Greg Hrinya, Associate Editor11.17.17

As narrow web label and packaging converters explore ways to optimize their business, they are increasingly looking toward out-of-the-box solutions. Even though it presents challenges, the folding carton market offers a viable channel for printers seeking another revenue stream for their customers.

“To remain competitive, converters need to squeeze every possible cost out of production,” explains Claudio Semenza, sales director at Omet Americas. “Increasing productivity remains the best way to do this. The inline flexo folding carton process offers significant productivity and value-added advantages. Productivity is the single biggest determinant of success in a commodity business such as folding cartons.”

According to AWA Alexander Watson Associates, 75% of folding cartons in North America are targeted for food applications, while the remaining 25% include items like detergents and pet foods. Health and beauty, pharmaceuticals and other high-end products also make use of folding cartons.

Folding carton growth has remained relatively static. In AWA’s North American Extrusion Coating Market Study 2015, the firm states that the market has historically grown by 1%, but the rate for 2014-2017 was forecasted to rise to 2%. That figure is consistent with the 1.8% growth rate from 2007-2014. AWA adds that board mills, with their integrated extrusion coating and laminating facilities, control 80% of the extrusion coated folding carton board business.

There is an opportunity in the digital folding carton market, though. Kim Hajec, marketing manager, folding cartons, HP, says that the market for digitally produced folding cartons is expected to grow by 36%.

“There is massive opportunity to convert to digital,” says Hajec. “Digital allows for low inventory, variable printing, low cost changes and faster time to market.”

Folding carton work goes beyond the typical steps involved with conventional printing. Most of these applications are printed on sheetfeed offset equipment with offline diecutting, embossing or debossing, folding and gluing processes.

“While normally printed on long run and wider webs, we do see low volume web-fed folding carton applications,” explains Nat Davis, digital product manager, new business development, at Mark Andy. “Generally, these short-run folding carton applications are printed on paperboard substrates. They are produced on a narrow web flexo or hybrid press to take advantage of the short make-readies and inline efficiency.”

Folding carton applications represent one of the largest segments in print, says Davis. The work printed on flexo presses tends to utilize flat tag stock like the backing of blister packs or small cartons like vitamin boxes.

New presses and converting equipment have made folding cartons more relevant. There are multiple enhancement capabilities available, including the use of metallic inks, UV/aqueous and specialty coatings, hot foil, cold foil, embossing, reverse printing and hologram insertions. In addition, the rise of hybrid presses–and their promotion of combination printing–have made the folding carton market more attractive.

“In recent years, a good amount of this short-run work has moved to digital presses,” says Larry Moore, Esko’s vice president of partner programs, North America. “Most are sheetfed, although a number are roll-fed. When a job is printed on a digital press, either the printed material is taken off the digital press and sent to digital finishing equipment like an AB Graphic machine or a flatbed diecutter like an Esko Kongsberg table.”

In a recent study entitled, “The Future of Folding Cartons to 2022,” Smithers Pira projects that the global demand for cartonboard used in packaging applications will grow by 4.0% CAGR. In terms of value, the market recently surpassed the $100 billion mark in 2016 and it should reach $124.1 billion by 2022. This market accounts for 40.3 million tons of folding carton material destined for packaging.

With the trend toward digital printing, press manufacturers have a range of options that are suitable for folding cartons. HP has presses that depending on the size of the carton – are optimized for this industry. The HP Indigo 30000, 12000, 7900 and 5900 digital presses are all applicable. Additionally, if a converter already has a 6000 series, they have the ability to print a wide range of applications.

“There is a growing trend of brands that have expressed to have their labels and cartons more closely matched in color and in the same environment,” says Hajec. “Because of the versatility of the HP Indigo 6000 Series, many label converters are using this press for both labels, shrink sleeves and folding cartons.”

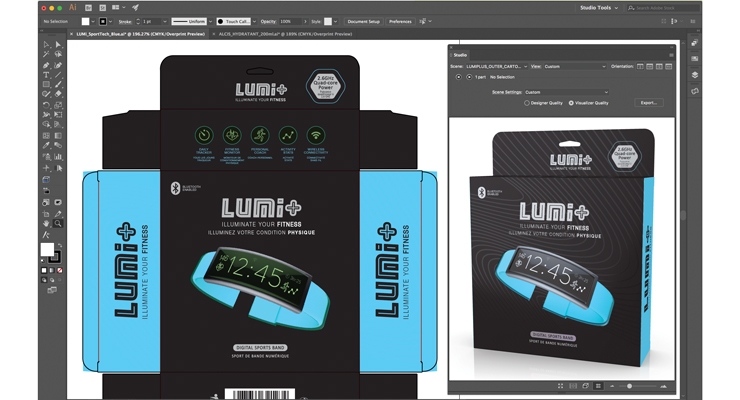

Outlook Group, a label and packaging converter based in Neenah, WI, USA, concurs that digital printing is viable for folding cartons. “This technology allows a folding carton producer to print using a computer image, then run the job through the printer,” says Joel Schmidt, director of market development at Outlook Group. “ The advantage of digital printing is that changeovers happen nearly instantaneously by simply changing the art file, and the presses in the market today cater to smaller run business and prototyping far more economically than offset technology.”

Gert Geens, business development manager, folding carton, at Xeikon, says that this market sees very specific materials utilized. The most popular materials include virgin fibers like SBS, GC1, GC2 for pharma applications, H&B for direct food contact and recycled fibers like a GD2 for non-contact food and low-margin products. “In the beverage sector we typically see kraft-based boards used because of their strength,” he adds. For finishing, flat-bed diecutting machines are generally the solution of choice, Geens says, noting that laser diecutters are attempting to enter the market as well, but traditional converters have been slow to accept these practices.

“Folding carton work almost always involves a steel-on-steel diecut in a sheeting station if being diecut inline generally in association with a conveyor,” adds Davis. “Offline they would fold, pre-break and glue if needed.”

Entering this market can sometimes be a challenge, especially for narrow web label converters. “The biggest challenge for a converter looking to penetrate or grow business in this segment is its size and niche of applications,” says Davis. “Only a small portion of this market fits an inline flexographic press perfectly. It also tends to be a specialized market requiring knowledge of packaging design and specialized offline finishing equipment.”

A trending market for narrow web?

According to Outlook Group’s Schmidt, the folding carton market presents an opportunity for label converters. “Label converters view folding carton production as a natural progression or growth strategy for their company,” he says. “A successful label converter will own a book of business, from which there is likely folding carton opportunity. Label converters already have a fundamental understanding of matching materials to an application, how to print successfully and consistently, and offer technical support assuring labels will run on application equipment. The same needs exist in folding carton, but the competencies are a bit different.

Mark Andy’s Davis believes that the folding carton market is tough to break into without the requisite experience in it. “Normally, narrow web folding carton is used as a short-run alternative to traditional processes to keep wider and faster presses available for longer runs,” he explains. “Because of the specialized tooling and knowledge required to be efficient, penetrating this market from the traditional label market can be a challenge.”

Many traditional label presses are limited in terms of what boards they can run, Davis adds. Once a converter exceeds a 14-point board, the company must evaluate if it would be better served investing in a designated board press.

According to Omet’s Semenza, inline flexo presses are extremely efficient manufacturing production lines that offer multiple value-added options, which can greatly enhance profitability.

“The folding carton market has been a challenge for the last 20 years, and it’s still a possibility to move in,” says Semenza. “The only thing constant in today’s folding carton business is change itself. The biggest question for converters is not, “Should I add flexo as a capability?” but rather, “What am I doing to remain competitive?”

Even though the market can be difficult to penetrate, Xeikon’s Geens points to recent independent studies from InfoTrends and Smithers Pira to confirm the growing interesting in digitalal printing for folding cartons. With new digital technologies, more converters are inquiring about the possibilities. “Yes, it’s definitely a trend,” he says. “Drupa 2016 did a great job and lots of converters now see that they need to be prepared for the future. As a result, they are investigating the digital printing arena more and more and are exploring the technologies available.”

There are advantages that narrow web converters can provide to the folding carton market, says Esko’s Moore. Narrow web flexo and roll-fed digital printing are faster and easier than conventional sheetfed. “Imagine printing a two-sided blister card. Conventionally, a printer creates a step and repeat layout for a 40" sheet,” explains Moore. “They print the front of the box, let it dry overnight and print the back the next day. The pieces are left to dry overnight before they are sent to an auto platen to diecut the job. Just in printing and finishing alone, the job will take three days – a week, at least, if you include prepress and other tasks. The other problem is that each of these steps requires a 5% overrun. This means that you will need to start with at least 15% more sheets to produce the job.”

By utilizing a narrow web press, it is possible to print a 6-color job inline with a turn bar. The back of the piece can be simultaneously printed with 2-4 more colors. Then, the job is sent inline to a diecutter. A press can produce a few hundred feet of material in a minute. Even if printed one-up, this is much faster than a conventional press, says Moore. What started as a roll ends up, very quickly, as blister cards.

“I have seen where large sheetfed converters have adopted and purchased narrow web digital and flexo presses,” says Moore. “Meanwhile, some narrow web companies have ventured into boutique boxes that they can print on their existing narrow web presses. This offers a lot of versatility, from inline narrow web cutting and creasing to presses with turn bars that can print both the front and back of a box simultaneously.”

Despite presenting certain challenges, Davis says that folding carton growth is definitely possible. “Given the prevalence of online shopping and the amount of goods being shipped, I would not be surprised if this market grew,” he adds.

Efficient equipment

Today’s presses are well equipped to handle folding cartons. For Omet, the Varyflex is a multi-purpose hybrid line that is suitable for versatile configurations. It can be tailored to the converter’s production requirements. The Varyflex enables the combination of different printing processes like flexo, rotogravure, silk-screen, offset, hot foil and cold foil.

“Omet was one of the pioneers of narrow web machine manufacturers to enter the folding carton market about 20 years ago,” says Semenza. “Its machinery takes advantage of the ‘one shot’ production cycle, and its assembly line operations are far more competitive, with just one operation required from the reel to the finished packaging.”

Mark Andy has produced a number of board presses with varying web widths. The Performance Series, Digital Series and Versamax product lines are all available in board configurations. These presses typically feature a modular die system, which allows heavy-duty die cassettes to be set up offline for embossing, debossing and diecutting.

Like any method of package printing, prepress plays a critical role in the finished product. Esko offers multiple products that can help converters with their folding carton requirements.

According to Esko’s Moore, ArtiosCAD – a structural design packaging software program – fits into all markets. Label printers are able to use the same production systems, like Esko Plato and Esko Automation Engine, for prepress and assembly design work. “These two prepress applications also offer the versatility to be able to send work to either a digital front end (frequently produced by Esko) on a digital press, or out to an Esko CDI for digital imaging of plates,” explains Moore.

Esko prepress and HD Flexo allow converters a great deal of flexibility, too. If a pilot design is printed on a digital press, the printer can be assured that jobs printed from HD Flexo plates will match. “So, if a pilot or test market job graduates to full distribution, a converter can be comfortable moving from digital to flexo,” adds Moore. “It should also be noted that many companies with digital presses use Kongsberg tables to cut and crease folded cartons.”

In prepress for folding cartons, many of the tasks are the same as printing labels. There is, however, the added element of structure, and some companies might even utilize 3D virtual proofing. “Regardless of the printing process, you have to keep the structural design at the forefront because it is going to be the same whether printed digitally, on an offset press, or a combination of the two,” says Moore.

Meanwhile, Xeikon offers several digital solutions for folding carton applications. The Xeikon 3050 and Xeikon 3050 with inline varnish offer a roll-to-roll solution for paper cups or a roll-to-sheet solution for folding cartons. “Our powerful front end allows people to either use their standard prepress workflow or utilize a WEB2Print module or integrated MIS system,” explains Xeikon’s Geens. “Afterwards the printing process sees the substrate unwound from the roll, printed, varnished inline with Xeikon’s web varnishing module and then cut to sheet and stacked in a high pile stacker.”

“To remain competitive, converters need to squeeze every possible cost out of production,” explains Claudio Semenza, sales director at Omet Americas. “Increasing productivity remains the best way to do this. The inline flexo folding carton process offers significant productivity and value-added advantages. Productivity is the single biggest determinant of success in a commodity business such as folding cartons.”

According to AWA Alexander Watson Associates, 75% of folding cartons in North America are targeted for food applications, while the remaining 25% include items like detergents and pet foods. Health and beauty, pharmaceuticals and other high-end products also make use of folding cartons.

Folding carton growth has remained relatively static. In AWA’s North American Extrusion Coating Market Study 2015, the firm states that the market has historically grown by 1%, but the rate for 2014-2017 was forecasted to rise to 2%. That figure is consistent with the 1.8% growth rate from 2007-2014. AWA adds that board mills, with their integrated extrusion coating and laminating facilities, control 80% of the extrusion coated folding carton board business.

There is an opportunity in the digital folding carton market, though. Kim Hajec, marketing manager, folding cartons, HP, says that the market for digitally produced folding cartons is expected to grow by 36%.

“There is massive opportunity to convert to digital,” says Hajec. “Digital allows for low inventory, variable printing, low cost changes and faster time to market.”

Folding carton work goes beyond the typical steps involved with conventional printing. Most of these applications are printed on sheetfeed offset equipment with offline diecutting, embossing or debossing, folding and gluing processes.

“While normally printed on long run and wider webs, we do see low volume web-fed folding carton applications,” explains Nat Davis, digital product manager, new business development, at Mark Andy. “Generally, these short-run folding carton applications are printed on paperboard substrates. They are produced on a narrow web flexo or hybrid press to take advantage of the short make-readies and inline efficiency.”

Folding carton applications represent one of the largest segments in print, says Davis. The work printed on flexo presses tends to utilize flat tag stock like the backing of blister packs or small cartons like vitamin boxes.

New presses and converting equipment have made folding cartons more relevant. There are multiple enhancement capabilities available, including the use of metallic inks, UV/aqueous and specialty coatings, hot foil, cold foil, embossing, reverse printing and hologram insertions. In addition, the rise of hybrid presses–and their promotion of combination printing–have made the folding carton market more attractive.

“In recent years, a good amount of this short-run work has moved to digital presses,” says Larry Moore, Esko’s vice president of partner programs, North America. “Most are sheetfed, although a number are roll-fed. When a job is printed on a digital press, either the printed material is taken off the digital press and sent to digital finishing equipment like an AB Graphic machine or a flatbed diecutter like an Esko Kongsberg table.”

In a recent study entitled, “The Future of Folding Cartons to 2022,” Smithers Pira projects that the global demand for cartonboard used in packaging applications will grow by 4.0% CAGR. In terms of value, the market recently surpassed the $100 billion mark in 2016 and it should reach $124.1 billion by 2022. This market accounts for 40.3 million tons of folding carton material destined for packaging.

With the trend toward digital printing, press manufacturers have a range of options that are suitable for folding cartons. HP has presses that depending on the size of the carton – are optimized for this industry. The HP Indigo 30000, 12000, 7900 and 5900 digital presses are all applicable. Additionally, if a converter already has a 6000 series, they have the ability to print a wide range of applications.

“There is a growing trend of brands that have expressed to have their labels and cartons more closely matched in color and in the same environment,” says Hajec. “Because of the versatility of the HP Indigo 6000 Series, many label converters are using this press for both labels, shrink sleeves and folding cartons.”

Outlook Group, a label and packaging converter based in Neenah, WI, USA, concurs that digital printing is viable for folding cartons. “This technology allows a folding carton producer to print using a computer image, then run the job through the printer,” says Joel Schmidt, director of market development at Outlook Group. “ The advantage of digital printing is that changeovers happen nearly instantaneously by simply changing the art file, and the presses in the market today cater to smaller run business and prototyping far more economically than offset technology.”

Gert Geens, business development manager, folding carton, at Xeikon, says that this market sees very specific materials utilized. The most popular materials include virgin fibers like SBS, GC1, GC2 for pharma applications, H&B for direct food contact and recycled fibers like a GD2 for non-contact food and low-margin products. “In the beverage sector we typically see kraft-based boards used because of their strength,” he adds. For finishing, flat-bed diecutting machines are generally the solution of choice, Geens says, noting that laser diecutters are attempting to enter the market as well, but traditional converters have been slow to accept these practices.

“Folding carton work almost always involves a steel-on-steel diecut in a sheeting station if being diecut inline generally in association with a conveyor,” adds Davis. “Offline they would fold, pre-break and glue if needed.”

Entering this market can sometimes be a challenge, especially for narrow web label converters. “The biggest challenge for a converter looking to penetrate or grow business in this segment is its size and niche of applications,” says Davis. “Only a small portion of this market fits an inline flexographic press perfectly. It also tends to be a specialized market requiring knowledge of packaging design and specialized offline finishing equipment.”

A trending market for narrow web?

According to Outlook Group’s Schmidt, the folding carton market presents an opportunity for label converters. “Label converters view folding carton production as a natural progression or growth strategy for their company,” he says. “A successful label converter will own a book of business, from which there is likely folding carton opportunity. Label converters already have a fundamental understanding of matching materials to an application, how to print successfully and consistently, and offer technical support assuring labels will run on application equipment. The same needs exist in folding carton, but the competencies are a bit different.

Mark Andy’s Davis believes that the folding carton market is tough to break into without the requisite experience in it. “Normally, narrow web folding carton is used as a short-run alternative to traditional processes to keep wider and faster presses available for longer runs,” he explains. “Because of the specialized tooling and knowledge required to be efficient, penetrating this market from the traditional label market can be a challenge.”

Many traditional label presses are limited in terms of what boards they can run, Davis adds. Once a converter exceeds a 14-point board, the company must evaluate if it would be better served investing in a designated board press.

According to Omet’s Semenza, inline flexo presses are extremely efficient manufacturing production lines that offer multiple value-added options, which can greatly enhance profitability.

“The folding carton market has been a challenge for the last 20 years, and it’s still a possibility to move in,” says Semenza. “The only thing constant in today’s folding carton business is change itself. The biggest question for converters is not, “Should I add flexo as a capability?” but rather, “What am I doing to remain competitive?”

Even though the market can be difficult to penetrate, Xeikon’s Geens points to recent independent studies from InfoTrends and Smithers Pira to confirm the growing interesting in digitalal printing for folding cartons. With new digital technologies, more converters are inquiring about the possibilities. “Yes, it’s definitely a trend,” he says. “Drupa 2016 did a great job and lots of converters now see that they need to be prepared for the future. As a result, they are investigating the digital printing arena more and more and are exploring the technologies available.”

There are advantages that narrow web converters can provide to the folding carton market, says Esko’s Moore. Narrow web flexo and roll-fed digital printing are faster and easier than conventional sheetfed. “Imagine printing a two-sided blister card. Conventionally, a printer creates a step and repeat layout for a 40" sheet,” explains Moore. “They print the front of the box, let it dry overnight and print the back the next day. The pieces are left to dry overnight before they are sent to an auto platen to diecut the job. Just in printing and finishing alone, the job will take three days – a week, at least, if you include prepress and other tasks. The other problem is that each of these steps requires a 5% overrun. This means that you will need to start with at least 15% more sheets to produce the job.”

By utilizing a narrow web press, it is possible to print a 6-color job inline with a turn bar. The back of the piece can be simultaneously printed with 2-4 more colors. Then, the job is sent inline to a diecutter. A press can produce a few hundred feet of material in a minute. Even if printed one-up, this is much faster than a conventional press, says Moore. What started as a roll ends up, very quickly, as blister cards.

“I have seen where large sheetfed converters have adopted and purchased narrow web digital and flexo presses,” says Moore. “Meanwhile, some narrow web companies have ventured into boutique boxes that they can print on their existing narrow web presses. This offers a lot of versatility, from inline narrow web cutting and creasing to presses with turn bars that can print both the front and back of a box simultaneously.”

Despite presenting certain challenges, Davis says that folding carton growth is definitely possible. “Given the prevalence of online shopping and the amount of goods being shipped, I would not be surprised if this market grew,” he adds.

Efficient equipment

Today’s presses are well equipped to handle folding cartons. For Omet, the Varyflex is a multi-purpose hybrid line that is suitable for versatile configurations. It can be tailored to the converter’s production requirements. The Varyflex enables the combination of different printing processes like flexo, rotogravure, silk-screen, offset, hot foil and cold foil.

“Omet was one of the pioneers of narrow web machine manufacturers to enter the folding carton market about 20 years ago,” says Semenza. “Its machinery takes advantage of the ‘one shot’ production cycle, and its assembly line operations are far more competitive, with just one operation required from the reel to the finished packaging.”

Mark Andy has produced a number of board presses with varying web widths. The Performance Series, Digital Series and Versamax product lines are all available in board configurations. These presses typically feature a modular die system, which allows heavy-duty die cassettes to be set up offline for embossing, debossing and diecutting.

Like any method of package printing, prepress plays a critical role in the finished product. Esko offers multiple products that can help converters with their folding carton requirements.

According to Esko’s Moore, ArtiosCAD – a structural design packaging software program – fits into all markets. Label printers are able to use the same production systems, like Esko Plato and Esko Automation Engine, for prepress and assembly design work. “These two prepress applications also offer the versatility to be able to send work to either a digital front end (frequently produced by Esko) on a digital press, or out to an Esko CDI for digital imaging of plates,” explains Moore.

Esko prepress and HD Flexo allow converters a great deal of flexibility, too. If a pilot design is printed on a digital press, the printer can be assured that jobs printed from HD Flexo plates will match. “So, if a pilot or test market job graduates to full distribution, a converter can be comfortable moving from digital to flexo,” adds Moore. “It should also be noted that many companies with digital presses use Kongsberg tables to cut and crease folded cartons.”

In prepress for folding cartons, many of the tasks are the same as printing labels. There is, however, the added element of structure, and some companies might even utilize 3D virtual proofing. “Regardless of the printing process, you have to keep the structural design at the forefront because it is going to be the same whether printed digitally, on an offset press, or a combination of the two,” says Moore.

Meanwhile, Xeikon offers several digital solutions for folding carton applications. The Xeikon 3050 and Xeikon 3050 with inline varnish offer a roll-to-roll solution for paper cups or a roll-to-sheet solution for folding cartons. “Our powerful front end allows people to either use their standard prepress workflow or utilize a WEB2Print module or integrated MIS system,” explains Xeikon’s Geens. “Afterwards the printing process sees the substrate unwound from the roll, printed, varnished inline with Xeikon’s web varnishing module and then cut to sheet and stacked in a high pile stacker.”