Steve Katz, Contributing Editor11.11.21

The cannabis packaging market is lighting up cash registers and profit margins. Globally, it is expected to witness a CAGR of 24.3% over the forecast period from 2021 to 2026, according to market research firm Research and Markets, and is anticipated to witness notable growth over the next few years. The forecasted growth is due to rising consumer demand for medical and recreational cannabis products for consumption. And the increasing legalization of cannabis in various countries – much as it’s occurring within the United States – is likely to continue.

Legal, recreational cannabis is expected to be a huge driver for the packaging market, as it has shown unprecedented growth in recent years. The Marijuana Business Daily reports “flower” – the plant matter, aka “buds” – as the most preferred form of cannabis sold in the United States. Flower is usually packed in jars or flexible packaging.

In North America in particular, the rapid legalization of the consumption of cannabis in the United States and the overall legal environment in Canada is anticipated to drive the ancillary demand for cannabis packaging. In the US, 36 out of 50 states allow patients to use medical cannabis with a proper prescription. Meanwhile, recreational cannabis is now legal in 19 states, as well as Washington, DC and Guam. Another 13 states and the US Virgin Islands have recently decriminalized its use.

The packaging of cannabis is a crucial component of the sector, owing to various regulations imposed by different municipalities. Cannabis is available in various forms. In addition to the aforementioned flower, growing in popularity are oils, extracts and edibles, as well as topicals and beverages. Types of edibles run the gamut – gummies, chocolates, cookies and sauces are among a host of products fighting for market share.

A notable trend in the cannabis packaging industry is to tap into the rising consumption of recreational cannabis among the younger population. Due to high brand saturation among cannabis players, packaging plays a key role with smaller and emerging players to establish and strengthen brand image, according to Research and Markets.

The firm also reports that the nationwide lockdowns during the Covid-19 pandemic sparked increased demand for cannabis. “Multiple retail stores registered havoc traffic from consumers as the general idea of stocking up cannabis products in fear of its scarcity became prevalent. Statistics suggest the high growth of retail sales of cannabis products in March of 2020, creating an ancillary demand for cannabis packaging products,” Research and Markets reports.

The focus on sustainability, regulations and branding has heavily impacted the packaging of cannabis and has facilitated the shift from traditional methods – which relied on manual labor for processing and packaging – to more sophisticated, automated methodologies. The incorporation of automation is slowly gaining traction in the cannabis packaging industry as brands become aware of the benefits. This is envisaged to become more popular with the standardization of the legal landscape of cannabis, the firm says.

In light of the growth and evolution of the industry, label and packaging companies are putting R&D resources into providing products and services to meet this new demand. Cannabis brand owners now have market-specific solutions that address aesthetics, functionality and legal compliance.

It’s high time to take a look at the some of these suppliers, as well as the latest innovations, issues and trends affecting the cannabis labels and packaging market.

Introducing Packwolves

Packwolves, positioned as an on-demand cannabis packaging platform, has announced a collaboration with Mohave Cannabis Co., an Arizona and California-based cannabis brand with quality cultivation and premium indoor flower products. In addition to designing and manufacturing custom packaging and products, Packwolves also allows manufacturers to purchase pre-designed, child-resistant packaging for faster deployment of their cannabis products.

The company’s collaboration with Mohave Cannabis Co. came through a jointly designed custom-produced glass jar inspired by the design and feel of fine spirit bottles. The rounded square jar features embossed letters and convex inner glass, which magnifies the jar’s contents, providing a deeper look at the nuances of the product. The jar also features a dark, oak-pattern, child-resistant lid, with an air-and-water-tight “twist and seal” feature that keeps cannabis more potent for a longer amount of time than other products in the industry.

“There is frankly nothing else like this on the market,” says Curtis Devine, owner and founder of Mohave Cannabis Co. “Our collaboration with Packwolves delivers an experience that’s as curated, nuanced and sophisticated as the product itself.”

Packwolves was founded by Tom Vickers, who left product design in the advertising world to pursue his passion of helping cannabis companies grow and market themselves. The company brings a design-forward approach to the cannabis industry, helping both newcomers and established companies quickly create high-quality packaging, swag and other products.

“With more and more states legalizing the use of cannabis, too many entrepreneurs must resort to a piecemeal approach to deploying their branded products such as buying packaging, boxes and product stickers from various vendors on Amazon,” Vickers says. “We are confident that our distinctive, one-stop solution will be a welcome resource for many manufacturers.”

In addition to custom packaging, Packwolves offers pre-designed pouches for quick deployment of products. The company also offers packaging programs for products such as: Jar & Box, Jar & Paper Tube, Pouch & PET Insert, and Pouch & PET Insert for Pre-Rolls, among other options. They also have an expert internal design team that can aid customers in launching a brand.

Packwolves also offers customizable pouches, jars, folding boxes, magnetic boxes, paper tubes and shipper boxes, as well as swag items such as customizable rolling trays, ashtrays and carabiners.

“Design can elevate the image of cannabis,” Vickers says, adding, “We’re building a design-forward platform that can positively influence and educate the public about the often-stigmatized cannabis plant.”

S-OneLP’s free Cannabis Resource Guide

S-One Labels & Packaging has introduced a free Cannabis Resource Guide to help label and flexible packaging converters navigate the emerging legal cannabis marketplace.

“In recent years, many of S-OneLP’s customers have diversified into the legal cannabis market in what was essentially an entirely new range of packaging applications that emerged overnight,” says Tom Hauenstein, S-OneLP’s VP of sales. “As with any new endeavor, there came questions about the legal cannabis market as our customers struggled to find information on child-resistance packaging requirements, changing regulations, and film barrier properties that keep cannabis products fresh. Customers often turned to the experts at S-OneLP for help navigating this new and dynamic landscape.”

The Cannabis Resource Guide is a website designed for label and packaging manufacturers looking to provide sophisticated high-end packaging with superior shelf appeal that complies with state regulations, keeps the product fresh, and in many cases, is environmentally friendly. The Cannabis Resource Guide brings together industry knowledge, interviews with customers on the front line, and information about S-OneLP products.

The highlight of the Cannabis Resource Guide is an interactive map detailing US packaging laws by state. A top concern from customers is ensuring that cannabis packaging is compliant with state laws. The colorful map allows visitors to quickly see which states have legalized recreational or medical cannabis laws, and the places where cannabis remains illegal. Once a visitor clicks on a particular state, they are directed to the state statute regulating cannabis labels and packaging.

The Cannabis Resource Guide also covers child-resistant packaging, how it’s achieved, and what this standard means for the wider cannabis packaging industry. The Cannabis Resource Guide can be found at https://info.sonelp.com/cannabis-resource-guide.

Form and Function from Mactac

Mactac has engineered new pressure sensitive paper and film cannabis labeling products, announcing the company’s foray into this fast-growing market.

Mactac’s materials for cannabis labeling feature excellent form and function, including adhesion to small mandrel containers and vials. They are also proven to withstand a range of environmental and other challenging conditions such as moisture, heat and humidity.

“Today’s cannabis market is fast-growing and full of opportunity for dispensaries, growers and processors,” says Sara Damante, senior marketing manager, Mactac Performance Adhesives. “In fact, the global cannabis market size is expected to reach $73.6 billion by 2027, an unprecedented 18.1% CAGR. Mactac is poised to grow in tandem with the cannabis industry through our understanding of market and packaging trends and needs.”

Available in paper and film constructions, Mactac’s cannabis labels are designed to meet labeling needs for all forms of cannabis – from solid and semi-solid to viscous and liquid. They can be used in a wide range of applications, including glass, pop-top and reversible cap vials, cartons, stock glasses, bags and pouches.

Additionally, the products cater to both consumer and medical cannabis segments. Market analysis by Grand View Research notes that medical cannabis held the leading market revenue share in 2019 at 71%. As with all pharmaceutical and medical labeling, Mactac’s cannabis labels were developed to meet the stringent needs of the medical cannabis market, ensuring enhanced label readability with secure, long-lasting performance.

Go ‘Green’ with Acucote

Acucote has expanded its portfolio of stocked label materials for the cannabis industry. According to Melissa Harton, marketing manager, “Increasing legalization of cannabis for medical, as well as adult use, is fueling an outstanding growth curve in this market. We created a portfolio of stocked cannabis facestocks, adhesives and liners so that our customers can quickly and easily meet the needs of dispensaries and attract consumer attention.”

The portfolio features a new environmentally friendly facestock, 60# Hemp paper. It is made from 25% hemp and 75% post-consumer wood. Additional stocked substrates for retail and decorative labels include prime films (2 mil Clear, 2 mil Metallized and 2.6 mil Gloss White Elite BOPPs), variable print films (46# C1S Syntherm), and prime papers (35# C1S Litho, 54# Semi Gloss, and 50# Brown Kraft). Foils and metalized papers are also popular with cannabis producers, and Acucote offers bright and dull silver and gold foils and silver metalized paper.

As product security is a major concern in this market, the portfolio also features tamper-evident materials (2.5 mil Silver Scratch Off Polystyrene, 55# Tamper Evident Litho, 2 mil Silver Void PET, 2 mil White Void PET, Syntherm TE, and 2 mil Clear Acetate UD).

Lastly, the portfolio includes material for plant life cycle labels (Kimdura Inkjet Ultra and 2.6 mil Matte White Premium TT BOPP) and digitally topcoated materials (for dye, pigment, laser, UV inkjet and HP presses).

Seven different adhesives are included in the Acucote Cannabis Portfolio, including P2000 (durable rubber resin for plant life cycle), P50 (durable acrylic for plant life cycle), CP1 (environmental rubber resin with biodegradable components), SX780 (tackified acrylic for tamper-evident applications), GPX (general purpose permanent acrylic), GPX Blockout (black opaque permanent acrylic) and 31PB (tackified acrylic for tight mandrel applications).

By Nicole Rivera, Director of Administration and Marketing, K Laser

Cold foil substrates have been used for years by top brands in the tobacco, wine and spirits markets to help grow brand presence. Considering the cannabis market has a similar audience, cold foil embellishments could be the final piece that perfects packaging.

Here are a few ways cold foil substrates can elevate cannabis packaging:

Pop off the shelf with cold foil embellishments. Dispensaries around the US have different, but similar environments in their stores. Usually, they are dimly lit with products displayed on wall shelves and in glass cases. The walls are a dark color and there’s usually a black light somewhere in the room. New, trendier stores look like boutiques, with brighter lights and mixtures of greenery, wood and metal, giving a hipster, boho vibe. These are all things you need to consider when designing cannabis packaging, and cold foil is perfect for attracting the eye in different retail environments. Also, millennials make up most of this new market, and this demographic is known for their tendency to impulse buy. Couple that with the newness of the market, and the audience is more than willing to try new brands and test different products until they find one they love. To win that impulse buy from millennials, your product needs to look cooler, different and better in various settings.

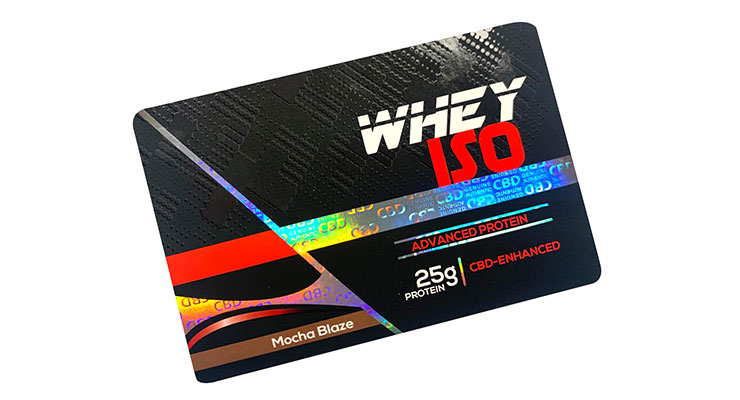

Quality matters. How does one convey quality? Cold foil, of course! You can scream high quality from the rooftops, but if your packaging is basic then your customers won’t be able to tell the difference between your premium cannabis products and the low-quality scams. Just like in the wine and spirits market, using cold foil embellishments on your labels and packaging elevates your product to a premium status. Customers and retail store owners assess by the look, the feel and the thoughtful design of the package if a brand is of a higher caliber. Superior brands use superior packaging and cheap CBD products use cheap packaging – plain and simple. Using a sophisticated holographic cold foil pattern, the K Laser exclusive CBD hologram, or even designing your own custom-branded hologram, will visually tell the market that your brand invests in high-quality products that can be trusted.

Security from counterfeits with cold foil. There is incredible opportunity in this market to be “The First” in a new product category. However, in the wise words of Coco Chanel, “If you want to be original, be ready to be copied.” You put your blood, sweat and tears into building your unique brand, but if you don’t invest in quality packaging, it leaves opportunity for a believable knock-off to cause confusion in the marketplace. Using anti-counterfeiting details on your labels and boxes, like cold foil patterns or a security cold foil hologram, helps retail store owners spot low-quality knock-off products before putting them on the shelves. Custom holograms containing your company logo and brand colors combined with cold foil substrates take product security to the next level and is a great investment to secure your brand’s future. Educating your customers on your brand packaging will also help your buyers spot a knock-off and protect them from consuming a counterfeit. The ability to distinguish between your original, premium product and a fake knock-off starts with the design of your product packaging – use cold foil and counterfeiters will struggle to take your market share.

Legal, recreational cannabis is expected to be a huge driver for the packaging market, as it has shown unprecedented growth in recent years. The Marijuana Business Daily reports “flower” – the plant matter, aka “buds” – as the most preferred form of cannabis sold in the United States. Flower is usually packed in jars or flexible packaging.

In North America in particular, the rapid legalization of the consumption of cannabis in the United States and the overall legal environment in Canada is anticipated to drive the ancillary demand for cannabis packaging. In the US, 36 out of 50 states allow patients to use medical cannabis with a proper prescription. Meanwhile, recreational cannabis is now legal in 19 states, as well as Washington, DC and Guam. Another 13 states and the US Virgin Islands have recently decriminalized its use.

The packaging of cannabis is a crucial component of the sector, owing to various regulations imposed by different municipalities. Cannabis is available in various forms. In addition to the aforementioned flower, growing in popularity are oils, extracts and edibles, as well as topicals and beverages. Types of edibles run the gamut – gummies, chocolates, cookies and sauces are among a host of products fighting for market share.

A notable trend in the cannabis packaging industry is to tap into the rising consumption of recreational cannabis among the younger population. Due to high brand saturation among cannabis players, packaging plays a key role with smaller and emerging players to establish and strengthen brand image, according to Research and Markets.

The firm also reports that the nationwide lockdowns during the Covid-19 pandemic sparked increased demand for cannabis. “Multiple retail stores registered havoc traffic from consumers as the general idea of stocking up cannabis products in fear of its scarcity became prevalent. Statistics suggest the high growth of retail sales of cannabis products in March of 2020, creating an ancillary demand for cannabis packaging products,” Research and Markets reports.

The focus on sustainability, regulations and branding has heavily impacted the packaging of cannabis and has facilitated the shift from traditional methods – which relied on manual labor for processing and packaging – to more sophisticated, automated methodologies. The incorporation of automation is slowly gaining traction in the cannabis packaging industry as brands become aware of the benefits. This is envisaged to become more popular with the standardization of the legal landscape of cannabis, the firm says.

In light of the growth and evolution of the industry, label and packaging companies are putting R&D resources into providing products and services to meet this new demand. Cannabis brand owners now have market-specific solutions that address aesthetics, functionality and legal compliance.

It’s high time to take a look at the some of these suppliers, as well as the latest innovations, issues and trends affecting the cannabis labels and packaging market.

Introducing Packwolves

Packwolves, positioned as an on-demand cannabis packaging platform, has announced a collaboration with Mohave Cannabis Co., an Arizona and California-based cannabis brand with quality cultivation and premium indoor flower products. In addition to designing and manufacturing custom packaging and products, Packwolves also allows manufacturers to purchase pre-designed, child-resistant packaging for faster deployment of their cannabis products.

The company’s collaboration with Mohave Cannabis Co. came through a jointly designed custom-produced glass jar inspired by the design and feel of fine spirit bottles. The rounded square jar features embossed letters and convex inner glass, which magnifies the jar’s contents, providing a deeper look at the nuances of the product. The jar also features a dark, oak-pattern, child-resistant lid, with an air-and-water-tight “twist and seal” feature that keeps cannabis more potent for a longer amount of time than other products in the industry.

“There is frankly nothing else like this on the market,” says Curtis Devine, owner and founder of Mohave Cannabis Co. “Our collaboration with Packwolves delivers an experience that’s as curated, nuanced and sophisticated as the product itself.”

Packwolves was founded by Tom Vickers, who left product design in the advertising world to pursue his passion of helping cannabis companies grow and market themselves. The company brings a design-forward approach to the cannabis industry, helping both newcomers and established companies quickly create high-quality packaging, swag and other products.

“With more and more states legalizing the use of cannabis, too many entrepreneurs must resort to a piecemeal approach to deploying their branded products such as buying packaging, boxes and product stickers from various vendors on Amazon,” Vickers says. “We are confident that our distinctive, one-stop solution will be a welcome resource for many manufacturers.”

In addition to custom packaging, Packwolves offers pre-designed pouches for quick deployment of products. The company also offers packaging programs for products such as: Jar & Box, Jar & Paper Tube, Pouch & PET Insert, and Pouch & PET Insert for Pre-Rolls, among other options. They also have an expert internal design team that can aid customers in launching a brand.

Packwolves also offers customizable pouches, jars, folding boxes, magnetic boxes, paper tubes and shipper boxes, as well as swag items such as customizable rolling trays, ashtrays and carabiners.

“Design can elevate the image of cannabis,” Vickers says, adding, “We’re building a design-forward platform that can positively influence and educate the public about the often-stigmatized cannabis plant.”

S-OneLP’s free Cannabis Resource Guide

S-One Labels & Packaging has introduced a free Cannabis Resource Guide to help label and flexible packaging converters navigate the emerging legal cannabis marketplace.

“In recent years, many of S-OneLP’s customers have diversified into the legal cannabis market in what was essentially an entirely new range of packaging applications that emerged overnight,” says Tom Hauenstein, S-OneLP’s VP of sales. “As with any new endeavor, there came questions about the legal cannabis market as our customers struggled to find information on child-resistance packaging requirements, changing regulations, and film barrier properties that keep cannabis products fresh. Customers often turned to the experts at S-OneLP for help navigating this new and dynamic landscape.”

The Cannabis Resource Guide is a website designed for label and packaging manufacturers looking to provide sophisticated high-end packaging with superior shelf appeal that complies with state regulations, keeps the product fresh, and in many cases, is environmentally friendly. The Cannabis Resource Guide brings together industry knowledge, interviews with customers on the front line, and information about S-OneLP products.

The highlight of the Cannabis Resource Guide is an interactive map detailing US packaging laws by state. A top concern from customers is ensuring that cannabis packaging is compliant with state laws. The colorful map allows visitors to quickly see which states have legalized recreational or medical cannabis laws, and the places where cannabis remains illegal. Once a visitor clicks on a particular state, they are directed to the state statute regulating cannabis labels and packaging.

The Cannabis Resource Guide also covers child-resistant packaging, how it’s achieved, and what this standard means for the wider cannabis packaging industry. The Cannabis Resource Guide can be found at https://info.sonelp.com/cannabis-resource-guide.

Form and Function from Mactac

Mactac has engineered new pressure sensitive paper and film cannabis labeling products, announcing the company’s foray into this fast-growing market.

Mactac’s materials for cannabis labeling feature excellent form and function, including adhesion to small mandrel containers and vials. They are also proven to withstand a range of environmental and other challenging conditions such as moisture, heat and humidity.

“Today’s cannabis market is fast-growing and full of opportunity for dispensaries, growers and processors,” says Sara Damante, senior marketing manager, Mactac Performance Adhesives. “In fact, the global cannabis market size is expected to reach $73.6 billion by 2027, an unprecedented 18.1% CAGR. Mactac is poised to grow in tandem with the cannabis industry through our understanding of market and packaging trends and needs.”

Available in paper and film constructions, Mactac’s cannabis labels are designed to meet labeling needs for all forms of cannabis – from solid and semi-solid to viscous and liquid. They can be used in a wide range of applications, including glass, pop-top and reversible cap vials, cartons, stock glasses, bags and pouches.

Additionally, the products cater to both consumer and medical cannabis segments. Market analysis by Grand View Research notes that medical cannabis held the leading market revenue share in 2019 at 71%. As with all pharmaceutical and medical labeling, Mactac’s cannabis labels were developed to meet the stringent needs of the medical cannabis market, ensuring enhanced label readability with secure, long-lasting performance.

Go ‘Green’ with Acucote

Acucote has expanded its portfolio of stocked label materials for the cannabis industry. According to Melissa Harton, marketing manager, “Increasing legalization of cannabis for medical, as well as adult use, is fueling an outstanding growth curve in this market. We created a portfolio of stocked cannabis facestocks, adhesives and liners so that our customers can quickly and easily meet the needs of dispensaries and attract consumer attention.”

The portfolio features a new environmentally friendly facestock, 60# Hemp paper. It is made from 25% hemp and 75% post-consumer wood. Additional stocked substrates for retail and decorative labels include prime films (2 mil Clear, 2 mil Metallized and 2.6 mil Gloss White Elite BOPPs), variable print films (46# C1S Syntherm), and prime papers (35# C1S Litho, 54# Semi Gloss, and 50# Brown Kraft). Foils and metalized papers are also popular with cannabis producers, and Acucote offers bright and dull silver and gold foils and silver metalized paper.

As product security is a major concern in this market, the portfolio also features tamper-evident materials (2.5 mil Silver Scratch Off Polystyrene, 55# Tamper Evident Litho, 2 mil Silver Void PET, 2 mil White Void PET, Syntherm TE, and 2 mil Clear Acetate UD).

Lastly, the portfolio includes material for plant life cycle labels (Kimdura Inkjet Ultra and 2.6 mil Matte White Premium TT BOPP) and digitally topcoated materials (for dye, pigment, laser, UV inkjet and HP presses).

Seven different adhesives are included in the Acucote Cannabis Portfolio, including P2000 (durable rubber resin for plant life cycle), P50 (durable acrylic for plant life cycle), CP1 (environmental rubber resin with biodegradable components), SX780 (tackified acrylic for tamper-evident applications), GPX (general purpose permanent acrylic), GPX Blockout (black opaque permanent acrylic) and 31PB (tackified acrylic for tight mandrel applications).

By Nicole Rivera, Director of Administration and Marketing, K Laser

Cold foil substrates have been used for years by top brands in the tobacco, wine and spirits markets to help grow brand presence. Considering the cannabis market has a similar audience, cold foil embellishments could be the final piece that perfects packaging.

Here are a few ways cold foil substrates can elevate cannabis packaging:

Pop off the shelf with cold foil embellishments. Dispensaries around the US have different, but similar environments in their stores. Usually, they are dimly lit with products displayed on wall shelves and in glass cases. The walls are a dark color and there’s usually a black light somewhere in the room. New, trendier stores look like boutiques, with brighter lights and mixtures of greenery, wood and metal, giving a hipster, boho vibe. These are all things you need to consider when designing cannabis packaging, and cold foil is perfect for attracting the eye in different retail environments. Also, millennials make up most of this new market, and this demographic is known for their tendency to impulse buy. Couple that with the newness of the market, and the audience is more than willing to try new brands and test different products until they find one they love. To win that impulse buy from millennials, your product needs to look cooler, different and better in various settings.

Quality matters. How does one convey quality? Cold foil, of course! You can scream high quality from the rooftops, but if your packaging is basic then your customers won’t be able to tell the difference between your premium cannabis products and the low-quality scams. Just like in the wine and spirits market, using cold foil embellishments on your labels and packaging elevates your product to a premium status. Customers and retail store owners assess by the look, the feel and the thoughtful design of the package if a brand is of a higher caliber. Superior brands use superior packaging and cheap CBD products use cheap packaging – plain and simple. Using a sophisticated holographic cold foil pattern, the K Laser exclusive CBD hologram, or even designing your own custom-branded hologram, will visually tell the market that your brand invests in high-quality products that can be trusted.

Security from counterfeits with cold foil. There is incredible opportunity in this market to be “The First” in a new product category. However, in the wise words of Coco Chanel, “If you want to be original, be ready to be copied.” You put your blood, sweat and tears into building your unique brand, but if you don’t invest in quality packaging, it leaves opportunity for a believable knock-off to cause confusion in the marketplace. Using anti-counterfeiting details on your labels and boxes, like cold foil patterns or a security cold foil hologram, helps retail store owners spot low-quality knock-off products before putting them on the shelves. Custom holograms containing your company logo and brand colors combined with cold foil substrates take product security to the next level and is a great investment to secure your brand’s future. Educating your customers on your brand packaging will also help your buyers spot a knock-off and protect them from consuming a counterfeit. The ability to distinguish between your original, premium product and a fake knock-off starts with the design of your product packaging – use cold foil and counterfeiters will struggle to take your market share.