Greg Hrinya, Editor06.04.20

Attracting the next-generation workforce is one of the greatest challenges a label company will face. As printing technologies undergo rapid changes and a segment of workers

approach retirement age, converters must prepare for the future while also safe-guarding their current processes.

Add in the uncertain future presented by the COVID-19 pandemic, and workforce challenges are at the forefront of mind for label

industry professionals.

According to a Deloitte study referenced in Forbes, “Estimates put the manufacturing labor shortage at 2.4 million by 2028…and we can’t assume this gap will be solved by a sudden influx of employees after COVID-19 restrictions are eased. The number of retirees continues to increase as the working population ages; meaning there will still be a lack of sufficient qualified applicants to replace them. Manufacturers must prepare for the long-term reality they are facing – operating with fewer people on the floor and insulating themselves from the loss of domain knowledge.”

The label industry has faced difficulties in attracting new workers, and image certainly plays a role. While it may not seem like a “sexy” industry, there are a plethora of advantages to working in manufacturing.

Conveying that message is key, though.

“Print in general has image problems, and I believe it is a lack of an image causing us problems,” explains Shawn Oetjen, flexo trainer at Flexographic Tech. “Most people don’t even realize this industry exists, while others are under the false impression that print is dying. The fact is, labels and packaging is a booming industry. Most of us in this industry fell into it by chance, as I don’t know anyone who said as a kid, ‘I want to make labels.’ In contrast, there are millions who want to be doctors or members of extremely visible careers.”

“Most of our employees in the plant have been with us for many, many years,” says Kristen Shields, president, Graymills Corporation. “They appreciate working for a family business. We retain them through fair wages and benefits, of course – but also through open communication. They know where we’re going and what it will take to get there.”

Part of that messaging can be accelerated during the COVID-19 crisis. Label printing has proven itself to be an essential business, operating on the front lines to get the most critical items to the store shelves.

“The one thing I’ve taken out of this coronavirus crisis, and I’ve shared it with our employees, is really a sense of pride,” says Robert Parker, owner, Label King. “What we’re doing keeps the nation going. It may not seem all that important because it’s just a label, but the reality is what we do is very important and will continue to be important. Without a label, there will be nothing sold, period. You can’t sell a product without a label on it.

“What we do is tangible and visible,” adds Parker. “Our industry is exciting for the people who are passionate about it, and there are a lot of people who are very passionate about this industry and do an amazing job.”

There are other challenges besides changing the industry’s image. According to Oetjen, many high schools and trade schools are shuttering their press programs due to low enrollment or budget cuts. This diminishing exposure limits visibility to a younger generation.

“My high school had a Heidelberg press, and because of that I found out about this industry,” notes Oetjen. “The elimination of these types of programs will have lasting negative impacts on the skilled trades in the US for decades to come.”

Compensation is also a significant hurdle that must be overcome. As unemployment has risen in pockets of the country, not all companies have increased their wages to a competitive level to attract good talent. The rising cost of living makes salary a deciding factor for job seekers.

“It’s difficult to say what a competitive rate is because it varies from location to location and job to job,” explains Oetjen. “I know if I see Target is paying $15 an hour, I better offer more than that if I want to attract good talent. Where I live, Amazon is paying $16 an hour with 401K and health benefits. The Costco around the corner is paying $19 an hour with health benefits, 401K and PTO. The warehouse across the street is offering $21.58 for warehouse order selectors. Bank of America recently announced by the year 2021 it would raise the starting pay for all its employees to $20 an hour. There are numerous studies that unequivocally show paying a few more dollars an hour results in better recruitment, happier, more loyal and productive employees.”

Retirement is also a challenge that many converters and suppliers must face, especially when many companies have employees tenured for 30 years and more.

“We have an aging workforce, so it’s been a real challenge to find highly-skilled labor to replace retirees and their tribal knowledge,” Shields emphasizes.

Oetjen adds that printing and manufacturing tend to feature a male-dominated working environment. While not by design, this fact can shrink the pool of applicants by 50%. “It’s not that women can’t apply for these jobs, but I think we need to figure out how we can make printing more attractive to women seeking jobs in manufacturing and look at the culture on the pressroom floors to assure that women feel safe and welcome,” he says.

Shields has worked tirelessly to promote women’s entrance into the manufacturing space. She currently serves on the Women in Illinois Manufacturing Council, which is part of the Illinois

Manufacturers Association.

“Women are a huge part of our workforce,” she states. “We are working to support women working in manufacturing, and I’m also proud to be a part of the FTA’s Women in Flexo Committee.”

When it comes to employee retention, treating employees fairly and with respect is paramount. “I think the most important thing for any industry is to treat your employees like human beings and value them,” says Parker. “Something that I do every single day is I say hello to every single employee. I make it a point, because if people are treated with respect and valued, then they have a lot more pride in what they do. It’s just common sense. With people who are working hard, you should treat them with respect and you should treat them well. They’re good people who I think the world of.”

Back to school

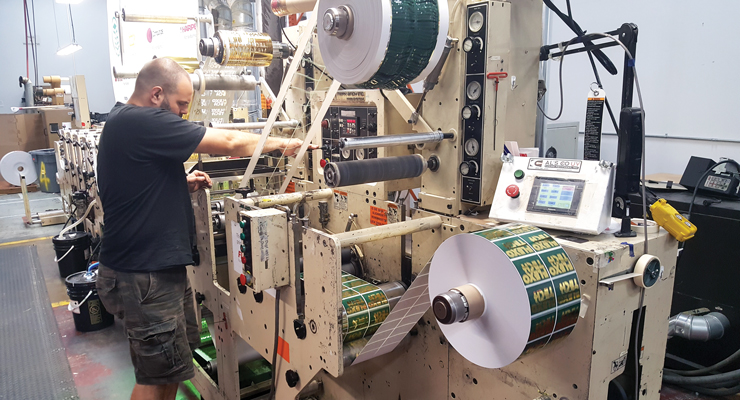

We must then question what our industry needs to do to better attract employees? Oetjen’s Flexo Tech is one such avenue, as the not-for-profit educational resource exposes students to the world of flexography and labels.

Flexo Tech prides itself on providing real-world, hands-on skills training in a compressed time frame. The curriculum is developed with skills the industry has identified as critical for new employees to possess. The hands-on and frequent evaluation of skills assure the students are learning the proper content before they move on, providing them with a solid foundation to enter the workforce.

Label King’s Parker, on the other hand, is an alumnus of the Fullerton Junior College Flexo Program. He is a big proponent of education and will often send employees to school in order to hone their skills. Parker followed this strategy with his production manager.

“I think education is really important, and it’s a great way to develop employees,” says Parker. “If there’s a program close by, you can pay for your employee to take a class and it will help you in spades. When we hired our production manager, I said, ‘If you take this class for a semester, I’ll pay for your gas and pay for the class, but you’ll go on your own time. If you finish the class, then I’m going to give you an increase in pay.’ That individual has turned out to be a fantastic leader in our company. I think education is great to build and foster the industry, but I don’t think we do a good job at all of doing that.”

No converter is immune from these challenges, either. “To be blunt, I have yet to find a printer that does not struggle with finding new employees,” says Oetjen. “Companies can invest in themselves by investing in training. All too often in the country, training is reactive and treated as a cost not an investment. Simply put, companies can send us people to train.”

Flexo Tech prepares students for real-world situations, highlighting countless tasks that will be encountered on a daily basis. It also does so with manageable numbers to promote learning, as every student will learn at a different pace. The press class will include four students while 10 students will take part in the three-day Flexo 101 class.

“All the students we train are sent to us by flexo companies from around the US and in some cases around the world,” says Oetjen. “Many of the companies we work with use our training to entice new employees and illustrate the opportunities they have to move up within their organization.”

Graymills has accepted this challenge head-on. While the company does not require press operators, they instead are searching for qualified welders and machinists.

“We have participated in local job fairs at high schools and community college, and participated in a work internship program sponsored by the city of Chicago,” says Shields. “It’s important that we are not perceived as ‘dirty’ or ‘old school.’ We need to stress the computerization of our industry, the need for ongoing education and, most of all, the security that comes with joining a successful manufacturing company. We make real things that will always be needed by the industry.”

Graymills has also taken an active role in supporting Flexo Tech.

When hiring new employees, attitude is everything. “In general, it’s important to find someone who is reliable and hard working,” notes Parker. “When you find someone who has a good work ethic, you can convert that person to almost anything from a manufacturing standpoint.”

To engage with potential prospects, Oetjen has even reached out to the Boy Scouts of America to offer the Graphic Arts Merit Badge to local troops. “In 2018, only five boy scouts (in Minnesota) received the merit badge, so there is a great opportunity to promote our industry. In about five hours, the scouts, both boys and girls, can earn a merit badge and learn about the great career opportunities our industry has to offer.”

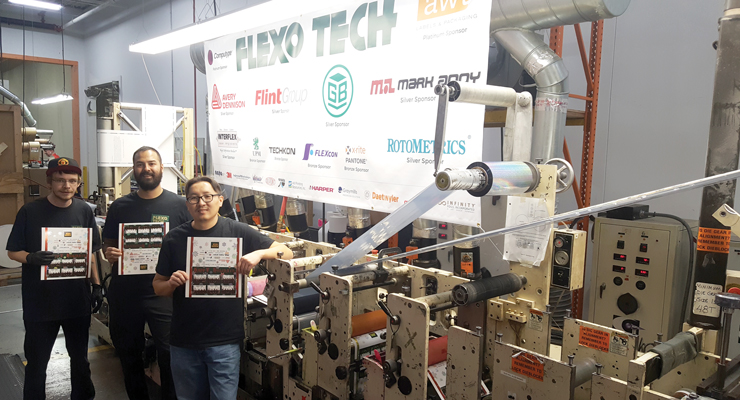

Flexo Tech relies on a wide range of industry support to make this educational program possible. Among the sponsors are 3M, acpo, All Printing Resources, AWT Labels & Packaging, Avery Dennison, Daetwyler, Diversified Innovative Products (Dipco), DuPont, Eaglewood Technologies, FLEXcon, Flint Group, FTA, Graymills, Green Bay Packaging, Harper, Interflex Laser Engravers, INX, K Laser, Mactac, Mark Andy, Ritrama, RotoMetrics, Siegwerk, Techkon, TLMI, UPM Raflatac, Xeikon and X-Rite Pantone.

A new world

As Graymills’ Shields notes, the industry should not be perceived as “old school” or “dirty.” Many of the latest and greatest products target automation and a workforce that has grown up with computerized technologies.

Digital and hybrid presses, for example, are providing a new point of entry for students. Some jobs will start going to tech or computer savvy candidates, which the industry has not historically had access to.

“Print is not a dirty, dying industry but one that is cutting edge,” says Flexo Tech’s Oetjen. “The new technologies provide a state-of-the-art look into what we are doing, and it has a positive impact on our industry. I believe this is going to help us promote opportunities in our industry by showcasing the cool new technologies we have to offer. Just imagine a new, clean, well-lit digital press room versus a stereotypical dark, dirty, loud and gear-driven press. The dichotomy between the two showcase why this new technology is important.”

As more suppliers and customers establish sustainability goals, printing can appeal to the upcoming generation in new ways.

“With the focus on global warming and the impact that consumers directly have on the environment, the younger generation is taking that to heart,” adds Oetjen. “Promoting jobs that can directly impact and reduce the environmental impact can provide opportunities to future employees that other industries can’t.”

Pandemic effect

The COVID-19 pandemic continues to evolve on a daily basis, but the label printing industry has proven to be a consistent source of employment. As an essential business, label suppliers and converters have remained open – operating on a daily basis while adhering to social distancing practices.

Label King has been partaking in meetings every two days to discuss all the ramifications of the coronavirus and how it impacts business. “We are on the front lines – and we can be on the front lines in a safe environment,” says Label King’s Parker. “It’s a good feeling to know that the products that we make are critical to the well-being of the nation. And there should be a lot of pride in that.”

The essential nature of business also provides job security.

“Many printers have been designated as an essential business, so job security is a major bonus,” explains Flexo Tech’s Oetjen. “When millions of Americans are being laid off, the labels we produce are extremely important and in some cases are part of life-saving equipment. The job security that this industry offers – and knowing you will have a paycheck – is truly a positive aspect, especially when there is so much unknown in the world right now.”

According to Parker, the current economic downturn could prompt more candidates looking to enter the workforce. However, label companies might have more candidates to choose from, but candidates might find it tougher finding quality jobs.

“With high unemployment right now, people are hungry for jobs, and as time goes on, people will become hungrier for jobs,” he says. “It will then be a question of finding people you can trust and will fit in to your company culture.”

The life of a Flexo Tech student encompasses a wide range of responsibilities. For those considering sending a new – or prospective – employee to a flexo school, here is an idea of what will be gained.

Flexo Tech, which is based in Minneapolis, MN, USA, features small class sizes, especially when working on a press. The four students learning on a press will not run any live work, as training is the focus. The course mimics a real-life printing environment, from setting up a flexo press to analyzing paperwork.

“I purposely place errors in the job tickets to make sure the students are reading and understanding them,” explains Shawn Oetjen, flexo trainer. “Each press run is deconstructed after sign-off but before the student runs, with an 8-page grading rubric looking at everything from tension settings, anilox roll selection, doctor blade settings and even waste and time metrics. When the students are on-press, I do not touch anything unless the student requests hands-on assistance. This allows the student to immerse themselves with hands-on training and promotes comprehension and troubleshooting in the long run.”

There is a comprehensive structure to the class, as well. The core competencies included in the curriculum are reviewed before moving on to more complex skills. A 12-week snapshot of the course is as follows:

Week 1: Intro and Webbing the Press

Week 2: Diecutting

Week 3: Plate Mounting and Kiss Impressions

Week 4: 2 and 3 Color Jobs

Week 5: 3 and 4 Color Jobs

Week 6: 4 Color Process

Week 7: Turn Bar and Top Cut/Undercut Dies

Week 8: Delam Relam

Week 9: Turret/Butt Splicer

Week 10: 6 Color Jobs + Varnish

Week 11: Final

Week 12: Cold Foil & Embossing

“The class accelerates at a rapid pace, considering many of the students have never operated a flexo press before,” says Oetjen. “If you look closely, the content builds on itself. For instance, if you do not have a good understanding of tension, delam/relam is going to be difficult to complete.”

The training is broken down into two sections: lecture and press room. The lecture portion of the class starts with a quiz, evaluating each student’s comprehension of the previous concepts. “We dive deep into the technical aspects, allowing the students to understand the why’s and the how’s of the press room,” Oetjen adds. “When we are troubleshooting in the press room, I will often refer back to these concepts. We make sure the content aligns with industry best practices and assure the students are being taught the correct way to execute tasks.”

After the press is set up, the students request a sign-off. While this typically involves generic paperwork, Flexo Tech has used company-specific forms before. The students are required to verify the bar code will scan, get a color verification, make sure the dimensions are correct (+/- .03125”) along with many other print specifics from unwind direction to print quality. Students must be able to complete a range of tasks. For example, they need to be able to install a die and get it cutting and stripping in under five minutes, or set a kiss impression in under 60 feet or register four colors accurately in 100 feet of material. These checkpoints can be re-attempted by the students up to the due date, encouraging them to practice and improve their grade.

Students then take two final exams. One is a 160-question written final, as well as a press final consisting of a tight register, 6-color job with a flood varnish, diecut and linneals. “To earn maximum points the student needs to properly set up, run and clean up the job in 3.5 hours and use less than 900 feet of material,” states Oetjen. “This is an intense training program that encourages the students to perform at a high level with a focus on productivity, but more importantly doing things right and producing high quality product.”

approach retirement age, converters must prepare for the future while also safe-guarding their current processes.

Add in the uncertain future presented by the COVID-19 pandemic, and workforce challenges are at the forefront of mind for label

industry professionals.

According to a Deloitte study referenced in Forbes, “Estimates put the manufacturing labor shortage at 2.4 million by 2028…and we can’t assume this gap will be solved by a sudden influx of employees after COVID-19 restrictions are eased. The number of retirees continues to increase as the working population ages; meaning there will still be a lack of sufficient qualified applicants to replace them. Manufacturers must prepare for the long-term reality they are facing – operating with fewer people on the floor and insulating themselves from the loss of domain knowledge.”

The label industry has faced difficulties in attracting new workers, and image certainly plays a role. While it may not seem like a “sexy” industry, there are a plethora of advantages to working in manufacturing.

Conveying that message is key, though.

“Print in general has image problems, and I believe it is a lack of an image causing us problems,” explains Shawn Oetjen, flexo trainer at Flexographic Tech. “Most people don’t even realize this industry exists, while others are under the false impression that print is dying. The fact is, labels and packaging is a booming industry. Most of us in this industry fell into it by chance, as I don’t know anyone who said as a kid, ‘I want to make labels.’ In contrast, there are millions who want to be doctors or members of extremely visible careers.”

“Most of our employees in the plant have been with us for many, many years,” says Kristen Shields, president, Graymills Corporation. “They appreciate working for a family business. We retain them through fair wages and benefits, of course – but also through open communication. They know where we’re going and what it will take to get there.”

Part of that messaging can be accelerated during the COVID-19 crisis. Label printing has proven itself to be an essential business, operating on the front lines to get the most critical items to the store shelves.

“The one thing I’ve taken out of this coronavirus crisis, and I’ve shared it with our employees, is really a sense of pride,” says Robert Parker, owner, Label King. “What we’re doing keeps the nation going. It may not seem all that important because it’s just a label, but the reality is what we do is very important and will continue to be important. Without a label, there will be nothing sold, period. You can’t sell a product without a label on it.

“What we do is tangible and visible,” adds Parker. “Our industry is exciting for the people who are passionate about it, and there are a lot of people who are very passionate about this industry and do an amazing job.”

There are other challenges besides changing the industry’s image. According to Oetjen, many high schools and trade schools are shuttering their press programs due to low enrollment or budget cuts. This diminishing exposure limits visibility to a younger generation.

“My high school had a Heidelberg press, and because of that I found out about this industry,” notes Oetjen. “The elimination of these types of programs will have lasting negative impacts on the skilled trades in the US for decades to come.”

Compensation is also a significant hurdle that must be overcome. As unemployment has risen in pockets of the country, not all companies have increased their wages to a competitive level to attract good talent. The rising cost of living makes salary a deciding factor for job seekers.

“It’s difficult to say what a competitive rate is because it varies from location to location and job to job,” explains Oetjen. “I know if I see Target is paying $15 an hour, I better offer more than that if I want to attract good talent. Where I live, Amazon is paying $16 an hour with 401K and health benefits. The Costco around the corner is paying $19 an hour with health benefits, 401K and PTO. The warehouse across the street is offering $21.58 for warehouse order selectors. Bank of America recently announced by the year 2021 it would raise the starting pay for all its employees to $20 an hour. There are numerous studies that unequivocally show paying a few more dollars an hour results in better recruitment, happier, more loyal and productive employees.”

Retirement is also a challenge that many converters and suppliers must face, especially when many companies have employees tenured for 30 years and more.

“We have an aging workforce, so it’s been a real challenge to find highly-skilled labor to replace retirees and their tribal knowledge,” Shields emphasizes.

Oetjen adds that printing and manufacturing tend to feature a male-dominated working environment. While not by design, this fact can shrink the pool of applicants by 50%. “It’s not that women can’t apply for these jobs, but I think we need to figure out how we can make printing more attractive to women seeking jobs in manufacturing and look at the culture on the pressroom floors to assure that women feel safe and welcome,” he says.

Shields has worked tirelessly to promote women’s entrance into the manufacturing space. She currently serves on the Women in Illinois Manufacturing Council, which is part of the Illinois

Manufacturers Association.

“Women are a huge part of our workforce,” she states. “We are working to support women working in manufacturing, and I’m also proud to be a part of the FTA’s Women in Flexo Committee.”

When it comes to employee retention, treating employees fairly and with respect is paramount. “I think the most important thing for any industry is to treat your employees like human beings and value them,” says Parker. “Something that I do every single day is I say hello to every single employee. I make it a point, because if people are treated with respect and valued, then they have a lot more pride in what they do. It’s just common sense. With people who are working hard, you should treat them with respect and you should treat them well. They’re good people who I think the world of.”

Back to school

We must then question what our industry needs to do to better attract employees? Oetjen’s Flexo Tech is one such avenue, as the not-for-profit educational resource exposes students to the world of flexography and labels.

Flexo Tech prides itself on providing real-world, hands-on skills training in a compressed time frame. The curriculum is developed with skills the industry has identified as critical for new employees to possess. The hands-on and frequent evaluation of skills assure the students are learning the proper content before they move on, providing them with a solid foundation to enter the workforce.

Label King’s Parker, on the other hand, is an alumnus of the Fullerton Junior College Flexo Program. He is a big proponent of education and will often send employees to school in order to hone their skills. Parker followed this strategy with his production manager.

“I think education is really important, and it’s a great way to develop employees,” says Parker. “If there’s a program close by, you can pay for your employee to take a class and it will help you in spades. When we hired our production manager, I said, ‘If you take this class for a semester, I’ll pay for your gas and pay for the class, but you’ll go on your own time. If you finish the class, then I’m going to give you an increase in pay.’ That individual has turned out to be a fantastic leader in our company. I think education is great to build and foster the industry, but I don’t think we do a good job at all of doing that.”

No converter is immune from these challenges, either. “To be blunt, I have yet to find a printer that does not struggle with finding new employees,” says Oetjen. “Companies can invest in themselves by investing in training. All too often in the country, training is reactive and treated as a cost not an investment. Simply put, companies can send us people to train.”

Flexo Tech prepares students for real-world situations, highlighting countless tasks that will be encountered on a daily basis. It also does so with manageable numbers to promote learning, as every student will learn at a different pace. The press class will include four students while 10 students will take part in the three-day Flexo 101 class.

“All the students we train are sent to us by flexo companies from around the US and in some cases around the world,” says Oetjen. “Many of the companies we work with use our training to entice new employees and illustrate the opportunities they have to move up within their organization.”

Graymills has accepted this challenge head-on. While the company does not require press operators, they instead are searching for qualified welders and machinists.

“We have participated in local job fairs at high schools and community college, and participated in a work internship program sponsored by the city of Chicago,” says Shields. “It’s important that we are not perceived as ‘dirty’ or ‘old school.’ We need to stress the computerization of our industry, the need for ongoing education and, most of all, the security that comes with joining a successful manufacturing company. We make real things that will always be needed by the industry.”

Graymills has also taken an active role in supporting Flexo Tech.

When hiring new employees, attitude is everything. “In general, it’s important to find someone who is reliable and hard working,” notes Parker. “When you find someone who has a good work ethic, you can convert that person to almost anything from a manufacturing standpoint.”

To engage with potential prospects, Oetjen has even reached out to the Boy Scouts of America to offer the Graphic Arts Merit Badge to local troops. “In 2018, only five boy scouts (in Minnesota) received the merit badge, so there is a great opportunity to promote our industry. In about five hours, the scouts, both boys and girls, can earn a merit badge and learn about the great career opportunities our industry has to offer.”

Flexo Tech relies on a wide range of industry support to make this educational program possible. Among the sponsors are 3M, acpo, All Printing Resources, AWT Labels & Packaging, Avery Dennison, Daetwyler, Diversified Innovative Products (Dipco), DuPont, Eaglewood Technologies, FLEXcon, Flint Group, FTA, Graymills, Green Bay Packaging, Harper, Interflex Laser Engravers, INX, K Laser, Mactac, Mark Andy, Ritrama, RotoMetrics, Siegwerk, Techkon, TLMI, UPM Raflatac, Xeikon and X-Rite Pantone.

A new world

As Graymills’ Shields notes, the industry should not be perceived as “old school” or “dirty.” Many of the latest and greatest products target automation and a workforce that has grown up with computerized technologies.

Digital and hybrid presses, for example, are providing a new point of entry for students. Some jobs will start going to tech or computer savvy candidates, which the industry has not historically had access to.

“Print is not a dirty, dying industry but one that is cutting edge,” says Flexo Tech’s Oetjen. “The new technologies provide a state-of-the-art look into what we are doing, and it has a positive impact on our industry. I believe this is going to help us promote opportunities in our industry by showcasing the cool new technologies we have to offer. Just imagine a new, clean, well-lit digital press room versus a stereotypical dark, dirty, loud and gear-driven press. The dichotomy between the two showcase why this new technology is important.”

As more suppliers and customers establish sustainability goals, printing can appeal to the upcoming generation in new ways.

“With the focus on global warming and the impact that consumers directly have on the environment, the younger generation is taking that to heart,” adds Oetjen. “Promoting jobs that can directly impact and reduce the environmental impact can provide opportunities to future employees that other industries can’t.”

Pandemic effect

The COVID-19 pandemic continues to evolve on a daily basis, but the label printing industry has proven to be a consistent source of employment. As an essential business, label suppliers and converters have remained open – operating on a daily basis while adhering to social distancing practices.

Label King has been partaking in meetings every two days to discuss all the ramifications of the coronavirus and how it impacts business. “We are on the front lines – and we can be on the front lines in a safe environment,” says Label King’s Parker. “It’s a good feeling to know that the products that we make are critical to the well-being of the nation. And there should be a lot of pride in that.”

The essential nature of business also provides job security.

“Many printers have been designated as an essential business, so job security is a major bonus,” explains Flexo Tech’s Oetjen. “When millions of Americans are being laid off, the labels we produce are extremely important and in some cases are part of life-saving equipment. The job security that this industry offers – and knowing you will have a paycheck – is truly a positive aspect, especially when there is so much unknown in the world right now.”

According to Parker, the current economic downturn could prompt more candidates looking to enter the workforce. However, label companies might have more candidates to choose from, but candidates might find it tougher finding quality jobs.

“With high unemployment right now, people are hungry for jobs, and as time goes on, people will become hungrier for jobs,” he says. “It will then be a question of finding people you can trust and will fit in to your company culture.”

The life of a Flexo Tech student encompasses a wide range of responsibilities. For those considering sending a new – or prospective – employee to a flexo school, here is an idea of what will be gained.

Flexo Tech, which is based in Minneapolis, MN, USA, features small class sizes, especially when working on a press. The four students learning on a press will not run any live work, as training is the focus. The course mimics a real-life printing environment, from setting up a flexo press to analyzing paperwork.

“I purposely place errors in the job tickets to make sure the students are reading and understanding them,” explains Shawn Oetjen, flexo trainer. “Each press run is deconstructed after sign-off but before the student runs, with an 8-page grading rubric looking at everything from tension settings, anilox roll selection, doctor blade settings and even waste and time metrics. When the students are on-press, I do not touch anything unless the student requests hands-on assistance. This allows the student to immerse themselves with hands-on training and promotes comprehension and troubleshooting in the long run.”

There is a comprehensive structure to the class, as well. The core competencies included in the curriculum are reviewed before moving on to more complex skills. A 12-week snapshot of the course is as follows:

Week 1: Intro and Webbing the Press

Week 2: Diecutting

Week 3: Plate Mounting and Kiss Impressions

Week 4: 2 and 3 Color Jobs

Week 5: 3 and 4 Color Jobs

Week 6: 4 Color Process

Week 7: Turn Bar and Top Cut/Undercut Dies

Week 8: Delam Relam

Week 9: Turret/Butt Splicer

Week 10: 6 Color Jobs + Varnish

Week 11: Final

Week 12: Cold Foil & Embossing

“The class accelerates at a rapid pace, considering many of the students have never operated a flexo press before,” says Oetjen. “If you look closely, the content builds on itself. For instance, if you do not have a good understanding of tension, delam/relam is going to be difficult to complete.”

The training is broken down into two sections: lecture and press room. The lecture portion of the class starts with a quiz, evaluating each student’s comprehension of the previous concepts. “We dive deep into the technical aspects, allowing the students to understand the why’s and the how’s of the press room,” Oetjen adds. “When we are troubleshooting in the press room, I will often refer back to these concepts. We make sure the content aligns with industry best practices and assure the students are being taught the correct way to execute tasks.”

After the press is set up, the students request a sign-off. While this typically involves generic paperwork, Flexo Tech has used company-specific forms before. The students are required to verify the bar code will scan, get a color verification, make sure the dimensions are correct (+/- .03125”) along with many other print specifics from unwind direction to print quality. Students must be able to complete a range of tasks. For example, they need to be able to install a die and get it cutting and stripping in under five minutes, or set a kiss impression in under 60 feet or register four colors accurately in 100 feet of material. These checkpoints can be re-attempted by the students up to the due date, encouraging them to practice and improve their grade.

Students then take two final exams. One is a 160-question written final, as well as a press final consisting of a tight register, 6-color job with a flood varnish, diecut and linneals. “To earn maximum points the student needs to properly set up, run and clean up the job in 3.5 hours and use less than 900 feet of material,” states Oetjen. “This is an intense training program that encourages the students to perform at a high level with a focus on productivity, but more importantly doing things right and producing high quality product.”