L&NW Staff09.21.20

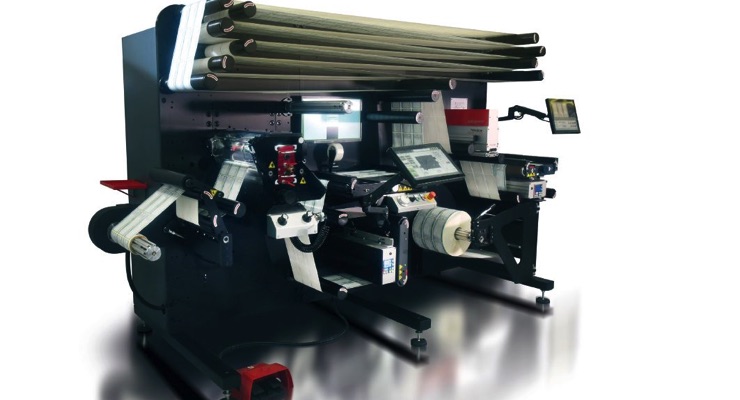

Rotocontrol has launched the RSC 2.0, its next-generation RSC-Series inspection slitter rewinder. With higher speeds and larger roll handling capacity, the RSC 2.0 will help meet demanding requirements in today’s label market.

RSC 2.0 features include transport speeds up to 550 m/min (1800fpm); user-friendly touch screen panel with 2,000 job memory; vertical or horizontal inspection configurations; and unwind diameter support up to 1020mm (40"). Automatic tension control, S-drive servo operation, and operator ease-of-use are standard design features.

A vertical vacuum splice table allows for simple web splices and eliminates the need for web clamping. The waste rewind is ergonomically positioned below the splice table eliminating the requirement for operator bending throughout the entire splicing operation.

A horizontal splice table is also an available option with the RSC 2.0. Tension control is maintained during high speed stops through the automated web tension management system.

The RSC 2.0 quick change slitting cartridge system allows operators faster set up times with less down time for job or blade changes. Tool-less cartridge exchange with pre-mounted set-up gauge rules offers safe changeovers - in as little as thirty seconds.

Engineered and manufactured in Hobart, WI, USA, EMT/Rotocontrol will provide direct 24/7 technical support and remote service for the RSC 2.0.

“As our flagship Rotocontrol inspection slitter rewinder, the RSC-Series has always focused on high-quality components and operator efficiency,” says Marco Aengenvoort, Rotocontrol managing director. “With the next-generation RSC 2.0, all the essential features for inspection and slitting various types of labels are made possible.”

RSC 2.0 features include transport speeds up to 550 m/min (1800fpm); user-friendly touch screen panel with 2,000 job memory; vertical or horizontal inspection configurations; and unwind diameter support up to 1020mm (40"). Automatic tension control, S-drive servo operation, and operator ease-of-use are standard design features.

A vertical vacuum splice table allows for simple web splices and eliminates the need for web clamping. The waste rewind is ergonomically positioned below the splice table eliminating the requirement for operator bending throughout the entire splicing operation.

A horizontal splice table is also an available option with the RSC 2.0. Tension control is maintained during high speed stops through the automated web tension management system.

The RSC 2.0 quick change slitting cartridge system allows operators faster set up times with less down time for job or blade changes. Tool-less cartridge exchange with pre-mounted set-up gauge rules offers safe changeovers - in as little as thirty seconds.

Engineered and manufactured in Hobart, WI, USA, EMT/Rotocontrol will provide direct 24/7 technical support and remote service for the RSC 2.0.

“As our flagship Rotocontrol inspection slitter rewinder, the RSC-Series has always focused on high-quality components and operator efficiency,” says Marco Aengenvoort, Rotocontrol managing director. “With the next-generation RSC 2.0, all the essential features for inspection and slitting various types of labels are made possible.”