Greg Hrinya, Associate Editor03.14.19

American Label Technologies, Inc.

343 Technology Drive, Unit# 2106, Garner, NC, USA

www.americanlabeltech.com

Darrin Schmitt has built American Label Technologies (ALT) into a commanding presence in North America – even if the large brands using his tags never encounter the converter based in Garner, NC, USA.

What began as a small flexo shop in 2015 has grown into something quite successful in a relatively short amount of time. While ALT boasts a strong portfolio of local customers with products such as craft beer and barbecue sauces, the company has made its name in the RFID market. ALT’s RFID business is targeted primarily at industrial applications, although the company will do some retail work, as well.

Schmitt is ALT’s president. He along with Mike Stone, senior sales executive, and 80% of the company’s workforce, came from Carolina Graphic Press, which was also based in Garner. After Carolina Graphic Press was acquired, Schmitt decided he wanted to venture out on his own, and he found several partners along the way.

By partnering with sister company Progressive Label, which is based in Commerce, CA, ALT gained an international footprint. Progressive Label has two plants in Mexico and one in Hong Kong. Prior to the partnership, Progressive Label served as Schmitt’s largest RFID customer.

“With RFID, there’s a lot of business overseas, so that move gave us an international presence,” explains Schmitt. “We went from a small company to playing on an international stage – and we grew pretty quickly after we joined with Progressive Label. Our sales are continually growing.”

In order to remain successful, especially in the industrial market, ALT is going through multiple quality assurance programs, including ISO certification.

Schmitt comes from humble beginnings, and has experienced the labels and packaging industry from all sides. “I’m a printer by trade,” he says. “I went to school for offset printing, where I worked on small duplicators and moved my way up to Heidelbergs and Komoris. Then, I moved up to production manager. So, after being in offset for many years, I had an opportunity to be a print buyer for a company called CarQuest Auto Parts.”

Schmitt ultimately left to join Carolina Graphic Press, where he learned about flexo and RFID. “I ran a press, I managed press operators, I was a buyer, and then I worked in sales,” says Schmitt. “I’ve seen the industry from all parts, so when buyers call me, I know the pains they’re going through. When my guys come to my office and tell me they’re having problems on a press, I understand it because I ran a press. If Mike comes in with sales problems, I’ve been a salesman, so I’ve kind of experienced ‘the whole nine yards’ in the industry.”

Schmitt runs the day-to-day operations at ALT and owns 33% of the company, with the remaining ownership belonging to his two partners who own Progressive Label. Schmitt elevated himself through sweat equity. “It’s always been a dream of mine to own a company, but I never expected it, especially the way I got percentage ownership,” he says. “The first year I worked for the original partners, I didn’t take a paycheck, and that’s how I gained ownership. I basically lived off a small percentage of my sales. If I didn’t sell for the first three months, I didn’t take a paycheck. It’s like people say, there’s risk versus reward. What are you willing to give to own something?”

ALT has grown by partnering with service bureau companies and resellers. ALT has leveraged its knowledge of RFID tags to find a niche in the industry. The company sells RFID consumables at a slight markup, allowing ALT and its partners to become profitable.

“We don’t have the resources to go into major brands to try to win accounts because it’s a global business,” Schmitt explains. “We’ve partnered with companies that were producing regular non-RFID stickers that kind of got pushed out of the market a little bit because they didn’t know anything about RFID. They can’t compete with the big conglomerates who do RFID, so we came up with a plan to buy from all these big companies in order to get a lower price on RFID, and then we can sell these products and make a small profit, and they can sell some and make a small profit, and now they’re competing against the big companies. Suddenly, we do have the bigger name companies that you see in the stores. It’s actually our tag, but they will never know us.

“We want to compete against the big players, but like I tell everybody, we’re the littlest big company you’ll see, because we do some work for big-name brands but nobody knows who we are,” adds Schmitt. “And we push an American theme. We have an American-made RFID machine, while most of them come out of Germany or China. We’re going to be the alternative to the international companies trying to push all the RFID here.”

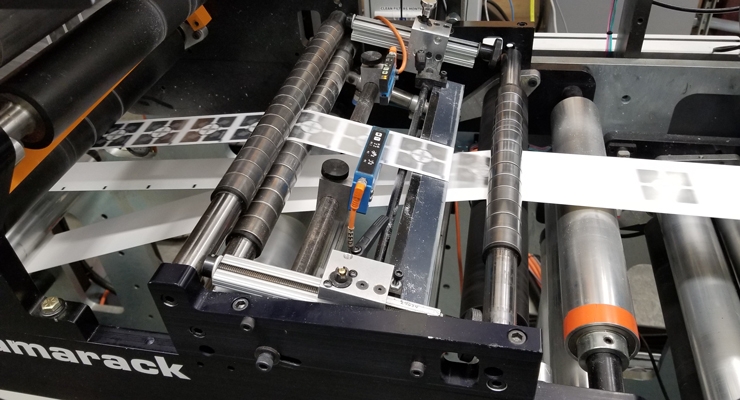

ALT owns two Webtron presses and recently invested in its first digital press, a Colordyne 2600 Series Mini Press. In addition, ALT utilizes a Tamarack machine for its RFID capabilities.

With a small workforce, ALT prides itself on customer service. “I think our biggest advantage of being a small company is we’re incredibly responsive,” notes Stone. “The customer gets what they want within hours – not days. It’s all about customer satisfaction.

“It’s a fast-paced world, and people want a quick response,” says Schmitt. “We will do a crazy test and go through six revisions to get the customer what they want, all while knowing we’re losing money to start with, but we’re not charging them for that test because we know we’re going to win a customer and make it up in the long run. There are ways to make money, and we want to do it by providing our customers with high-end, high-quality work.”

Growing with Colordyne

ALT has experienced considerable growth following the addition of the Colordyne 2600 Series Mini Press, although not for its intended purpose. Schmitt initially selected the Colordyne press to help with retail RFID work. However, ALT never really pursued the market.

“We went with the Colordyne to win short-run digital orders,” he explains. “The big thing about retail is color-by-size, where you have all different colors. Companies might only be ordering five tickets of 10x, so we thought the Colordyne would be able to do the short-run, color-by-size for retail and then use RFID to be competitive. But we kind of strayed away from the retail market a little bit and we’re not really doing a lot of color-by-size.”

The Colordyne 2600 has served a pivotal purpose at ALT, though. The Mini Press has allowed ALT to print labels for the beer and food markets. “Originally, the Colordyne was bought for RFID, but I would say 80% of the business we run on the press is for food applications,” says Schmitt. “What I like about the Colordyne is the color – it’s fantastic, as is the quality of the print.”

ALT is running high-gloss and polypropylene substrates on the Colordyne press. Schmitt says, “It produces high quality labels, with no need for plates. Plus, it’s easy to operate. I’ve got a guy operating it who previously didn’t know anything about printing,” he says. “With the Webtron presses I have to go out and hire a specialist to run flexo, whereas with digital I can hire someone who knows tech – that person can operate the Colordyne.”

Ultimately, the Colordyne has enabled ALT to grab brand owner customers when they’re small, running up to 1,000 labels. As the customers grow in size, ALT has been able to retain their business.

“Everybody and their brother in North Carolina does BBQ sauce, and they always start out small and want 500 to 1,000 labels,” explains Schmitt. “That’s where the press comes in handy. You start with them and they’re doing 500 labels – actually we have one customer like that – then they became a grilling competition champion. So we won their short run business, but now they’re up to 15,000 labels per order.”

‘The Tipping Point’

In his bestselling book The Tipping Point, Malcolm Gladwell defined “The Tipping Point” as the critical moment in an evolving situation that leads to a new and irreversible development. While the labels and packaging industry may not have arrived just yet at that juncture with RFID and smart labeling, it’s on its way.

With the capabilities provided by converters like ALT, there exists a real possibility to cut costs and drive efficiency throughout the supply chain, from cars to lawn mowers to sporting goods.

“Look at bar codes,” exclaims Stone. “They weren’t always here. Now, they’re on everything. Why wouldn’t RFID be the same way?”

In some department stores, they will order five pairs of socks, 10 ties, 15 undershirts, and they must go through a “pick and pack” process. The items go down the line, and the company has seven people at the end of a line taking these boxes, pulling out the PO, and physically counting to make sure they have each color and size as part of the validation process. By installing a tunnel, and putting RFID tags on all the items, the box will pass through the checkpoint without ever needing to be opened up.

Many companies are often faced with chargebacks, where the distributor receives an order for 100 socks and only packs 90. The company will charge for the missing socks, plus a fee, for not correctly filling the original order.

“We did a test pilot with a company, and they loaded their trucks in six hours instead of eight hours with RFID,” says Schmitt. “So, what’s your return on investment now? Another company calls us and says, ‘I think we’re at the tipping point, and maybe we want to have this technology in our warehouse. We have it on 60% of our products, so how much more is it going to cost?’ They can eliminate costs here, load their trucks faster, and they’re not getting the chargebacks for shipping the wrong product because it’s going to be verified without having someone counting all the boxes. There you go, that’s your tipping point.”

“You don’t have to rework or repack or reopen the box, count how many are in there, find the wrong one and retag the product,” adds Stone. “That takes a lot of time. With RFID, you know from the source, and you can track it from the source.”

RFID can provide substantial cost savings by fighting counterfeiting, too. Be it sporting goods or college books, companies have the ability to protect their costs by tracing the point of sale location. “A little tag could save your company a lot of money,” says Schmitt.

A bright future

A booming local economy has helped ALT, but Schmitt notes that the company’s international presence has it positioned for a bright future. Currently, only 10% of ALT’s shipments are local. This small printer has created a large platform, shipping all over the United States and recently notching an account in Brazil.

“When I got into business, I thought it was going to be small barbecue sauce and meat companies that I had as a salesman, and it would be local,” says Schmitt. “I didn’t plan on being an RFID company. That was not the plan, but people just started following us.”

ALT has built a strong reputation in the industry, despite just opening its doors in 2015. According to Schmitt, 95% of the company’s customer acquisition is through word of mouth. The market for RFID tagging will only continue to expand, too.

“The majority of markets have no idea how RFID can help them, – they really don’t,” says Stone. “They’re just like apparel was initially. They’re just doing it to be compliant, or there’s a mandate and they have to do it. It’s nothing but an extra cost. They have blinders on. Very few people are open-minded enough to realize that if you stop focusing on the initial cost and realize what it can do for you long term, there is an ROI in it for you.”

ALT sees further needs in the automotive industry, as well as in manufacturing, pharmaceuticals and nutraceuticals.

“We do a lot of neat stuff; we get excited,” says Schmitt. “To me, it’s exciting when you talk to people and ask them, do you know what RFID is? And then you tell them that there’s RFID in a lot of products that they use, like their Speed Pass.

“If costs keep coming down, I really think there’s a bright future. Like with bar coding, I really think you’re going to be able to walk up to the checkout in a supermarket – because your credit card is RFID – and push your groceries through a little tunnel, or your clothing through a little tunnel at a retail store, and it’s going to ring up your items that fast and get you out the door that fast,” he adds.

“A big thing at a lot of stores is self-checkout. If a little tunnel is added, you could push your cart through and it captures your cart. Food will take a while because of what food costs, but I can see it in retail.” Concludes Stone, “For an apple, it might not make sense, but maybe for an Apple computer, it makes a lot of sense.”

343 Technology Drive, Unit# 2106, Garner, NC, USA

www.americanlabeltech.com

Darrin Schmitt has built American Label Technologies (ALT) into a commanding presence in North America – even if the large brands using his tags never encounter the converter based in Garner, NC, USA.

What began as a small flexo shop in 2015 has grown into something quite successful in a relatively short amount of time. While ALT boasts a strong portfolio of local customers with products such as craft beer and barbecue sauces, the company has made its name in the RFID market. ALT’s RFID business is targeted primarily at industrial applications, although the company will do some retail work, as well.

Schmitt is ALT’s president. He along with Mike Stone, senior sales executive, and 80% of the company’s workforce, came from Carolina Graphic Press, which was also based in Garner. After Carolina Graphic Press was acquired, Schmitt decided he wanted to venture out on his own, and he found several partners along the way.

By partnering with sister company Progressive Label, which is based in Commerce, CA, ALT gained an international footprint. Progressive Label has two plants in Mexico and one in Hong Kong. Prior to the partnership, Progressive Label served as Schmitt’s largest RFID customer.

“With RFID, there’s a lot of business overseas, so that move gave us an international presence,” explains Schmitt. “We went from a small company to playing on an international stage – and we grew pretty quickly after we joined with Progressive Label. Our sales are continually growing.”

In order to remain successful, especially in the industrial market, ALT is going through multiple quality assurance programs, including ISO certification.

Schmitt comes from humble beginnings, and has experienced the labels and packaging industry from all sides. “I’m a printer by trade,” he says. “I went to school for offset printing, where I worked on small duplicators and moved my way up to Heidelbergs and Komoris. Then, I moved up to production manager. So, after being in offset for many years, I had an opportunity to be a print buyer for a company called CarQuest Auto Parts.”

Schmitt ultimately left to join Carolina Graphic Press, where he learned about flexo and RFID. “I ran a press, I managed press operators, I was a buyer, and then I worked in sales,” says Schmitt. “I’ve seen the industry from all parts, so when buyers call me, I know the pains they’re going through. When my guys come to my office and tell me they’re having problems on a press, I understand it because I ran a press. If Mike comes in with sales problems, I’ve been a salesman, so I’ve kind of experienced ‘the whole nine yards’ in the industry.”

Schmitt runs the day-to-day operations at ALT and owns 33% of the company, with the remaining ownership belonging to his two partners who own Progressive Label. Schmitt elevated himself through sweat equity. “It’s always been a dream of mine to own a company, but I never expected it, especially the way I got percentage ownership,” he says. “The first year I worked for the original partners, I didn’t take a paycheck, and that’s how I gained ownership. I basically lived off a small percentage of my sales. If I didn’t sell for the first three months, I didn’t take a paycheck. It’s like people say, there’s risk versus reward. What are you willing to give to own something?”

ALT has grown by partnering with service bureau companies and resellers. ALT has leveraged its knowledge of RFID tags to find a niche in the industry. The company sells RFID consumables at a slight markup, allowing ALT and its partners to become profitable.

“We don’t have the resources to go into major brands to try to win accounts because it’s a global business,” Schmitt explains. “We’ve partnered with companies that were producing regular non-RFID stickers that kind of got pushed out of the market a little bit because they didn’t know anything about RFID. They can’t compete with the big conglomerates who do RFID, so we came up with a plan to buy from all these big companies in order to get a lower price on RFID, and then we can sell these products and make a small profit, and they can sell some and make a small profit, and now they’re competing against the big companies. Suddenly, we do have the bigger name companies that you see in the stores. It’s actually our tag, but they will never know us.

“We want to compete against the big players, but like I tell everybody, we’re the littlest big company you’ll see, because we do some work for big-name brands but nobody knows who we are,” adds Schmitt. “And we push an American theme. We have an American-made RFID machine, while most of them come out of Germany or China. We’re going to be the alternative to the international companies trying to push all the RFID here.”

ALT owns two Webtron presses and recently invested in its first digital press, a Colordyne 2600 Series Mini Press. In addition, ALT utilizes a Tamarack machine for its RFID capabilities.

With a small workforce, ALT prides itself on customer service. “I think our biggest advantage of being a small company is we’re incredibly responsive,” notes Stone. “The customer gets what they want within hours – not days. It’s all about customer satisfaction.

“It’s a fast-paced world, and people want a quick response,” says Schmitt. “We will do a crazy test and go through six revisions to get the customer what they want, all while knowing we’re losing money to start with, but we’re not charging them for that test because we know we’re going to win a customer and make it up in the long run. There are ways to make money, and we want to do it by providing our customers with high-end, high-quality work.”

Growing with Colordyne

ALT has experienced considerable growth following the addition of the Colordyne 2600 Series Mini Press, although not for its intended purpose. Schmitt initially selected the Colordyne press to help with retail RFID work. However, ALT never really pursued the market.

“We went with the Colordyne to win short-run digital orders,” he explains. “The big thing about retail is color-by-size, where you have all different colors. Companies might only be ordering five tickets of 10x, so we thought the Colordyne would be able to do the short-run, color-by-size for retail and then use RFID to be competitive. But we kind of strayed away from the retail market a little bit and we’re not really doing a lot of color-by-size.”

The Colordyne 2600 has served a pivotal purpose at ALT, though. The Mini Press has allowed ALT to print labels for the beer and food markets. “Originally, the Colordyne was bought for RFID, but I would say 80% of the business we run on the press is for food applications,” says Schmitt. “What I like about the Colordyne is the color – it’s fantastic, as is the quality of the print.”

ALT is running high-gloss and polypropylene substrates on the Colordyne press. Schmitt says, “It produces high quality labels, with no need for plates. Plus, it’s easy to operate. I’ve got a guy operating it who previously didn’t know anything about printing,” he says. “With the Webtron presses I have to go out and hire a specialist to run flexo, whereas with digital I can hire someone who knows tech – that person can operate the Colordyne.”

Ultimately, the Colordyne has enabled ALT to grab brand owner customers when they’re small, running up to 1,000 labels. As the customers grow in size, ALT has been able to retain their business.

“Everybody and their brother in North Carolina does BBQ sauce, and they always start out small and want 500 to 1,000 labels,” explains Schmitt. “That’s where the press comes in handy. You start with them and they’re doing 500 labels – actually we have one customer like that – then they became a grilling competition champion. So we won their short run business, but now they’re up to 15,000 labels per order.”

‘The Tipping Point’

In his bestselling book The Tipping Point, Malcolm Gladwell defined “The Tipping Point” as the critical moment in an evolving situation that leads to a new and irreversible development. While the labels and packaging industry may not have arrived just yet at that juncture with RFID and smart labeling, it’s on its way.

With the capabilities provided by converters like ALT, there exists a real possibility to cut costs and drive efficiency throughout the supply chain, from cars to lawn mowers to sporting goods.

“Look at bar codes,” exclaims Stone. “They weren’t always here. Now, they’re on everything. Why wouldn’t RFID be the same way?”

In some department stores, they will order five pairs of socks, 10 ties, 15 undershirts, and they must go through a “pick and pack” process. The items go down the line, and the company has seven people at the end of a line taking these boxes, pulling out the PO, and physically counting to make sure they have each color and size as part of the validation process. By installing a tunnel, and putting RFID tags on all the items, the box will pass through the checkpoint without ever needing to be opened up.

Many companies are often faced with chargebacks, where the distributor receives an order for 100 socks and only packs 90. The company will charge for the missing socks, plus a fee, for not correctly filling the original order.

“We did a test pilot with a company, and they loaded their trucks in six hours instead of eight hours with RFID,” says Schmitt. “So, what’s your return on investment now? Another company calls us and says, ‘I think we’re at the tipping point, and maybe we want to have this technology in our warehouse. We have it on 60% of our products, so how much more is it going to cost?’ They can eliminate costs here, load their trucks faster, and they’re not getting the chargebacks for shipping the wrong product because it’s going to be verified without having someone counting all the boxes. There you go, that’s your tipping point.”

“You don’t have to rework or repack or reopen the box, count how many are in there, find the wrong one and retag the product,” adds Stone. “That takes a lot of time. With RFID, you know from the source, and you can track it from the source.”

RFID can provide substantial cost savings by fighting counterfeiting, too. Be it sporting goods or college books, companies have the ability to protect their costs by tracing the point of sale location. “A little tag could save your company a lot of money,” says Schmitt.

A bright future

A booming local economy has helped ALT, but Schmitt notes that the company’s international presence has it positioned for a bright future. Currently, only 10% of ALT’s shipments are local. This small printer has created a large platform, shipping all over the United States and recently notching an account in Brazil.

“When I got into business, I thought it was going to be small barbecue sauce and meat companies that I had as a salesman, and it would be local,” says Schmitt. “I didn’t plan on being an RFID company. That was not the plan, but people just started following us.”

ALT has built a strong reputation in the industry, despite just opening its doors in 2015. According to Schmitt, 95% of the company’s customer acquisition is through word of mouth. The market for RFID tagging will only continue to expand, too.

“The majority of markets have no idea how RFID can help them, – they really don’t,” says Stone. “They’re just like apparel was initially. They’re just doing it to be compliant, or there’s a mandate and they have to do it. It’s nothing but an extra cost. They have blinders on. Very few people are open-minded enough to realize that if you stop focusing on the initial cost and realize what it can do for you long term, there is an ROI in it for you.”

ALT sees further needs in the automotive industry, as well as in manufacturing, pharmaceuticals and nutraceuticals.

“We do a lot of neat stuff; we get excited,” says Schmitt. “To me, it’s exciting when you talk to people and ask them, do you know what RFID is? And then you tell them that there’s RFID in a lot of products that they use, like their Speed Pass.

“If costs keep coming down, I really think there’s a bright future. Like with bar coding, I really think you’re going to be able to walk up to the checkout in a supermarket – because your credit card is RFID – and push your groceries through a little tunnel, or your clothing through a little tunnel at a retail store, and it’s going to ring up your items that fast and get you out the door that fast,” he adds.

“A big thing at a lot of stores is self-checkout. If a little tunnel is added, you could push your cart through and it captures your cart. Food will take a while because of what food costs, but I can see it in retail.” Concludes Stone, “For an apple, it might not make sense, but maybe for an Apple computer, it makes a lot of sense.”