Greg Hrinya, Associate Editor04.12.19

As the city of Louisville, KY, USA prepares for the Kentucky Derby, visitors from April 9-11 were treated to a different kind of speed–as a host of labels and packaging suppliers showcased their latest product innovations at ICE USA 2019.

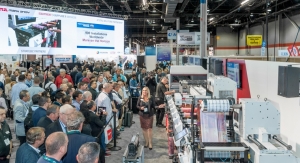

ICE USA and the co-located InPrint welcomed more than 2,500 attendees and 260 exhibitors to the Kentucky International Convention Center, highlighting the latest converting technologies associated with paper, film, foil, nonwovens and other flexible web-based materials.

"ICE has always been a key event in the Meech calendar, and we were delighted to be exhibiting here once again," said Matt Fyffe, general manager at Meech USA. "Bringing together a vast audience in the printing, converting and plastics industries, ICE gives Meech the perfect platform to present the latest additions to its well established product ranges."

In addition to an action-packed show floor and an opportunity for networking, the event featured hands-on demonstrations and interactive education sessions. The next edition of ICE USA and InPrint will take place in the spring of 2021.

ICE USA included a wide range of products, from die technology from Wilson Manufacturing and RotoMetrics to UV LED curing systems with Phoseon Technology and paper cores from Yazoo Mills. Among other exhibitors, Kao Collins showcased its selection of eco-friendly inks, while Harper representatives were on-hand to discuss the latest in anilox rolls and sleeving.

“I think the quality has been phenomenal at this show. Most everyone that has come is a plant manager, or an executive or a president who has buying power. It’s who we need to talk to, so we’ve had excellent leads,” said Benjamin Bowlware, marketing manager, Maxcess.

Maxcess unveiled its VEO-700 print inspection system from Fife. Featuring LED strobe lighting for longer life, a graphical user interface for ease of use, programmable positioning for precise imaging locations and an available touchscreen interface, the VEO-700 joins the entry-level VEO-600 from Fife.

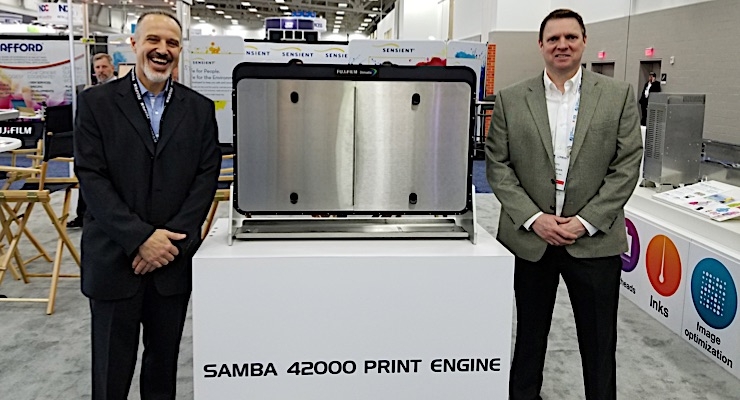

Fujifilm highlighted its Samba printhead technology, as well as its corresponding ink development. Fujifilm’s Scott Leger showcased how converters can integrate digital components into analog systems.

“We’ll custom-develop an ink system so that it performs in your desired application,” explained Gary Barnes, marketing manager at Fujifilm. “We have UV technology, water-based technology and a hybrid UV technology that’s able to cover a wide range of applications.

“We put together not only the ink systems, but the fluids that allow you to coat materials so that when you get the ultimate print, it’s as high quality as it can be,” he added.

Meech USA, meanwhile, displayed its new Hyperion IonCharge 30 and IonCharge 50 static generators, and the Hyperion 929IPS v2 mid-range Pulsed DC Ionizing Bar. The Hyperion IonCharge 30 and IonCharge 50 are upgrades of Meech's 992V3 30kV and 50kV generators respectively. Both versatile and technologically advanced, IonCharge 30 is compact and simple to install, while IonCharge 50 is Meech's most powerful static generator.

Delta ModTech and Frontier exhibited a host of converting solutions at booth 911. Delta ModTech displayed the Crusader Converter, while Frontier – a Delta ModTech Company – featured DynaCoat.

Roll-2-Roll Technologies launched two new products in Louisville. The two new sensor products came in the form of the WPS 221 and WPS 112 sensors for the converting industry. The WPS 221 is being upgraded with improved resolution of 63.5 microns, providing greater accuracy in edge detection of all materials, without the need for calibration. The WPS 112 provides a sensing window of 4.4” with a resolution of 63.5 microns, bridging the gap in the Roll-2-Roll Technologies line of sensors between the WPS 48 and WPS 221.

“We have worked closely with our customers through these last years, listening and supporting them closely so that we develop products that are based on their needs,” said Aravind Seshadri, president of Roll-2-Roll Technologies.

Experts from Contiweb were on-hand to illustrate how can quickly and cost-effectively produce smaller jobs using the Contiweb Thallo. Using the web offset press with variable cut-off dimensions, packaging print providers can produce premium quality prints that ensure brand owners can stand out with attention-grabbing packaging. According to Contiweb, its products will also be on display at INFOFLEX in New Orleans, LA, from May 6-7.

ICE USA and the co-located InPrint welcomed more than 2,500 attendees and 260 exhibitors to the Kentucky International Convention Center, highlighting the latest converting technologies associated with paper, film, foil, nonwovens and other flexible web-based materials.

"ICE has always been a key event in the Meech calendar, and we were delighted to be exhibiting here once again," said Matt Fyffe, general manager at Meech USA. "Bringing together a vast audience in the printing, converting and plastics industries, ICE gives Meech the perfect platform to present the latest additions to its well established product ranges."

In addition to an action-packed show floor and an opportunity for networking, the event featured hands-on demonstrations and interactive education sessions. The next edition of ICE USA and InPrint will take place in the spring of 2021.

ICE USA included a wide range of products, from die technology from Wilson Manufacturing and RotoMetrics to UV LED curing systems with Phoseon Technology and paper cores from Yazoo Mills. Among other exhibitors, Kao Collins showcased its selection of eco-friendly inks, while Harper representatives were on-hand to discuss the latest in anilox rolls and sleeving.

“I think the quality has been phenomenal at this show. Most everyone that has come is a plant manager, or an executive or a president who has buying power. It’s who we need to talk to, so we’ve had excellent leads,” said Benjamin Bowlware, marketing manager, Maxcess.

Maxcess unveiled its VEO-700 print inspection system from Fife. Featuring LED strobe lighting for longer life, a graphical user interface for ease of use, programmable positioning for precise imaging locations and an available touchscreen interface, the VEO-700 joins the entry-level VEO-600 from Fife.

Fujifilm highlighted its Samba printhead technology, as well as its corresponding ink development. Fujifilm’s Scott Leger showcased how converters can integrate digital components into analog systems.

“We’ll custom-develop an ink system so that it performs in your desired application,” explained Gary Barnes, marketing manager at Fujifilm. “We have UV technology, water-based technology and a hybrid UV technology that’s able to cover a wide range of applications.

“We put together not only the ink systems, but the fluids that allow you to coat materials so that when you get the ultimate print, it’s as high quality as it can be,” he added.

Meech USA, meanwhile, displayed its new Hyperion IonCharge 30 and IonCharge 50 static generators, and the Hyperion 929IPS v2 mid-range Pulsed DC Ionizing Bar. The Hyperion IonCharge 30 and IonCharge 50 are upgrades of Meech's 992V3 30kV and 50kV generators respectively. Both versatile and technologically advanced, IonCharge 30 is compact and simple to install, while IonCharge 50 is Meech's most powerful static generator.

Delta ModTech and Frontier exhibited a host of converting solutions at booth 911. Delta ModTech displayed the Crusader Converter, while Frontier – a Delta ModTech Company – featured DynaCoat.

Roll-2-Roll Technologies launched two new products in Louisville. The two new sensor products came in the form of the WPS 221 and WPS 112 sensors for the converting industry. The WPS 221 is being upgraded with improved resolution of 63.5 microns, providing greater accuracy in edge detection of all materials, without the need for calibration. The WPS 112 provides a sensing window of 4.4” with a resolution of 63.5 microns, bridging the gap in the Roll-2-Roll Technologies line of sensors between the WPS 48 and WPS 221.

“We have worked closely with our customers through these last years, listening and supporting them closely so that we develop products that are based on their needs,” said Aravind Seshadri, president of Roll-2-Roll Technologies.

Experts from Contiweb were on-hand to illustrate how can quickly and cost-effectively produce smaller jobs using the Contiweb Thallo. Using the web offset press with variable cut-off dimensions, packaging print providers can produce premium quality prints that ensure brand owners can stand out with attention-grabbing packaging. According to Contiweb, its products will also be on display at INFOFLEX in New Orleans, LA, from May 6-7.