Steve Katz, Editor04.05.19

The packaging industry has come a long way since the development of the first label applicators – the human hand. All kidding aside, though, hands are still being used to apply self-adhesive labels, particularly in the craft, short run markets. While hand application can be quite accurate, the method can also be inconsistent and slow.

The label application process is not usually the responsibility of the label converter. It’s a downright critical step, and one of the final ones in the product decoration process. A mislabeled product – in terms of label placement – can lead to a product landing in the trash bin, or left on the shelf past its expiration date. Thus, label application should not be overlooked.

Some label converters sell or rent applicators to their customers, thus adding further value. It’s another way of being a one-stop-shop and a source for more revenue.

In fact, the label applicator sector of the packaging industry is big business. According to market research firm Future Market Insights (FMI), the global market for label applicators was valued at more than $2 billion in 2017. In FMI’s recently published report titled Global Label Applicators Market: Industry Analysis and Opportunity Assessment, 2018–2028, the market is expected to expand at a CAGR of 5.2% over the forecast period 2018-2028. The food & beverage end use segment for label applicators is fueling much of the growth, with FMI valuing it at over $1 billion in 2017, and the segment is expected to expand at a CAGR of 4.8% over the forecast period.

In addition to food & beverage, global revenue for the label applicators market is driven by growth in end use sectors such as chemicals, personal care & cosmetics, and logistics & warehousing, among other industries. FMI notes that ease of application and growing demand for labels in manufacturing sectors are factors expected to drive the market during the forecast period. The firm says, “Use of label applicators at the end of the production line is quite simple. Also, regulatory requirement of labeling in almost all industries is one of the key drivers for the demand of label applicators. The global market for label applicators is witnessing innovations resulting from product development activities pertaining to packaging material development and design technology of packaging.”

Label applicators are suitable for manufacturers with high output. FMI says, “But cost of labeling machines are quite high and therefore not affordable for manufacturers with lower production capacity. It might hamper the global label applicators market over the forecast period. But post establishment of these machines provide a cost effective solution in the operation phase.”

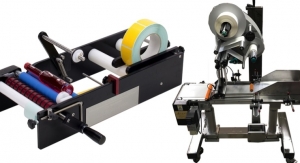

What follows is a look at a few of the newer label applicators on the market today, and the advantages they provide.

Herma US

Herma US Inc., the subsidiary of Herma GmbH, a Germany-based provider of labeling machinery and self-adhesive labels and materials to the global packaging marketplace, has introduced the Herma 500 label applicator, an IoT-enabled machine utilizing real-time metrics to optimize production efficiency and consistency, even in a multi-factory setting. Capable of achieving labeling speeds up to 200 m/min, the Herma 500 can handle label widths between 80-320mm and roll diameters from 300–600mm.

Since launching North American operations in 2016, Herma has enjoyed impressive sales of its signature Herma 400 label applicator. Herma sold more than 4,000 of the label applicators in 2018 – half of which were provided to original equipment manufacturers (OEMs). The Herma 500 is a next-generation label applicator that builds upon its predecessor’s best features and integrates Industry 4.0 connectivity.

The Herma 500 also is exceptionally fast with a maximum speed 70 fpm higher than the Herma 400. A maximum speed of 650 fpm can be reached. The module offers short make-ready time and offers industrial-grade Ethernet connection, amongst a number of comprehensive I/O options.

Jet Marking Systems

Jet Marking Systems (JMS), a division of Jet Label & Packaging, Western Canada’s largest label manufacturer, recently announced the addition of Dan Stickney as general manager. According to Stickney, JMS offers a wide range of label application equipment, with options designed to meet various needs. He says, “The CTM 360a Series from JMS is great for providing both mainstream and many custom solutions.”

The 360a Series label applicator evolved from the industry standard 360 Series Platform. The 360a can be configured as a merge, blow-on or tamp-blow applicator in 5", 7.5" or 10" widths and each module can also be easily switched to the opposite hand with few or no change parts in a minimum amount of time. Stickney explains, “All units are stepper motor driven to include state-of-the-art electronics and a ‘self-teaching’ label sensor. File encryption of the 360a allows for easy ‘on-site’ software revisions and upgrades.”

The 360a stepper drive uses a micro pulse driver for increased accuracy and performance, and is programmable to dispense labels at up to 3000 inches per minute.

The 360a features a combined power supply, amplifier and position controller to comprise a single drive package. The new single axis digital stepper/servo controller controls up to five tasks simultaneously plus management of variables with expanded I/O making this drive well-suited for the most demanding production applications. The 360a controller is also equipped with onboard I/O prewired to external connectors to accommodate the following: low label; single, double or triple lightstack web break; encoder velocity compensation loose loop control; product shape profiling imprinting; and zero downtime configuration. Each machine is shipped preprogrammed and can have the additional hardware installed at a later date for simple “plug and play” operation. The electronic control assembly is packaged as a module and can be easily removed for repair or replacement, eliminating costly downtime and servicing.

Weber Packaging Solutions

With the packaging industry asking for higher labeling speeds and more flexibility, Weber Packaging Solutions has just announced the arrival of its newest label applicator: the Alpha HSM. Featuring modular construction, this high-speed labeling system can be configured in a variety of models that can handle multiple speeds and label sizes.

Every packaging line is different, so Weber engineered the modular Alpha HSM so that it can be ordered in ten different versions to fit just about any labeling application. Available in right- or left-hand versions, the Alpha HSM has 5.3" (135mm), 7.8" (200mm), 9.8" (250mm) and 12.6" (320mm) label width versions. The HSM can keep up with line speeds up to 500 fpm.

With a labeling accuracy of ±0.01", the Alpha HSM can handle labels as small as 0.39" x 0.39" (10mm x 10mm) and up to 12.5" x 78.7" (320mm x 2000mm) (W x L). Depending on the label width configuration, the HSM can handle label rolls up to 19" in diameter on 3" diameter cores.

Three different user interfaces are available including OLED display, external PLC module or a web-based control. And the system is IP65 certified for dust and water spray protection and is constructed of durable aluminum with high rigidity for all working label widths.

The standard mechanical label unwinder and rewinder can be upgraded to a motorized servo-controlled system for higher speeds. Application modules for the HSM include a fixed peeler plate, a swiveling peeler plate, a pneumatic peeler plate, and adjustable peeler plate or a pneumatic applicator. Label sensors can handle standard and transparent labels.

Multiple interfaces allow connections for HMI display, product detector, rotary encoder, I/O signal, Ethernet network, and an aux in and aux out for sensor attachment.

The label application process is not usually the responsibility of the label converter. It’s a downright critical step, and one of the final ones in the product decoration process. A mislabeled product – in terms of label placement – can lead to a product landing in the trash bin, or left on the shelf past its expiration date. Thus, label application should not be overlooked.

Some label converters sell or rent applicators to their customers, thus adding further value. It’s another way of being a one-stop-shop and a source for more revenue.

In fact, the label applicator sector of the packaging industry is big business. According to market research firm Future Market Insights (FMI), the global market for label applicators was valued at more than $2 billion in 2017. In FMI’s recently published report titled Global Label Applicators Market: Industry Analysis and Opportunity Assessment, 2018–2028, the market is expected to expand at a CAGR of 5.2% over the forecast period 2018-2028. The food & beverage end use segment for label applicators is fueling much of the growth, with FMI valuing it at over $1 billion in 2017, and the segment is expected to expand at a CAGR of 4.8% over the forecast period.

In addition to food & beverage, global revenue for the label applicators market is driven by growth in end use sectors such as chemicals, personal care & cosmetics, and logistics & warehousing, among other industries. FMI notes that ease of application and growing demand for labels in manufacturing sectors are factors expected to drive the market during the forecast period. The firm says, “Use of label applicators at the end of the production line is quite simple. Also, regulatory requirement of labeling in almost all industries is one of the key drivers for the demand of label applicators. The global market for label applicators is witnessing innovations resulting from product development activities pertaining to packaging material development and design technology of packaging.”

Label applicators are suitable for manufacturers with high output. FMI says, “But cost of labeling machines are quite high and therefore not affordable for manufacturers with lower production capacity. It might hamper the global label applicators market over the forecast period. But post establishment of these machines provide a cost effective solution in the operation phase.”

What follows is a look at a few of the newer label applicators on the market today, and the advantages they provide.

Herma US

Herma US Inc., the subsidiary of Herma GmbH, a Germany-based provider of labeling machinery and self-adhesive labels and materials to the global packaging marketplace, has introduced the Herma 500 label applicator, an IoT-enabled machine utilizing real-time metrics to optimize production efficiency and consistency, even in a multi-factory setting. Capable of achieving labeling speeds up to 200 m/min, the Herma 500 can handle label widths between 80-320mm and roll diameters from 300–600mm.

Since launching North American operations in 2016, Herma has enjoyed impressive sales of its signature Herma 400 label applicator. Herma sold more than 4,000 of the label applicators in 2018 – half of which were provided to original equipment manufacturers (OEMs). The Herma 500 is a next-generation label applicator that builds upon its predecessor’s best features and integrates Industry 4.0 connectivity.

The Herma 500 also is exceptionally fast with a maximum speed 70 fpm higher than the Herma 400. A maximum speed of 650 fpm can be reached. The module offers short make-ready time and offers industrial-grade Ethernet connection, amongst a number of comprehensive I/O options.

Jet Marking Systems

Jet Marking Systems (JMS), a division of Jet Label & Packaging, Western Canada’s largest label manufacturer, recently announced the addition of Dan Stickney as general manager. According to Stickney, JMS offers a wide range of label application equipment, with options designed to meet various needs. He says, “The CTM 360a Series from JMS is great for providing both mainstream and many custom solutions.”

The 360a Series label applicator evolved from the industry standard 360 Series Platform. The 360a can be configured as a merge, blow-on or tamp-blow applicator in 5", 7.5" or 10" widths and each module can also be easily switched to the opposite hand with few or no change parts in a minimum amount of time. Stickney explains, “All units are stepper motor driven to include state-of-the-art electronics and a ‘self-teaching’ label sensor. File encryption of the 360a allows for easy ‘on-site’ software revisions and upgrades.”

The 360a stepper drive uses a micro pulse driver for increased accuracy and performance, and is programmable to dispense labels at up to 3000 inches per minute.

The 360a features a combined power supply, amplifier and position controller to comprise a single drive package. The new single axis digital stepper/servo controller controls up to five tasks simultaneously plus management of variables with expanded I/O making this drive well-suited for the most demanding production applications. The 360a controller is also equipped with onboard I/O prewired to external connectors to accommodate the following: low label; single, double or triple lightstack web break; encoder velocity compensation loose loop control; product shape profiling imprinting; and zero downtime configuration. Each machine is shipped preprogrammed and can have the additional hardware installed at a later date for simple “plug and play” operation. The electronic control assembly is packaged as a module and can be easily removed for repair or replacement, eliminating costly downtime and servicing.

Weber Packaging Solutions

With the packaging industry asking for higher labeling speeds and more flexibility, Weber Packaging Solutions has just announced the arrival of its newest label applicator: the Alpha HSM. Featuring modular construction, this high-speed labeling system can be configured in a variety of models that can handle multiple speeds and label sizes.

Every packaging line is different, so Weber engineered the modular Alpha HSM so that it can be ordered in ten different versions to fit just about any labeling application. Available in right- or left-hand versions, the Alpha HSM has 5.3" (135mm), 7.8" (200mm), 9.8" (250mm) and 12.6" (320mm) label width versions. The HSM can keep up with line speeds up to 500 fpm.

With a labeling accuracy of ±0.01", the Alpha HSM can handle labels as small as 0.39" x 0.39" (10mm x 10mm) and up to 12.5" x 78.7" (320mm x 2000mm) (W x L). Depending on the label width configuration, the HSM can handle label rolls up to 19" in diameter on 3" diameter cores.

Three different user interfaces are available including OLED display, external PLC module or a web-based control. And the system is IP65 certified for dust and water spray protection and is constructed of durable aluminum with high rigidity for all working label widths.

The standard mechanical label unwinder and rewinder can be upgraded to a motorized servo-controlled system for higher speeds. Application modules for the HSM include a fixed peeler plate, a swiveling peeler plate, a pneumatic peeler plate, and adjustable peeler plate or a pneumatic applicator. Label sensors can handle standard and transparent labels.

Multiple interfaces allow connections for HMI display, product detector, rotary encoder, I/O signal, Ethernet network, and an aux in and aux out for sensor attachment.