Greg Hrinya, Editor10.09.20

Without a clean anilox roll, achieving excellent print quality becomes nearly impossible. And with converters facing greater demands for speed and quality than ever before, neglecting the anilox roll can prove detrimental to a label printing business.

The COVID-19 pandemic has seen converters inundated with orders, especially in the food, beverage and personal care markets. Although demand has stabilized since March and April, printers must be prepared. A dirty anilox roll will affect print quality, lead to more downtime and create greater headaches for business owners.

New technologies, such as faster printing presses, improved ink technology (learn more on page 52), faster changeover times, among others, have required anilox rolls and cleaners to be up to the task. Between enhanced printing technologies and shorter lead times, aniloxes have passed the test with flying colors.

“It’s just becoming more important than ever for printers to become as efficient as possible,” says Joe Walczak, president of Sonic Solutions. “All of these developments have meant that keeping your anilox clean is even more important. No company can waste any efficiencies due to dirty anilox rolls or sleeves. Idle press time, wasted labor hours, inks and substrates all add up to big dollars. Everyone needs to remain as competitive as possible.”

There is not one right answer for cleaning an anilox roll, though. Anilox technologies have evolved, offering thinner cell walls, higher line screens and tougher inks. There is also the choice of liquid, laser or ultrasonic cleaning.

Harper Corporation of America, a manufacturer of anilox rolls, offers a list of recommendations when exploring anilox cleaning methods. According to Harper, converters should first look at their anilox handling practices and whether they promote preventative maintenance and proper cleaning. The anilox handling practice should detail the type of ink being used, a cleaner selection process, the step-by-step process for using the appropriate cleaner such as when to use it, dilution or mixing requirements, how to apply the cleaner such as the use of automated cleaning machines, brushes, rags or sponges, the rinsing requirements, and drying procedures.

“While this process needs to be detailed, it needs to also be simple and easy to follow,” the Harper team states. “Harper’s technical team is always happy to assist its customers in developing a custom anilox cleaning practice to prevent unnecessary damage and downtime.

“The anilox is the heart of the printing press,” the Harper team adds. “As such, proper cleaning is essential to maintaining consistent volumes and performance. Color matching, make-ready time, material waste and downtime are all factors that can be improved with proper cleaning.”

Like other printing technologies, the latest and greatest in anilox cleaning have resulted from partnerships and collaboration.

“At PCMC, we have always taken pride in the fact that we partner with our customers to learn about what issues affect their business and work with them to develop solutions,” states Rodney Pennings, PCMC’s Printing, Coating and Laminating sales director. “The concept of our Meridian Elite started over a year ago with innovation sessions from a team of engineers, product managers, and several

PCMC customers.”

“Customer feedback has immensely shaped the development of our products,” comments Mark Principato, director of flexographic products at Tower Products. “One of Tower’s core values is to listen to our customers’ feedback – both positive and negative. We pride ourselves on having the ability to solve production problems quickly.”

Anilox roll cleaning has become easier to use over the years, too. For example, Eaglewood Technologies’ Sitexco System aided one customer by telling its production team when and what anilox needed cleaning on a daily basis.

“This is an amazingly simple technology to use and operate,” states Peter Mulheran, vice president and general manager at Eaglewood Technologies. “Simply find the name or serial number of anilox on the touch screen, select it and turn the machine on. This assures your production team that each anilox is cleaned the same way every time, and it will perform the same way once back on press.

“We have also created a custom software package capable of auto-populating a list of aniloxes every morning based on serial number,” he adds. “This list is presented on the touch screen every morning. In addition, the machine emails the entire production team as to which aniloxes need to be cleaned. This allows them to never worry about anilox maintenance, and they trust the machine to do it for them.”

Liquid, laser or ultrasonic?

There are multiple options when it comes to cleaning an anilox roll. Converters can utilize liquid, laser or ultrasonic methods, which all have their benefits in a pressroom.

“Laser Cleaning has been around for years and is quickly becoming the industry standard for timely and effective cleaning of rollers in the printing and coating industry,” states PCMC’s Pennings. “A laser beam ablates the residue from the cells of the roll – bringing the cell back to near volume. When the cells perform at correct volumes, it allows better color matching and print repeatability – saving time, ink and waste.”

Flexo Wash’s Potter says time and capacity seem to be two of the biggest factors when making a decision between laser and liquid anilox cleaning. “Our classic Liquid Anilox Cleaner is a powerhouse cleaner, using proven technology to deep clean multiple anilox rolls of any size – safely and effectively. It cleans aniloxes in just 10-20 minutes and is effective on all ink types. Our new Laser Anilox Cleaner is unique in that Flexo Wash developed and created it from scratch; it is not a rebadged machine from another manufacturer. Because we developed it in total, it uses cutting-edge technology to deep clean anilox rolls, with no waste and no need for a water source. It, too, is very effective on all sorts of inks.”

Potter adds that laser cleaning is an ideal choice for companies with a corporate focus on waste-free cleaning and a desire to eliminate ongoing consumables costs. There is no waste steam, and it does not require harsh chemicals or water consumption. Only electricity is required – making the cost of ownership low and the return on investment high. Additionally, laser cleaning boasts location flexibility, making it beneficial to companies without easy access to utility connections and drainage.

Laser cleaning is not without challenges, though. Traditional lasers utilize oscillating reflectors in which hot spots are created when the motor needs to reverse directions. When the reflector is slowing down to stop and reverse directions, there is a buildup of laser energy in those locations.

“This buildup of energy can result in increased surface temperature and possible damage to a roll over time,” explains Pennings. “These laser cleaners utilize shutters to shield these spots from reaching the surface of the roll but are completely dependent on setup to be successful.

“The Meridian Elite’s patented rotational scanner is in constant motion at a controlled speed, which eliminates the possibilities of any hot spots and allowing the entire cleaning line to be utilized for a faster, safer and more effective clean,” he adds.

According to Tower Products, liquid anilox cleaning offers speed and efficiency. “In comparison to a typical laser unit, our liquid anilox cleaner, Smartflex High Tech Anilox Cleaner, has the ability to travel deep into plugged cells all at once, immersing the entire roller. This results in a cleaner roll in a quicker amount of time.”

Ultrasonic cleaning offers its own list of advantages, says Sonic Solutions’ Walczak.

“Ultrasonic cleaning for anilox rolls is significantly lower in cost than wash and laser systems – many times at half the cost even if you factor in consumables,” notes Walczak. “The quality of cleaning is just as good or better. Plus, our systems are so easy to use. Wash and laser systems can be quite complicated, especially when something goes wrong.”

Potter adds that there are a number of factors to keep in mind when selecting an anilox cleaner. They include changeovers per day, production schedule concerns, number of anilox rolls to be cleaned each day, location flexibility in your plant for anilox cleaning, environmental questions and consumables cost.

“Both the liquid and laser anilox cleaners provide the optimal time to clean your dirty anilox rolls and put them back on press or return them to storage,” Potter concludes. “Flexo Wash uses a safe and gentle cleaning method that can both deep clean your rolls and be used for daily maintenance without harming even the most delicate anilox rolls.”

Preparing for the “New Normal”

While there are certainly benefits to operating in an essential industry, there are challenges. The workforce challenge is ever-present, and the need to socially distance during the pandemic highlighted the need for “doing more with less.” The goal remains reducing downtime, waste and labor costs for the customer.

“We have seen over the last 10-15 years that jobs are becoming shorter and profit margins are becoming smaller,” explains Flexo Wash’s Potter. “Doing more work with less labor is the real new normal. Companies are now running the same amount of jobs in a week that they used to run in a month.”

The advent of new technology has enabled manufacturers to assist customers in ways that were never thought possible.

“New technology is now allowing PCMC to lead machine improvements without ever stepping foot in a customer’s facility,” says Pennings. “Through a tablet and mobile app, PCMC’s Accelerate Live acts as the eyes and ears for a virtual machine audit. The live audio/video connection allows PCMC technicians and aftermarket experts to conduct a similar current state inspection of the machine.”

The ability to perform remote troubleshooting has been a boon to printers. Suppliers and converters alike were forced to adapt on the fly during the height of the pandemic. The products need to promote efficiency, but the service must evolve, as well.

“We have seen our prospective customers eager to continue engaging with us via web-based platforms such as Zoom and Microsoft Teams,” says Eaglewood Technologies’ Mulheran. “We have conducted countless private webinars and private virtual demonstrations to get accurate information into the hands of decision makers. While we miss meeting face-to-face, this new – hopefully temporary – world has been accepted with open arms. We have also completed many virtual installations, both domestically and internationally, for all our technologies. While this had a bit of an initial learning curve, our technical team adapted quickly, and we can continue to deliver equipment on time and install right away to assure there are no delays on our end.”

“We began a full campaign of virtual sales, service, installations and trainings, all in lieu of the regular face-to-face meetings,” adds Potter. “These adaptations have benefited everyone in the process as it allows for continuous production, all while keeping employees safe.”

PCMC has seen similar success with this strategy. “COVID-19 has caused us to pivot in the way of how we work with our customers, as well as provide demonstrations of our technology,” says Pennings. “The biggest impact has been the elimination of traveling to customers and prospects to provide them in-person presentations, as well as live on-site demos at our facility. Thankfully, we have been able to utilize technology to still have virtual meetings with our customers, as well as doing live virtual demos. COVID-19 only caused a momentary disruption as we navigated and found a way to successfully still provide these valuable meetings and demos.”

Harper Corporation, meanwhile, recently introduced its latest version of its popular road show, the “Harper Road Show – Virtual Edition.” These are free monthly educational webinars that occur on the first Wednesday of every month, promoting education. Topics cover multiple aspects of printing and best practices, from care and maintenance, anilox fundamentals, color management and more.

Keeping it clean

Product development in the anilox cleaning space has moved at a rapid pace. For Eaglewood Technologies, the future is now. The newest Sitexco Laser System will be unveiled in the coming weeks. “The Sitexco + will be the most game-changing cleaning technology ever,” says Mulheran. “The Sitexco + will be capable of cleaning over 95% of all ink, coating, adhesive, varnish chemistries completely in one cleaning cycle at unthinkable speeds. The features and cleaning capabilities that won us the FTA Technical Innovation Award will be dramatically improved upon.”

The Sitexco + will also have IoT 4.0 features and better remote access capabilities for more streamlined technical support, in addition to enhanced safety features to assure machine safety well into the future. Eaglewood’s Sanilox System, on the other hand, uses a proprietary formulation of baking soda to deep clean aniloxes. The Sanilox System tends to be popular for the corrugated and specialty market segments of flexography.

Eaglewood Technologies has also partnered with Alphasonics to provide a wider breadth of products. Eaglewood represents the Alphasonics line of ultrasonic systems to provide its customers with versatile options.

“Our years of experience in all market segments of flexo have shown us that one technology is not a fit for all,” comments Mulheran. “The lowest cost of operation, the ability to integrate a dosing station to assure the proper mixture of cleaning agent to water is always present, the medical grade ultrasonics, and the technical team themselves makes the Alphasonics systems a value-add for any narrow web shop. There is no equal with their warranty, and their roll safety guarantee assures all future customers that this technology will never damage an anilox – and they stand by it.”

Flexo Wash’s cleaning technology has adapted to meet modern printing advancements, and the company has the added benefit of offering both liquid and laser solutions. Flexo Wash currently has over 20 anilox cleaners on the market, four of which are laser anilox cleaners.

Flexo Wash utilizes a safe and gentle cleaning method that does not damage even the thinnest of cell walls, notes Potter. “You can both deep clean the rolls and wash them on a daily basis without harming even the highest line screens,” he says. “It does not matter if the anilox is wet or dry. It does not matter if you need to clean water-based, solvent and/or UV inks, adhesives, lacquers, varnishes, laminates and so on. It all can be cleaned by a Flexo Wash Anilox Cleaning System, whether that is our Liquid or our Laser Cleaner.

Flexo Wash’s technology has also been engineered with sustainability in mind. The new FW 850-2 Laser Anilox Cleaner cleans two narrow web rolls at a time, and it is a waste-free and sustainable cleaning method with no liquid handling or consumption. Meanwhile, the recently-launched FW Handy Mini 2 will clean two anilox rolls or sleeves in 15 minutes. This machine replaces the FW Handy Automatic, which only cleaned one roll per cycle for the same price.

In addition, many of Flexo Wash’s liquid cleaners have been updated with the .NXT product features to ensure better reuse, better draining and less consumption of both water and cleaning liquid.

For Harper, collaboration is key in assisting customers working with their latest anilox roll technology. “Reliability is the standard in flexography, and Harper continues to be the leader in the industry,” the company states. “We have maintained the industry’s highest standard for porosity and continue to enhance the release characteristics through a number of mechanical and chemical processes. This ensures longevity, consistency and reliability in every Harper anilox product.”

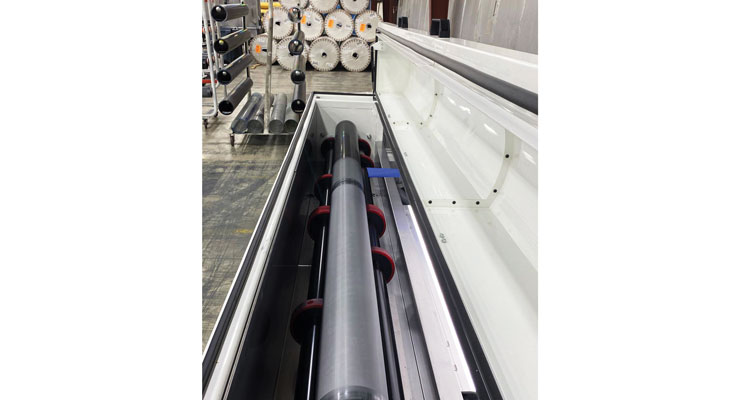

PCMC’s Meridian Elite laser anilox cleaner offers a host of advantages, including smart technology to better automate the cleaning process. Printers and converters will also see improved first pull color match and more color consistency, along with the elimination of hot spots.

According to PCMC’s Pennings, the Meridian Elite’s cleaning times are up to four times faster than other laser cleaner technologies. “The Meridian Elite is the first and only cleaner that utilizes a cloud-based database,” he says. “After a roll is cleaned, the information is logged into the roll database and can be accessed locally or from the cloud via an interactive roll reporting dashboard. It can be accessed via computer, phone or tablet – anytime and anywhere.”

The dashboard keeps an inventory of each roll, the cleaning type, total cleaning cycle and volume measurements. The operator then has the option to receive email or SMS alerts from the Meridian Elite such as when a cleaning cycle is complete. Other smart and connected features include a sensor to alert the operator when the vacuum filter needs maintenance, industrial PLC control with I/O link components, and a closed loop laser, scanner and focus system.

“Through evaluation, design reviews, and customer feedback of current technology, we developed the new cleaner utilizing rotational motion to provide higher performance and reliability,” adds Pennings. “The cleaner was put through vigorous testing and analysis to validate and continuously improve the design.”

Sonic Solutions, which has worked with printers across the globe, has developed a plethora of ultrasonic anilox roll cleaners. The company remains excited about its sleeve cleaning systems.

“In the past, companies with anilox sleeves needed to go to the expensive but not as effective wash systems,” explains Walczak. “They’re pretty expensive. By stretching our existing tanks, we can provide a tremendously effective system at a significant discount. Wash and laser systems can reach near or over $100,000 for these anilox sleeve cleaners. Sonic Solutions can provide a safe and effective alternative for nearly half the cost – including consumables.”

Sonic Solutions also boasts ease of use with its systems. “There’s no need to be a brain surgeon here,” adds Walczak. “Customers just love these sleeves systems. They are usually familiar with our smaller systems, so adaptability is just so easy. We also clean as good as or better than any system out there.”

Plus, all of Sonic Solutions’ equipment and solutions are made in the US, making parts availability an advantage. According to Walczak, customers rarely have to wait for out-of-stock parts.

Tower Products has developed the Smartflex flexographic line of cleaners, which includes two versions of anilox cleaner: a gel and liquid. The gel is used for quick turnaround to minimize press downtime, whereas the liquid is used in ultrasonic and hot tank units.

According to Principato, Tower’s products have been designed to keep pace with the newest printing technologies on the market. “If anything, the advancement of printing speeds has made the cleaning process faster,” he says. “Today’s ever-changing flexo landscape demands efficient and effective solutions that can be plainly solved with better chemistry. This is where Tower Products has earned its reputation as a leader in technical problem solving.”

Paper Converting Machine Company (PCMC), part of Barry-Wehmiller, has received the Award for Innovation, one of the key categories of the Label Industry Global Awards 2020.

Shortlisted as one of four finalists, PCMC eventually notched the award for its recent introduction of the Meridian Elite laser anilox cleaner. The Meridian Elite holds a patent for its brand-new laser technology, which eliminates hot spots and offers fast cleaning cycles, making the device more efficient for printers and converters.

This is not the first accolade for PCMC, either. The company has also garnered an FTA Technical Innovation Award for the second year in a row. Recognizing PCMC’s Meridian Elite laser anilox cleaner, the award was presented during Virtual Forum 2020.

“We worked very hard over the past year to develop the Meridian Elite and make it the fastest, smartest, safest laser cleaner available in the industry today,” says Rodney Pennings, PCMC’s Printing, Coating and Laminating sales director. “Winning both the Technical Innovation Award and the Label Industry Global Award is a testament to the fact that the Meridian Elite is an exceptional innovation. We are passionate about driving innovation within PCMC and the industry, and are proud to partner with our customers to learn about what issues affect their business and work with them to develop solutions.”

The product deep-cleans anilox cells by vaporizing deposited particles, improving print quality and saving time, ink and waste. Additionally, the Meridian Elite is the first and only cleaner that utilizes a cloud-based database, the company says. After a roll is cleaned, the information is logged into the roll inventory database and can be accessed locally or in the cloud via an interactive roll reporting dashboard.

The COVID-19 pandemic has seen converters inundated with orders, especially in the food, beverage and personal care markets. Although demand has stabilized since March and April, printers must be prepared. A dirty anilox roll will affect print quality, lead to more downtime and create greater headaches for business owners.

New technologies, such as faster printing presses, improved ink technology (learn more on page 52), faster changeover times, among others, have required anilox rolls and cleaners to be up to the task. Between enhanced printing technologies and shorter lead times, aniloxes have passed the test with flying colors.

“It’s just becoming more important than ever for printers to become as efficient as possible,” says Joe Walczak, president of Sonic Solutions. “All of these developments have meant that keeping your anilox clean is even more important. No company can waste any efficiencies due to dirty anilox rolls or sleeves. Idle press time, wasted labor hours, inks and substrates all add up to big dollars. Everyone needs to remain as competitive as possible.”

There is not one right answer for cleaning an anilox roll, though. Anilox technologies have evolved, offering thinner cell walls, higher line screens and tougher inks. There is also the choice of liquid, laser or ultrasonic cleaning.

Harper Corporation of America, a manufacturer of anilox rolls, offers a list of recommendations when exploring anilox cleaning methods. According to Harper, converters should first look at their anilox handling practices and whether they promote preventative maintenance and proper cleaning. The anilox handling practice should detail the type of ink being used, a cleaner selection process, the step-by-step process for using the appropriate cleaner such as when to use it, dilution or mixing requirements, how to apply the cleaner such as the use of automated cleaning machines, brushes, rags or sponges, the rinsing requirements, and drying procedures.

“While this process needs to be detailed, it needs to also be simple and easy to follow,” the Harper team states. “Harper’s technical team is always happy to assist its customers in developing a custom anilox cleaning practice to prevent unnecessary damage and downtime.

“The anilox is the heart of the printing press,” the Harper team adds. “As such, proper cleaning is essential to maintaining consistent volumes and performance. Color matching, make-ready time, material waste and downtime are all factors that can be improved with proper cleaning.”

Like other printing technologies, the latest and greatest in anilox cleaning have resulted from partnerships and collaboration.

“At PCMC, we have always taken pride in the fact that we partner with our customers to learn about what issues affect their business and work with them to develop solutions,” states Rodney Pennings, PCMC’s Printing, Coating and Laminating sales director. “The concept of our Meridian Elite started over a year ago with innovation sessions from a team of engineers, product managers, and several

PCMC customers.”

“Customer feedback has immensely shaped the development of our products,” comments Mark Principato, director of flexographic products at Tower Products. “One of Tower’s core values is to listen to our customers’ feedback – both positive and negative. We pride ourselves on having the ability to solve production problems quickly.”

Anilox roll cleaning has become easier to use over the years, too. For example, Eaglewood Technologies’ Sitexco System aided one customer by telling its production team when and what anilox needed cleaning on a daily basis.

“This is an amazingly simple technology to use and operate,” states Peter Mulheran, vice president and general manager at Eaglewood Technologies. “Simply find the name or serial number of anilox on the touch screen, select it and turn the machine on. This assures your production team that each anilox is cleaned the same way every time, and it will perform the same way once back on press.

“We have also created a custom software package capable of auto-populating a list of aniloxes every morning based on serial number,” he adds. “This list is presented on the touch screen every morning. In addition, the machine emails the entire production team as to which aniloxes need to be cleaned. This allows them to never worry about anilox maintenance, and they trust the machine to do it for them.”

Liquid, laser or ultrasonic?

There are multiple options when it comes to cleaning an anilox roll. Converters can utilize liquid, laser or ultrasonic methods, which all have their benefits in a pressroom.

“Laser Cleaning has been around for years and is quickly becoming the industry standard for timely and effective cleaning of rollers in the printing and coating industry,” states PCMC’s Pennings. “A laser beam ablates the residue from the cells of the roll – bringing the cell back to near volume. When the cells perform at correct volumes, it allows better color matching and print repeatability – saving time, ink and waste.”

Flexo Wash’s Potter says time and capacity seem to be two of the biggest factors when making a decision between laser and liquid anilox cleaning. “Our classic Liquid Anilox Cleaner is a powerhouse cleaner, using proven technology to deep clean multiple anilox rolls of any size – safely and effectively. It cleans aniloxes in just 10-20 minutes and is effective on all ink types. Our new Laser Anilox Cleaner is unique in that Flexo Wash developed and created it from scratch; it is not a rebadged machine from another manufacturer. Because we developed it in total, it uses cutting-edge technology to deep clean anilox rolls, with no waste and no need for a water source. It, too, is very effective on all sorts of inks.”

Potter adds that laser cleaning is an ideal choice for companies with a corporate focus on waste-free cleaning and a desire to eliminate ongoing consumables costs. There is no waste steam, and it does not require harsh chemicals or water consumption. Only electricity is required – making the cost of ownership low and the return on investment high. Additionally, laser cleaning boasts location flexibility, making it beneficial to companies without easy access to utility connections and drainage.

Laser cleaning is not without challenges, though. Traditional lasers utilize oscillating reflectors in which hot spots are created when the motor needs to reverse directions. When the reflector is slowing down to stop and reverse directions, there is a buildup of laser energy in those locations.

“This buildup of energy can result in increased surface temperature and possible damage to a roll over time,” explains Pennings. “These laser cleaners utilize shutters to shield these spots from reaching the surface of the roll but are completely dependent on setup to be successful.

“The Meridian Elite’s patented rotational scanner is in constant motion at a controlled speed, which eliminates the possibilities of any hot spots and allowing the entire cleaning line to be utilized for a faster, safer and more effective clean,” he adds.

According to Tower Products, liquid anilox cleaning offers speed and efficiency. “In comparison to a typical laser unit, our liquid anilox cleaner, Smartflex High Tech Anilox Cleaner, has the ability to travel deep into plugged cells all at once, immersing the entire roller. This results in a cleaner roll in a quicker amount of time.”

Ultrasonic cleaning offers its own list of advantages, says Sonic Solutions’ Walczak.

“Ultrasonic cleaning for anilox rolls is significantly lower in cost than wash and laser systems – many times at half the cost even if you factor in consumables,” notes Walczak. “The quality of cleaning is just as good or better. Plus, our systems are so easy to use. Wash and laser systems can be quite complicated, especially when something goes wrong.”

Potter adds that there are a number of factors to keep in mind when selecting an anilox cleaner. They include changeovers per day, production schedule concerns, number of anilox rolls to be cleaned each day, location flexibility in your plant for anilox cleaning, environmental questions and consumables cost.

“Both the liquid and laser anilox cleaners provide the optimal time to clean your dirty anilox rolls and put them back on press or return them to storage,” Potter concludes. “Flexo Wash uses a safe and gentle cleaning method that can both deep clean your rolls and be used for daily maintenance without harming even the most delicate anilox rolls.”

Preparing for the “New Normal”

While there are certainly benefits to operating in an essential industry, there are challenges. The workforce challenge is ever-present, and the need to socially distance during the pandemic highlighted the need for “doing more with less.” The goal remains reducing downtime, waste and labor costs for the customer.

“We have seen over the last 10-15 years that jobs are becoming shorter and profit margins are becoming smaller,” explains Flexo Wash’s Potter. “Doing more work with less labor is the real new normal. Companies are now running the same amount of jobs in a week that they used to run in a month.”

The advent of new technology has enabled manufacturers to assist customers in ways that were never thought possible.

“New technology is now allowing PCMC to lead machine improvements without ever stepping foot in a customer’s facility,” says Pennings. “Through a tablet and mobile app, PCMC’s Accelerate Live acts as the eyes and ears for a virtual machine audit. The live audio/video connection allows PCMC technicians and aftermarket experts to conduct a similar current state inspection of the machine.”

The ability to perform remote troubleshooting has been a boon to printers. Suppliers and converters alike were forced to adapt on the fly during the height of the pandemic. The products need to promote efficiency, but the service must evolve, as well.

“We have seen our prospective customers eager to continue engaging with us via web-based platforms such as Zoom and Microsoft Teams,” says Eaglewood Technologies’ Mulheran. “We have conducted countless private webinars and private virtual demonstrations to get accurate information into the hands of decision makers. While we miss meeting face-to-face, this new – hopefully temporary – world has been accepted with open arms. We have also completed many virtual installations, both domestically and internationally, for all our technologies. While this had a bit of an initial learning curve, our technical team adapted quickly, and we can continue to deliver equipment on time and install right away to assure there are no delays on our end.”

“We began a full campaign of virtual sales, service, installations and trainings, all in lieu of the regular face-to-face meetings,” adds Potter. “These adaptations have benefited everyone in the process as it allows for continuous production, all while keeping employees safe.”

PCMC has seen similar success with this strategy. “COVID-19 has caused us to pivot in the way of how we work with our customers, as well as provide demonstrations of our technology,” says Pennings. “The biggest impact has been the elimination of traveling to customers and prospects to provide them in-person presentations, as well as live on-site demos at our facility. Thankfully, we have been able to utilize technology to still have virtual meetings with our customers, as well as doing live virtual demos. COVID-19 only caused a momentary disruption as we navigated and found a way to successfully still provide these valuable meetings and demos.”

Harper Corporation, meanwhile, recently introduced its latest version of its popular road show, the “Harper Road Show – Virtual Edition.” These are free monthly educational webinars that occur on the first Wednesday of every month, promoting education. Topics cover multiple aspects of printing and best practices, from care and maintenance, anilox fundamentals, color management and more.

Keeping it clean

Product development in the anilox cleaning space has moved at a rapid pace. For Eaglewood Technologies, the future is now. The newest Sitexco Laser System will be unveiled in the coming weeks. “The Sitexco + will be the most game-changing cleaning technology ever,” says Mulheran. “The Sitexco + will be capable of cleaning over 95% of all ink, coating, adhesive, varnish chemistries completely in one cleaning cycle at unthinkable speeds. The features and cleaning capabilities that won us the FTA Technical Innovation Award will be dramatically improved upon.”

The Sitexco + will also have IoT 4.0 features and better remote access capabilities for more streamlined technical support, in addition to enhanced safety features to assure machine safety well into the future. Eaglewood’s Sanilox System, on the other hand, uses a proprietary formulation of baking soda to deep clean aniloxes. The Sanilox System tends to be popular for the corrugated and specialty market segments of flexography.

Eaglewood Technologies has also partnered with Alphasonics to provide a wider breadth of products. Eaglewood represents the Alphasonics line of ultrasonic systems to provide its customers with versatile options.

“Our years of experience in all market segments of flexo have shown us that one technology is not a fit for all,” comments Mulheran. “The lowest cost of operation, the ability to integrate a dosing station to assure the proper mixture of cleaning agent to water is always present, the medical grade ultrasonics, and the technical team themselves makes the Alphasonics systems a value-add for any narrow web shop. There is no equal with their warranty, and their roll safety guarantee assures all future customers that this technology will never damage an anilox – and they stand by it.”

Flexo Wash’s cleaning technology has adapted to meet modern printing advancements, and the company has the added benefit of offering both liquid and laser solutions. Flexo Wash currently has over 20 anilox cleaners on the market, four of which are laser anilox cleaners.

Flexo Wash utilizes a safe and gentle cleaning method that does not damage even the thinnest of cell walls, notes Potter. “You can both deep clean the rolls and wash them on a daily basis without harming even the highest line screens,” he says. “It does not matter if the anilox is wet or dry. It does not matter if you need to clean water-based, solvent and/or UV inks, adhesives, lacquers, varnishes, laminates and so on. It all can be cleaned by a Flexo Wash Anilox Cleaning System, whether that is our Liquid or our Laser Cleaner.

Flexo Wash’s technology has also been engineered with sustainability in mind. The new FW 850-2 Laser Anilox Cleaner cleans two narrow web rolls at a time, and it is a waste-free and sustainable cleaning method with no liquid handling or consumption. Meanwhile, the recently-launched FW Handy Mini 2 will clean two anilox rolls or sleeves in 15 minutes. This machine replaces the FW Handy Automatic, which only cleaned one roll per cycle for the same price.

In addition, many of Flexo Wash’s liquid cleaners have been updated with the .NXT product features to ensure better reuse, better draining and less consumption of both water and cleaning liquid.

For Harper, collaboration is key in assisting customers working with their latest anilox roll technology. “Reliability is the standard in flexography, and Harper continues to be the leader in the industry,” the company states. “We have maintained the industry’s highest standard for porosity and continue to enhance the release characteristics through a number of mechanical and chemical processes. This ensures longevity, consistency and reliability in every Harper anilox product.”

PCMC’s Meridian Elite laser anilox cleaner offers a host of advantages, including smart technology to better automate the cleaning process. Printers and converters will also see improved first pull color match and more color consistency, along with the elimination of hot spots.

According to PCMC’s Pennings, the Meridian Elite’s cleaning times are up to four times faster than other laser cleaner technologies. “The Meridian Elite is the first and only cleaner that utilizes a cloud-based database,” he says. “After a roll is cleaned, the information is logged into the roll database and can be accessed locally or from the cloud via an interactive roll reporting dashboard. It can be accessed via computer, phone or tablet – anytime and anywhere.”

The dashboard keeps an inventory of each roll, the cleaning type, total cleaning cycle and volume measurements. The operator then has the option to receive email or SMS alerts from the Meridian Elite such as when a cleaning cycle is complete. Other smart and connected features include a sensor to alert the operator when the vacuum filter needs maintenance, industrial PLC control with I/O link components, and a closed loop laser, scanner and focus system.

“Through evaluation, design reviews, and customer feedback of current technology, we developed the new cleaner utilizing rotational motion to provide higher performance and reliability,” adds Pennings. “The cleaner was put through vigorous testing and analysis to validate and continuously improve the design.”

Sonic Solutions, which has worked with printers across the globe, has developed a plethora of ultrasonic anilox roll cleaners. The company remains excited about its sleeve cleaning systems.

“In the past, companies with anilox sleeves needed to go to the expensive but not as effective wash systems,” explains Walczak. “They’re pretty expensive. By stretching our existing tanks, we can provide a tremendously effective system at a significant discount. Wash and laser systems can reach near or over $100,000 for these anilox sleeve cleaners. Sonic Solutions can provide a safe and effective alternative for nearly half the cost – including consumables.”

Sonic Solutions also boasts ease of use with its systems. “There’s no need to be a brain surgeon here,” adds Walczak. “Customers just love these sleeves systems. They are usually familiar with our smaller systems, so adaptability is just so easy. We also clean as good as or better than any system out there.”

Plus, all of Sonic Solutions’ equipment and solutions are made in the US, making parts availability an advantage. According to Walczak, customers rarely have to wait for out-of-stock parts.

Tower Products has developed the Smartflex flexographic line of cleaners, which includes two versions of anilox cleaner: a gel and liquid. The gel is used for quick turnaround to minimize press downtime, whereas the liquid is used in ultrasonic and hot tank units.

According to Principato, Tower’s products have been designed to keep pace with the newest printing technologies on the market. “If anything, the advancement of printing speeds has made the cleaning process faster,” he says. “Today’s ever-changing flexo landscape demands efficient and effective solutions that can be plainly solved with better chemistry. This is where Tower Products has earned its reputation as a leader in technical problem solving.”

Paper Converting Machine Company (PCMC), part of Barry-Wehmiller, has received the Award for Innovation, one of the key categories of the Label Industry Global Awards 2020.

Shortlisted as one of four finalists, PCMC eventually notched the award for its recent introduction of the Meridian Elite laser anilox cleaner. The Meridian Elite holds a patent for its brand-new laser technology, which eliminates hot spots and offers fast cleaning cycles, making the device more efficient for printers and converters.

This is not the first accolade for PCMC, either. The company has also garnered an FTA Technical Innovation Award for the second year in a row. Recognizing PCMC’s Meridian Elite laser anilox cleaner, the award was presented during Virtual Forum 2020.

“We worked very hard over the past year to develop the Meridian Elite and make it the fastest, smartest, safest laser cleaner available in the industry today,” says Rodney Pennings, PCMC’s Printing, Coating and Laminating sales director. “Winning both the Technical Innovation Award and the Label Industry Global Award is a testament to the fact that the Meridian Elite is an exceptional innovation. We are passionate about driving innovation within PCMC and the industry, and are proud to partner with our customers to learn about what issues affect their business and work with them to develop solutions.”

The product deep-cleans anilox cells by vaporizing deposited particles, improving print quality and saving time, ink and waste. Additionally, the Meridian Elite is the first and only cleaner that utilizes a cloud-based database, the company says. After a roll is cleaned, the information is logged into the roll inventory database and can be accessed locally or in the cloud via an interactive roll reporting dashboard.