Greg Hrinya, Editor08.30.23

To produce eye-catching labels, the latest and greatest equipment advancements in finishing are required. These products can deliver the types of visual and tactile effects on labels that make an impact with consumers.

One of the most prominent developments in the finishing arena has been the inclusion of automation. Automated capabilities help label converters complete tasks with less manpower, and they promote efficiency at busy shops.

“Run lengths are becoming shorter and shorter, and at the same time the quality requirements are increasing,” states Frank Hasselberg, president, Prati USA. “Digital finishing machines are becoming more complex and have more features than ever before.”

LemuGroup has prioritized Lean Manufacturing principles to deliver maximum daily output. The company’s goal is to provide solutions to customers’ challenges – with workforce, quality, speed, and sustainability chief among them.

“How to produce the same or more products with fewer people is the pinnacle issue that I find people are researching and trying to solve economically in today’s industry,” explains Andre Beaudoin, director of North American sales and marketing, LemuGroup USA. “We are also finding that by incorporating higher speeds and tying in end-of-line automation, there has been a reduction in waste, which is always created when human interplay is involved,” he says, adding, “An example of this is when a product has been converted, that product then needs to be moved to a second rewinding process and then finally packaging. With high-speed converting/inline packaging, we have eliminated the waste factor. At these speeds, people cannot keep up with the packaging and palletizing part of their throughput. With our new technology, daily productivity increases 40% on average.”

“The primary benefits of automation are the reduction in make-ready times closely followed by the reduction of make-ready waste,” comments Jim Wright, sales manager, Canada, A B Graphic International (ABG). “There is another side to automation and that is the incorporation of techniques such as Single Minute Exchange of Die (SMED). Exploited by the auto industry, SMED is transplantable to the label printing and finishing industry. SMED uses simple techniques such as make-ready benches with tools that might be required mounted on shadow boards for quick access and easy confirmation that the tool is there. Similar common sense moves reduce stress on the operator and make it easier to maintain quality while reducing waste.”

Automation adds speed and efficiency, but it also decreases the risk of error. “In past years, all of our energy has been focused on developing devices that favor the automation of processes and decline part of the work that the operator does in automatic systems, where the error margin is close to zero,” remarks Enrica Lodi, sales and marketing, Cartes. “This is a very important part for us, and our future developments must be focused on the automation concept, which itself reduces production costs and erases several risky variables.”

While automation and speed are critical, the final labels adorning products on the shelf are paramount. Quality cannot take a back seat to speed.

“We have always developed technologies that guarantee the quality of the final products with optimal production performance,” says Lodi. “That’s the reason why our machines are configured with all the newest gadgets to highlight final products with top-end added-value applications. We will always aim to find solutions and develop innovations where quality, mechanical strength, precision and high production speed are intrinsic.”

Delta ModTech has engineered finishing equipment that is ideally suited to deliver in a number of high-value areas, including smart labels (page 50). “With the RFID mandates that have been imposed by Walmart and other retailers, precision and accurate insertion of tags and antennas into labels is a hot topic,” explains Dave Grenwis, marketing manager, Delta ModTech. “With the increase of projects in this area, our RFID tag insertion modules continue to evolve. Using our patented Island Transfer process, Delta ModTech machines are capable of inserting under label tags at high speeds, up to 2,500 parts per minute. Our machines are also capable of UHF and HF encoding and either wet or dry inlay, depending on your application.”

Of course, the emergence of digital printing has also necessitated greater finishing solutions. Most recently, L&NW has visited converters that have married effective digital printing and finishing units together to ramp up production. For example, Penmar Industries has installed a Screen inkjet press with an off-line finisher from Grafotronic, while this month’s Narrow Web Profile, American Non Stop Label Corp., (page 44) utilizes a Durst Tau press with a finisher from AZTECH Converting Systems.

“With more and more digital machines coming into the market, finishing has become a crucial part of the label manufacturing process,” says Hasselberg. “We also see digital roll-to-roll machines opening the label business for commercial printers. Here, often a relatively simple finisher is required.”

When dealing with diecutting, Kocher+Beck has emphasized operator friendliness with its automated features. The GapMaster EM, for example, offers an intuitive graphic user interface HMI that provides an easy to use live visual representation of the cylinder’s gap adjustment. The EM system also has job saving functions, selectable maximum adjustment warnings and limits, quick gap open position, and user modifiable start positions.

“At Kocher+Beck we highly value working closely with our customers and getting their input and feedback, as they are the ones that are using our products on a daily basis,” says David Morris, president of Kocher+Beck USA. “We remain committed to continued investment in R&D, equipment, software, additional technology, and resources to enable it to bring the very latest technology to customers.”

In the future, there are several trends to be mindful of. “Since we see more embellishments on labels, the finishing machines are also becoming longer, and it takes more time to set up, which manufacturers are trying to shorten and automate,” says Hasselberg. “We also see a trend to digitalization, with digital embellishment units and laser diecutting.”

“When running inline, jobs that are longer in run length – especially when the label shape is consistent – do well,” explains ABG’s Wright. “If the press run is made up of smaller job runs with changing label shapes, the inline process requires a buffer to manage the stopping and starting of the finishing system for die changes to eliminate press waste. Also, if either side of the inline process has an issue, the entire process is stopped. Our inline interface incorporates a festoon for handling controlled press stops, and it includes an unwind so that any printed rolls can be processed during press downtime.”

According to Wright, off-line or near-line finishing are often the more popular choice because it decouples the two processes, allowing the finishing process to be made ready without impacting the printing process and vice versa. “It can also allow the finishing process to run at higher speeds than the press, allowing for the potential to handle two presses with one finishing machine,” he says. “Off-line finishing is especially desirable with premium labels that require embellishments of foil, embossing, screen printing, etc., as printing can continue while the finisher is readied.”

Prati’s Hasselberg notes previous excitement surrounding hybrid machines. In future decision-making, flexibility will be key. “As more conventional units and embellishment units were added, it makes hybrid machines very long with a long web path,” he notes. “We see this trend going back to off-line finishing since job sizes are getting shorter and it makes long hybrid machines inefficient. We see customers printing on their roll-to-roll digital machines now almost non-stop, and having any conventional and/or embellishment units off-line. This makes the whole process more flexible.”

According to Cartes’ Lodi, finishing solutions – like others aspects of production – should be tailored to the needs of the customer. “We believe there is a best solution for every client, but only if this one perfectly suits their business,” she says. “There is no magical formula to help everyone in the same way, so it is our duty to analyze each real-world production environment and advise them according to our experience.”

“Regarding print, the most important aspect is confirmation that the job to be finished is the correct job. We can facilitate that with our fleyeVision inspection system,” states ABG’s Wright. “We can compare the printed image to the approved PDF, and if correct finishing can proceed. If the printed image is not correct, the job can be removed from the machine.

“Sometimes the material that was originally planned for the job is not available and a substitution is needed,” adds Wright. “If the substitute material is sufficiently different from what was specified, the die plate that was to be used may not cut correctly. By configuring the machine with an adjustable anvil, such as Kocher + Beck’s GapMaster, at order time, an adjustment to the anvil can be made by the operator to perfect cutting.”

One of the big challenges, Delta ModTech’s Grenwis notes, centers around speed. “Waste reduction for both materials and time are always the top challenges we encounter with label converters,” he says. “We’re continuously updating our equipment to limit material waste and time lost for changeovers. Our registration controls limit operator interaction, allowing for higher speeds and less waste.”

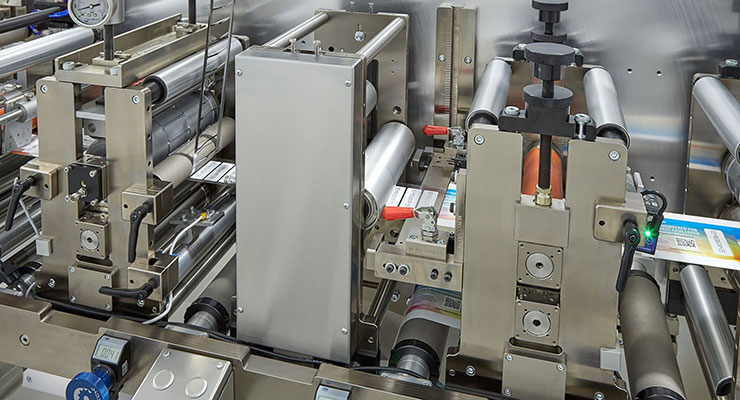

Finishing can often be a complex process, too. The finishing required for a high-end beverage label could include foil decoration, embossing, tactile printing, and complicated matrix removal.

“To ensure that the task can be completed correctly, we have an incredible range of modules and options to address any finishing task,” comments Wright. “For example, for a task like hot foil/embossing we have a 50-ton flatbed hot foil/embossing system called Big Foot. It enables the operator to apply the correct foil(s) in the correct places and emboss where needed. Our high-speed flatbed screen print module is our evolution of the common flatbed screen printer, as well. And when label designers stretch their wings, the resultant labels can often have shape characteristics that make conventional matrix removal virtually impossible. Our finishing machines can be configured with a contact matrix stripper that easily handles the challenging shape matrix removal, as well as the more ‘normal’ label shapes.”

The advanced automation commonly seen in label finishing equipment also helps tackle the challenge of finding and retaining qualified operators. “Whether it is the automation of something as simple as trimming to the correct finished width or as complex as a ‘lights out’ production run, automation is now an integral requirement,” explains Wright. “The future benefits of automation will include the continued advancement of productivity and product consistency. It will also encourage competent individuals to enter and stay in the label and packaging industry.”

“LemuGroup equipment allows the converter to do much more with far less,” adds LemuGroup’s Beaudoin. “We spare our clients of the day-to-day HR business of trying to hire and retain employees, providing the employees who are there the ability to get back to label production – and doing it better than they had ever done it before. Simply put, more production equates to higher revenue and increased profitability. We are not just automating individual and multiple press lines. We are, in fact, automating entire production facilities. The industry has led us here, and the solution is available today.”

Cartes’ latest technology is the Jet D-Screen (JDS), which is a digital screen-printing unit designed to create high raised embellishment. The JDS also adds hot foil transferring, a “metal doming” effect, and is suitable to be completed with a fully automated concept where laser converting, auto-slitting and rewinding can be part of the configuration.

Delta ModTech has developed its newly updated Crusader Converter. This system features a precision RFID antennae placement application, and a variety of processes such as rotary diecutting, winding, conveying and precise part placement. “Customer and supplier demands continue to push innovation in converting technologies,” says Grenwis. “More automation can mean more advanced first-time job setups, so in 2023 we’re offering more options for training, from operators to process engineers to maintenance staff.”

Most recently, LemuGroup enhanced its modular GTU converting system, which is now able to run, diecut, perf and turret rewind at 820 fpm at web widths up to 26" wide. This system complements LemuGroup’s GTU Glueless turret rewinder, which allows the company to offer what it says is the fastest and most complete non-stop converting system in the industry. Plus, Lemu has received strong feedback for its ultra-compact, end-of-line boxing and palletizing to this line.

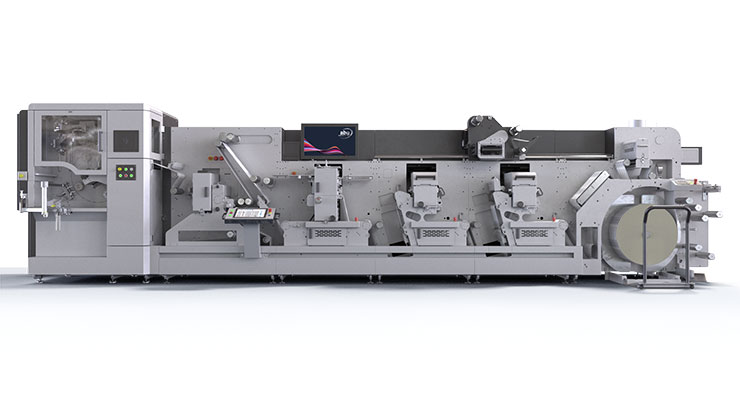

Prati has developed the new Prati DigiCompact. This machine is eco-friendly, efficient, and highly productive. According to Prati’s Hasselberg, the machine requires minimal space and is user friendly. Prati’s DigiFast One platform is a versatile machine platform, and the company has installed machines with flatbed embossing and hot foiling, several semi rotary flexo units, booklet onserters, and more.

One of the most prominent developments in the finishing arena has been the inclusion of automation. Automated capabilities help label converters complete tasks with less manpower, and they promote efficiency at busy shops.

“Run lengths are becoming shorter and shorter, and at the same time the quality requirements are increasing,” states Frank Hasselberg, president, Prati USA. “Digital finishing machines are becoming more complex and have more features than ever before.”

LemuGroup has prioritized Lean Manufacturing principles to deliver maximum daily output. The company’s goal is to provide solutions to customers’ challenges – with workforce, quality, speed, and sustainability chief among them.

“How to produce the same or more products with fewer people is the pinnacle issue that I find people are researching and trying to solve economically in today’s industry,” explains Andre Beaudoin, director of North American sales and marketing, LemuGroup USA. “We are also finding that by incorporating higher speeds and tying in end-of-line automation, there has been a reduction in waste, which is always created when human interplay is involved,” he says, adding, “An example of this is when a product has been converted, that product then needs to be moved to a second rewinding process and then finally packaging. With high-speed converting/inline packaging, we have eliminated the waste factor. At these speeds, people cannot keep up with the packaging and palletizing part of their throughput. With our new technology, daily productivity increases 40% on average.”

“The primary benefits of automation are the reduction in make-ready times closely followed by the reduction of make-ready waste,” comments Jim Wright, sales manager, Canada, A B Graphic International (ABG). “There is another side to automation and that is the incorporation of techniques such as Single Minute Exchange of Die (SMED). Exploited by the auto industry, SMED is transplantable to the label printing and finishing industry. SMED uses simple techniques such as make-ready benches with tools that might be required mounted on shadow boards for quick access and easy confirmation that the tool is there. Similar common sense moves reduce stress on the operator and make it easier to maintain quality while reducing waste.”

Automation adds speed and efficiency, but it also decreases the risk of error. “In past years, all of our energy has been focused on developing devices that favor the automation of processes and decline part of the work that the operator does in automatic systems, where the error margin is close to zero,” remarks Enrica Lodi, sales and marketing, Cartes. “This is a very important part for us, and our future developments must be focused on the automation concept, which itself reduces production costs and erases several risky variables.”

While automation and speed are critical, the final labels adorning products on the shelf are paramount. Quality cannot take a back seat to speed.

“We have always developed technologies that guarantee the quality of the final products with optimal production performance,” says Lodi. “That’s the reason why our machines are configured with all the newest gadgets to highlight final products with top-end added-value applications. We will always aim to find solutions and develop innovations where quality, mechanical strength, precision and high production speed are intrinsic.”

Delta ModTech has engineered finishing equipment that is ideally suited to deliver in a number of high-value areas, including smart labels (page 50). “With the RFID mandates that have been imposed by Walmart and other retailers, precision and accurate insertion of tags and antennas into labels is a hot topic,” explains Dave Grenwis, marketing manager, Delta ModTech. “With the increase of projects in this area, our RFID tag insertion modules continue to evolve. Using our patented Island Transfer process, Delta ModTech machines are capable of inserting under label tags at high speeds, up to 2,500 parts per minute. Our machines are also capable of UHF and HF encoding and either wet or dry inlay, depending on your application.”

Of course, the emergence of digital printing has also necessitated greater finishing solutions. Most recently, L&NW has visited converters that have married effective digital printing and finishing units together to ramp up production. For example, Penmar Industries has installed a Screen inkjet press with an off-line finisher from Grafotronic, while this month’s Narrow Web Profile, American Non Stop Label Corp., (page 44) utilizes a Durst Tau press with a finisher from AZTECH Converting Systems.

“With more and more digital machines coming into the market, finishing has become a crucial part of the label manufacturing process,” says Hasselberg. “We also see digital roll-to-roll machines opening the label business for commercial printers. Here, often a relatively simple finisher is required.”

When dealing with diecutting, Kocher+Beck has emphasized operator friendliness with its automated features. The GapMaster EM, for example, offers an intuitive graphic user interface HMI that provides an easy to use live visual representation of the cylinder’s gap adjustment. The EM system also has job saving functions, selectable maximum adjustment warnings and limits, quick gap open position, and user modifiable start positions.

“At Kocher+Beck we highly value working closely with our customers and getting their input and feedback, as they are the ones that are using our products on a daily basis,” says David Morris, president of Kocher+Beck USA. “We remain committed to continued investment in R&D, equipment, software, additional technology, and resources to enable it to bring the very latest technology to customers.”

In the future, there are several trends to be mindful of. “Since we see more embellishments on labels, the finishing machines are also becoming longer, and it takes more time to set up, which manufacturers are trying to shorten and automate,” says Hasselberg. “We also see a trend to digitalization, with digital embellishment units and laser diecutting.”

Finishing touch

Inline and off-line finishing are common considerations for label converters. Inline finishing means that the finishing process is directly connected to the printing process, thereby eliminating the rewinding process. Off-line finishing is separate from the printing process and uses the rewound roll from the press. Off-line and near-line are terms that are often used interchangeably. Technically speaking, near-line finishing allows for either inline or off-line finishing depending on production requirements.“When running inline, jobs that are longer in run length – especially when the label shape is consistent – do well,” explains ABG’s Wright. “If the press run is made up of smaller job runs with changing label shapes, the inline process requires a buffer to manage the stopping and starting of the finishing system for die changes to eliminate press waste. Also, if either side of the inline process has an issue, the entire process is stopped. Our inline interface incorporates a festoon for handling controlled press stops, and it includes an unwind so that any printed rolls can be processed during press downtime.”

According to Wright, off-line or near-line finishing are often the more popular choice because it decouples the two processes, allowing the finishing process to be made ready without impacting the printing process and vice versa. “It can also allow the finishing process to run at higher speeds than the press, allowing for the potential to handle two presses with one finishing machine,” he says. “Off-line finishing is especially desirable with premium labels that require embellishments of foil, embossing, screen printing, etc., as printing can continue while the finisher is readied.”

Prati’s Hasselberg notes previous excitement surrounding hybrid machines. In future decision-making, flexibility will be key. “As more conventional units and embellishment units were added, it makes hybrid machines very long with a long web path,” he notes. “We see this trend going back to off-line finishing since job sizes are getting shorter and it makes long hybrid machines inefficient. We see customers printing on their roll-to-roll digital machines now almost non-stop, and having any conventional and/or embellishment units off-line. This makes the whole process more flexible.”

According to Cartes’ Lodi, finishing solutions – like others aspects of production – should be tailored to the needs of the customer. “We believe there is a best solution for every client, but only if this one perfectly suits their business,” she says. “There is no magical formula to help everyone in the same way, so it is our duty to analyze each real-world production environment and advise them according to our experience.”

Overcoming challenges

Equipment manufacturers have worked tirelessly to address a plethora of associated challenges. Label finishing challenges and issues tend to involve the printed material, including the print itself, the choice of substrate, and the scope of the finishing task.“Regarding print, the most important aspect is confirmation that the job to be finished is the correct job. We can facilitate that with our fleyeVision inspection system,” states ABG’s Wright. “We can compare the printed image to the approved PDF, and if correct finishing can proceed. If the printed image is not correct, the job can be removed from the machine.

“Sometimes the material that was originally planned for the job is not available and a substitution is needed,” adds Wright. “If the substitute material is sufficiently different from what was specified, the die plate that was to be used may not cut correctly. By configuring the machine with an adjustable anvil, such as Kocher + Beck’s GapMaster, at order time, an adjustment to the anvil can be made by the operator to perfect cutting.”

One of the big challenges, Delta ModTech’s Grenwis notes, centers around speed. “Waste reduction for both materials and time are always the top challenges we encounter with label converters,” he says. “We’re continuously updating our equipment to limit material waste and time lost for changeovers. Our registration controls limit operator interaction, allowing for higher speeds and less waste.”

Finishing can often be a complex process, too. The finishing required for a high-end beverage label could include foil decoration, embossing, tactile printing, and complicated matrix removal.

“To ensure that the task can be completed correctly, we have an incredible range of modules and options to address any finishing task,” comments Wright. “For example, for a task like hot foil/embossing we have a 50-ton flatbed hot foil/embossing system called Big Foot. It enables the operator to apply the correct foil(s) in the correct places and emboss where needed. Our high-speed flatbed screen print module is our evolution of the common flatbed screen printer, as well. And when label designers stretch their wings, the resultant labels can often have shape characteristics that make conventional matrix removal virtually impossible. Our finishing machines can be configured with a contact matrix stripper that easily handles the challenging shape matrix removal, as well as the more ‘normal’ label shapes.”

The advanced automation commonly seen in label finishing equipment also helps tackle the challenge of finding and retaining qualified operators. “Whether it is the automation of something as simple as trimming to the correct finished width or as complex as a ‘lights out’ production run, automation is now an integral requirement,” explains Wright. “The future benefits of automation will include the continued advancement of productivity and product consistency. It will also encourage competent individuals to enter and stay in the label and packaging industry.”

“LemuGroup equipment allows the converter to do much more with far less,” adds LemuGroup’s Beaudoin. “We spare our clients of the day-to-day HR business of trying to hire and retain employees, providing the employees who are there the ability to get back to label production – and doing it better than they had ever done it before. Simply put, more production equates to higher revenue and increased profitability. We are not just automating individual and multiple press lines. We are, in fact, automating entire production facilities. The industry has led us here, and the solution is available today.”

Ongoing R&D

ABG’s newest launch is ABG Connect, which Wright describes as “a complete revolution for the labels and packaging market.” ABG Connect provides elevated productivity, reduced downtime and waste by fully automating and integrating an ABG finishing line. Integrated with an MIS/ERP system, job data is automatically sent to the machine via a scanned barcode and live production data is sent back for accurate real-time production reporting. We’ve also broadened our Digicon Series 3 line with our new 17" wide system.”Cartes’ latest technology is the Jet D-Screen (JDS), which is a digital screen-printing unit designed to create high raised embellishment. The JDS also adds hot foil transferring, a “metal doming” effect, and is suitable to be completed with a fully automated concept where laser converting, auto-slitting and rewinding can be part of the configuration.

Delta ModTech has developed its newly updated Crusader Converter. This system features a precision RFID antennae placement application, and a variety of processes such as rotary diecutting, winding, conveying and precise part placement. “Customer and supplier demands continue to push innovation in converting technologies,” says Grenwis. “More automation can mean more advanced first-time job setups, so in 2023 we’re offering more options for training, from operators to process engineers to maintenance staff.”

Most recently, LemuGroup enhanced its modular GTU converting system, which is now able to run, diecut, perf and turret rewind at 820 fpm at web widths up to 26" wide. This system complements LemuGroup’s GTU Glueless turret rewinder, which allows the company to offer what it says is the fastest and most complete non-stop converting system in the industry. Plus, Lemu has received strong feedback for its ultra-compact, end-of-line boxing and palletizing to this line.

Prati has developed the new Prati DigiCompact. This machine is eco-friendly, efficient, and highly productive. According to Prati’s Hasselberg, the machine requires minimal space and is user friendly. Prati’s DigiFast One platform is a versatile machine platform, and the company has installed machines with flatbed embossing and hot foiling, several semi rotary flexo units, booklet onserters, and more.