Greg Hrinya, Associate Editor01.22.19

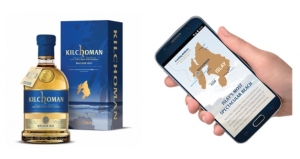

A product’s label and packaging are often the greatest indicator of quality–whether true or not. Brands frequently employ multiple techniques to stand out on a crowded shelf, which might include some 250 competitors.

Various decoration methods might include hot stamping foils, cold foils, digital foils, or a combination to achieve the brand’s required results. Health and beauty aids, cosmetics, wine and spirits, and consumer goods are all markets that can benefit from metallic effects. New markets could also include specialty markets such as craft beers and spirits.

“The benefits of using foil on a label are numerous for a brand,” explains Allan Quimby, sales and marketing manager at Kurz. “The primary benefit is shelf appeal, differentiating your product on the shelf at the time of purchase. There have been many studies conducted that show foil decoration increases purchases versus traditional print by 40%, and the likelihood of positive eye tracking results by up to 80%. Wine and spirits have already exhibited how transforming the perceived value of the product is achievable through foil decoration. Including foil and embossing effects into the design gives a unique and premium look with visibly tactile brilliance and texture.”

Kurz provides a wide range of products to help brands accomplish their goals. “Our traditional hot stamping foils have been used in this market for over a century, our formulations modified and evolving over time to meet the demands of print application and substrates,” says Quimby.

Kurz provides multiple colors and formulations that are designed to provide excellent performance and meet market demand. The company’s cold foil line features specific developments for a label printing environment as the popularity of the technology continues to increase and evolve. Kurz also offers several different machine solutions that can be incorporated into an existing print environment, as well as the foil products that work with them.

“Our focus as a supplier is to ensure that we have foils available for any commercial application and substrate,” says Quimby. “This really brings the freedom of design back to the brand to determine what is best suited for their needs. We can also recommend the best foil and/or application method depending on the design and converting method selected.”

The Kurz DM-Liner UV-Ink Roll-to-Roll: Built-in works inline with digital label printing presses. “Real metal foil from Kurzis applied inline, which means that metal decoration can include variable content, for large commercial and smaller economical runs,” says Quimby. “Digital Metal foils can then be overprinted, opening up the pallet for color to nearly endless possibilities.”

Meanwhile, the Kurz DM-Liner UV-Ink Roll-to-Roll: Built-on version features technology that mounts to the press and can be placed up-stream or downstream and offers the same benefits, including variable content and endless design potentials.

According to Quimby, cold foiling requires a press station for the metal and the adhesive, which is applied with a plate similarly to an ink color. “The right formulation of foil is married with the substrate and the length of run as well as the design,” he says. “No added heat or offline equipment is required in most cases.”

For hot stamping, there are two basic processes that can be considered. One process is inline with the printing press and the other is a secondary/offline solution. Hot foil stamping will also require the purchase of stamping dies for the application. In today’s market, Quimby says this is a relatively common practice that is easily managed.

“Foil is being used in clever and strategic ways, as well as being a key tool in defining design elements,” says Quimby. “Labels have become more interactive, more bold. Foil has always been a successful part of that strategy. In printing today, foil is no longer a limiting factor for speed, quality, or color availability. These same trends and advancements continue to repeat as digital printing and foil requirements technologies continue to develop and grow.

“Truthfully, any market can benefit from foil enhancements from the premium or luxury space down to the commodity items,” adds Quimby. “Foil has become such a heavily used and affordable marketing medium that it’s a requirement of most brand owner today rather than the exception.”

Various decoration methods might include hot stamping foils, cold foils, digital foils, or a combination to achieve the brand’s required results. Health and beauty aids, cosmetics, wine and spirits, and consumer goods are all markets that can benefit from metallic effects. New markets could also include specialty markets such as craft beers and spirits.

“The benefits of using foil on a label are numerous for a brand,” explains Allan Quimby, sales and marketing manager at Kurz. “The primary benefit is shelf appeal, differentiating your product on the shelf at the time of purchase. There have been many studies conducted that show foil decoration increases purchases versus traditional print by 40%, and the likelihood of positive eye tracking results by up to 80%. Wine and spirits have already exhibited how transforming the perceived value of the product is achievable through foil decoration. Including foil and embossing effects into the design gives a unique and premium look with visibly tactile brilliance and texture.”

Kurz provides a wide range of products to help brands accomplish their goals. “Our traditional hot stamping foils have been used in this market for over a century, our formulations modified and evolving over time to meet the demands of print application and substrates,” says Quimby.

Kurz provides multiple colors and formulations that are designed to provide excellent performance and meet market demand. The company’s cold foil line features specific developments for a label printing environment as the popularity of the technology continues to increase and evolve. Kurz also offers several different machine solutions that can be incorporated into an existing print environment, as well as the foil products that work with them.

“Our focus as a supplier is to ensure that we have foils available for any commercial application and substrate,” says Quimby. “This really brings the freedom of design back to the brand to determine what is best suited for their needs. We can also recommend the best foil and/or application method depending on the design and converting method selected.”

The Kurz DM-Liner UV-Ink Roll-to-Roll: Built-in works inline with digital label printing presses. “Real metal foil from Kurzis applied inline, which means that metal decoration can include variable content, for large commercial and smaller economical runs,” says Quimby. “Digital Metal foils can then be overprinted, opening up the pallet for color to nearly endless possibilities.”

Meanwhile, the Kurz DM-Liner UV-Ink Roll-to-Roll: Built-on version features technology that mounts to the press and can be placed up-stream or downstream and offers the same benefits, including variable content and endless design potentials.

According to Quimby, cold foiling requires a press station for the metal and the adhesive, which is applied with a plate similarly to an ink color. “The right formulation of foil is married with the substrate and the length of run as well as the design,” he says. “No added heat or offline equipment is required in most cases.”

For hot stamping, there are two basic processes that can be considered. One process is inline with the printing press and the other is a secondary/offline solution. Hot foil stamping will also require the purchase of stamping dies for the application. In today’s market, Quimby says this is a relatively common practice that is easily managed.

“Foil is being used in clever and strategic ways, as well as being a key tool in defining design elements,” says Quimby. “Labels have become more interactive, more bold. Foil has always been a successful part of that strategy. In printing today, foil is no longer a limiting factor for speed, quality, or color availability. These same trends and advancements continue to repeat as digital printing and foil requirements technologies continue to develop and grow.

“Truthfully, any market can benefit from foil enhancements from the premium or luxury space down to the commodity items,” adds Quimby. “Foil has become such a heavily used and affordable marketing medium that it’s a requirement of most brand owner today rather than the exception.”