Steve Katz, Associate Editor10.09.20

Coveris is one of Europe’s leading packaging companies, with more than 800 million euro in annual sales and over 4,500 customers. The company employs more than 4,100 people throughout its 26 production facilities, and is divided into three business units – Films, Flexibles and Labels & Board.

Amberley Labels is part of Coveris’ pan-European packaging group, and its luxury product offering has recently been extended to offer multiple print and embellishment technologies at its twin Blandford and Boston (UK) sites. Continued investment in production technologies has established the Blandford site as a leader in digital print, achieving multiple award wins, industry accolades and some of the world’s most iconic brand campaigns.

Amberley’s Blandford site is primarily focused on digital printing, supported by three HP Indigo presses. All of these HP presses offer inline priming along with specialty inks, and can cover the widest of color gamut design requirements as demanded by the markets the company serves. These markets include cosmetics, health and personal care, and other premium sectors in beverage and consumer goods, among others. In addition, Amberley Labels has been a longtime supplier to the artist paints industry, where color matching of specific colors is absolutely critical.

At Amberley Labels’ Blandford facility, the company has begun implementing the new Siteline ordering module from Label Traxx for enhancing its customer service capabilities. The move to Siteline has allowed Amberley to provide its customers with a new level of customer service.

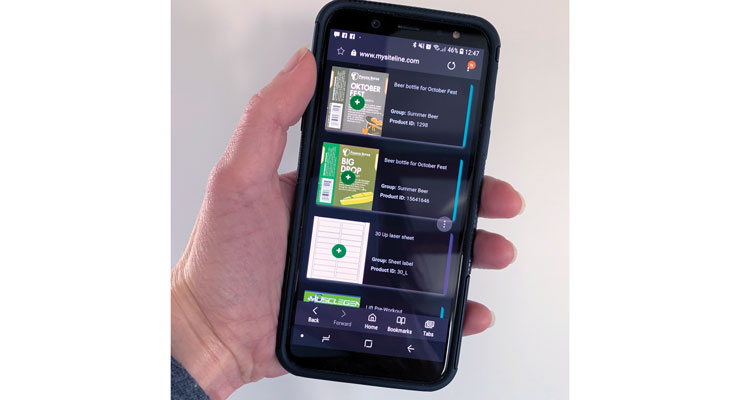

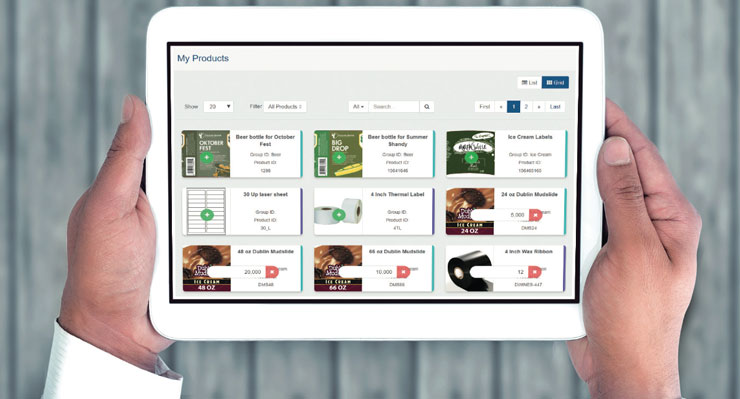

The Siteline web interface was created by Label Traxx in response to label buyer demands for online access to product information and ordering 24 hours a day. Siteline allows for self-service access for label customers to data about orders, labels and artwork. It also allows customers the ability to perform the simple functions themselves – place reorders, check order status, look at past invoices, packing slips and estimates. With Siteline, label buyers can easily place repeat orders via a computer, phone or tablet, and the jobs then automatically load into their Label Traxx MIS system awaiting scheduling.

“We wanted our customers to have full access to all their product specifications, order history and the Siteline collaboration tools,” explains David Richards, managing director for Amberley Labels. “This is critical for the cosmetics industry where long project timings of 18-24 months result in extensive data, which could otherwise be lost in phone calls and emails. The ability to order online for all customers at all times was a real advantage when making this decision, as we work with many smaller start-up brands with limited procurement resources. The ability to order on your PC, Mac, tablet, IOS or Android from anywhere in the world is a competitive edge for us without doubt.”

Chris Spooner, business development manager, Label Traxx, says, “End users want to move at a pace that is convenient for them. This means they may want to place orders after hours, check inventory levels from their mobile devices, and approve proofs while they are traveling. You cannot afford to burden your customers with having to communicate directly with your customer service staff to get anything done.

“Your customers are on the move and are using their mobile devices as their primary way of connecting online,” adds Spooner. “They are no longer tied to desks and are working at all hours from all places. They want to be able to access information about their orders, their label products and their artwork, at all times, from their mobile.”

Amberley Labels is still in the early stages of implementation at its Blandford site, and the company’s customers are already enjoying the benefits. Richards says, “While we enjoy the daily contact with our customers, there are times in their busy lives where they need information and need it now. Siteline allows immediate access 24/7 to capture information about the range of specifications we hold for our customers, without the need for additional software/hardware upgrades.”

According to Richards, a huge benefit of Siteline is how it allows Amberley Labels’ customers the ability to view a “customer version” of Amberley’s own Labeltraxx MIS. “This allows our team to talk about Siteline with confidence, as they know it’s simply a portal into the system they know and use every single day. This, in turn, gives confidence to our customers – knowing that we have a team of experts on hand to support them when increasing their use of our new site, which we have branded as ‘Amberley Online.’”

Richards continues, “If you have modified your own internal processes over the years and how you use Label Traxx, then there may be times where you need to amend your own practices to ensure the customers using Siteline make the most of the information available to them. The Siteline team has created a portal that assumes best practices when using Label Traxx, but we all have to admit that in our daily work actions, everyone creates the odd ‘workaround’ here and there, but this can mean the data customers can access is limited.”

All new Blandford customers of Amberley’s are being invited to have access to Amberley Online, which serves as a huge benefit to both Amberley Labels and any start-up business. “Our next stage will be to implement the artwork approval module, then to include further automation via our workflows to deliver customer-approved files directly to press,” Richards says.

User feedback from Amberley customers regarding Siteline has been glowing, Richards says. He adds, “Customers that have received demos have all said what a great system this is, and we have received nothing but positivity. Our customer service team is also seeing huge benefits, but I also appreciate that entering our own orders for over 40 years to a system where customers will place them themselves will require time to adapt, but I am fortunate enough to have a dedicated, award-winning customer service team, who I know will take on this new approach with open arms and sell it to our customers for mutual benefit.”

While Amberley Labels began its rollout of Siteline earlier this year, amid the start of the coronavirus pandemic, Richards notes that Siteline could be a valuable tool when unforeseen circumstances arise. He says, “We were still rolling this out at the time in which the pandemic impacted most, however this would have been the perfect system for us during this time as our customers would continue to have access, regardless of the new circumstances brought on by the pandemic.”

Label Traxx’s Spooner concludes, “E-commerce is expected to ramp up in all aspects of modern life and a label printing business should be no different. Speed to market is key for any brand, and converters should be looking at how they can support their customers. Siteline gives them the buying experience they expect from a modern business and reduces the amount of time between initial enquiry and the order being printed in production. It’s also the ultimate sales tool for reps to offer to new prospects.”

Pro Label’s ‘extreme, maniacal’ customer service

Ramon Fernandez attributes much of Pro Label Inc.’s success to what he calls “extreme, maniacal” customer service. “This is what puts us on the map,” he says, while also crediting his South Florida label company’s strong growth trajectory to a bold move into becoming a digital-only label manufacturer.

Pro Label has been around since 1995, and after achieving more than two decades of success, Fernandez felt the way to take his business to the next level was by forgoing flexo and embracing solely digital as a print technology. In 2014, the company made the jump to digital-only, and today is soaring to new heights with its Domino and HP Indigo digital presses.

Digital printing has allowed Pro Label to meet evolving customer demands for just-in-time delivery while also proving to be a cost-effective alternative to flexo. Both print speeds and quality have improved with digital, as have the development of compatible label materials. While these are all good things for Pro Label, Fernandez emphasizes that what really allows for his team to deliver that “extreme” level of customer service he refers to is a tried-and-true technology that he’s used for a long while – Label Traxx.

“We use Label Traxx to its full effect,” Fernandez says. “This allows us to have all kinds of vital information at our fingertips that we can deliver to our customers – in real time. We never tell a customer we’ll call them back. Whatever the question or issue is, we resolve it at that moment – that’s customer service.”

Everyone on the Pro Label team is trained to use Label Traxx. “It’s so user-friendly,” Fernandez says of the MIS software dedicated to the label industry. “Everyone here has access to job information. We put a lot of data into Label Traxx, so we can track inventory and track which roll went on what job. With Label Traxx, we have cradle-to-cradle accountability on anything we run. Whether it’s the person who answers the phone at reception, people in the warehouse, or our shipping coordinator, everyone can tell a customer the status of their order. Plus, we capture all kinds of data – both at press side and finishing – and we use it for accounting, estimating and so much more.

“When you call your mechanic and ask when your car is going to be ready, you want to hear ‘3 o’clock,’ not ‘I’ll call you back.’ People just want to know the situation and get accurate information. Label Traxx gives us this ability – to give our customers answers to their questions in real time. We take customer service to the next level, and Label Traxx let’s us do this,” Fernandez says.

Label Traxx continues to be been an invaluable asset to Pro Label. “It’s absolutely vital,” says Fernandez. “I cannot imagine running this business without Label Traxx. In fact, I can’t imagine anybody running any label business without it. All of our efficiencies are because of Label Traxx – we get every single penny out of our presses. It lets us track and schedule our jobs; my production team can see what’s running on what presses and which specific tools we need. We can really get organized to run as efficiently as possible.”

Fernandez points out that in addition to it being an excellent customer service tool and the key to maximizing efficiencies, Label Traxx also helps the company resolve issues before they even happen. He says, “We don’t have problems, because thanks to Label Traxx we can foresee them. We use it to forecast our material usage, our ink, press time – everything. We can place our orders for materials through Label Traxx, receive it and populate our inventory. There are so many tools within the software that make life easy for the modern day label manufacturer.”

The current management of CERM, a global provider of Management Information System (MIS) software for the printing industry, acquired full independence through a Management Buyout (MBO) from Heidelberger Druckmaschinen AG (Heidelberg) on July 31, 2020. With this autonomous positioning of the CERM software and brand, the CERM management aspires to boost the worldwide expansion of its automation solution for labels and packaging printers.

CERM became part of the Heidelberg group in 2011. CERM’s software is touted as one of the most powerful ecosystems in the market for any printer, regardless of its size or application focus. To this day, CERM serves over 400 customers worldwide and partners with a plethora of market players.

The growing trend to digital label printing is further challenging the optimization focus in the label and packaging segment with an increasing variety of products, small order quantities and short lead times. Automation is a high priority for any printer looking to work more profitably now and in the future. “Our software has proven expertise in increasing the service, quality and efficiency levels of label and packaging printers globally. We are constantly focusing on existing and new customer needs and technological evolution. To explore our full potential and fuel that growth, we needed to regain independence, and welcome additional distribution and support channels,” says Geert Van Damme, CEO of CERM and one of the managers involved in the MBO.

Heidelberg and CERM will both continue to develop and distribute the CERM software as “Prinect Business Manager” for the commercial print segment. All existing Heidelberg customer contracts and support channels remain in place.

“We highly value the cooperation throughout the years and will continue to collaborate with Heidelberg sales and service units. We are also looking forward to expanding our deep industry expertise offering in the label and packaging market as an independent, innovative and agile niche player through additional sales and service channels,” Geert Van Damme concludes.

Amberley Labels is part of Coveris’ pan-European packaging group, and its luxury product offering has recently been extended to offer multiple print and embellishment technologies at its twin Blandford and Boston (UK) sites. Continued investment in production technologies has established the Blandford site as a leader in digital print, achieving multiple award wins, industry accolades and some of the world’s most iconic brand campaigns.

Amberley’s Blandford site is primarily focused on digital printing, supported by three HP Indigo presses. All of these HP presses offer inline priming along with specialty inks, and can cover the widest of color gamut design requirements as demanded by the markets the company serves. These markets include cosmetics, health and personal care, and other premium sectors in beverage and consumer goods, among others. In addition, Amberley Labels has been a longtime supplier to the artist paints industry, where color matching of specific colors is absolutely critical.

At Amberley Labels’ Blandford facility, the company has begun implementing the new Siteline ordering module from Label Traxx for enhancing its customer service capabilities. The move to Siteline has allowed Amberley to provide its customers with a new level of customer service.

The Siteline web interface was created by Label Traxx in response to label buyer demands for online access to product information and ordering 24 hours a day. Siteline allows for self-service access for label customers to data about orders, labels and artwork. It also allows customers the ability to perform the simple functions themselves – place reorders, check order status, look at past invoices, packing slips and estimates. With Siteline, label buyers can easily place repeat orders via a computer, phone or tablet, and the jobs then automatically load into their Label Traxx MIS system awaiting scheduling.

“We wanted our customers to have full access to all their product specifications, order history and the Siteline collaboration tools,” explains David Richards, managing director for Amberley Labels. “This is critical for the cosmetics industry where long project timings of 18-24 months result in extensive data, which could otherwise be lost in phone calls and emails. The ability to order online for all customers at all times was a real advantage when making this decision, as we work with many smaller start-up brands with limited procurement resources. The ability to order on your PC, Mac, tablet, IOS or Android from anywhere in the world is a competitive edge for us without doubt.”

Chris Spooner, business development manager, Label Traxx, says, “End users want to move at a pace that is convenient for them. This means they may want to place orders after hours, check inventory levels from their mobile devices, and approve proofs while they are traveling. You cannot afford to burden your customers with having to communicate directly with your customer service staff to get anything done.

“Your customers are on the move and are using their mobile devices as their primary way of connecting online,” adds Spooner. “They are no longer tied to desks and are working at all hours from all places. They want to be able to access information about their orders, their label products and their artwork, at all times, from their mobile.”

Amberley Labels is still in the early stages of implementation at its Blandford site, and the company’s customers are already enjoying the benefits. Richards says, “While we enjoy the daily contact with our customers, there are times in their busy lives where they need information and need it now. Siteline allows immediate access 24/7 to capture information about the range of specifications we hold for our customers, without the need for additional software/hardware upgrades.”

According to Richards, a huge benefit of Siteline is how it allows Amberley Labels’ customers the ability to view a “customer version” of Amberley’s own Labeltraxx MIS. “This allows our team to talk about Siteline with confidence, as they know it’s simply a portal into the system they know and use every single day. This, in turn, gives confidence to our customers – knowing that we have a team of experts on hand to support them when increasing their use of our new site, which we have branded as ‘Amberley Online.’”

Richards continues, “If you have modified your own internal processes over the years and how you use Label Traxx, then there may be times where you need to amend your own practices to ensure the customers using Siteline make the most of the information available to them. The Siteline team has created a portal that assumes best practices when using Label Traxx, but we all have to admit that in our daily work actions, everyone creates the odd ‘workaround’ here and there, but this can mean the data customers can access is limited.”

All new Blandford customers of Amberley’s are being invited to have access to Amberley Online, which serves as a huge benefit to both Amberley Labels and any start-up business. “Our next stage will be to implement the artwork approval module, then to include further automation via our workflows to deliver customer-approved files directly to press,” Richards says.

User feedback from Amberley customers regarding Siteline has been glowing, Richards says. He adds, “Customers that have received demos have all said what a great system this is, and we have received nothing but positivity. Our customer service team is also seeing huge benefits, but I also appreciate that entering our own orders for over 40 years to a system where customers will place them themselves will require time to adapt, but I am fortunate enough to have a dedicated, award-winning customer service team, who I know will take on this new approach with open arms and sell it to our customers for mutual benefit.”

While Amberley Labels began its rollout of Siteline earlier this year, amid the start of the coronavirus pandemic, Richards notes that Siteline could be a valuable tool when unforeseen circumstances arise. He says, “We were still rolling this out at the time in which the pandemic impacted most, however this would have been the perfect system for us during this time as our customers would continue to have access, regardless of the new circumstances brought on by the pandemic.”

Label Traxx’s Spooner concludes, “E-commerce is expected to ramp up in all aspects of modern life and a label printing business should be no different. Speed to market is key for any brand, and converters should be looking at how they can support their customers. Siteline gives them the buying experience they expect from a modern business and reduces the amount of time between initial enquiry and the order being printed in production. It’s also the ultimate sales tool for reps to offer to new prospects.”

Pro Label’s ‘extreme, maniacal’ customer service

Ramon Fernandez attributes much of Pro Label Inc.’s success to what he calls “extreme, maniacal” customer service. “This is what puts us on the map,” he says, while also crediting his South Florida label company’s strong growth trajectory to a bold move into becoming a digital-only label manufacturer.

Pro Label has been around since 1995, and after achieving more than two decades of success, Fernandez felt the way to take his business to the next level was by forgoing flexo and embracing solely digital as a print technology. In 2014, the company made the jump to digital-only, and today is soaring to new heights with its Domino and HP Indigo digital presses.

Digital printing has allowed Pro Label to meet evolving customer demands for just-in-time delivery while also proving to be a cost-effective alternative to flexo. Both print speeds and quality have improved with digital, as have the development of compatible label materials. While these are all good things for Pro Label, Fernandez emphasizes that what really allows for his team to deliver that “extreme” level of customer service he refers to is a tried-and-true technology that he’s used for a long while – Label Traxx.

“We use Label Traxx to its full effect,” Fernandez says. “This allows us to have all kinds of vital information at our fingertips that we can deliver to our customers – in real time. We never tell a customer we’ll call them back. Whatever the question or issue is, we resolve it at that moment – that’s customer service.”

Everyone on the Pro Label team is trained to use Label Traxx. “It’s so user-friendly,” Fernandez says of the MIS software dedicated to the label industry. “Everyone here has access to job information. We put a lot of data into Label Traxx, so we can track inventory and track which roll went on what job. With Label Traxx, we have cradle-to-cradle accountability on anything we run. Whether it’s the person who answers the phone at reception, people in the warehouse, or our shipping coordinator, everyone can tell a customer the status of their order. Plus, we capture all kinds of data – both at press side and finishing – and we use it for accounting, estimating and so much more.

“When you call your mechanic and ask when your car is going to be ready, you want to hear ‘3 o’clock,’ not ‘I’ll call you back.’ People just want to know the situation and get accurate information. Label Traxx gives us this ability – to give our customers answers to their questions in real time. We take customer service to the next level, and Label Traxx let’s us do this,” Fernandez says.

Label Traxx continues to be been an invaluable asset to Pro Label. “It’s absolutely vital,” says Fernandez. “I cannot imagine running this business without Label Traxx. In fact, I can’t imagine anybody running any label business without it. All of our efficiencies are because of Label Traxx – we get every single penny out of our presses. It lets us track and schedule our jobs; my production team can see what’s running on what presses and which specific tools we need. We can really get organized to run as efficiently as possible.”

Fernandez points out that in addition to it being an excellent customer service tool and the key to maximizing efficiencies, Label Traxx also helps the company resolve issues before they even happen. He says, “We don’t have problems, because thanks to Label Traxx we can foresee them. We use it to forecast our material usage, our ink, press time – everything. We can place our orders for materials through Label Traxx, receive it and populate our inventory. There are so many tools within the software that make life easy for the modern day label manufacturer.”

The current management of CERM, a global provider of Management Information System (MIS) software for the printing industry, acquired full independence through a Management Buyout (MBO) from Heidelberger Druckmaschinen AG (Heidelberg) on July 31, 2020. With this autonomous positioning of the CERM software and brand, the CERM management aspires to boost the worldwide expansion of its automation solution for labels and packaging printers.

CERM became part of the Heidelberg group in 2011. CERM’s software is touted as one of the most powerful ecosystems in the market for any printer, regardless of its size or application focus. To this day, CERM serves over 400 customers worldwide and partners with a plethora of market players.

The growing trend to digital label printing is further challenging the optimization focus in the label and packaging segment with an increasing variety of products, small order quantities and short lead times. Automation is a high priority for any printer looking to work more profitably now and in the future. “Our software has proven expertise in increasing the service, quality and efficiency levels of label and packaging printers globally. We are constantly focusing on existing and new customer needs and technological evolution. To explore our full potential and fuel that growth, we needed to regain independence, and welcome additional distribution and support channels,” says Geert Van Damme, CEO of CERM and one of the managers involved in the MBO.

Heidelberg and CERM will both continue to develop and distribute the CERM software as “Prinect Business Manager” for the commercial print segment. All existing Heidelberg customer contracts and support channels remain in place.

“We highly value the cooperation throughout the years and will continue to collaborate with Heidelberg sales and service units. We are also looking forward to expanding our deep industry expertise offering in the label and packaging market as an independent, innovative and agile niche player through additional sales and service channels,” Geert Van Damme concludes.