Greg Hrinya, Editor03.05.20

A flexo press is one of the most substantial investments a label converter will make. With flexography playing such a dominant role in the North American label market, choosing the right press can literally make or break a business.

It’s no secret that there are a multitude of factors that must be considered when selecting a press. Converters must assess pricing, return on investment (ROI), make-ready, service and support, spare parts availability, technical specifications, comfortability with a manufacturer and more. Perhaps most importantly, the press must satisfy the requirements of the individual converter. It sounds simple, but one manufacturer’s press might satisfy one converter’s needs more so than a competing OEM.

With each press increasingly becoming configured to the individual needs of the converter, the complexity of the flexo process also increases. The ability to successfully navigate rote functions, such as changeover times, must be considered with more complex needs.

According to Perry Lichon, president of Retroflex, converters must consider whether they need a press for longer or shorter runs, the inks (water-based, solvent, or UV), substrates used, coatings and colors required, and countless others. “Determining the affordability of a flexo press involves many variables and considerations,” says Lichon. “Realistic answers to your questions will help a flexo press supplier determine the equipment and features that are required. In general, the cost of a new flexo press is a very affordable way to meet nearly any printing need.”

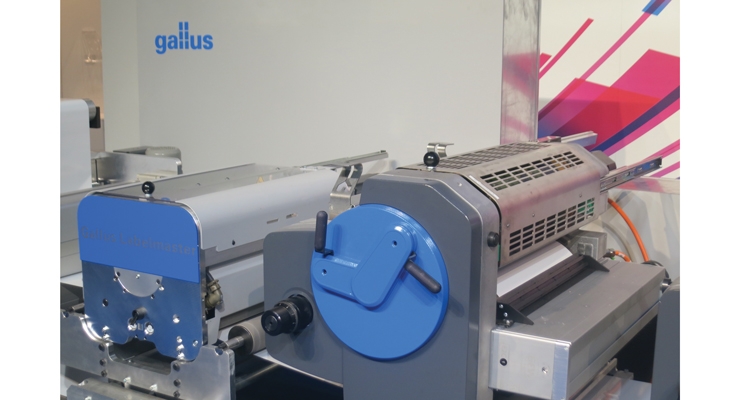

As technology has evolved, so too has the investment process – specifically for flexo. Waste reduction, for example, can be one facet of the process that lowers a label printer’s bottom line. “Presses today are more technologically advanced than ever before, which means they are easier for operators to run and lessen the amount of human error that can affect the press run,” explains Andre Blais, national account manager, Heidelberg-Gallus USA. “Flexo presses are running more efficiently and providing higher throughput. As converters are being pressured to lower costs to their customers, they are also facing price increases from their suppliers for materials, inks, plates, etc. With more efficient production, converters can produce more in a shorter period of time – helping lower their costs and giving them more press time to sell.”

As Chris Baldwin, director of sales and marketing at Omet Americas, notes, there are a number of factors that affect price. The price of the machine is just one number that goes into the cost-benefit analysis.

“When looking at how affordable a new press is, more has to be taken into consideration than only the price of the press,” he explains. “You have to determine how much waste can be reduced, whether the new press can replace multiple presses in your shop, can new press operators easily learn to operate it, and whether or not this investment can attract new business due to higher quality, more capacity, etc.”

It is also critical for label converters to account for the long-term viability of their press. “Since a flexo press is a long-term investment, consideration must be given to a manufacturer’s ability to support the equipment long term,” says Jeff Cowan, director of business development at Mark Andy. “This includes technical service, replacement parts and upgradability, as well as throughput, sellable product yield and reliability, which all contribute to the value proposition of a press purchase.”

While purchasing a flexo press is a capital investment, it is not as daunting as one might think. The rise in automation and servo motors has led to increased turnaround times and greater overall efficiency.

“The cost of new technology is much more affordable than ever before,” says Paul Teachout, vice president of sales and marketing, Nilpeter USA. “It also has a major impact on the total cost of operation over the life cycle of the machine. No longer do we build presses with gear drives, line shafts and gear boxes, with all the associated maintenance and assembly it takes to maintain them. This is all added cost. The modern press is based on a very simplistic mechanical design and driven by multiple motion control motors, with full automation through digital controls, saved data and feedback. The great thing about automation is that it provides feedback on performance and history. This makes presses much easier to troubleshoot, maintain and more cost effective for total cost of operation. Yesteryear’s presses were 80% mechanical and 20% software, while modern presses are just the opposite and provide years of consistent higher performance with a lower operating cost.”

Like many suppliers, Omet offers a wide range of flexo press configurations. The company’s press range spans 14" to 33", allowing label converters to tap into a wider range of markets, which might include wider runs like those needed for flexible packaging. That, too, can affect a converter’s financials.

“With all of the innovation that Omet’s press lines offer, the value and cost justification is a lot better than converters may think,” says Baldwin.

There is also the old adage of spending money to make money. When it comes to a flexo press, a higher initial investment could yield a great return in a shorter period of time. “There should always be a balance between user-friendliness, robustness, quality and efficiency,” says Michael Weyermann, vice president of sales and marketing for MPS Systems North America. “Even if the price of a press is a bit on the higher side, it’s worth looking at the ROI. An MPS press may not be the cheapest available, but if it saves work, waste and therefore money, it’s definitely worth the investment.”

Even the purchasing timeframe is a factor that must be accounted for. The needs of the customer and the complexity of the press can drastically change installation times. “Some converters need a press as soon as possible because they landed a new contract and the sales cycle is quick,” notes Blais. “In other cases, some presses are so complex that the sales cycle can take up to two years to complete.”

It is rare for two presses to be exactly the same. Each converter will require a setup unique to his or her company, and flexo press manufacturers are more than willing to accommodate these needs – from press setup to discussing financing. “Our presses are never standard, as we will always think along with the customer and create a tailor-made solution,” says Weyermann. “At our Technology & Expertise Centers in Philadelphia, PA and Arnhem, the Netherlands, we will perform live demonstrations with the customer’s jobs, showing what we’re capable of. And of course, we have a lot of existing customers who are keen to share their experiences and open up their facility for a reference visit. This is often included in the sales process.”

Even though the purchasing process is significant, the research and trial phase of the investment is just as critical. “First, there has to be a need. Whether the spark that highlights the need for new equipment is for capacity, change or even feelings of malcontent with existing equipment, converters generally have to identify why they are on the hunt for a new asset first,” says Cowan. “The converter goes through a learning stage by researching the capabilities necessary for a solution and then comparison leads to identifying a preference. Before making a buying decision, fear often needs to be overcome prior to a commitment being made, and commitment is made by making a selection and approving the purchase. Most sales cycles end here, but not with Mark Andy. Exceeding expectations with things like lead times and service coverage, for example, is where the real value comes. Then the process repeats itself when another need arises.”

“Communication is key,” stresses Lichon. “The flexo press provider should learn all they can about the buyer’s wants and needs. In turn, the buyer must be able to provide a realistic list of their wants and needs to the press supplier. Having honest and realistic dialogue by all parties is the best approach to providing a solution that will be profitable to the buyer, as well as the seller. Keep in mind that unlike many everyday purchases, the purchase of a printing press is a business decision and should be based on its ability to maximize profitability for the job you need it to perform.”

Omet’s Baldwin recommends a hands-on experience for more than just the investors at a label company. “Once we have discussed the needs of the converter to make sure Omet has a solution, we then analyze the types of work they print, the width and type of press they need, and help the client with a cost justification/ROI,” he says. “From there, we will typically bring the client in for a demonstration and test their jobs and materials. We encourage the client to allow their press operators and key plant personnel to attend the demonstration so they can have a hands-on experience with the press and answer any questions they may have.”

Converters have options, too, when looking into buying a new flexo press. If money is tight, there is always the option of upgrading an existing flexo asset. “Mark Andy has engineering resources dedicated to enhancing existing equipment through our retrofits and upgrade solutions,” notes Cowan. “Additionally, there is also a used market that can be considered.”

“Upgrading the tension system, drive, dryers, ink doctoring systems, adding an automated unwind or rewind, additional color stations and numerous other features may allow the buyer to reduce their overall investment,” notes Lichon. “The equipment provider should be able to review the buyer’s existing equipment and help them determine the feasibility and cost of modifying that equipment.”

The next wave

The modern flexo press is not your father’s press. While there is still a considerable investment required, the innovation and subsequent return on investment have changed the entire process. What once required an intense amount of manual labor has benefited from automation, robotics and modularity.

“Like anything else we use in our daily lives, the press is now a computer that performs a function,” explains Nilpeter’s Teachout. “This is the generation of Internet of Things and clean-hand technologies. Presses have evolved from very mechanical machines that required a specific skillset and a little bit of ‘voodoo magic’ to be productive. Those days are gone. Now, it is very common to replace that old mentality with new and innovative thinking. The current technology will easily replace two older presses and be more productive. This not only improves a converter’s bottom line, it also cuts its workforce challenge in half.”

At MPS, the platform “Talk to Me” has been designed to connect MPS printing presses with prepress and post-press systems, as well as MIS. This exchange of real-time data promotes efficiency and time savings.

“With modern options for connectivity providing insight into press performance, there are many ways to improve the ROI. When the efficiency is higher, the investment of a press is easily returned,” states MPS’ Weyermann. “MPS uses the highest levels of automation utilizing direct servo motors and drives. This allows us to capture and record every occurrence on the press and output it to live data. With Talk to Me, we are able to provide statistical insight into the press performance and help guide our customers to better press optimization.”

In addition, the modularity of many modern flexo presses ensures a longer lifespan of the investment. “There are many opportunities to improve existing presses with retrofits or accessories to accomplish these goals,” says Teachout.” But it is always a compromise in production. The platforms we offer today have the ability to grow as your business needs grow. The modular construction in both mechanical design and software make adding new innovations much easier on a new platform than trying to get an old dog to do new tricks.”

Addressing digital

While the industry has taken note that flexography and digital can profitably exist side-by-side, there is the realization that converters are allocating more assets than ever before into digital. This investment strategy could have an impact on flexography. Even though the vast majority of label printing is done flexographically, more converters are looking at digital to handle shorter runs that are better equipped for digital.

“Three years ago, only 20% of converters had a digital asset,” says Heidelberg-Gallus’ Blais. “Today, it is closer to 50%, with the expectation of that number growing to 70% in the next year or two. More digital presses are being sold, and it can take dollars away from a flexo investment. However, flexo is not going away, and digital is a complement to flexo. But we do see that the market today – and in the future – will see more digital purchases, and the competition for digital dollars is very competitive.”

Hybrid presses, which include partnerships between many of the top names in both the flexographic and digital markets, are also a consideration for converters investing in flexo.

“Digital technology plays a big part in packaging today,” says Omet’s Baldwin. “Although it will not replace flexographic printing, it has affected the decision of converters in their choice of technologies. Omet’s partnership with Durst has allowed us to offer converters solutions in both the flexo and digital markets.”

Mark Andy’s Cowan adds that flexo is in a better position than ever before to compete with digital printing. “If a converter is comparing older flexo technology against modern digital technology, he or she is not seeing the whole picture,” he says. “Modern flexo machines have changed the cost position for short-run flexo jobs. With simplified changeovers and automation to reduce waste, shorter runs can be done with flexo equipment more profitably than ever before. In the end, the decision to invest in flexo or digital comes down to a converter’s business and where their needs lie. Fortunately, Mark Andy provides both digital and flexo solutions and can help converters through this process of selection.”

Even though flexo presses offer considerably more in the way of flexibility, they also might lead to losses in changeover times, pressure stability, and varied performance on-press. There are other considerations like rail systems and drop-in variants. With a host of variables worth monitoring, choosing the right press is ever-more critical. Making the correct choice can launch a printing business, however.

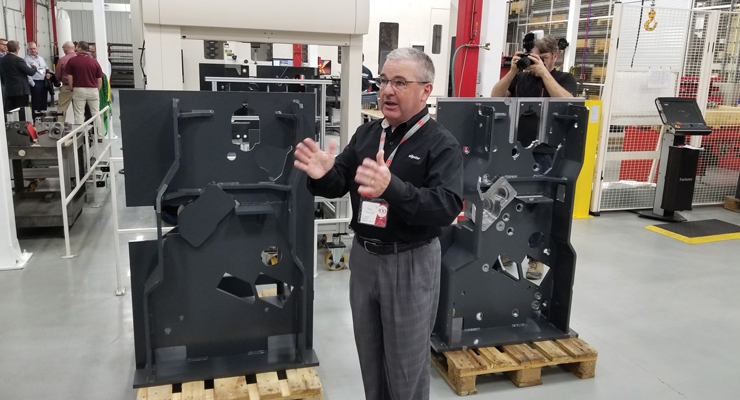

A recent study from Heidelberg-Gallus sees process changes as a macro trend, with the flexo manufacturer capable of delivering the shortest possible changes leading to the greatest productivity of the machine. The study, which focused on the Heidelberg-Gallus Labelmaster, assumed two process changes per shift. The customized configuration of the Labelmaster led to annual savings of 38,400 euros compared to a rail system, or 76,800 euros compared to a drop-in variant.

In the case of the Labelmaster Advanced, the press does not have to be switched off during the process change, as this occurs while the machine is running. Other factors can also influence the bottom line. In the case of the Labelmaster, it takes 1.4 meters for the web to travel from printing unit to printing unit. According to Heidelberg-Gallus, this is made possible by arranging all the essential processes on the primary level, whereby no change to another level is necessary. The use of a screen printing unit on a rail, for example, causes an additional path of 4-6 meters. The arrangement of the printing units on the primary level, however, saves material, time and costs during setup and becomes even more important with increasing job and material changes.

There is a myth, though, that a converter must spend an exorbitant amount of money to realize these savings. According to Heidelberg-Gallus’ Andre Blais, the misperception of flexo press costs persists, especially in North America. “A high percentage of converters in North America feel like Heidelberg-Gallus has high-quality equipment, however, they have an incorrect perception that they cannot afford our equipment,” he says. “Our recent press platforms are actually very competitive in price to other manufacturers, and less expensive in some cases.

“Presses are extremely affordable today and the technical aspects are much more advanced,” adds Blais. “They’re all servo driven, operator friendly, computerized and they come with minimum mechanical parts.”

Gallus has also seen an assortment of benefits from its integration with Heidelberg, including press optimization and enhanced service and support. “Gallus is now able to leverage Heidelberg’s well-known service and parts infrastructure here in North America,” explains Blais. “Additionally, it means that Gallus and Heidelberg can continue to work together on projects like Labelfire – bringing together their respective expertise to build better products for customers.”

It’s no secret that there are a multitude of factors that must be considered when selecting a press. Converters must assess pricing, return on investment (ROI), make-ready, service and support, spare parts availability, technical specifications, comfortability with a manufacturer and more. Perhaps most importantly, the press must satisfy the requirements of the individual converter. It sounds simple, but one manufacturer’s press might satisfy one converter’s needs more so than a competing OEM.

With each press increasingly becoming configured to the individual needs of the converter, the complexity of the flexo process also increases. The ability to successfully navigate rote functions, such as changeover times, must be considered with more complex needs.

According to Perry Lichon, president of Retroflex, converters must consider whether they need a press for longer or shorter runs, the inks (water-based, solvent, or UV), substrates used, coatings and colors required, and countless others. “Determining the affordability of a flexo press involves many variables and considerations,” says Lichon. “Realistic answers to your questions will help a flexo press supplier determine the equipment and features that are required. In general, the cost of a new flexo press is a very affordable way to meet nearly any printing need.”

As technology has evolved, so too has the investment process – specifically for flexo. Waste reduction, for example, can be one facet of the process that lowers a label printer’s bottom line. “Presses today are more technologically advanced than ever before, which means they are easier for operators to run and lessen the amount of human error that can affect the press run,” explains Andre Blais, national account manager, Heidelberg-Gallus USA. “Flexo presses are running more efficiently and providing higher throughput. As converters are being pressured to lower costs to their customers, they are also facing price increases from their suppliers for materials, inks, plates, etc. With more efficient production, converters can produce more in a shorter period of time – helping lower their costs and giving them more press time to sell.”

As Chris Baldwin, director of sales and marketing at Omet Americas, notes, there are a number of factors that affect price. The price of the machine is just one number that goes into the cost-benefit analysis.

“When looking at how affordable a new press is, more has to be taken into consideration than only the price of the press,” he explains. “You have to determine how much waste can be reduced, whether the new press can replace multiple presses in your shop, can new press operators easily learn to operate it, and whether or not this investment can attract new business due to higher quality, more capacity, etc.”

It is also critical for label converters to account for the long-term viability of their press. “Since a flexo press is a long-term investment, consideration must be given to a manufacturer’s ability to support the equipment long term,” says Jeff Cowan, director of business development at Mark Andy. “This includes technical service, replacement parts and upgradability, as well as throughput, sellable product yield and reliability, which all contribute to the value proposition of a press purchase.”

While purchasing a flexo press is a capital investment, it is not as daunting as one might think. The rise in automation and servo motors has led to increased turnaround times and greater overall efficiency.

“The cost of new technology is much more affordable than ever before,” says Paul Teachout, vice president of sales and marketing, Nilpeter USA. “It also has a major impact on the total cost of operation over the life cycle of the machine. No longer do we build presses with gear drives, line shafts and gear boxes, with all the associated maintenance and assembly it takes to maintain them. This is all added cost. The modern press is based on a very simplistic mechanical design and driven by multiple motion control motors, with full automation through digital controls, saved data and feedback. The great thing about automation is that it provides feedback on performance and history. This makes presses much easier to troubleshoot, maintain and more cost effective for total cost of operation. Yesteryear’s presses were 80% mechanical and 20% software, while modern presses are just the opposite and provide years of consistent higher performance with a lower operating cost.”

Like many suppliers, Omet offers a wide range of flexo press configurations. The company’s press range spans 14" to 33", allowing label converters to tap into a wider range of markets, which might include wider runs like those needed for flexible packaging. That, too, can affect a converter’s financials.

“With all of the innovation that Omet’s press lines offer, the value and cost justification is a lot better than converters may think,” says Baldwin.

There is also the old adage of spending money to make money. When it comes to a flexo press, a higher initial investment could yield a great return in a shorter period of time. “There should always be a balance between user-friendliness, robustness, quality and efficiency,” says Michael Weyermann, vice president of sales and marketing for MPS Systems North America. “Even if the price of a press is a bit on the higher side, it’s worth looking at the ROI. An MPS press may not be the cheapest available, but if it saves work, waste and therefore money, it’s definitely worth the investment.”

Even the purchasing timeframe is a factor that must be accounted for. The needs of the customer and the complexity of the press can drastically change installation times. “Some converters need a press as soon as possible because they landed a new contract and the sales cycle is quick,” notes Blais. “In other cases, some presses are so complex that the sales cycle can take up to two years to complete.”

It is rare for two presses to be exactly the same. Each converter will require a setup unique to his or her company, and flexo press manufacturers are more than willing to accommodate these needs – from press setup to discussing financing. “Our presses are never standard, as we will always think along with the customer and create a tailor-made solution,” says Weyermann. “At our Technology & Expertise Centers in Philadelphia, PA and Arnhem, the Netherlands, we will perform live demonstrations with the customer’s jobs, showing what we’re capable of. And of course, we have a lot of existing customers who are keen to share their experiences and open up their facility for a reference visit. This is often included in the sales process.”

Even though the purchasing process is significant, the research and trial phase of the investment is just as critical. “First, there has to be a need. Whether the spark that highlights the need for new equipment is for capacity, change or even feelings of malcontent with existing equipment, converters generally have to identify why they are on the hunt for a new asset first,” says Cowan. “The converter goes through a learning stage by researching the capabilities necessary for a solution and then comparison leads to identifying a preference. Before making a buying decision, fear often needs to be overcome prior to a commitment being made, and commitment is made by making a selection and approving the purchase. Most sales cycles end here, but not with Mark Andy. Exceeding expectations with things like lead times and service coverage, for example, is where the real value comes. Then the process repeats itself when another need arises.”

“Communication is key,” stresses Lichon. “The flexo press provider should learn all they can about the buyer’s wants and needs. In turn, the buyer must be able to provide a realistic list of their wants and needs to the press supplier. Having honest and realistic dialogue by all parties is the best approach to providing a solution that will be profitable to the buyer, as well as the seller. Keep in mind that unlike many everyday purchases, the purchase of a printing press is a business decision and should be based on its ability to maximize profitability for the job you need it to perform.”

Omet’s Baldwin recommends a hands-on experience for more than just the investors at a label company. “Once we have discussed the needs of the converter to make sure Omet has a solution, we then analyze the types of work they print, the width and type of press they need, and help the client with a cost justification/ROI,” he says. “From there, we will typically bring the client in for a demonstration and test their jobs and materials. We encourage the client to allow their press operators and key plant personnel to attend the demonstration so they can have a hands-on experience with the press and answer any questions they may have.”

Converters have options, too, when looking into buying a new flexo press. If money is tight, there is always the option of upgrading an existing flexo asset. “Mark Andy has engineering resources dedicated to enhancing existing equipment through our retrofits and upgrade solutions,” notes Cowan. “Additionally, there is also a used market that can be considered.”

“Upgrading the tension system, drive, dryers, ink doctoring systems, adding an automated unwind or rewind, additional color stations and numerous other features may allow the buyer to reduce their overall investment,” notes Lichon. “The equipment provider should be able to review the buyer’s existing equipment and help them determine the feasibility and cost of modifying that equipment.”

The next wave

The modern flexo press is not your father’s press. While there is still a considerable investment required, the innovation and subsequent return on investment have changed the entire process. What once required an intense amount of manual labor has benefited from automation, robotics and modularity.

“Like anything else we use in our daily lives, the press is now a computer that performs a function,” explains Nilpeter’s Teachout. “This is the generation of Internet of Things and clean-hand technologies. Presses have evolved from very mechanical machines that required a specific skillset and a little bit of ‘voodoo magic’ to be productive. Those days are gone. Now, it is very common to replace that old mentality with new and innovative thinking. The current technology will easily replace two older presses and be more productive. This not only improves a converter’s bottom line, it also cuts its workforce challenge in half.”

At MPS, the platform “Talk to Me” has been designed to connect MPS printing presses with prepress and post-press systems, as well as MIS. This exchange of real-time data promotes efficiency and time savings.

“With modern options for connectivity providing insight into press performance, there are many ways to improve the ROI. When the efficiency is higher, the investment of a press is easily returned,” states MPS’ Weyermann. “MPS uses the highest levels of automation utilizing direct servo motors and drives. This allows us to capture and record every occurrence on the press and output it to live data. With Talk to Me, we are able to provide statistical insight into the press performance and help guide our customers to better press optimization.”

In addition, the modularity of many modern flexo presses ensures a longer lifespan of the investment. “There are many opportunities to improve existing presses with retrofits or accessories to accomplish these goals,” says Teachout.” But it is always a compromise in production. The platforms we offer today have the ability to grow as your business needs grow. The modular construction in both mechanical design and software make adding new innovations much easier on a new platform than trying to get an old dog to do new tricks.”

Addressing digital

While the industry has taken note that flexography and digital can profitably exist side-by-side, there is the realization that converters are allocating more assets than ever before into digital. This investment strategy could have an impact on flexography. Even though the vast majority of label printing is done flexographically, more converters are looking at digital to handle shorter runs that are better equipped for digital.

“Three years ago, only 20% of converters had a digital asset,” says Heidelberg-Gallus’ Blais. “Today, it is closer to 50%, with the expectation of that number growing to 70% in the next year or two. More digital presses are being sold, and it can take dollars away from a flexo investment. However, flexo is not going away, and digital is a complement to flexo. But we do see that the market today – and in the future – will see more digital purchases, and the competition for digital dollars is very competitive.”

Hybrid presses, which include partnerships between many of the top names in both the flexographic and digital markets, are also a consideration for converters investing in flexo.

“Digital technology plays a big part in packaging today,” says Omet’s Baldwin. “Although it will not replace flexographic printing, it has affected the decision of converters in their choice of technologies. Omet’s partnership with Durst has allowed us to offer converters solutions in both the flexo and digital markets.”

Mark Andy’s Cowan adds that flexo is in a better position than ever before to compete with digital printing. “If a converter is comparing older flexo technology against modern digital technology, he or she is not seeing the whole picture,” he says. “Modern flexo machines have changed the cost position for short-run flexo jobs. With simplified changeovers and automation to reduce waste, shorter runs can be done with flexo equipment more profitably than ever before. In the end, the decision to invest in flexo or digital comes down to a converter’s business and where their needs lie. Fortunately, Mark Andy provides both digital and flexo solutions and can help converters through this process of selection.”

Even though flexo presses offer considerably more in the way of flexibility, they also might lead to losses in changeover times, pressure stability, and varied performance on-press. There are other considerations like rail systems and drop-in variants. With a host of variables worth monitoring, choosing the right press is ever-more critical. Making the correct choice can launch a printing business, however.

A recent study from Heidelberg-Gallus sees process changes as a macro trend, with the flexo manufacturer capable of delivering the shortest possible changes leading to the greatest productivity of the machine. The study, which focused on the Heidelberg-Gallus Labelmaster, assumed two process changes per shift. The customized configuration of the Labelmaster led to annual savings of 38,400 euros compared to a rail system, or 76,800 euros compared to a drop-in variant.

In the case of the Labelmaster Advanced, the press does not have to be switched off during the process change, as this occurs while the machine is running. Other factors can also influence the bottom line. In the case of the Labelmaster, it takes 1.4 meters for the web to travel from printing unit to printing unit. According to Heidelberg-Gallus, this is made possible by arranging all the essential processes on the primary level, whereby no change to another level is necessary. The use of a screen printing unit on a rail, for example, causes an additional path of 4-6 meters. The arrangement of the printing units on the primary level, however, saves material, time and costs during setup and becomes even more important with increasing job and material changes.

There is a myth, though, that a converter must spend an exorbitant amount of money to realize these savings. According to Heidelberg-Gallus’ Andre Blais, the misperception of flexo press costs persists, especially in North America. “A high percentage of converters in North America feel like Heidelberg-Gallus has high-quality equipment, however, they have an incorrect perception that they cannot afford our equipment,” he says. “Our recent press platforms are actually very competitive in price to other manufacturers, and less expensive in some cases.

“Presses are extremely affordable today and the technical aspects are much more advanced,” adds Blais. “They’re all servo driven, operator friendly, computerized and they come with minimum mechanical parts.”

Gallus has also seen an assortment of benefits from its integration with Heidelberg, including press optimization and enhanced service and support. “Gallus is now able to leverage Heidelberg’s well-known service and parts infrastructure here in North America,” explains Blais. “Additionally, it means that Gallus and Heidelberg can continue to work together on projects like Labelfire – bringing together their respective expertise to build better products for customers.”