L&NW Staff10.07.20

Since Simon J Burke set up IMEC Media in 1999 the company has enjoyed an extended period of solid growth – but it was the installation of a Mark Andy Evolution press in 2020 that really kick-started the business in terms of increased productivity and new market opportunities.

Today, the operation that began with four people in a small unit in Bray, County Wicklow, has grown into a modern 6,000 square foot facility in Rathcoole, near Dublin and employs a staff of 15.

Burke explains, “We started by building a customer base in the pharmaceutical and medical sectors that were booming at the time and moved into food labels when the production equipment was enhanced to allow us to serve that sector more efficiently. Now we have an extensive portfolio of customers in pharma, medical, food manufacturing and service, and general retail.”

Although IMEC’s first Mark Andy press is a newcomer, the relationship between the two companies dates back many years. General Manager, Joe Lynch takes up the story: “We started with Comco presses and grew to know the Mark Andy people after the two companies merged in 2001. We’ve always been aware of the strong Mark Andy brand, because the company is one of the market leaders in narrow web flexo, but it wasn’t until we started looking for a new press in 2018 that we realised how much they had to offer.”

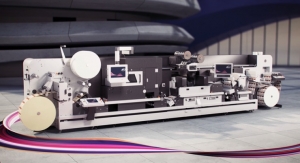

A visit to Labelexpo in Brussels last September, which happened to coincide with the launch of the new Evolution series of presses, was enough to whet the appetite of IMEC. Knowing of the manufacturer’s extensive knowledge and expertise in this sector and appreciating the quality of workmanship that goes into the design and functionality of its presses, a close evaluation of what the new Evolution series had to offer was a must. What they discovered was a press that featured an all-servo platform derived from the P7E Performance Series line, and the ability to ‘spec’ the press to exactly fit current requirements, safe in the knowledge that it can be upgraded as needs change.

IMEC’s existing Comco presses were both six-colour with 10” (254mm) web widths, and James Williams, Production Manager, knew that more colours and a wider web were required for them to hit the new markets they had in their sights. Consequently, the new Evolution installed in the company’s Rathcoole factory is an 8-colour flexo line with a 17” (431mm) web width. The servo control and automatic register allow for high-accuracy second pass printing, if needed, with no loss of quality, which opens a whole new area of business opportunity.

IMEC 1

Williams says, “It’s wider, quicker to make ready and change over, and runs faster across an extended range of substrates in perfect register – what’s not to like? The unwind and rewind capability allows us to use larger rolls with less downtime and waste during changeovers and we decided to add chilled impression cylinders and a chiller to allow us to convert unsupported films. This opens up the bottle wrap and sleeve markets for us, which are growing fast right now.” The Evolution also has lamination and cold foil facilities as well as delam/relam for reverse side printing, and a running speed of 750 fpm(230m/min).

Since full commissioning in the Spring, the Evolution has more than proved its worth to IMEC, bringing in new work from the beverage and other sectors to add to the growth in demand from the company’s traditional pharma and food industries, brought about by the coronavirus pandemic. With such pressure on production, even with the new press, IMEC is already looking to add a second Evolution flexo line and replace its existing digital capacity with the latest Mark Andy Digital Pro 3 toner- based technology for high-quality short run work. With a healthy €2.5m annual sales figure that will see a sharp rise in the first twelve months of the Evolution being in full production, it’s easy to see why IMEC is confident of its future success.

Burke concludes: “There’s no doubt that choosing the right manufacturing partner is key to success when you’re starting out in business. We’ve had great reliability from our Comco presses that have been well supported by Mark Andy technicians – so we’re looking forward to the same experience with our new Evolution, and a whole lot more besides! We know the market will continue to change but feel very comfortable that our choice of technology and manufacturer will support us throughout.”

Today, the operation that began with four people in a small unit in Bray, County Wicklow, has grown into a modern 6,000 square foot facility in Rathcoole, near Dublin and employs a staff of 15.

Burke explains, “We started by building a customer base in the pharmaceutical and medical sectors that were booming at the time and moved into food labels when the production equipment was enhanced to allow us to serve that sector more efficiently. Now we have an extensive portfolio of customers in pharma, medical, food manufacturing and service, and general retail.”

Although IMEC’s first Mark Andy press is a newcomer, the relationship between the two companies dates back many years. General Manager, Joe Lynch takes up the story: “We started with Comco presses and grew to know the Mark Andy people after the two companies merged in 2001. We’ve always been aware of the strong Mark Andy brand, because the company is one of the market leaders in narrow web flexo, but it wasn’t until we started looking for a new press in 2018 that we realised how much they had to offer.”

A visit to Labelexpo in Brussels last September, which happened to coincide with the launch of the new Evolution series of presses, was enough to whet the appetite of IMEC. Knowing of the manufacturer’s extensive knowledge and expertise in this sector and appreciating the quality of workmanship that goes into the design and functionality of its presses, a close evaluation of what the new Evolution series had to offer was a must. What they discovered was a press that featured an all-servo platform derived from the P7E Performance Series line, and the ability to ‘spec’ the press to exactly fit current requirements, safe in the knowledge that it can be upgraded as needs change.

IMEC’s existing Comco presses were both six-colour with 10” (254mm) web widths, and James Williams, Production Manager, knew that more colours and a wider web were required for them to hit the new markets they had in their sights. Consequently, the new Evolution installed in the company’s Rathcoole factory is an 8-colour flexo line with a 17” (431mm) web width. The servo control and automatic register allow for high-accuracy second pass printing, if needed, with no loss of quality, which opens a whole new area of business opportunity.

IMEC 1

Williams says, “It’s wider, quicker to make ready and change over, and runs faster across an extended range of substrates in perfect register – what’s not to like? The unwind and rewind capability allows us to use larger rolls with less downtime and waste during changeovers and we decided to add chilled impression cylinders and a chiller to allow us to convert unsupported films. This opens up the bottle wrap and sleeve markets for us, which are growing fast right now.” The Evolution also has lamination and cold foil facilities as well as delam/relam for reverse side printing, and a running speed of 750 fpm(230m/min).

Since full commissioning in the Spring, the Evolution has more than proved its worth to IMEC, bringing in new work from the beverage and other sectors to add to the growth in demand from the company’s traditional pharma and food industries, brought about by the coronavirus pandemic. With such pressure on production, even with the new press, IMEC is already looking to add a second Evolution flexo line and replace its existing digital capacity with the latest Mark Andy Digital Pro 3 toner- based technology for high-quality short run work. With a healthy €2.5m annual sales figure that will see a sharp rise in the first twelve months of the Evolution being in full production, it’s easy to see why IMEC is confident of its future success.

Burke concludes: “There’s no doubt that choosing the right manufacturing partner is key to success when you’re starting out in business. We’ve had great reliability from our Comco presses that have been well supported by Mark Andy technicians – so we’re looking forward to the same experience with our new Evolution, and a whole lot more besides! We know the market will continue to change but feel very comfortable that our choice of technology and manufacturer will support us throughout.”