and Asia,” says Olsson, “This technology has grown exponentially and growth will continue – for sure. The demand comes from global brand owners as they extend their requirements in other regions, but is also being gradually supported by local regulations. Additionally, demand for these inks is coming from cosmetic and pharmaceutical applications.

A Growing, Complicated Market

While ink migration may be a slow process, the same cannot be said for the state of the low migration ink market itself.

According to market research firm Smithers Pira, low migration inks and coatings are being increasingly adopted in packaging and label print applications with a total of 209,000 tons consumed globally in 2014, valued at $1.6 billion. The market will grow as the topic becomes more high profile, the firm reports, with volume up by an average CAGR of 7.7% between 2015 and 2020, while value will rise by an average of 8.7% as radiation curing grades increase their share.

Smithers Pira notes that much of the attention in low migration inks and coatings is focused on radiation curing formulations. This comes following the contamination, in 2005, of Nestle baby milk by ITX (isopropyl thioxanthone), a photoinitiator used in UV curing inks on the outside of the Tetra Pak cartons. “This incident set alarm bells ringing for regulatory authorities keen to ensure public safety. The principal that any packaging should not adversely affect the contents is followed everywhere, with varying degrees of testing in place. Potential corrective and legal actions also differ regionally. This means there is no globally accepted definition of what comprises a low migration formula,” says Jake Mercer, marketing specialist, marketing reports, at Smithers Pira.

In a new Smithers Pira report, the firm defines a low migration ink or coating as one considered to be a material used in the production of food packaging that conforms to the local regulations in force at the location of the converter, when used according to the manufacturers’ guidelines and following good manufacturing processes. Mercer says, “Brands, converters and ink/coating manufacturers are working to prevent a recurrence of such events, demonstrating their commitment to protect end users.”

Low migration inks make up a small proportion of the total graphics and packaging ink market. According to Smithers Pira, in 2010 it comprised 4.6% of the total tonnage, which is 4.5% of the market’s total value. The share has grown, in 2015 making up 5.5% of the value and 6.9% of the volume – over a quarter of all packaging inks and coatings – with 9.2% by weight in 2020. The 6.6% of the overall market value in 2020 reflects the growing proportion of high value digital grades in the overall sector. The higher value of the low migration inks and coatings in packaging reflects the predominantly analog types of products, with a significant price premium charged by suppliers over non-low migration grades, Smithers Pira reports.

The proportion of low migration inks is growing in packaging inks, from 19.5% of volume in 2010 to over 30% in 2020 by volume and 23.8% to 33.9% in value terms, the firm notes. Food (and beverage) packaging is the largest sector of the packaging market, accounting for well over half the market in 2014. This means that a significant amount of food packaging does not use low migration inks and coatings. Hence, opportunity abounds.

Minimizing Risk

When inks and coatings are separated from the packaged food by one or more layers of material, the suitability of those inks and coatings is determined by the barrier properties and the extraction properties of the packaged food.

“Possible sources of migration can come from paper, pressroom hygiene, fountain solution, press wash, type of inks and coatings, press operation procedures, and the environment around the printing, carton storage and transportation process, says Sun chemical’s Bishop. “The best way to ensure the lowest level of post-odor, off-flavor and residual extractables is to control each facet of the supply chain and printing process. It is important for brand owners to be aware of regulations around migration and to follow those rules. A careful choice of the right substrate and chemicals, combined with best-use application and handling practices helps to minimize chemical migration risk on food and beverage packaging,” says Bishop.

“However,” notes INX’s Rick Clendenning, “because there is a wide array of combinations of food types, packaging materials, and inks and coatings; there is a lack of clarity on the permeability of various combinations of plastic containers and film substrates. So, to be sure a packaging material acts as a functional barrier, migration tests with the final packaging construction are recommended.”

Containers such as pre-formed metal cans and glass bottles are considered low to no risk for migration. Clendenning says, “Low migration inks are recommended when it comes to UV/EB and conventional sheetfed printing – especially if thin film substrates or paper material with weak barrier properties are used as the primary packaging material.

“Low migration inks should be tested under standardized conditions to prove that they do not migrate above defined acceptable limits,” Clendenning continues. “Because these tests cannot simulate all possible food/substrate combinations, there cannot be 100% safety assurance without a suitable risk assessment. For every specific packaging and label application, it’s advisable to assess the risk of migration – this is especially recommended for packaging where no absolute barrier exists.”

For food packaging press runs, Clendenning suggests converters install extra controls to maintain the lowest possible levels of residual solvents and other volatile substances. “Such controls should also be employed to ensure sufficient dying occurs to meet requirements. Low odor and the elimination of any taint potential are important. Technical instructions from your consumable and equipment suppliers should be followed in full. If slow or low evaporating solvents are used for improved printability of solvent-based and water-based inks, care must be taken with these choices as slow solvents have a high potential to be retained in the printed product and could subsequently migrate to the packaged food,” he says.

To prevent accidents, it is suggested that no other general ink additives should be anywhere near the press. “To ensure that migration from inks or coatings in the finished package remains within legislative limits, additional graphic features that might be printed on top of the low migration ink design must also consist of materials that have proven low migration tendencies. And when converting a press from conventional printing ink to a low migration ink, the press must be thoroughly cleaned to avoid any contamination from those previously used high migration materials,” Clendenning says.

Niklas Olsson of Flint Group notes that it has become a common definition that “packaging” is what is sold over the counter – so this places any type of product decoration into scope – from PS labels on an outer pack of cheese, via shrink sleeves on PE bottles over to flexible packaging such as wrappers, bags, pouches and sachets. “There may be different end user demand depending on the application, and it should be pointed out that one always needs to consider the total packaging construction – as some of these constructions may possess full barrier properties,” Olsson explains, “such as glass, metal, and in some cases PET bottles. In these instances – where a true barrier is in use – low migration products are not necessary to use. Then again, the ultimate responsibility is with the ‘person placing the pack on the market.’ However, collaboration among all value chain partners is essential as responsibility for the compliance does not rest with just one individual member of the supply chain,” Olsson says.

Speaking of the supply chain, the label industry’s leading ink suppliers work in tandem with their respective raw material suppliers. “Siegwerk upholds a rigorous process of approving raw materials,” states Dean Radford. “We have an in-house team of experts who are responsible for the choice of suitable raw materials for our printing inks. Every new source material is checked using extensive and closely knit processes. Our raw material suppliers are required to answer comprehensive and highly detailed questions. In addition, they must provide evidence that the raw materials are neither toxic, mutagenic nor carcinogenic,” he says.

At Siegwerk, Radford stresses that strict purity criteria must also be fulfilled with regard to heavy metals and trace contamination with dioxins or primary aromatic amines – to cite just two examples. “This process ensures adherence to the strict requirements of the relevant chemical legislation of the various countries in which Siegwerk is active,” Radford says.

Concludes Sun Chemical’s Bishop, “Migration requirements for safe packaging are set by global government agencies, and depend on the end-use of the package. Secondary versus primary packaging and the type of food or drug that is placed in that container help delegate the type of chemicals that can be used, along with the type of testing that needs to be implemented to ensure that the package is consumer safe. Protocols usually call for extended temperature testing using food simulant chemicals over specific time frames to mimic a product sitting on a shelf for 6-9 months,” he says.

UV Curing and Low Migration

UV curing is a process where free radicals become excited under UV lamps and then initiate the cure process. According to Flint Group’s Olsson, traditionally low molecular weight photoinitiators are extremely efficient, and thus the first generation of low migration UV inks typically had much slower cure response, when compared to traditional products. “However,” Olsson says, “The traditional photoinitiators can also generate by-products which have an undesirable impact on taint and/or odor properties of the packaged product, so ink and coatings formulators are forced to combine these larger molecules in a way so that cure response is not impacted.”

Photoinitiators are not the only source of migrants when it comes to UV printing ink or coating. “The monomers,” Olsson explains, “which are the ‘solvents’ of these systems, differ from normal solvents as they are reactive and combine with the oligomers to form a film on curing. Many of the monomers which are effective in reducing the viscosity and controlling the rheological properties of a printing ink also have a low molecular weight themselves, or contain portions of low molecular weight materials, and can also contain other additives and stabilizers, which can potentially migrate.”

Another migration concern, although not restricted to UV inks alone, is the use of unsuitable pigments. A good example, Olsson points out, is so-called “fanal” pigments, which are often preferred by end users for their clarity, depth and cleanliness of color. “These can easily set-off on the backside of a print, or can bleed into foodstuffs and therefore also pose a potential risk,” he says.

Today’s low migration UV inks and varnishes are developed so that when correctly applied and cured, onto the correct choice of substrate, the legal migration limits are met. “Nevertheless, no ink or varnish supplier can guarantee that the formulated migration levels will always be achieved in practice, as so many practical factors have an impact,” Olsson says, “The printing ink or varnish manufacturer actually has only an obligation to formulate an ink, which when applied and cured under the correct conditions, should enable the end user to be in compliance with the framework regulation.”

Siegwerk’s Dean Radford emphasizes that low migration UV/LED systems consist of low odor, high purity raw materials that typically have high reactivity. Radford does a stellar job of putting an explanation of the process in layman’s terms, describing the relationship between the increased molecular weight of low migration monomers, and photoinitiators maximizing the degree of conversion of the inks while also reducing the potential for migration. “In other words,” Radford states, “the rather large size of the molecules cause them to become trapped in the tightly reacted network of the ink matrix. This concept can be compared to the net of a fisherman: Using a non-low migration UV system is like using a large mesh net that allows the smaller fish to swim through. Using a low migration UV system is equivalent to using a very tight mesh net and replacing all of the small fish with larger ones. Consequently, the bigger fish are trapped and unable to pass through the net.”

Migration Types and Testing

According to Flint Group’s Olsson, the sources of migration fit into four categories: inks/coatings, environment, substrate/barrier material, and the print/converting process. Migration occurs in four ways:

- Penetration Migration – through the substrate to the reverse-side of the print.

- Set-off Migration – from the printed side of a substrate to the reverse side of the substrate while stacked or stored on a roll.

- Vapor-phase migration – evaporation of volatile compounds when heated.

- Condensation Extraction – condensation of critical compounds when cooked or sterilized.

digital inkjet ink migration

With digital printing playing an increasingly more prominent role in the label industry, we’d be remiss not to mention the relationship between digital technology and low migration inks. Because this is an ink article, we’ll limit our area of focus to inkjet inks, while acknowledging that certain toner-based technologies such as Xeikon’s dry toners are very much safe and suitable for food packaging.

Mike Pruitt, SurePress product manager, Epson America, says Epson has UV and water-based ink options, which are both are low migration inks, yet the water-based ink has lower toxicity than the UV ink.

“In the digital inkjet space, low migration ink is different from other types of ink simply because the molecule in it is larger and has a much difficult time passing through the matrix of the media it is printed on,” Pruitt says, adding, “to get the ink to flow and dry both accurately and quickly, it’s easiest to use solvents in inks. Like flexo, inkjet has to use advanced chemistry to eliminate solvents of other toxic fluid modifiers.”

All Epson inks are low migration, which are offered for both the SurePress digital label press and the ColorWorks desktop label printers.Epson’s first single-pass industrial press, the SurePress L-6034VW, offers the technology with inline digital varnishing and high-opacity white using its own LED-UV inks. Epson publishes an extensive toxicity statement on both its water-based and UV ink sets.

Emily Kroll, business director, Labels & Packaging, Durst, is noticing more and more applications requiring inks with no or limited migration. “From our perspective, we see continued interest when it comes to inkjet low migration inks. Durst is installing year after year more and more Tau presses with low migration ink for specialized food, pharmaceutical and cosmetic applications,” Kroll says. For Durst press users, there are different ink requirements for different customers and applications, therefore the ink is part of the specification, qualification and decision process. “At present the low migration share is approximately 15% of all installs of Durst Tau 330 presses,”Kroll says.

In close partnership with Durst, Sunjet, a product group from Sun Chemical, developed high-pigmented UV inks which comply with the various different migration rules of regulatory agencies throughout the world including the EU, Swiss Ordinance, US FDA and NAPIM.

Adds Kroll, “The complexity of low-migration inks also takes into account the various different forms of migration, such as penetration, contact, evaporation and condensation, as well as the different packaging materials used. The Tau 330 was the first UV inkjet printing system for which low-migration inks were approved. Certification was carried out officially according to ISO 17025 by Sunjet and also by an independent lab. For printing primary packaging, the Tau 330 features an integrated chill roller for the processing of thin, heat-sensitive materials. In addition, the integrated inert gas system reduces the odors of UV inkjet printing so that the requirements of the food and pharma industries regarding low-odor printing processes are fulfilled. Currently, Durst and Sunjet’s focus is to educate the market on what low migration actually means and where the responsibility lies.”