Steve Katz, Editor11.16.18

The pace of change in the digital label printer and press market has never been more rapid. Whether they’re pulling back the curtain yearly in Brussels or Chicago, or a sole supplier is hosting an event at its headquarters, product launches are expected now more than ever. Converters that have not made an initial foray into digital are running out of excuses. If it’s about money, well, entry-level digital presses are all the rage. If it’s space, there are myriad label printer options that take up as much room as a desktop printer or copy machine. A valid reason for holding off, however, is waiting for the next launch. Perhaps you have a preferred supplier or there is a new entrant into the sector. What follows is an account of what’s new from suppliers, as well as what’s tried and true. Suppliers appear in alphabetical order. (Additional information on new digital printing products may be found in the Labelexpo Post-Show report, which begins on page 80.)

Afinia Label

Afinia Label recently launched the L701 Industrial Color Label Printer, the newest addition to Afinia’s family of products. The L701 offers the speed and performance of Memjet printing technology in a new, smaller and more affordable configuration geared toward installations requiring multiple printers across several production lines or locations.

This full-color printer can print directly to inkjet-printable, diecut labels and tag stock. The L701 supports printing roll-to-roll, roll-to-cut – with the option of printing and presenting the label – and can accept fanfold stock for applications where space is at a premium. The L701’s five color (CMYKK) 150ml capacity ink cartridges offer convenience and economy over smaller systems on the market, and can produce labels in full-color, with photo-quality, at print speeds up to 40 fpm.

Afinia Label touts the L701 as having a low price point, making it a more affordable option where multiple printers are required. It also has the smallest footprint available of any production class color label printer currently available, the company says.

Mike Atkins, national sales manager for Afinia Label, says, “The L701 has incredible print quality and speed, and it fits a perfect price point between the low volume, economy-priced color label printers, and the high volume, production-level printers on the market. This combination of speed and economy will enable manufacturers across many industries to implement full color label printing across multiple production lines.”

Allen Datagraph Systems Inc. (ADSI)

The iTech Centra HS digital label printer from ADSI is a digital label production system for converters with requirements up to 3,000 feet. The roll-to-roll iTech Centra has a 30 fpm LED toner print engine capable of printing consumer quality labels and is compatible with a wide range of substrates. The Centra HS Digital Label Printer can be standardized to print on substrate widths from 8.5" to 12" on rolls with a maximum outside diameter of 14". ADSI touts the iTech Centra HS as having a cost per label among the lowest in the industry.

ADSI also offers the iTech Spectrum, what the company describes as a fast, affordable, narrow web digital label printer. The roll-to-roll printer has an LED toner-based print engine capable of printing up to 25 fpm. Printers can create a wide range of applications due to extensive media choices, and the iTech Spectrum can print on substrates 6.5" to 8.5" wide on rolls with a maximum outside diameter of 12". The iTech Spectrum’s top, bottom and gap sensors allow printing on roll or pre-diecut label substrates.

Arrow Systems

Arrow Systems, Inc., has launched the compact Memjet-powered Anyjet into the North American market. Anyjet allows users to digitally print, laminate, cut and remove matrix all in one pass. The compact Anyjet uses a Memjet engine that has been integrated with the Anycut, a tabletop laser finishing system that has been on the market for over six years. The Anyjet is a turnkey digital press that can be combined with any flexographic or digital operation. It prints in 1600 x 1600 dpi using aqueous inks, and the laser diecutter uses an 80W system that allows users to cut even the most complex shapes in seconds.

“The feedback from the market has been great,” says Shaan Patel, business development manager at Arrow Systems, Inc, adding, “The next generation of Anyjet will integrate a UV print engine in lieu of the aqueous printer, as well as a more powerful laser. Anyjet fits perfectly into the budget of traditionally flexographic printers that are looking to add a digital component to their current operation.”

AstroNova

AstroNova offers a variety of compact digital label printing units from both the QuickLabel and TrojanLabel product lines. Recently launched from the QuickLabel portfolio is the Kiaro! QL-120. Based on the flagship QuickLabel Kiaro! digital inkjet label printer, the second generation Kiaro! QL-120 features enhanced print speeds increased by 50%, up to 12 ips (inches per second), seamless network integration into desktop or enterprise platforms, and high-quality color labels that AstroNova says rivals flexo-printed labels.

With the ability to generate both extremely short and particularly long runs – up to 10,000 labels per hour – the QL-120 is built for exceptionally flexible in-house label production for brand owners of all industries and sizes. Other benefits include the ability to print narrow widths as small as 0.5", seamless networking capabilities and extended printhead life. At a resolution of 1200 dpi, the Kiaro! QL-120 ensures that even the smallest font sizes and images look crisp, while its color management capabilities yield brilliant, true-to-life images. The QL-120’s durable ink formulation features an exceptional color range and allows printing on a wider variety of materials.

The Trojan T4 from AstroNova’s TrojanLabel portfolio is a compact digital label press and finishing system. T4 is fast, reliable and easy to use, and it enables small- to mid-sized commercial printers to move into the digital printing market with an all-in-one label production system. Designed for the professional label converting environment, the T4 offers a standalone solution for advanced, high-resolution (up to 1600 dpi) label print, laminating and finishing from start to finish at speeds of up to 164 fpm. Compared to similar systems, AstroNova stresses that the T4 is quite compact, with a footprint of only 7.5 feet. Also, the T4 efficiently adapts to frequent setup changes with minimum downtime for maximum profitability. The T4 incorporates simple integration options, intuitive GUI (graphical user interface) and economically formulated natural ink.

Colordyne Technologies

Colordyne has developed its second-generation 3600 Series AQ technology. Colordyne is using DuraLink, Memjet’s next-generation printing technology, to power its second-generation 3600 Series AQ engines. Colordyne is looking for additional sub OEM partners and beta sites for the second-generation engines. The first installations are targeted for the second half of 2019.

Colordyne is leveraging the modular design and scalability of the printhead technology to develop solutions across a wide range of market segments. The company plans to offer its second-generation 3600 Series AQ technology as a retrofit, a standalone solution and an engine integration kit. The kit allows Colordyne to offer development support and resources to other manufacturers who wish to jump-start their integration of digital inkjet printing. The second-generation 3600 Series AQ technology combines 10 times longer printhead life, durable pigmented ink, print quality up to 1600 x 1585 dpi and a range of versatile printhead modules.

Another one of Colordyne’s recent developments is the 3600 Series UV - Retrofit. As a complement to its current aqueous-based solutions, the 3600 Series UV - Retrofit provides a cost-effective method for adding process color UV inkjet printing capabilities to existing converting equipment. The 3600 Series UV - Retrofit is powered by Colordyne’s proprietary print engine control software, leveraging the latest in UV inkjet imaging technology.

Colordyne developed the new 3600 Series UV print engine in response to growing demand for digital 4-color process UV inkjet retrofit solutions. It offers users the opportunity to diversify their printing capabilities at a low capital cost. The 3600 Series UV - Retrofit prints digital CMYK plus white at speeds up to 246 fpm. The UV solution is available in 8.5" or 12.75" print width configurations and delivers a print resolution of 600 x 600 dpi.

Dantex

The latest innovation from Dantex’s UK-based Advanced Engineering team is the PicoJet, an inkjet press with a 13" web width that reaches print speeds up to 250 fpm at a print resolution of 600 x 600 dpi in 2.5pl dot size. PicoJet’s 7-color printing system with intuitive color management can be custom configured to offer a wider color gamut. Variable data, lamination and super fine resolution are all easily achievable with the Picojet, and printing can be done on any type of media. PicoJet’s LED final cure has a temperature controlled back-up roller for temperature-sensitive substrates and incorporates static control, web cleaning and corona treatment.

In addition to the PicoJet, Dantex also offers its PicoColour UV digital label press. Versatile and with a small footprint, PicoColour accommodates widths of 9.84" (210mm) and 82 fpm (25 m/m), is suitable for both short and long runs while delivering inline finishing, no waste and fast turnaround. The press is available with CMYK + White, chilled roller printing and full variable data options.

Discussing both presses, Richard Danon, Dantex Group chairman, says, “Following the success of PicoColour, it was a natural progression for our company to look to expand our range even further. We needed to go wider, faster and finer in resolution to offer more in digital capability, and that’s where the PicoJet comes into its own.”

Domino

The install base of Domino’s flagship offering, the N610i UV inkjet label press, continues to grow. Most recently, an N610i was installed at Pennsylvania-based Yerecic Label, an award-winning converter. “With our focus on Lean Manufacturing and serving at the ‘Speed of Fresh,’ our digital press cell must meet demanding standards,” says Yerecic Label President Art Yerecic. “The Domino digital press, along with our new ABG finishing unit, allows us to be even more nimble while achieving the consistent high quality our customers expect.”

Yerecic Label spent over a year researching over 10 digital press and finisher manufacturers’ quality, conformance to food safety requirements, capabilities, and equipment speed. After the thorough review process, Yerecic Label selected the Domino N610i digital UV inkjet label press with an inline ABG Digicon 3 finishing unit.

“We know that the importance of speed, uptime, and print quality are critical keys to our customers and the success of their businesses. Domino has ‘engineered out’ operator intervention on the N610i digital UV inkjet label press with automated features of printhead cleaning, stitching, and recirculating ink. What that means is that at the end of the day, our customers produce more labels in less time with consistent and repeatable high-quality printing,” says Bill Myers, marketing manager for Domino Digital Printing North America.

Yerecic Label vice president of production Brian Hurst says, “We are able to satisfy even the most color-sensitive customers with the high density dual white ink and six color expanded gamut (Cyan, Magenta, Yellow, Black, Orange and Violet) that accurately reproduces over 92% of Pantone colors. The press/finisher speed of over 200 fpm was just as important in convincing the Yerecic Label team that it was time to invest in digital capabilities.”

Durst

Durst offers the Tau 330 and Tau 330 E digital UV inkjet label presses, as well as the newly launched Tau 330 RSC. The Tau 330 RSC is a UV inkjet label and package printing press featuring a 13" print width combined with print speeds of up to 245 fpm at 1200 x 1200 dpi print resolution. The press achieves a production capacity of 1.485 m² per hour, and thanks to its 8-color stations (CMYK+W+OVG) with newly designed high-pigmented inks, it is capable of delivering flexo-like print quality with close to 98% pantone color gamut coverage.

Explains Durst’s Helmuth Munter, “With the RSC, the R stands for Resolution of 1200 x 1200 dpi, combined with a very small drop size of 2 picoliters. The S stands for Speed, as this press runs at a printing speed of 255 fpm, providing an unmatched productivity boost in digital label printing. Finally, the C stands for Color, and the available eight color stations that provide a color space to match over 95% of the pantone color gamut.”

The Tau 330 RSC is available as a standalone version or can be combined with inline digital laser diecutting in the LFS 330. Durst’s flagship Tau 330 with low migration ink for primary food and pharmaceutical packaging, as well as the economic entry model Tau 330E are also available with the specially-developed high pigmented UV inkjet inks.

In addition, Durst recently introduced its new Web2Print solution for online design, preview and ordering of all kinds of packaging products like labels, folding cartons and more. Durst’s proprietary Workflow-Label Application Suite is a modular, expandable prepress software for order entry, prepress, RIP, color management, ink-costing and production data management.

The Tau 330 RSC can be configured as “digital-flexo hybrid press” with Omet’s XFlex series. (See the section on Omet in this article.)

Epson

Epson has announced its SurePress L-6534VW digital label press. Joining the SurePress L-6034VW in Epson’s UV digital label press line, the SurePress L-6534VW will offer three print speed modes from 49 to 162 fpm. Designed for label converters investing in a digital label press for the first time or looking to expand production facilities with a reliable, easy-to-use press, the SurePress L-6534VW delivers three print speed modes to meet a range of converter needs: High density white – 49 fpm; Standard – 98 fpm; Productivity – 162 fpm.

The SurePress L-6534W digital LED UV inkjet press can produce high-quality, durable labels and integrates all of the functions required for label production, including a Corona treater, white ink, digital varnish, and an additional UV curing unit. The printheads, inks, LED pinning and curing lamp units, media feeding, and control system are all developed and manufactured by Epson. Additional features include Epson’s PrecisionCore Linehead, which enables high-speed, single-pass high print output quality and durability. A digital monitoring system maintains high productivity using Nozzle Verification Technology to automatically manage inkjet nozzles. For digital varnishing, a gloss or matte finish can be selected for the overall label, and partial accents can be added using glossy or matte spot varnish.

With regard to substrates, a center drum system feeds the substrate with precision, and is designed to achieve high accuracy color registration and reduce heat expansion or substrate shrinkage, enabling various types of off-the-shelf standard flexographic substrates to be used.

The SurePress’s quick-drying UV ink helps enhance productivity and offers excellent weather, scratch, chemical, and water resistance; LED light source saves space and offers a lower energy use, enabling printing on heat-sensitive substrates. For White ink printing, Surface White Print and Reverse-White Print are available to extend the range of expression on clear and metalized films. The variable web width of the press supports rolls from 3.15" to 13" wide up to 0.013" thick. Linehead maintenance is done automatically during the shift, and manual cleaning is limited to a short interval after the shift.

The SurePress L-6534VW, and a conversion kit for the existing SurePress L-6034VW, will be available by summer 2019.

Fujifilm

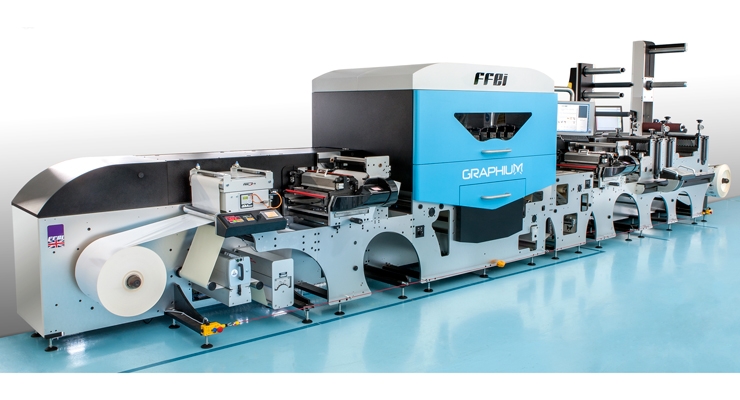

Fujifilm North America Corporation, Graphic Systems Division offers label printers and converters the Graphium UV digital hybrid inkjet press for labels, packaging and specialty print applications. Graphium, the result of a partnership between Fujifilm and FFEI, makes converting short to medium print jobs profitable, as the press streamlines workflow, requires less setup material, less ink/varnish/laminate, provides lower running waste and eliminates overruns. Furthermore, Graphium is a modular digital inkjet press offering the option to integrate true flexo and finishing stations for hybrid production and conversion, in a single pass, thus greatly expanding the opportunities that can be converted.

Graphium ensures excellent print quality and color gamut on a wide range of standard materials, with 39" (1,000mm), 400kg capacity. This capability comes from the integration of a web guide with ultra-sonic edge sensor, web cleaning and corona treatment being fitted as standard.

Graphium’s Xaar printheads and ink systems provide industrial grade reliability and optimal uptime, ensuring continuous trouble-free converting. Graphium’s wide web width of 420mm and fast print speed allows high productivity of up to 1134sqm/hr with up to six different inks. LED inter-color pinning across all six channels provides precise ink laydown and cure control. Graphium’s print engine is capable of printing with up to six ink color combinations. Printers have a choice of four, five or six types of UV-curable inks, including a varnish and under or over whites. Graphium’s color management system allows accurate ISO 12647-2 compliant CMYK printing and wide gamut spot color emulation.

Gallus / Heidelberg

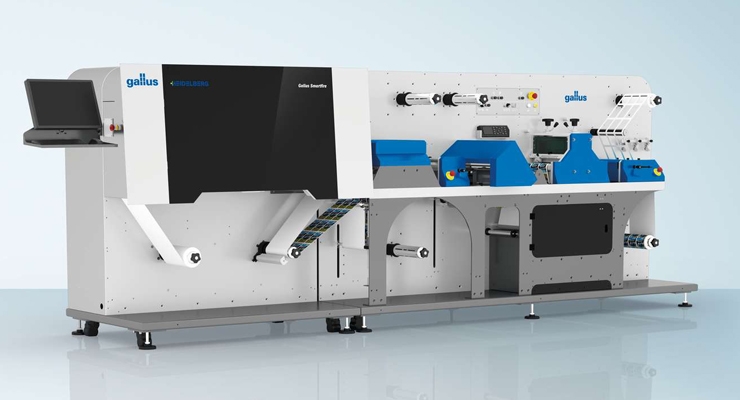

Gallus has expanded its product portfolio with the Smartfire, a new, full-featured, value offering for digital narrow web label printing that is an ideal solution on ultra-short runs. “The Smartfire focuses on new target groups who are looking for a low risk, easy entry into digital label printing,” explains Michael Ring, head of digital solutions at Gallus, who was also recently named TLMI Supplier of the Year (see page 33). He adds, “Incorporating Memjet technology allows us to offer an inkjet printing press that produces labels with a quality of 1600×1600 dpi – while establishing a new, low investment price point in the market.”

The Smartfire’s Memjet water-based inks and printheads mean that labels it produces have a minimal ecological footprint. Virtually “plug and play,” the Smartfire uses an ordinary power outlet, needs no exhaust equipment, is extremely compact, and does not emit VOCs. “It is the perfect press for any work environment,” Ring says. “The name says it all – the Smartfire is absolutely easy to operate via a self-explanatory touch panel. With this digital press, limited prepress skills are needed to create professional CMYK 4-color inkjet labels. Addressing the shortfall of other offerings in this space, a finishing unit is integrated into the press, where labels are laminated and cut, which means the Smartfire delivers finished diecut labels in one pass, ready for shipping.”

Also in the digital space, Gallus and Heidelberg offer the Labelfire 340, a hybrid press that improves speed-to-market while meeting cost reduction initiatives. Labelfire integrates flexo, digital, converting and a variety of embellishments on a single press, all in one-pass. A rotary screen module can even be added in one of the downstream flexo stations to produce tactile screen finishes.

Explains Ring, “All of these single-pass features provide virtually unlimited opportunities to enhance shelf appeal at manageable and competitive costs. Add to the fact that the Gallus Labelfire 340 produces exquisite detail thanks to its 1200 dpi resolution at 50 m/m running speeds, there is no technology on the market close to Labelfire’s performance and efficiency.”

INX International

The single-pass NW340 label press marketed by INX International Ink Co. is a UV digital press that gives label converters the opportunity to seamlessly transition to digital inkjet technology. The NW340 represents third-generation label technology and a natural progression. “It seems like only yesterday when we previewed the NW140 printer at Labelexpo,” says Jim Lambert, INX International’s vice president of digital sales, about its 2010 pre-launch debut. “A few years later, we followed with the NW210. Both of those printers offered resolutions of 360 x 360 dpi and produced labels at speeds up to 80 fpm. The main difference was the printing width of 140mm and later, 210mm.

“The NW340 is a whole different ballgame,” Lambert adds. “We’ve elevated the resolution to 1200 x 600 or 1200 x 1200 dpi, improved the width range to 340mm, and have increased the speed up to 300 fpm to satisfy market demand. Printers want faster equipment and higher resolution so they can more favorably compete with offset presses. This machine does that and more.”

HP

Earlier this year, the second dedicated shrink-sleeve HP Indigo 8000 was installed in the US for serving the fast-growing craft beverage market. The fastest press in the HP Indigo portfolio, the 8000 is positioned as a high speed digital alternative to flexo. The 8000 includes two WS6800 print engines, thus doubling production speeds of the 6000 series by reaching top speeds of 262 fpm.

New to the popular 6000 series of presses, the HP Indigo 6900 offers converters new solutions to enable accelerated business growth by a set of easy-to-use tools driving new applications while improving operational efficiency. The HP Indigo 6900 enables converters to print high-performance applications such as Pack Ready for Labels, which has been extended to HP’s entire labels and packaging portfolio. Labels produced on the 6900 feature improved performance against water, chemical and temperature exposure based on a new UV-curable additive added to off-the-shelf varnishes, cross-linking the label’s construction. With Pack Ready for Labels, converters can print more types of labels and eliminate costly lamination processes.

The HP Indigo 6900 supports a wide variety of solutions, including inks and software tools. The newly introduced HP Indigo ElectroInk Invisible Yellow and Blue are only visible under UV light, delivering high performance for security applications. Coupled with new software and cloud-based solutions that allow anti-counterfeiting marks, micro text fonts, and protected track and trace solutions, converters can offer unique layered security – static and serialized – for brand protection. In addition, the HP Indigo ElectroInk Silver combines metallic effects with digital capabilities in one printing process, saving on metallic substrates and allowing innovation with clear media. The HP Indigo 6900 digital press was showcased at Labelexpo with new applications and effects while running inline with the one-pass digital embellishment unit, the new HP Indigo GEM. For more details on GEM, including the first adoption in the US by ILS, check out the Labelexpo Post-Show report feature in this issue.

Konica Minolta

Konica Minolta recently marked a milestone for its label business - the sale of the 250th unit of its AccurioLabel 190 digital toner-based press. The AccurioLabel 190 is designed to target small to mid-size label converters by offering affordable entry to digital printing. It was developed to manage and deliver an increasing number of small to medium print jobs in ever-shorter processing times.

The highly flexible system runs on coated, uncoated and textured paper and film at speeds of up to 18.9 m/m at 1200 dpi. High quality and high precision label printing of 256 gradations is possible. The AccurioLabel 190 incorporates an intuitive screen for setup so there is no need for extensive user training.

Mark Andy

With a focus on hybrid printing, Mark Andy offers the Digital One and the Digital Series HD. The Digital Series HD can be configured with five through eight digital colors and can support integrated inline or future-proof near line converting options. The base roll-to-roll configuration is ideal for those just entering the production digital space. As a converter’s digital business expands, the modularity of the platform enables the shift to inline finishing to better utilize the high speed platform.

The Digital Series HD features expanded gamut printing in a high-chroma inkset (CMYK + OVG) that complements an existing richly pigmented white ink formulation that delivers rotary screen level output. Mark Andy reports the ink provides three times the opacity of flexo white and more than double that of conventional EP white, measured in excess of 80%. Digital white can be run without a trade-off in speed at the platform’s standard of 240 fpm.

The most notable alteration to the HD press compared to the original Digital Series is in the digital module. Once a flat table section, the new platform now showcases an arched IDS. The arch design accepts unsupported films and improves operator ergonomics, enabling quick and clean ink changeover. New printhead technology housed in the module also matches the 1200 dpi resolution.

The Digital One from Mark Andy Digital One was born after the Mark Andy development team sat down and interviewed 147 customers and asked them what it would take to create a practical digital label press for the everyday converter. The result was the The Digital One, an entry-level digital label press ideal for digitally printing and converting short run prime labels inline, at a low investment level. Digital One offers 4-color CMYK dry-toner printing at 1200 dpi resolution and print speeds up to 62 fpm, though speeds vary based on substrate and application. It has a single multi-purpose flexo station for advanced decoration, and inline or off-line finishing compatibility.

mprint

Germany-based mprint offers the mlabel GEN3. The base machine has a standard mechanical width of 13" but does not have to be outfitted with a print engine of the full print width from the beginning, thus allowing mprint adopters to start with a lower cost system and expand the print engine in the future, adding capacity without having to purchase a new machine. Aside from being equipped with CMYK+W, the machine can incorporate the Digital Metal Liner module – a fully digital foil embellishing unit, allowing printers to not only generate metallic effects on labels and packaging in a single pass, but also to customize these effects with every print. This module was developed in cooperation with Kurz Transfer Products using its Digital Metal UV Ink technology.

Recycling of the inks used for purging and flushing the printheads is engrained in mprint’s concept and has not only a big environmental impact, but also reduces ink cost by increasing ink utilization to over 99%. The machines can be equipped with a vast array of color options – CMYK+W+OV+G plus/or spot colors or spot varnishes, etc. – aside from analog options like flexo print stations.

With the mlabel GEN3, mprint has advanced its UV inkjet narrow web machine portfolio to cover print widths from 4.25" – 12.75" and single to multi-color (seven or more) by allowing for options in price and future machine expansion. Custom print widths of 17" and above are also available.

MPS

The hybrid EF SymJet press from MPS is a combination of a flexo press with the fully automated MPS EF platform and an integrated Domino N610i digital UV inkjet label press. The hybrid flexo inkjet press provides label printers the ability to choose how to run their jobs. In hybrid mode, this press provides the ability of flexo to add primers, spot colors, UV flexo white, metallics, cold foils, over-varnish, inline finishing and more; coupled with the efficiency benefits of digital, such as the ability to run multiple SKUs, versions, and colors, while making changes on the fly, all in a single pass. The EF SymJet also adds a wide range of inline converting solutions.

Mouvent

Mouvent, the Swiss start-up developed through a partnership with Bobst, has unveiled its Mouvent Cluster Technology. The Mouvent Cluster printhead is at the heart of the technology – an approach that uses extremely compact and lightweight clusters instead of fixed size print bars by color, arranging them in a modular, scalable matrix.

Mouvent plans on setting up a US showroom before offering and selling its solutions in the region, and it aims to launch the first of its machines in America in 2019. So far, Mouvent has launched three digital label printers in Europe – the LB701-UV mini label press, which is a small high-productivity label press; the LB702-UV label press, which allows fast and easy industrial label production at an excellent TCO; and the LB702-WB label press, which uses 100% water-based ink. The three label printers can all print up to seven colors on a large variety of substrates at speeds up to 100 m/m at 1200 x 1200 and optical 2000 dpi.

Nilpeter

The Panorama digital product line from Nilpeter features a 5-color inkjet print engine and web infeed for optimum web tension and fast register. The press is designed to be easy to operate from either the touch screen or tablets. It features 14" flexo printing units with quick-change CleanInking chambers. Diecutting is done with either the Semi-Rotative Die-Cutting Unit or Quick-Change Die. The press is also capable of inline integration with Nilpeter’s value-adding units, such as the FP-4 for hot foil and embossing.

Keith Nagle, digital product manager, says the standalone DP3 System offers the highest quality 600 x 600 resolution and finest 3 pt. text at market leading speeds of 160 fpm with CMYK and 100 fpm when white (W+CMYK) is added. Able to run most label and packaging substrates at widths that range from 4" up to 13" allows printers to maximize substrate usage while minimizing waste. Converters can realize uptime higher than 90% with Panorama’s Equios workflow and a simplified operator interface.

OMET

In a partnership with Durst, Omet offers a complete hybrid print and finishing line that offers enhanced flexibility for a wide range of final applications with a consistent cost reduction. Italian converter Italgrafica Sistemi recently chose the Omet XJet because of its ability for inline multi-process configurations that finalizes products in a single pass. With 18 printing lines already running at Italgrafica Sistemi, the new Omet XJet is expected to replace two of the flexo lines as demands continue to increase for short-run, personalized technology in a single pass. It will open up new opportunities for cold foiling, printing on reverse and adhesives, as well as varnish and diecutting.

Francesco Niorettini, general manager of Italgrafica Sistemi, says the total cost of ownership and benefits to his customers were crucial in the decision-making. “Other factors in our investment decision included the 50% increase in speed, the low service and consumable costs, as well as the fact that both Durst and Omet have good reputations in the marketplace,” he adds.

Screen

Screen offers label converters the Truepress Jet L350UV+ and the the L350UV+LM. While similar, the two machines are not identical, however both deliver the same fast run speeds of up to 60 m/m. The Truepress Jet L350 UV+ and Truepress Jet L350 UV+LM machines both feature Screen’s 3-picoliter drop size and four-level grayscale technology for high print quality and brilliant and wider color gamut achieved with Screen’s CMYK+W+Orange inks. The only difference between the two is The L350UV+LM is press equipped with low migration ink capabilities for food label print production.

Screen says many L350UV users have found the technology’s simplicity of use, high uptime and productivity, plus unmatched quality, are leading to significant conversion of many of their label jobs from offset to digital UV inkjet with the Truepress platform. The company believes its “Print. Ship. Bill. Repeat.” message reflects the real profitability that label companies are experiencing in producing prime, flexible, durable and standard labels digitally.

A recent Screen Truepress Jet 350UV installation in the US took place at Ample Industries in Missouri. Ample had investigated several manufacturers in their pursuit of new inkjet equipment. Part of Ample’s process included providing difficult-to-print test files to the several press candidates, and seeing the results the Truepress JetL350UV achieved, Natalie Spradlin, Ample Label’s vice president, says, “Screen is pretty great. We looked at all options in inkjet. Although many were very good, Screen’s quality of print is superior.”

Valloy

Valloy offers the all new Bizpress 13R, a 13" single-pass LED roll-to-roll label printer. The 13" (340 mm) digital roll to roll label printer, Bizpress13R uses an LED production printing engine. According to the company, the printing speed of 7.26 m/m can handle 1,000 m2 jobs easily by changing rolls 3-4 times with up to 1200 × 2400 dpi.

The Bizpress 13R can print on 60 to 300 micron thick papers, PET, BOPP, PE and PVC films. An embedded high-voltage ionizer prevents static problems while enabling easy printing on metallic coated foils. It uses 18K high-capacity toner (26K for black) and 100K high-capacity drum. In addition to an inherent low-temperature fusing system, embedded cooling system and instant fusing mechanism helps cover a wider range of media compatibility. A pneumatic auto-tension control system drives 1km length rolls in a stable way and an intuitive touch panel GUI promotes comfortable operation. A web guide system is optionally available.

Bizpress 13R is positioned as an ideal solution for conventional label converters looking to step into digital short-run production services. It’s also an ideal fit for converters in customized flexible package markets.

Xeikon

Xeikon recently announced an entry-level label printing and converting solution called Label Discovery. It consists of a Xeikon 3030, an entry-level web-fed digital label press and the new entryDcoat, a digital converting line that can be used inline or off-line with the Xeikon 3030.

David Wilkins, Xeikon’s vice president of sales for the North American market, says, “The lower cost of the Xeikon Label Discovery solution enables companies to embrace digital technology and capture a business potential that previously required a steep investment – the crucial business of producing short-run labels.

“The Label Discovery solution is a turnkey label production system that provides everything needed to offer an expanded range of services to their customers and to experience the benefits digital production can bring to their businesses. In addition to enabling an affordable entry into this lucrative market, the Label Discovery solution is a platform that can be field-upgraded in terms of productivity as the business grows, ensuring long-term viability of the investment,” says Wilkins.

The Xeikon 3030 digital label press is a dry toner solution ideal for producing labels for a broad range of applications using standard flexo materials. This avoids the need to use specially-treated substrates and eliminates the associated warehousing costs. Its 5-color printing features CMYK and White or even a special spot or gamut-extending color. Changing toner colors on the system is relatively easy, a clear benefit of dry toner compared to other printing technologies. In addition, dry toner is recognized as the best technology for food labels in terms of food safety due to its non-toxic nature, the company says. Xeikon dry toner has also received FDA certification for both indirect and direct food contact with dry food, which is a plus in the digital landscape.

The entryDCoat is a compact converting unit that consists of a varnish, diecut and rewind station. To limit startup and tooling costs, the diecut unit uses semi-rotary diecutting technology. This ensures low cost converting without loss of productivity while still delivering the well-known quality of conventional diecutting. With semi-rotary diecutting, costs can be reduced by as much as 50% with no need to acquire special tools and no setup time as required with conventional diecutting.

In addition to the Label Discovery, Xeikon also offered an extensive range of both inkjet and toner-based machines, including the Xeikon PX3000 UV inkjet label press, as well the toner-based Xeikon 3500 and Xeikon CX3 presses. For more on Xeikon’s latest dry toner and DFE developments, check out the Labelexpo Post-Show Report.

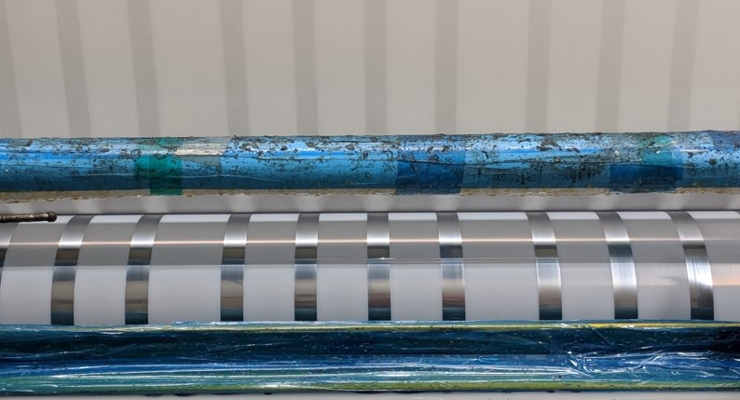

In the production of pressure sensitive labels using inkjet printing systems, speed is key. With the benefits of digital workflows and quicker setup times for jobs, the expectation on quick turnaround is high. So, the last thing an operator needs is to have to stop production for maintenance.

With the printing of labels, softer adhesives, like those classified as an All Temperature, can migrate onto the rolls of the printing transport system, especially as a printing system heats up during a job. Over time, there can be a buildup of this adhesive that causes speed, flow, and printing issues. So, time must be taken to clean the adhesive that has seeped onto the transport system.

Innovative suppliers, like Technicote in Miamisburg, OH, have taken note of this and offer products with what’s known as a dry edge. This is an ungummed margin on both sides of the roll that must be at least an eighth of an inch wide. This void of adhesive allows for soft adhesive migration from the center of the roll, without leaking onto the printer transport.

“The majority of our UV inkjet label products are available as a dry edge for this very reason,” says Dann Woellert, Technicote inkjet product manager. “We have seen customers increase uptime and reduce maintenance with the use of our dry edge products.”

Some suppliers offer deadened patterns, which use less adhesive instead of no adhesive. Technicote makes its own pattern bars in-house, specializing in true patterns of greater than 50% ungummed area. These are designed for applications that require easier lift edges like a sale label on a food dish or container.

Afinia Label

Afinia Label recently launched the L701 Industrial Color Label Printer, the newest addition to Afinia’s family of products. The L701 offers the speed and performance of Memjet printing technology in a new, smaller and more affordable configuration geared toward installations requiring multiple printers across several production lines or locations.

This full-color printer can print directly to inkjet-printable, diecut labels and tag stock. The L701 supports printing roll-to-roll, roll-to-cut – with the option of printing and presenting the label – and can accept fanfold stock for applications where space is at a premium. The L701’s five color (CMYKK) 150ml capacity ink cartridges offer convenience and economy over smaller systems on the market, and can produce labels in full-color, with photo-quality, at print speeds up to 40 fpm.

Afinia Label touts the L701 as having a low price point, making it a more affordable option where multiple printers are required. It also has the smallest footprint available of any production class color label printer currently available, the company says.

Mike Atkins, national sales manager for Afinia Label, says, “The L701 has incredible print quality and speed, and it fits a perfect price point between the low volume, economy-priced color label printers, and the high volume, production-level printers on the market. This combination of speed and economy will enable manufacturers across many industries to implement full color label printing across multiple production lines.”

Allen Datagraph Systems Inc. (ADSI)

The iTech Centra HS digital label printer from ADSI is a digital label production system for converters with requirements up to 3,000 feet. The roll-to-roll iTech Centra has a 30 fpm LED toner print engine capable of printing consumer quality labels and is compatible with a wide range of substrates. The Centra HS Digital Label Printer can be standardized to print on substrate widths from 8.5" to 12" on rolls with a maximum outside diameter of 14". ADSI touts the iTech Centra HS as having a cost per label among the lowest in the industry.

ADSI also offers the iTech Spectrum, what the company describes as a fast, affordable, narrow web digital label printer. The roll-to-roll printer has an LED toner-based print engine capable of printing up to 25 fpm. Printers can create a wide range of applications due to extensive media choices, and the iTech Spectrum can print on substrates 6.5" to 8.5" wide on rolls with a maximum outside diameter of 12". The iTech Spectrum’s top, bottom and gap sensors allow printing on roll or pre-diecut label substrates.

Arrow Systems

Arrow Systems, Inc., has launched the compact Memjet-powered Anyjet into the North American market. Anyjet allows users to digitally print, laminate, cut and remove matrix all in one pass. The compact Anyjet uses a Memjet engine that has been integrated with the Anycut, a tabletop laser finishing system that has been on the market for over six years. The Anyjet is a turnkey digital press that can be combined with any flexographic or digital operation. It prints in 1600 x 1600 dpi using aqueous inks, and the laser diecutter uses an 80W system that allows users to cut even the most complex shapes in seconds.

“The feedback from the market has been great,” says Shaan Patel, business development manager at Arrow Systems, Inc, adding, “The next generation of Anyjet will integrate a UV print engine in lieu of the aqueous printer, as well as a more powerful laser. Anyjet fits perfectly into the budget of traditionally flexographic printers that are looking to add a digital component to their current operation.”

AstroNova

AstroNova offers a variety of compact digital label printing units from both the QuickLabel and TrojanLabel product lines. Recently launched from the QuickLabel portfolio is the Kiaro! QL-120. Based on the flagship QuickLabel Kiaro! digital inkjet label printer, the second generation Kiaro! QL-120 features enhanced print speeds increased by 50%, up to 12 ips (inches per second), seamless network integration into desktop or enterprise platforms, and high-quality color labels that AstroNova says rivals flexo-printed labels.

With the ability to generate both extremely short and particularly long runs – up to 10,000 labels per hour – the QL-120 is built for exceptionally flexible in-house label production for brand owners of all industries and sizes. Other benefits include the ability to print narrow widths as small as 0.5", seamless networking capabilities and extended printhead life. At a resolution of 1200 dpi, the Kiaro! QL-120 ensures that even the smallest font sizes and images look crisp, while its color management capabilities yield brilliant, true-to-life images. The QL-120’s durable ink formulation features an exceptional color range and allows printing on a wider variety of materials.

The Trojan T4 from AstroNova’s TrojanLabel portfolio is a compact digital label press and finishing system. T4 is fast, reliable and easy to use, and it enables small- to mid-sized commercial printers to move into the digital printing market with an all-in-one label production system. Designed for the professional label converting environment, the T4 offers a standalone solution for advanced, high-resolution (up to 1600 dpi) label print, laminating and finishing from start to finish at speeds of up to 164 fpm. Compared to similar systems, AstroNova stresses that the T4 is quite compact, with a footprint of only 7.5 feet. Also, the T4 efficiently adapts to frequent setup changes with minimum downtime for maximum profitability. The T4 incorporates simple integration options, intuitive GUI (graphical user interface) and economically formulated natural ink.

Colordyne Technologies

Colordyne has developed its second-generation 3600 Series AQ technology. Colordyne is using DuraLink, Memjet’s next-generation printing technology, to power its second-generation 3600 Series AQ engines. Colordyne is looking for additional sub OEM partners and beta sites for the second-generation engines. The first installations are targeted for the second half of 2019.

Colordyne is leveraging the modular design and scalability of the printhead technology to develop solutions across a wide range of market segments. The company plans to offer its second-generation 3600 Series AQ technology as a retrofit, a standalone solution and an engine integration kit. The kit allows Colordyne to offer development support and resources to other manufacturers who wish to jump-start their integration of digital inkjet printing. The second-generation 3600 Series AQ technology combines 10 times longer printhead life, durable pigmented ink, print quality up to 1600 x 1585 dpi and a range of versatile printhead modules.

Another one of Colordyne’s recent developments is the 3600 Series UV - Retrofit. As a complement to its current aqueous-based solutions, the 3600 Series UV - Retrofit provides a cost-effective method for adding process color UV inkjet printing capabilities to existing converting equipment. The 3600 Series UV - Retrofit is powered by Colordyne’s proprietary print engine control software, leveraging the latest in UV inkjet imaging technology.

Colordyne developed the new 3600 Series UV print engine in response to growing demand for digital 4-color process UV inkjet retrofit solutions. It offers users the opportunity to diversify their printing capabilities at a low capital cost. The 3600 Series UV - Retrofit prints digital CMYK plus white at speeds up to 246 fpm. The UV solution is available in 8.5" or 12.75" print width configurations and delivers a print resolution of 600 x 600 dpi.

Dantex

The latest innovation from Dantex’s UK-based Advanced Engineering team is the PicoJet, an inkjet press with a 13" web width that reaches print speeds up to 250 fpm at a print resolution of 600 x 600 dpi in 2.5pl dot size. PicoJet’s 7-color printing system with intuitive color management can be custom configured to offer a wider color gamut. Variable data, lamination and super fine resolution are all easily achievable with the Picojet, and printing can be done on any type of media. PicoJet’s LED final cure has a temperature controlled back-up roller for temperature-sensitive substrates and incorporates static control, web cleaning and corona treatment.

In addition to the PicoJet, Dantex also offers its PicoColour UV digital label press. Versatile and with a small footprint, PicoColour accommodates widths of 9.84" (210mm) and 82 fpm (25 m/m), is suitable for both short and long runs while delivering inline finishing, no waste and fast turnaround. The press is available with CMYK + White, chilled roller printing and full variable data options.

Discussing both presses, Richard Danon, Dantex Group chairman, says, “Following the success of PicoColour, it was a natural progression for our company to look to expand our range even further. We needed to go wider, faster and finer in resolution to offer more in digital capability, and that’s where the PicoJet comes into its own.”

Domino

The install base of Domino’s flagship offering, the N610i UV inkjet label press, continues to grow. Most recently, an N610i was installed at Pennsylvania-based Yerecic Label, an award-winning converter. “With our focus on Lean Manufacturing and serving at the ‘Speed of Fresh,’ our digital press cell must meet demanding standards,” says Yerecic Label President Art Yerecic. “The Domino digital press, along with our new ABG finishing unit, allows us to be even more nimble while achieving the consistent high quality our customers expect.”

Yerecic Label spent over a year researching over 10 digital press and finisher manufacturers’ quality, conformance to food safety requirements, capabilities, and equipment speed. After the thorough review process, Yerecic Label selected the Domino N610i digital UV inkjet label press with an inline ABG Digicon 3 finishing unit.

“We know that the importance of speed, uptime, and print quality are critical keys to our customers and the success of their businesses. Domino has ‘engineered out’ operator intervention on the N610i digital UV inkjet label press with automated features of printhead cleaning, stitching, and recirculating ink. What that means is that at the end of the day, our customers produce more labels in less time with consistent and repeatable high-quality printing,” says Bill Myers, marketing manager for Domino Digital Printing North America.

Yerecic Label vice president of production Brian Hurst says, “We are able to satisfy even the most color-sensitive customers with the high density dual white ink and six color expanded gamut (Cyan, Magenta, Yellow, Black, Orange and Violet) that accurately reproduces over 92% of Pantone colors. The press/finisher speed of over 200 fpm was just as important in convincing the Yerecic Label team that it was time to invest in digital capabilities.”

Durst

Durst offers the Tau 330 and Tau 330 E digital UV inkjet label presses, as well as the newly launched Tau 330 RSC. The Tau 330 RSC is a UV inkjet label and package printing press featuring a 13" print width combined with print speeds of up to 245 fpm at 1200 x 1200 dpi print resolution. The press achieves a production capacity of 1.485 m² per hour, and thanks to its 8-color stations (CMYK+W+OVG) with newly designed high-pigmented inks, it is capable of delivering flexo-like print quality with close to 98% pantone color gamut coverage.

Explains Durst’s Helmuth Munter, “With the RSC, the R stands for Resolution of 1200 x 1200 dpi, combined with a very small drop size of 2 picoliters. The S stands for Speed, as this press runs at a printing speed of 255 fpm, providing an unmatched productivity boost in digital label printing. Finally, the C stands for Color, and the available eight color stations that provide a color space to match over 95% of the pantone color gamut.”

The Tau 330 RSC is available as a standalone version or can be combined with inline digital laser diecutting in the LFS 330. Durst’s flagship Tau 330 with low migration ink for primary food and pharmaceutical packaging, as well as the economic entry model Tau 330E are also available with the specially-developed high pigmented UV inkjet inks.

In addition, Durst recently introduced its new Web2Print solution for online design, preview and ordering of all kinds of packaging products like labels, folding cartons and more. Durst’s proprietary Workflow-Label Application Suite is a modular, expandable prepress software for order entry, prepress, RIP, color management, ink-costing and production data management.

The Tau 330 RSC can be configured as “digital-flexo hybrid press” with Omet’s XFlex series. (See the section on Omet in this article.)

Epson

Epson has announced its SurePress L-6534VW digital label press. Joining the SurePress L-6034VW in Epson’s UV digital label press line, the SurePress L-6534VW will offer three print speed modes from 49 to 162 fpm. Designed for label converters investing in a digital label press for the first time or looking to expand production facilities with a reliable, easy-to-use press, the SurePress L-6534VW delivers three print speed modes to meet a range of converter needs: High density white – 49 fpm; Standard – 98 fpm; Productivity – 162 fpm.

The SurePress L-6534W digital LED UV inkjet press can produce high-quality, durable labels and integrates all of the functions required for label production, including a Corona treater, white ink, digital varnish, and an additional UV curing unit. The printheads, inks, LED pinning and curing lamp units, media feeding, and control system are all developed and manufactured by Epson. Additional features include Epson’s PrecisionCore Linehead, which enables high-speed, single-pass high print output quality and durability. A digital monitoring system maintains high productivity using Nozzle Verification Technology to automatically manage inkjet nozzles. For digital varnishing, a gloss or matte finish can be selected for the overall label, and partial accents can be added using glossy or matte spot varnish.

With regard to substrates, a center drum system feeds the substrate with precision, and is designed to achieve high accuracy color registration and reduce heat expansion or substrate shrinkage, enabling various types of off-the-shelf standard flexographic substrates to be used.

The SurePress’s quick-drying UV ink helps enhance productivity and offers excellent weather, scratch, chemical, and water resistance; LED light source saves space and offers a lower energy use, enabling printing on heat-sensitive substrates. For White ink printing, Surface White Print and Reverse-White Print are available to extend the range of expression on clear and metalized films. The variable web width of the press supports rolls from 3.15" to 13" wide up to 0.013" thick. Linehead maintenance is done automatically during the shift, and manual cleaning is limited to a short interval after the shift.

The SurePress L-6534VW, and a conversion kit for the existing SurePress L-6034VW, will be available by summer 2019.

Fujifilm

Fujifilm North America Corporation, Graphic Systems Division offers label printers and converters the Graphium UV digital hybrid inkjet press for labels, packaging and specialty print applications. Graphium, the result of a partnership between Fujifilm and FFEI, makes converting short to medium print jobs profitable, as the press streamlines workflow, requires less setup material, less ink/varnish/laminate, provides lower running waste and eliminates overruns. Furthermore, Graphium is a modular digital inkjet press offering the option to integrate true flexo and finishing stations for hybrid production and conversion, in a single pass, thus greatly expanding the opportunities that can be converted.

Graphium ensures excellent print quality and color gamut on a wide range of standard materials, with 39" (1,000mm), 400kg capacity. This capability comes from the integration of a web guide with ultra-sonic edge sensor, web cleaning and corona treatment being fitted as standard.

Graphium’s Xaar printheads and ink systems provide industrial grade reliability and optimal uptime, ensuring continuous trouble-free converting. Graphium’s wide web width of 420mm and fast print speed allows high productivity of up to 1134sqm/hr with up to six different inks. LED inter-color pinning across all six channels provides precise ink laydown and cure control. Graphium’s print engine is capable of printing with up to six ink color combinations. Printers have a choice of four, five or six types of UV-curable inks, including a varnish and under or over whites. Graphium’s color management system allows accurate ISO 12647-2 compliant CMYK printing and wide gamut spot color emulation.

Gallus / Heidelberg

Gallus has expanded its product portfolio with the Smartfire, a new, full-featured, value offering for digital narrow web label printing that is an ideal solution on ultra-short runs. “The Smartfire focuses on new target groups who are looking for a low risk, easy entry into digital label printing,” explains Michael Ring, head of digital solutions at Gallus, who was also recently named TLMI Supplier of the Year (see page 33). He adds, “Incorporating Memjet technology allows us to offer an inkjet printing press that produces labels with a quality of 1600×1600 dpi – while establishing a new, low investment price point in the market.”

The Smartfire’s Memjet water-based inks and printheads mean that labels it produces have a minimal ecological footprint. Virtually “plug and play,” the Smartfire uses an ordinary power outlet, needs no exhaust equipment, is extremely compact, and does not emit VOCs. “It is the perfect press for any work environment,” Ring says. “The name says it all – the Smartfire is absolutely easy to operate via a self-explanatory touch panel. With this digital press, limited prepress skills are needed to create professional CMYK 4-color inkjet labels. Addressing the shortfall of other offerings in this space, a finishing unit is integrated into the press, where labels are laminated and cut, which means the Smartfire delivers finished diecut labels in one pass, ready for shipping.”

Also in the digital space, Gallus and Heidelberg offer the Labelfire 340, a hybrid press that improves speed-to-market while meeting cost reduction initiatives. Labelfire integrates flexo, digital, converting and a variety of embellishments on a single press, all in one-pass. A rotary screen module can even be added in one of the downstream flexo stations to produce tactile screen finishes.

Explains Ring, “All of these single-pass features provide virtually unlimited opportunities to enhance shelf appeal at manageable and competitive costs. Add to the fact that the Gallus Labelfire 340 produces exquisite detail thanks to its 1200 dpi resolution at 50 m/m running speeds, there is no technology on the market close to Labelfire’s performance and efficiency.”

INX International

The single-pass NW340 label press marketed by INX International Ink Co. is a UV digital press that gives label converters the opportunity to seamlessly transition to digital inkjet technology. The NW340 represents third-generation label technology and a natural progression. “It seems like only yesterday when we previewed the NW140 printer at Labelexpo,” says Jim Lambert, INX International’s vice president of digital sales, about its 2010 pre-launch debut. “A few years later, we followed with the NW210. Both of those printers offered resolutions of 360 x 360 dpi and produced labels at speeds up to 80 fpm. The main difference was the printing width of 140mm and later, 210mm.

“The NW340 is a whole different ballgame,” Lambert adds. “We’ve elevated the resolution to 1200 x 600 or 1200 x 1200 dpi, improved the width range to 340mm, and have increased the speed up to 300 fpm to satisfy market demand. Printers want faster equipment and higher resolution so they can more favorably compete with offset presses. This machine does that and more.”

HP

Earlier this year, the second dedicated shrink-sleeve HP Indigo 8000 was installed in the US for serving the fast-growing craft beverage market. The fastest press in the HP Indigo portfolio, the 8000 is positioned as a high speed digital alternative to flexo. The 8000 includes two WS6800 print engines, thus doubling production speeds of the 6000 series by reaching top speeds of 262 fpm.

New to the popular 6000 series of presses, the HP Indigo 6900 offers converters new solutions to enable accelerated business growth by a set of easy-to-use tools driving new applications while improving operational efficiency. The HP Indigo 6900 enables converters to print high-performance applications such as Pack Ready for Labels, which has been extended to HP’s entire labels and packaging portfolio. Labels produced on the 6900 feature improved performance against water, chemical and temperature exposure based on a new UV-curable additive added to off-the-shelf varnishes, cross-linking the label’s construction. With Pack Ready for Labels, converters can print more types of labels and eliminate costly lamination processes.

The HP Indigo 6900 supports a wide variety of solutions, including inks and software tools. The newly introduced HP Indigo ElectroInk Invisible Yellow and Blue are only visible under UV light, delivering high performance for security applications. Coupled with new software and cloud-based solutions that allow anti-counterfeiting marks, micro text fonts, and protected track and trace solutions, converters can offer unique layered security – static and serialized – for brand protection. In addition, the HP Indigo ElectroInk Silver combines metallic effects with digital capabilities in one printing process, saving on metallic substrates and allowing innovation with clear media. The HP Indigo 6900 digital press was showcased at Labelexpo with new applications and effects while running inline with the one-pass digital embellishment unit, the new HP Indigo GEM. For more details on GEM, including the first adoption in the US by ILS, check out the Labelexpo Post-Show report feature in this issue.

Konica Minolta

Konica Minolta recently marked a milestone for its label business - the sale of the 250th unit of its AccurioLabel 190 digital toner-based press. The AccurioLabel 190 is designed to target small to mid-size label converters by offering affordable entry to digital printing. It was developed to manage and deliver an increasing number of small to medium print jobs in ever-shorter processing times.

The highly flexible system runs on coated, uncoated and textured paper and film at speeds of up to 18.9 m/m at 1200 dpi. High quality and high precision label printing of 256 gradations is possible. The AccurioLabel 190 incorporates an intuitive screen for setup so there is no need for extensive user training.

Mark Andy

With a focus on hybrid printing, Mark Andy offers the Digital One and the Digital Series HD. The Digital Series HD can be configured with five through eight digital colors and can support integrated inline or future-proof near line converting options. The base roll-to-roll configuration is ideal for those just entering the production digital space. As a converter’s digital business expands, the modularity of the platform enables the shift to inline finishing to better utilize the high speed platform.

The Digital Series HD features expanded gamut printing in a high-chroma inkset (CMYK + OVG) that complements an existing richly pigmented white ink formulation that delivers rotary screen level output. Mark Andy reports the ink provides three times the opacity of flexo white and more than double that of conventional EP white, measured in excess of 80%. Digital white can be run without a trade-off in speed at the platform’s standard of 240 fpm.

The most notable alteration to the HD press compared to the original Digital Series is in the digital module. Once a flat table section, the new platform now showcases an arched IDS. The arch design accepts unsupported films and improves operator ergonomics, enabling quick and clean ink changeover. New printhead technology housed in the module also matches the 1200 dpi resolution.

The Digital One from Mark Andy Digital One was born after the Mark Andy development team sat down and interviewed 147 customers and asked them what it would take to create a practical digital label press for the everyday converter. The result was the The Digital One, an entry-level digital label press ideal for digitally printing and converting short run prime labels inline, at a low investment level. Digital One offers 4-color CMYK dry-toner printing at 1200 dpi resolution and print speeds up to 62 fpm, though speeds vary based on substrate and application. It has a single multi-purpose flexo station for advanced decoration, and inline or off-line finishing compatibility.

mprint

Germany-based mprint offers the mlabel GEN3. The base machine has a standard mechanical width of 13" but does not have to be outfitted with a print engine of the full print width from the beginning, thus allowing mprint adopters to start with a lower cost system and expand the print engine in the future, adding capacity without having to purchase a new machine. Aside from being equipped with CMYK+W, the machine can incorporate the Digital Metal Liner module – a fully digital foil embellishing unit, allowing printers to not only generate metallic effects on labels and packaging in a single pass, but also to customize these effects with every print. This module was developed in cooperation with Kurz Transfer Products using its Digital Metal UV Ink technology.

Recycling of the inks used for purging and flushing the printheads is engrained in mprint’s concept and has not only a big environmental impact, but also reduces ink cost by increasing ink utilization to over 99%. The machines can be equipped with a vast array of color options – CMYK+W+OV+G plus/or spot colors or spot varnishes, etc. – aside from analog options like flexo print stations.

With the mlabel GEN3, mprint has advanced its UV inkjet narrow web machine portfolio to cover print widths from 4.25" – 12.75" and single to multi-color (seven or more) by allowing for options in price and future machine expansion. Custom print widths of 17" and above are also available.

MPS

The hybrid EF SymJet press from MPS is a combination of a flexo press with the fully automated MPS EF platform and an integrated Domino N610i digital UV inkjet label press. The hybrid flexo inkjet press provides label printers the ability to choose how to run their jobs. In hybrid mode, this press provides the ability of flexo to add primers, spot colors, UV flexo white, metallics, cold foils, over-varnish, inline finishing and more; coupled with the efficiency benefits of digital, such as the ability to run multiple SKUs, versions, and colors, while making changes on the fly, all in a single pass. The EF SymJet also adds a wide range of inline converting solutions.

Mouvent

Mouvent, the Swiss start-up developed through a partnership with Bobst, has unveiled its Mouvent Cluster Technology. The Mouvent Cluster printhead is at the heart of the technology – an approach that uses extremely compact and lightweight clusters instead of fixed size print bars by color, arranging them in a modular, scalable matrix.

Mouvent plans on setting up a US showroom before offering and selling its solutions in the region, and it aims to launch the first of its machines in America in 2019. So far, Mouvent has launched three digital label printers in Europe – the LB701-UV mini label press, which is a small high-productivity label press; the LB702-UV label press, which allows fast and easy industrial label production at an excellent TCO; and the LB702-WB label press, which uses 100% water-based ink. The three label printers can all print up to seven colors on a large variety of substrates at speeds up to 100 m/m at 1200 x 1200 and optical 2000 dpi.

Nilpeter

The Panorama digital product line from Nilpeter features a 5-color inkjet print engine and web infeed for optimum web tension and fast register. The press is designed to be easy to operate from either the touch screen or tablets. It features 14" flexo printing units with quick-change CleanInking chambers. Diecutting is done with either the Semi-Rotative Die-Cutting Unit or Quick-Change Die. The press is also capable of inline integration with Nilpeter’s value-adding units, such as the FP-4 for hot foil and embossing.

Keith Nagle, digital product manager, says the standalone DP3 System offers the highest quality 600 x 600 resolution and finest 3 pt. text at market leading speeds of 160 fpm with CMYK and 100 fpm when white (W+CMYK) is added. Able to run most label and packaging substrates at widths that range from 4" up to 13" allows printers to maximize substrate usage while minimizing waste. Converters can realize uptime higher than 90% with Panorama’s Equios workflow and a simplified operator interface.

OMET

In a partnership with Durst, Omet offers a complete hybrid print and finishing line that offers enhanced flexibility for a wide range of final applications with a consistent cost reduction. Italian converter Italgrafica Sistemi recently chose the Omet XJet because of its ability for inline multi-process configurations that finalizes products in a single pass. With 18 printing lines already running at Italgrafica Sistemi, the new Omet XJet is expected to replace two of the flexo lines as demands continue to increase for short-run, personalized technology in a single pass. It will open up new opportunities for cold foiling, printing on reverse and adhesives, as well as varnish and diecutting.

Francesco Niorettini, general manager of Italgrafica Sistemi, says the total cost of ownership and benefits to his customers were crucial in the decision-making. “Other factors in our investment decision included the 50% increase in speed, the low service and consumable costs, as well as the fact that both Durst and Omet have good reputations in the marketplace,” he adds.

Screen

Screen offers label converters the Truepress Jet L350UV+ and the the L350UV+LM. While similar, the two machines are not identical, however both deliver the same fast run speeds of up to 60 m/m. The Truepress Jet L350 UV+ and Truepress Jet L350 UV+LM machines both feature Screen’s 3-picoliter drop size and four-level grayscale technology for high print quality and brilliant and wider color gamut achieved with Screen’s CMYK+W+Orange inks. The only difference between the two is The L350UV+LM is press equipped with low migration ink capabilities for food label print production.

Screen says many L350UV users have found the technology’s simplicity of use, high uptime and productivity, plus unmatched quality, are leading to significant conversion of many of their label jobs from offset to digital UV inkjet with the Truepress platform. The company believes its “Print. Ship. Bill. Repeat.” message reflects the real profitability that label companies are experiencing in producing prime, flexible, durable and standard labels digitally.

A recent Screen Truepress Jet 350UV installation in the US took place at Ample Industries in Missouri. Ample had investigated several manufacturers in their pursuit of new inkjet equipment. Part of Ample’s process included providing difficult-to-print test files to the several press candidates, and seeing the results the Truepress JetL350UV achieved, Natalie Spradlin, Ample Label’s vice president, says, “Screen is pretty great. We looked at all options in inkjet. Although many were very good, Screen’s quality of print is superior.”

Valloy

Valloy offers the all new Bizpress 13R, a 13" single-pass LED roll-to-roll label printer. The 13" (340 mm) digital roll to roll label printer, Bizpress13R uses an LED production printing engine. According to the company, the printing speed of 7.26 m/m can handle 1,000 m2 jobs easily by changing rolls 3-4 times with up to 1200 × 2400 dpi.

The Bizpress 13R can print on 60 to 300 micron thick papers, PET, BOPP, PE and PVC films. An embedded high-voltage ionizer prevents static problems while enabling easy printing on metallic coated foils. It uses 18K high-capacity toner (26K for black) and 100K high-capacity drum. In addition to an inherent low-temperature fusing system, embedded cooling system and instant fusing mechanism helps cover a wider range of media compatibility. A pneumatic auto-tension control system drives 1km length rolls in a stable way and an intuitive touch panel GUI promotes comfortable operation. A web guide system is optionally available.

Bizpress 13R is positioned as an ideal solution for conventional label converters looking to step into digital short-run production services. It’s also an ideal fit for converters in customized flexible package markets.

Xeikon

Xeikon recently announced an entry-level label printing and converting solution called Label Discovery. It consists of a Xeikon 3030, an entry-level web-fed digital label press and the new entryDcoat, a digital converting line that can be used inline or off-line with the Xeikon 3030.

David Wilkins, Xeikon’s vice president of sales for the North American market, says, “The lower cost of the Xeikon Label Discovery solution enables companies to embrace digital technology and capture a business potential that previously required a steep investment – the crucial business of producing short-run labels.

“The Label Discovery solution is a turnkey label production system that provides everything needed to offer an expanded range of services to their customers and to experience the benefits digital production can bring to their businesses. In addition to enabling an affordable entry into this lucrative market, the Label Discovery solution is a platform that can be field-upgraded in terms of productivity as the business grows, ensuring long-term viability of the investment,” says Wilkins.

The Xeikon 3030 digital label press is a dry toner solution ideal for producing labels for a broad range of applications using standard flexo materials. This avoids the need to use specially-treated substrates and eliminates the associated warehousing costs. Its 5-color printing features CMYK and White or even a special spot or gamut-extending color. Changing toner colors on the system is relatively easy, a clear benefit of dry toner compared to other printing technologies. In addition, dry toner is recognized as the best technology for food labels in terms of food safety due to its non-toxic nature, the company says. Xeikon dry toner has also received FDA certification for both indirect and direct food contact with dry food, which is a plus in the digital landscape.

The entryDCoat is a compact converting unit that consists of a varnish, diecut and rewind station. To limit startup and tooling costs, the diecut unit uses semi-rotary diecutting technology. This ensures low cost converting without loss of productivity while still delivering the well-known quality of conventional diecutting. With semi-rotary diecutting, costs can be reduced by as much as 50% with no need to acquire special tools and no setup time as required with conventional diecutting.

In addition to the Label Discovery, Xeikon also offered an extensive range of both inkjet and toner-based machines, including the Xeikon PX3000 UV inkjet label press, as well the toner-based Xeikon 3500 and Xeikon CX3 presses. For more on Xeikon’s latest dry toner and DFE developments, check out the Labelexpo Post-Show Report.

In the production of pressure sensitive labels using inkjet printing systems, speed is key. With the benefits of digital workflows and quicker setup times for jobs, the expectation on quick turnaround is high. So, the last thing an operator needs is to have to stop production for maintenance.

With the printing of labels, softer adhesives, like those classified as an All Temperature, can migrate onto the rolls of the printing transport system, especially as a printing system heats up during a job. Over time, there can be a buildup of this adhesive that causes speed, flow, and printing issues. So, time must be taken to clean the adhesive that has seeped onto the transport system.

Innovative suppliers, like Technicote in Miamisburg, OH, have taken note of this and offer products with what’s known as a dry edge. This is an ungummed margin on both sides of the roll that must be at least an eighth of an inch wide. This void of adhesive allows for soft adhesive migration from the center of the roll, without leaking onto the printer transport.

“The majority of our UV inkjet label products are available as a dry edge for this very reason,” says Dann Woellert, Technicote inkjet product manager. “We have seen customers increase uptime and reduce maintenance with the use of our dry edge products.”

Some suppliers offer deadened patterns, which use less adhesive instead of no adhesive. Technicote makes its own pattern bars in-house, specializing in true patterns of greater than 50% ungummed area. These are designed for applications that require easier lift edges like a sale label on a food dish or container.